a 3d printer

A technology of 3D printer and printing device, applied in the direction of 3D object support structure, coating device, manufacturing tool, etc., can solve the problem of uncontrollable changes in viscous cooling speed of connection parts with different layers, slow cooling efficiency of fans, and material blanking. Inaccurate and other problems, to achieve high transmission accuracy and bearing capacity, reduce printing accuracy, and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0037] The basic principles, main features and advantages of the present invention have been shown and described above. Those skilled in the art should understand that the present invention is not limited by the above-mentioned embodiments. What are described in the above-mentioned embodiments and the description are only the principles of the present invention. Variations and improvements, which fall within the scope of the claimed invention. The scope of protection required by the present invention is defined by the appended claims and their equivalents.

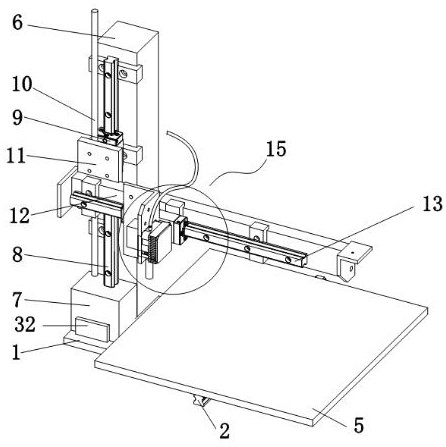

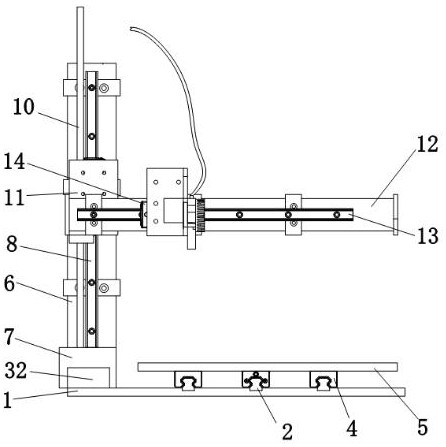

[0038] refer to Figure 1-9 , the present invention provides a 3D printer, including an underframe 1, a power unit and a printing device 15 are arranged on the top of the underframe 1.

[0039] The power device includes a plurality of first slide rails 2, the first slide rails 2 are evenly distributed in an array and are fixedly connected to the top of the chassis 1, and the inside of the first slide rail 2 is slidingly ...

no. 2 example

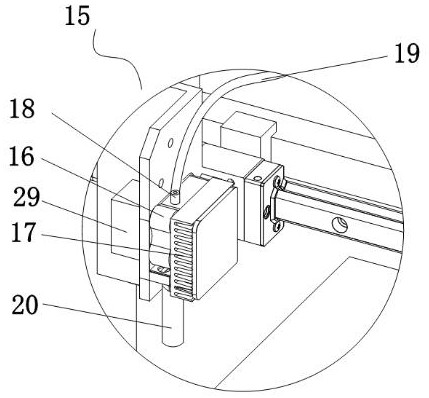

[0051] Based on the 3D printer provided in the first embodiment, the same layer printing can effectively realize rapid cooling in specific use, but when printing layer by layer, especially when printing, the thickness of the printed part increases continuously with the increase of the number of layers. When it is too large, if the bottom is too thin, the viscosity of the connection position is poor, and because the width of the molten material ejected from the nozzle 20 is constant, if the second layer wants to increase the thickness, it needs to be stacked in a staggered manner. It is very easy to tilt or collapse when it is in place. At the same time, if the wall thickness of one side is increased, if the width of the nozzle 20 does not change, it will not be able to process at all. To solve this problem, improve the stability of the connection position when 3D printing is printing layer by layer , combined with Figure 10-11 , the 3D printer also includes: electromagnetic v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com