Intelligent nail selection method and storage medium

A storage medium and intelligent technology, applied in the fields of instrumentation, computing, electrical and digital data processing, etc., can solve the problems of long time and complicated process of customizing the nail bed of the circuit board.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

[0029] The bed of nails is made to jack up the board and level the surface, the surface needs to be printed with ink during work, there is pressure. The thinner the board is, the easier it is to collapse under pressure, so the thinner the board, the more nails are needed to support it below. The more nails, the smaller the distance between nails. The current process stipulates that the distance between the nails with a plate thickness of 1.6mm and above can be stressed at a distance of 50mm, while the distance between the nails for plates with a thickness of 1.0 to 1.2mm should be 30mm, and the distance between the nails for smaller plates such as 0.6 and 0.8mm should be 20mm. .

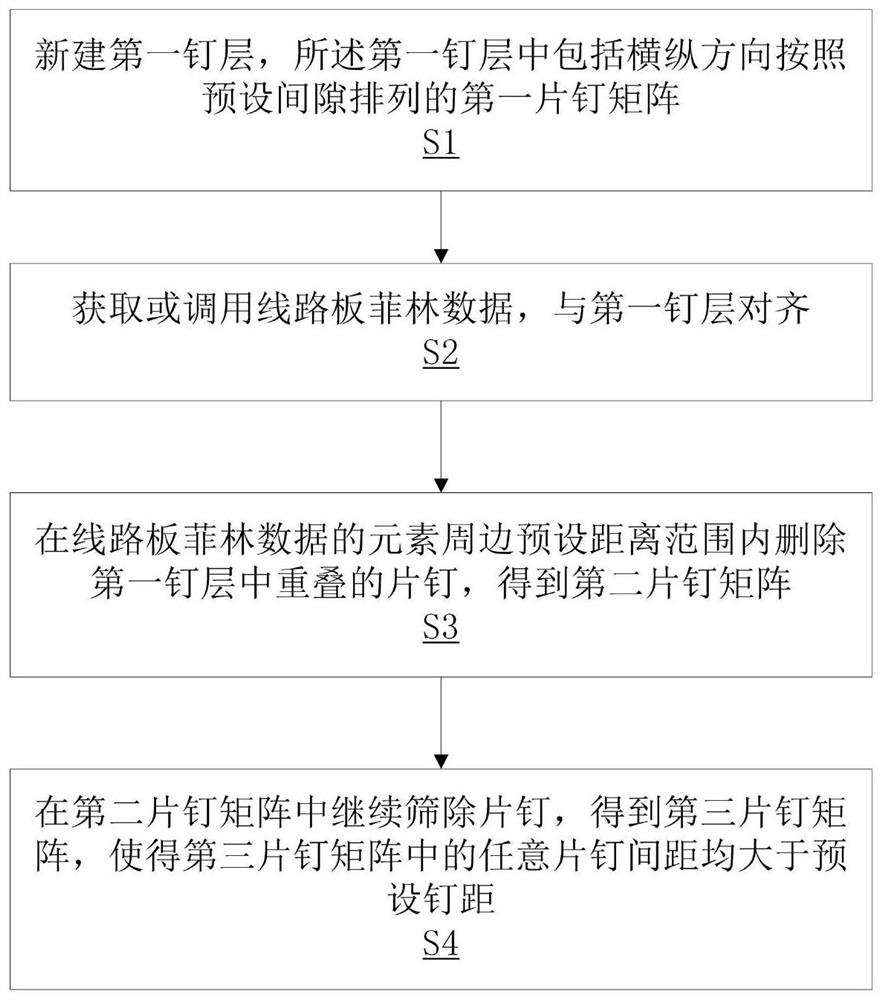

[0030] see below figure 1 , in order to meet the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com