Device for monitoring grouting compactness of prefabricated building, automatically compensating and verifying strength of grouting material

An automatic compensation and plumpness technology, which is used in devices for automatic compensation and verification of grouting material strength, and in the field of grouting plumpness monitoring for prefabricated buildings. application and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings. It should be understood that the materials and methods involved in the following specific devices are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

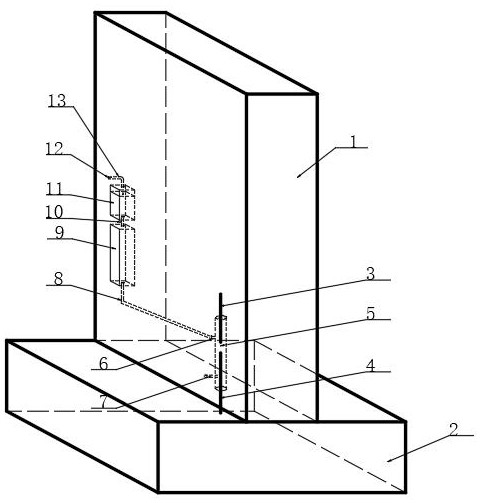

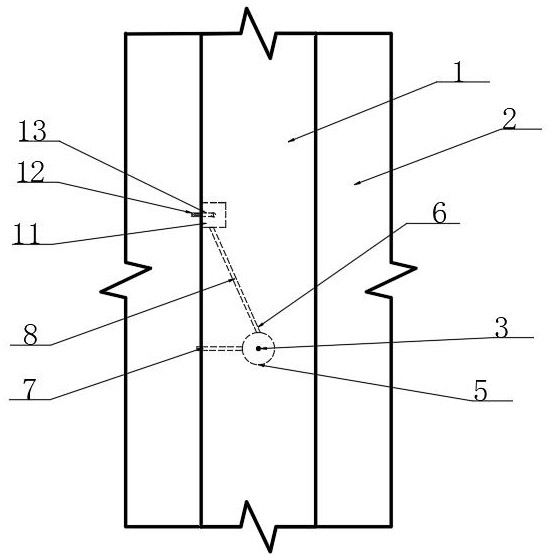

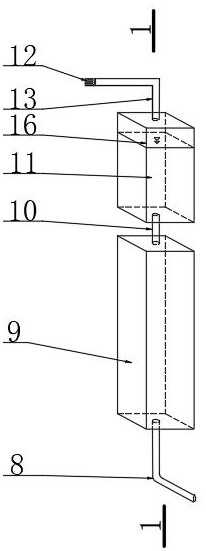

[0040] see Figure 1 to Figure 7 , this embodiment provides a device for monitoring the fullness of grouting in prefabricated buildings, automatic compensation and verification of grouting material strength, including a standard sample holder 9, a compensation and observer 11, an anti-backflow device 12, a first communication Pipe 8, second connecting pipe 10, third connecting pipe 13. The internal size of the standard sample retainer 9 is 160mm×40mm×40mm, it is pre-embedded in the vertical member 1, flush with the outer surface of the vertical member 1, and the standard grouting material can be directly observed fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com