Self-installation and disassembly equipment for cement decompression cone formwork

A decompression cone and formwork technology, which is applied in the processing of formwork, the preparation of building components on site, construction, etc., can solve the problems of high cost and difficult construction of decompression cone structure, and achieve short construction period and high operation safety. Increased width and ease of construction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Attached below Figure 1-18 The present invention will be described in detail.

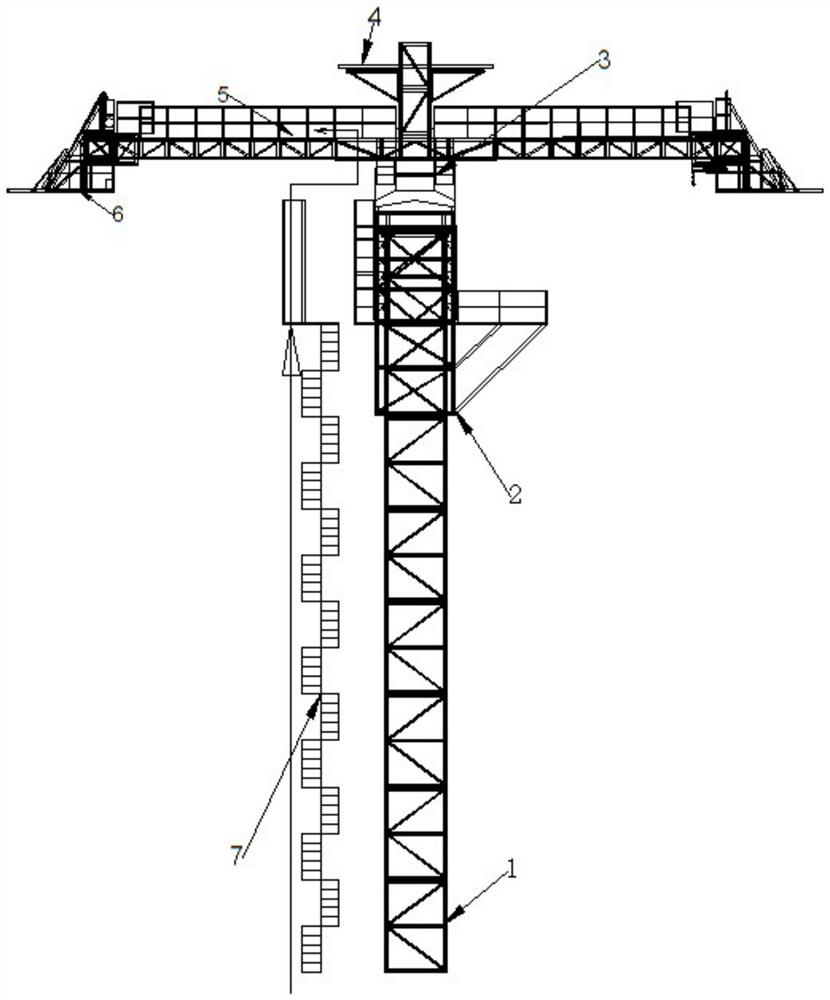

[0047] like figure 1 As shown, the cement decompression cone formwork self-installation and disassembly equipment in this embodiment includes a central support 1, an integral jacking mechanism 2, a rotary assembly 3, a top fixed platform 4, a length-adjustable balance arm 5, and formwork self-installation and disassembly. trolley6. The overall jacking mechanism 2, the slewing assembly 3 and the length-adjustable balance arm 5 are sequentially arranged on the central prop 1 from bottom to top. The bottom of the top fixed platform 4 is connected with the integral jacking mechanism 2, and its top stretches out the slewing assembly 3 and the length-adjustable balance arm 5 vertically upwards. The central support 1 is formed by connecting the standard sections of the tower crane.

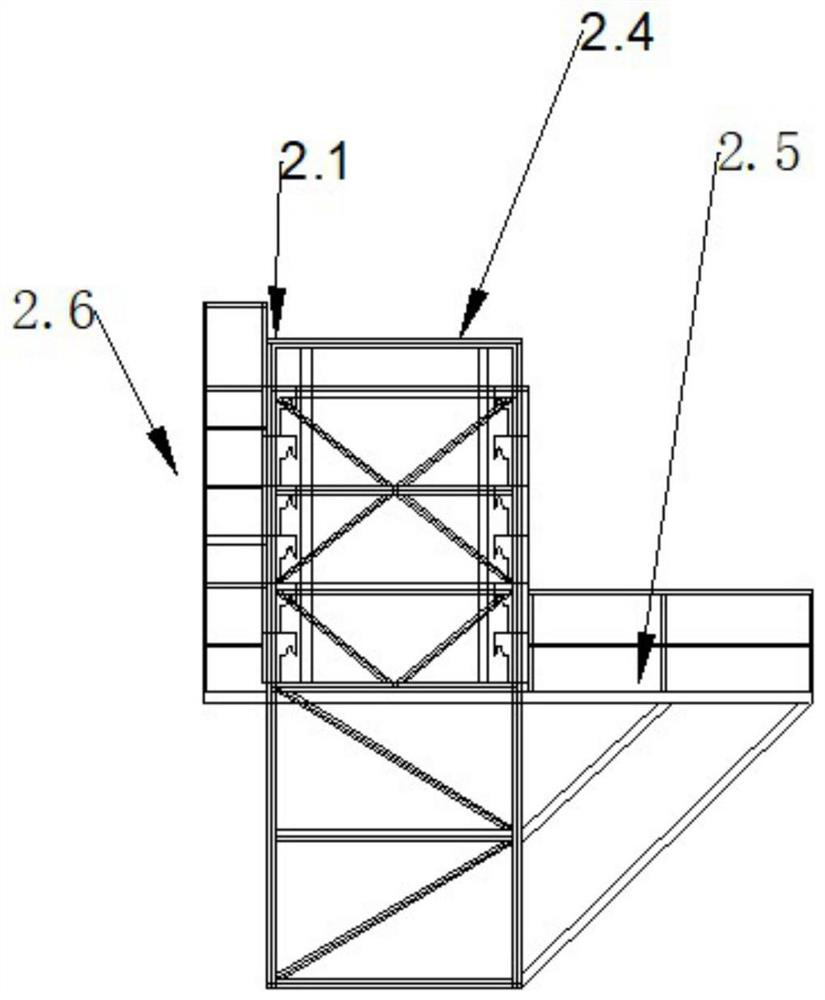

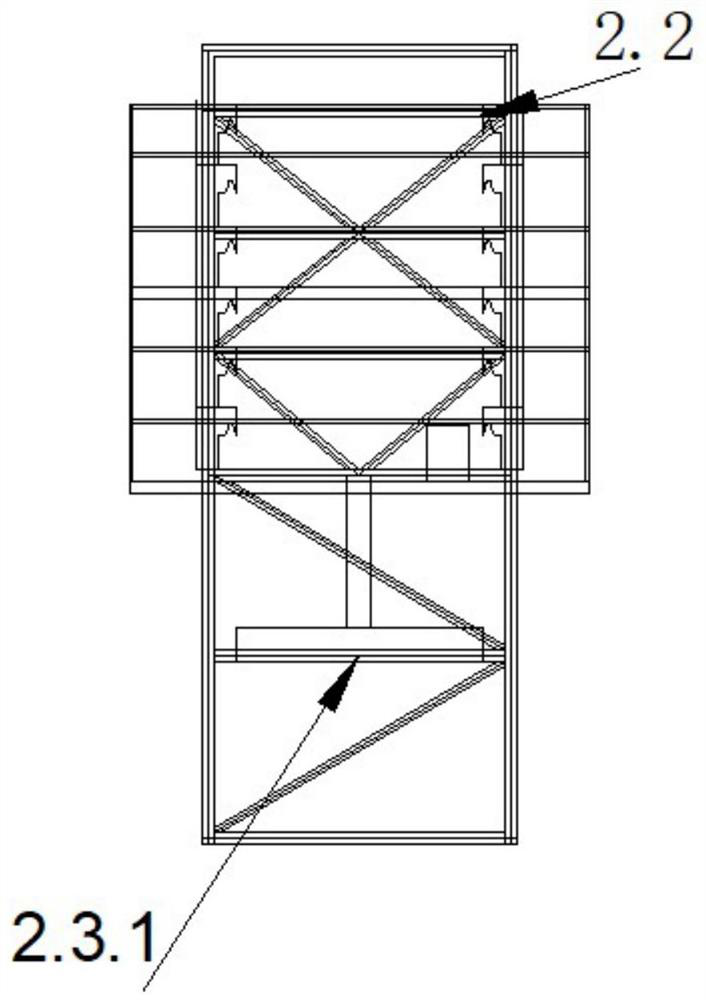

[0048] like Figure 2-3 As shown, the overall jacking mechanism 2 is mainly composed of the jacking frame oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com