Anti-collision buffer guardrail structure for bridge engineering

A technology of bridge engineering and guardrail structure, which is applied in the direction of bridges, bridge construction, bridge parts, etc., can solve the problems of secondary collision, secondary injury, and aggravated accident hazards, so as to ensure the anti-collision buffer performance and facilitate operation and use , the effect of reducing the impact kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

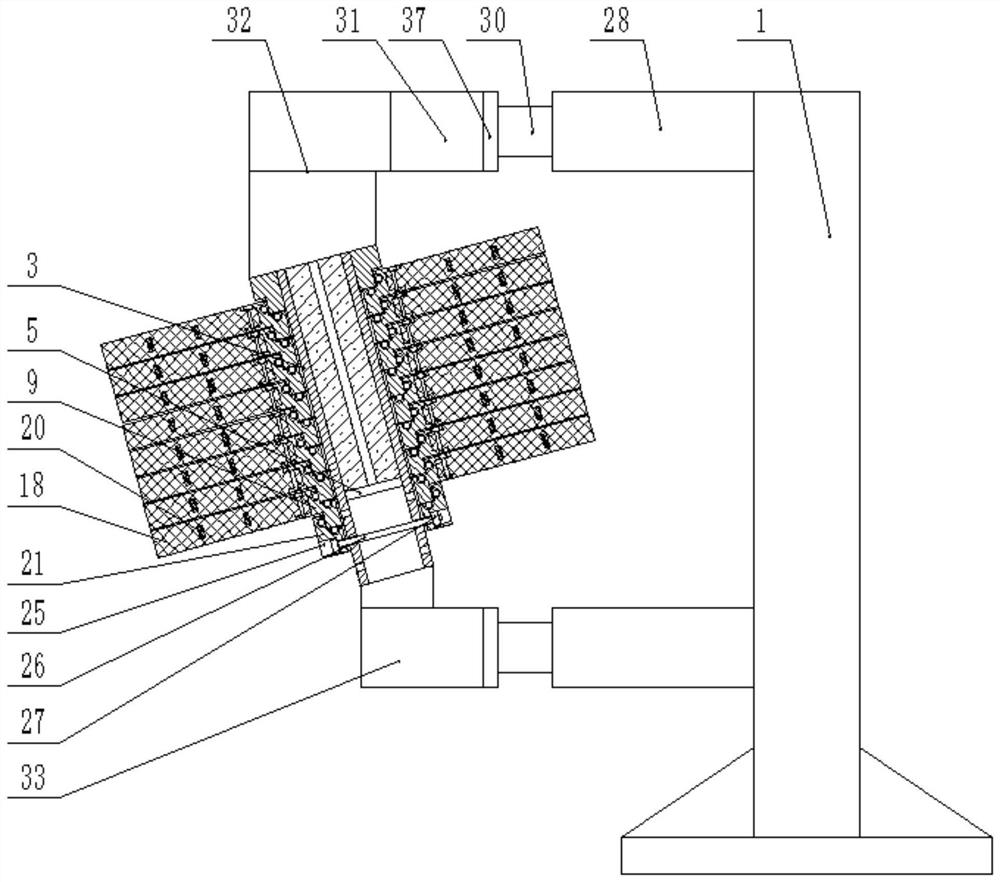

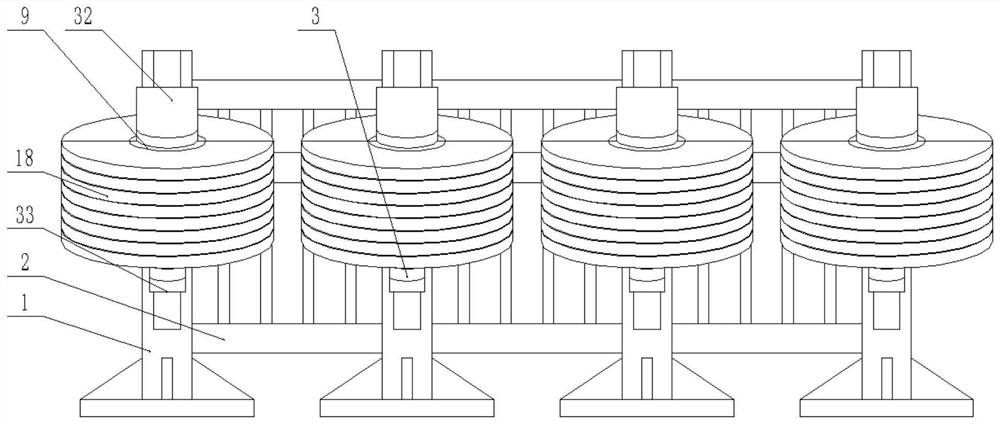

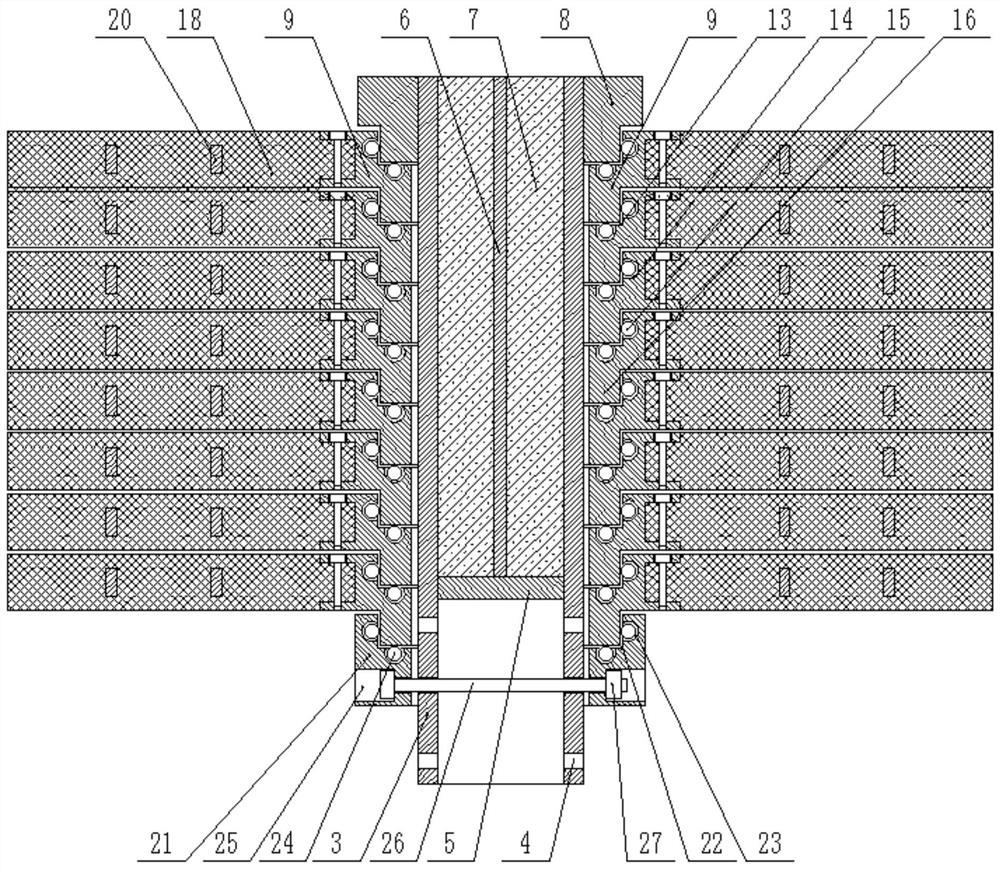

[0032] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-9 shown.

[0033] The creative point of this scheme lies in the structural design of the assembled rotating anti-collision buffer device, combined with the attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , attached Image 6 , attached Figure 7, the assembled rotary anti-collision buffer device includes a fixed sleeve 3, and the lower end of the outer surface of the fixed sleeve 3 is provided with several groups of fixed through holes 4, and several groups of fixed through holes 4 are evenly distributed on the fixed sleeve 3, and each group of fixed through holes 4 is divided into two, the two fixed through holes 4 of the same group are located on both sides of the fixed sleeve 3, a sealing baffle 5 is installed below the inner center of the fixed sleeve 3, and a cross support frame 6 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com