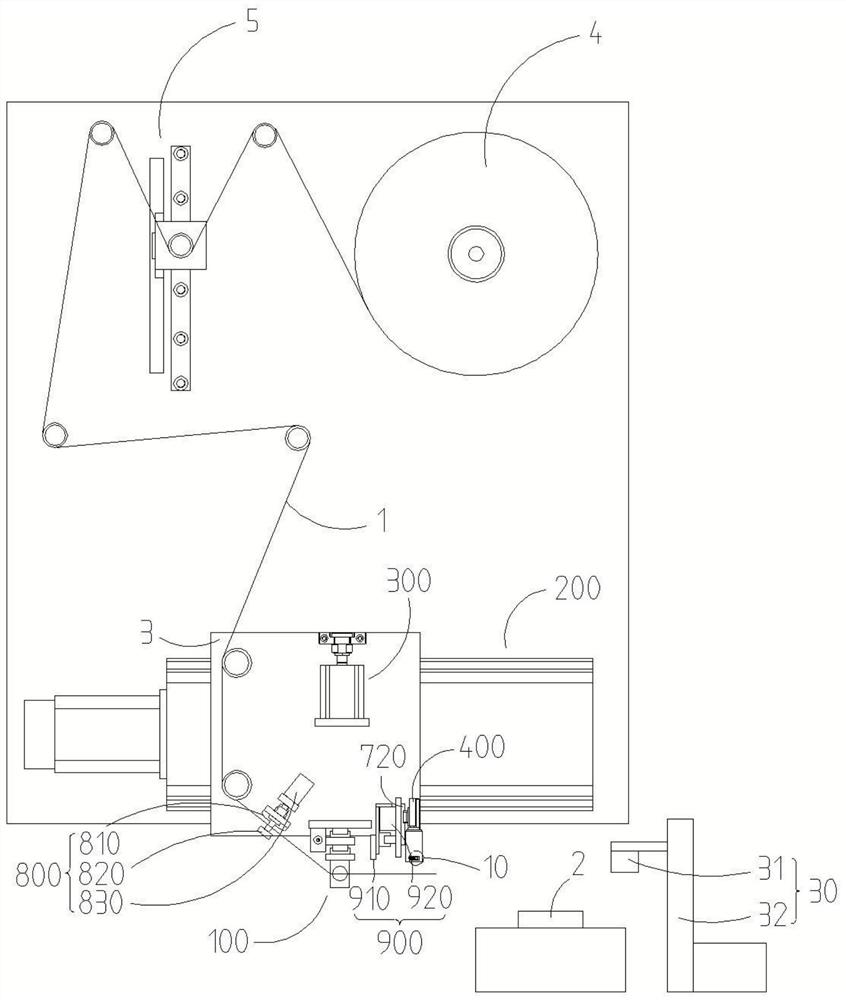

Adhesive tape pasting mechanism and adhesive tape pasting device

A glue sticking mechanism and tape technology are applied in transportation and packaging, assembling battery machines, electrochemical generators, etc., which can solve the problems of many technological processes and large equipment occupation of the sticking device, so as to save tape preparation and handling. Tape, easy to cut, to speed up the effect of glue sticking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

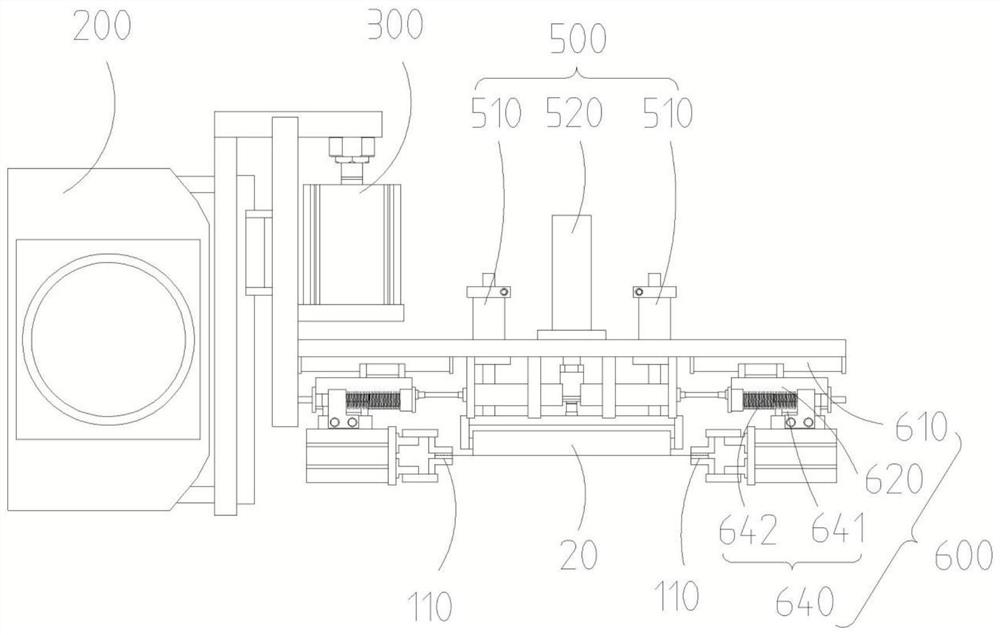

[0033] In other embodiments, according to the configuration or arrangement of the parts to be glued 2, the paths of the first drive assembly 200 and the second drive assembly 300 may also be inclined or curved, as long as the drive pull assembly 100 can be driven to pull the adhesive tape 1 to the position to be glued, stick the tape 1 to the part 2 to be glued, and the first pressure roller 10 smoothes the tape 1 and realizes the bending and pasting of the tape 1.

[0034] It should be explained that the above-mentioned "position to be glued" refers to the first surface of the piece to be glued 2, the initial position to be glued, and the end of the adhesive tape 1 held by the glue pulling assembly 100 is attached to this position. According to the needs of the process, this position may be on the edge of the piece to be glued 2, and may also be in the middle of the piece to be glued 2. Because the glue pulling assembly 100 pulls the end of the adhesive tape 1, when the end o...

other Embodiment approach

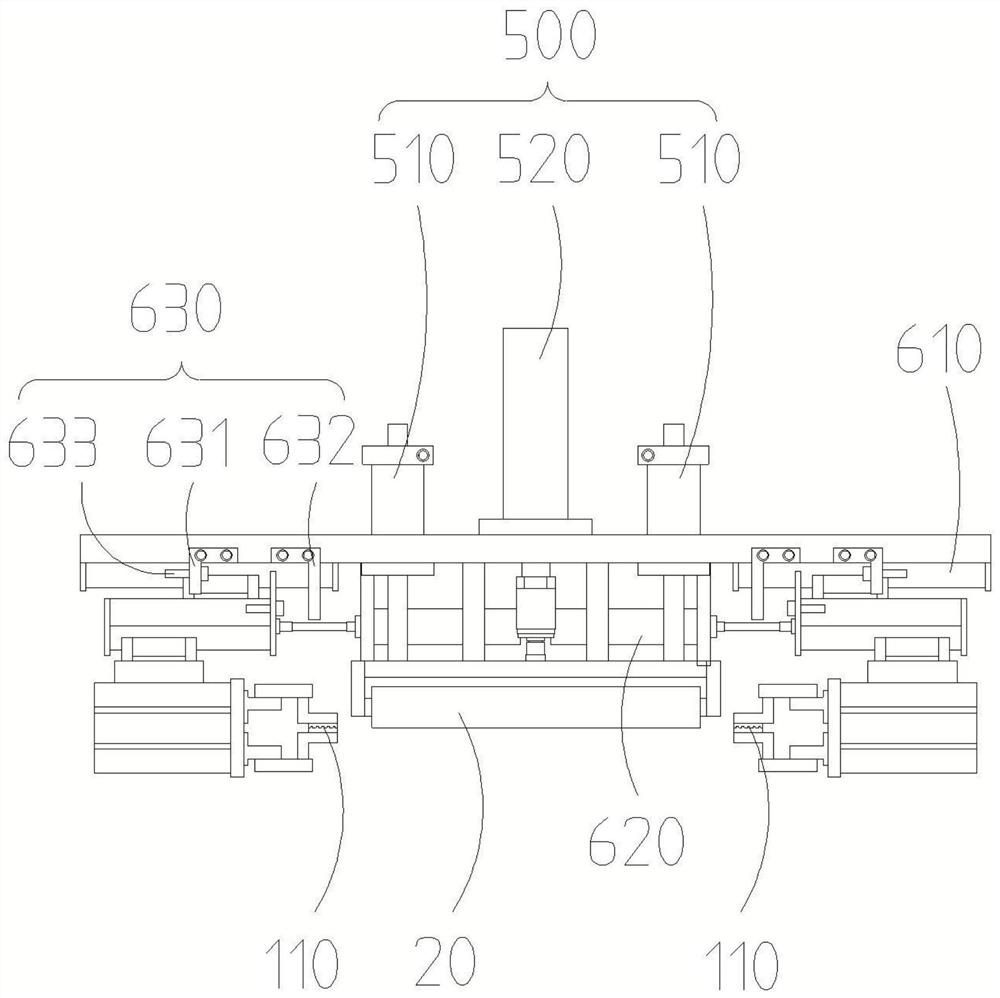

[0059] In other embodiments, the first pressure roller buffer 720 can also use elastic members such as springs; at this time, by setting the first pressure roller buffer 720 between the first pressure roller 10 and the first pressure roller drive assembly 400; Alternatively, when the first pressing roller 10 and the first pressing roller driving assembly 400 are connected together, the first pressing roller buffer 720 is arranged between the first pressing roller driving assembly 400 and the frame on which the first pressing roller driving assembly 400 is installed. Between; through the elastic deformation of the elastic member, offset the excess travel of the first pressing roller driving assembly 400 .

[0060] Further, the first pressing roller 10 is arranged on the first pressing roller seat 30, the first pressing roller seat 30 is provided with a mounting hole 31, the end of the first pressing roller 10 is arranged in the mounting hole 31, and the first pressing roller An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com