Dismounting tool for plummer block bearing

A vertical technology with a seat bearing, applied in the field of disassembly tools, can solve problems such as normal disassembly, inability to rotate the base space, corrosion of bearings and bushings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

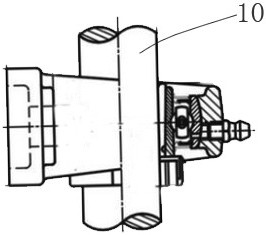

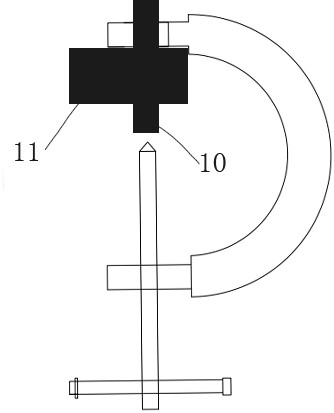

[0016] The invention relates to a dismounting device for a vertical bearing with seat, which mainly includes: an arm 1 of a holding mechanism, a positioning stopper 2 of the holding mechanism, a nut 6 of a drawing screw mechanism, a screw rod 5 of a drawing mechanism, a pulling Pull mechanism screw handle 9, connecting mechanism 3 to form.

[0017] In this embodiment, the total length of the arm is 10 cm, the middle of the arm is connected to a positioning block of 1 cm*1 cm cube, the screw is 1 cm thick, the total length of the screw is 32 cm, and the connecting mechanism is C-shaped and the thickness is 3 cm.

[0018] Working process of the present invention:

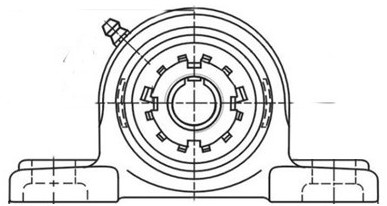

[0019] Taking UKP210J as an example, stick the arm close to UKP210J, and match the positioning stopper with UKP210J, so that the clamping mechanism as a whole holds UKP210J tightly. Shaft 10, continue to rotate the screw to separate the shaft 10 from UKP210J.

[0020] The above-mentioned embodiment is an illustratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com