Natural sweetener composition and preparation method thereof

A technology of natural sweeteners and compositions, applied in the field of food processing, can solve the problems of high cost of sweeteners, insufficient sweetness, poor solubility, etc., and achieve the advantages of not easy crystallization, improved solubility, and high sweetness multiple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of natural sweetener composition formula, comprises the following steps:

[0048] Step S01, dissolving γ-cyclodextrin in water at 50°C-60°C, pouring it into a stirring tank, and holding it at a constant temperature for 25-40min; stirring in one direction at a constant speed, the speed of the stirring paddle is 500-800R / min

[0049] Step S02, adding β-cyclodextrin to continue inclusion for 25-40 minutes;

[0050] Step S03, adding rebaudioside D (RD95) and edible essence into the solution after inclusion according to the ratio, and continue inclusion for 10-20min

[0051] Step S04, spray drying after heating to obtain solid sugar.

[0052] Specifically, in the step S04, the solution is first heated to 100° C. by a tube heater, and then spray-dried, with an inlet air temperature of 120° C. and a spray pressure of 22 mpa to obtain solid sugar.

[0053] According to above-mentioned natural sweetener composition formula and preparation method, illustrat...

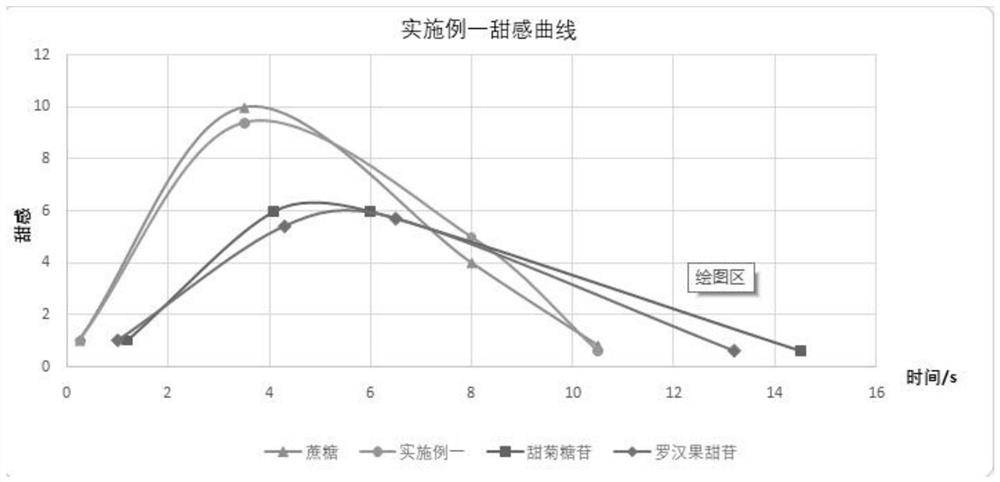

Embodiment 1

[0055] 1. The natural sweetener composition formula, in parts by mass, including 50 g of rebaudioside A (RA95), 1 g of rebaudioside D (RD95), 1 g of β-cyclodextrin, 20 g of γ-cyclodextrin and Edible essence 5g.

[0056] 2. A preparation method for a natural sweetener composition formula, comprising the following steps:

[0057] Step S01, first dissolving 20g of γ-cyclodextrin in water at 25°C, pouring it into a mixing tank, adding 50g of rebaudioside A (RA95) for inclusion at a constant temperature for 40 minutes, stirring at a uniform speed in one direction, and the rotation speed of the stirring paddle is 1200 R / min;

[0058] Step S02, add 1g of β-cyclodextrin and continue inclusion for 40 minutes;

[0059] Step S03, adding 1 g of rebaudioside D (RD95) and 5 g of edible essence into the inclusion solution according to the ratio, and continuing the inclusion for 40 minutes;

[0060] Step S04, spray drying after heating to obtain solid sugar.

[0061] In the step S04, the s...

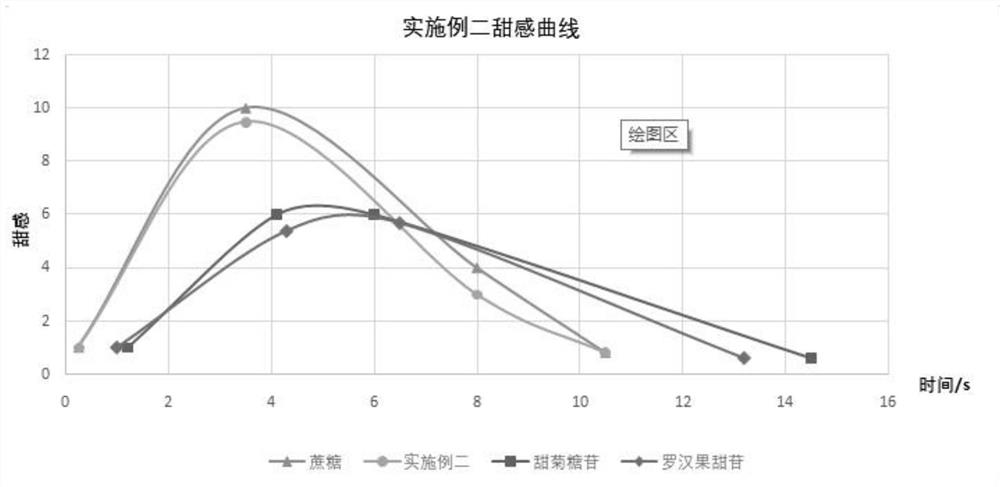

Embodiment 2

[0063] 1. The natural sweetener composition formula, in parts by mass, including rebaudioside A (RA95) 46g, rebaudioside D (RD95) 4g, β-cyclodextrin 5g, γ-cyclodextrin 16g and Edible essence 10g.

[0064] 2. A preparation method for a natural sweetener composition formula, comprising the following steps:

[0065] Step S01, first dissolving 16g of γ-cyclodextrin in water at 30°C, pouring it into a mixing tank, adding 46g of rebaudioside A (RA95) for inclusion at a constant temperature for 35 minutes, stirring at a uniform speed in one direction, and the rotation speed of the stirring paddle is 1100 R / min;

[0066] Step S02, add 5g of β-cyclodextrin and continue inclusion for 35 minutes;

[0067] Step S03, adding 4g of rebaudioside D (RD95) and 10g of edible essence into the inclusion solution according to the ratio, and continuing inclusion for 35 minutes;

[0068] Step S04, spray drying after heating to obtain solid sugar.

[0069] In the step S04, the solution is firstly h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com