High-voltage outdoor industrial wall lamp capable of achieving low-temperature emergency and implementation method of high-voltage outdoor industrial wall lamp

A high-voltage, outdoor technology, applied in the parts of lighting devices, safety devices of lighting devices, lighting and heating equipment, etc., can solve the problems of poor applicability, insufficient lamp life, no emergency effect, etc., and prolong the use time. , to ensure the light intensity, to ensure the effect of waterproof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

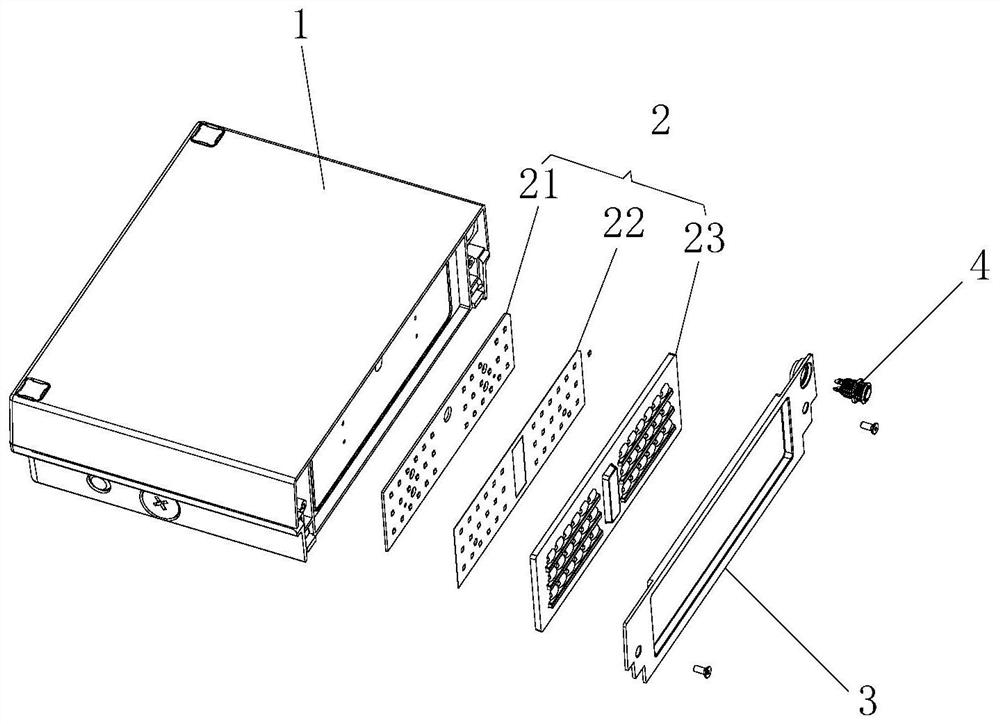

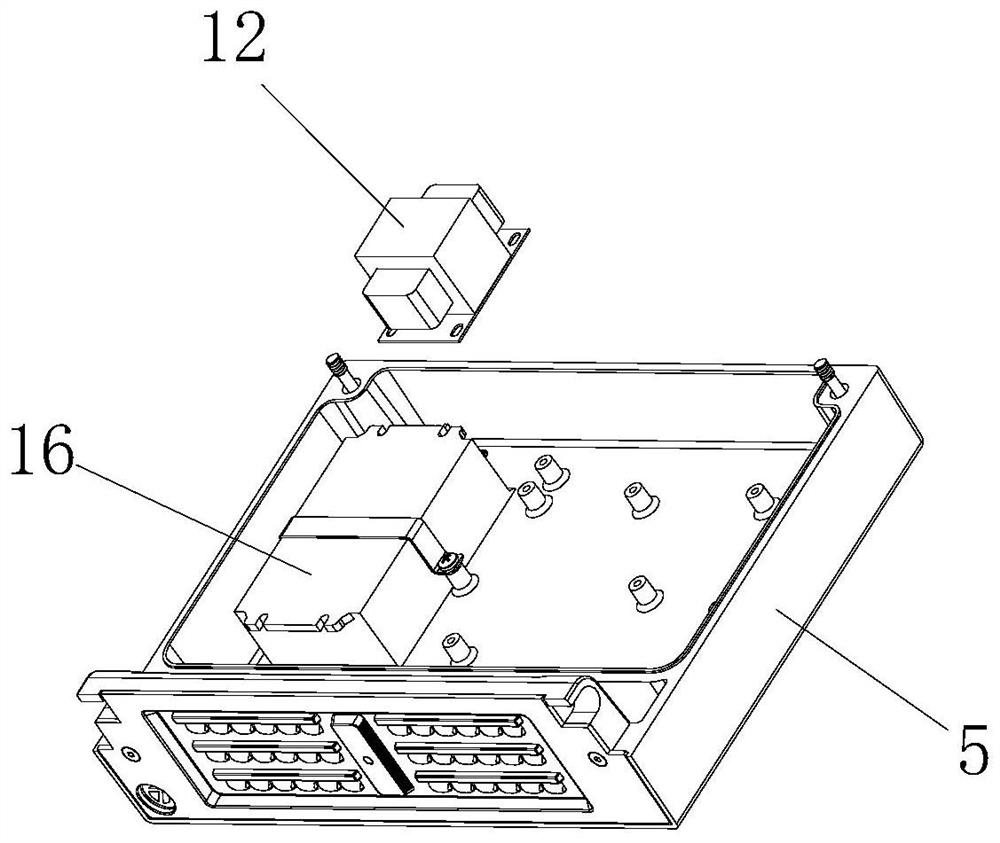

[0037] see Figure 1-6 , the present invention provides the following technical solutions: a low-temperature emergency high-voltage outdoor industrial wall lamp, including a lamp body 1, the interior of the lamp body 1 is respectively connected with a high-voltage transformer 12 and a light source driver 16, and the light source driver 16 is located on one side of the high-voltage transformer 12 , the high-voltage transformer 12 is electrically connected to the light source driver 16 , one side of the lamp body 1 is connected to the light source 2 through the cover 3 , and the light source 2 is electrically connected to the light source driver 16 .

[0038] By adopting the above technical solution, the high-voltage transformer 12 realizes the voltage transformation from 347-480V to 120V, so that the wall lamp in the present invention can be applied to the high-voltage lines of industrial factories.

[0039] Further, the interior of the lamp body 1 is also connected with an eme...

Embodiment 2

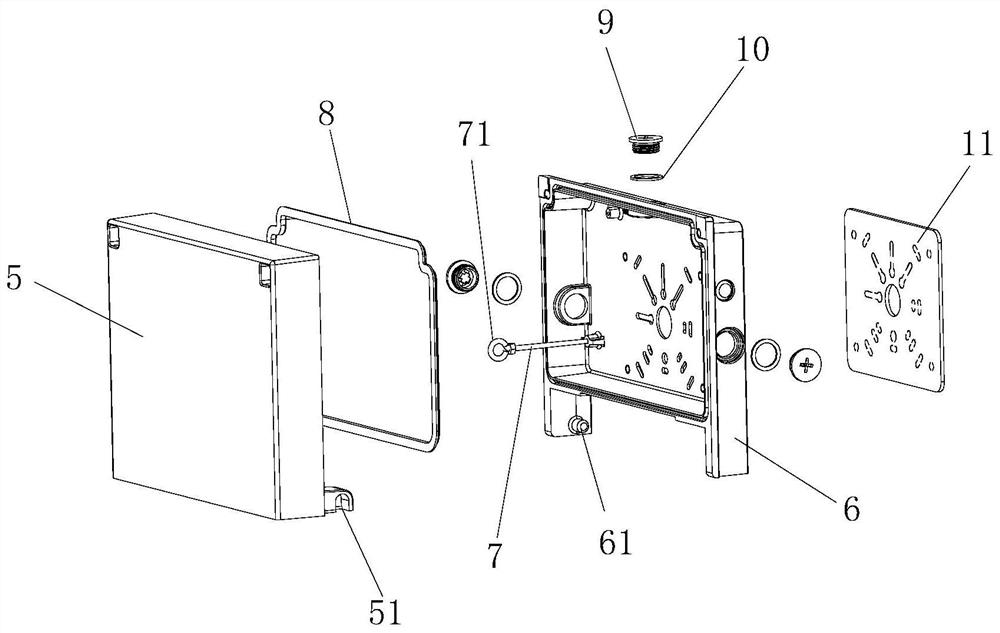

[0053] The difference between this embodiment and Embodiment 1 is that further, the upper side and both sides of the rear cover 6 are respectively provided with side inlet pipe holes, and the side inlet pipe holes are provided with side inlet pipe waterproof rings 10, And the side inlet pipe hole is also connected with a side inlet pipe sealing plug 9 .

[0054] By adopting the above-mentioned technical scheme and setting the hole of the side-entry pipe, the structure can be applied to various wiring methods. When the side-entry line is required, the corresponding side-entry pipe sealing plug 9 can be removed for wiring. ; The side inlet tube waterproof ring 10 and the side inlet tube sealing plug 9 are set to achieve IP65 protection level for the internal components of the lamp body 1, ensuring the waterproofness of the lamp body 1.

Embodiment 3

[0056] The difference between this embodiment and Embodiment 1 lies in that further, several protrusions are provided on the back of the rear cover 6 , and the protrusions are made of rubber, and the gasket 11 is provided with through holes corresponding to the protrusions.

[0057] By adopting the above technical solution, after the back cover 6 is installed on the wall, the rubber protrusions can increase the friction between the back cover 6 and the wall, thereby making the connection between the back cover 6 and the wall more stable.

[0058] Further, the realization method of the low-temperature emergency high-voltage outdoor industrial wall lamp according to the present invention includes the following steps:

[0059] (1), installation: fix the back cover 6 on the wall, put the rotating seat 51 on the rotating shaft 61, and connect the two buckles 71 together through the lock 15, and then perform the wiring operation. After the wiring is completed, Close the front cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com