Patents

Literature

45results about How to "Resolved Accuracy Decrease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

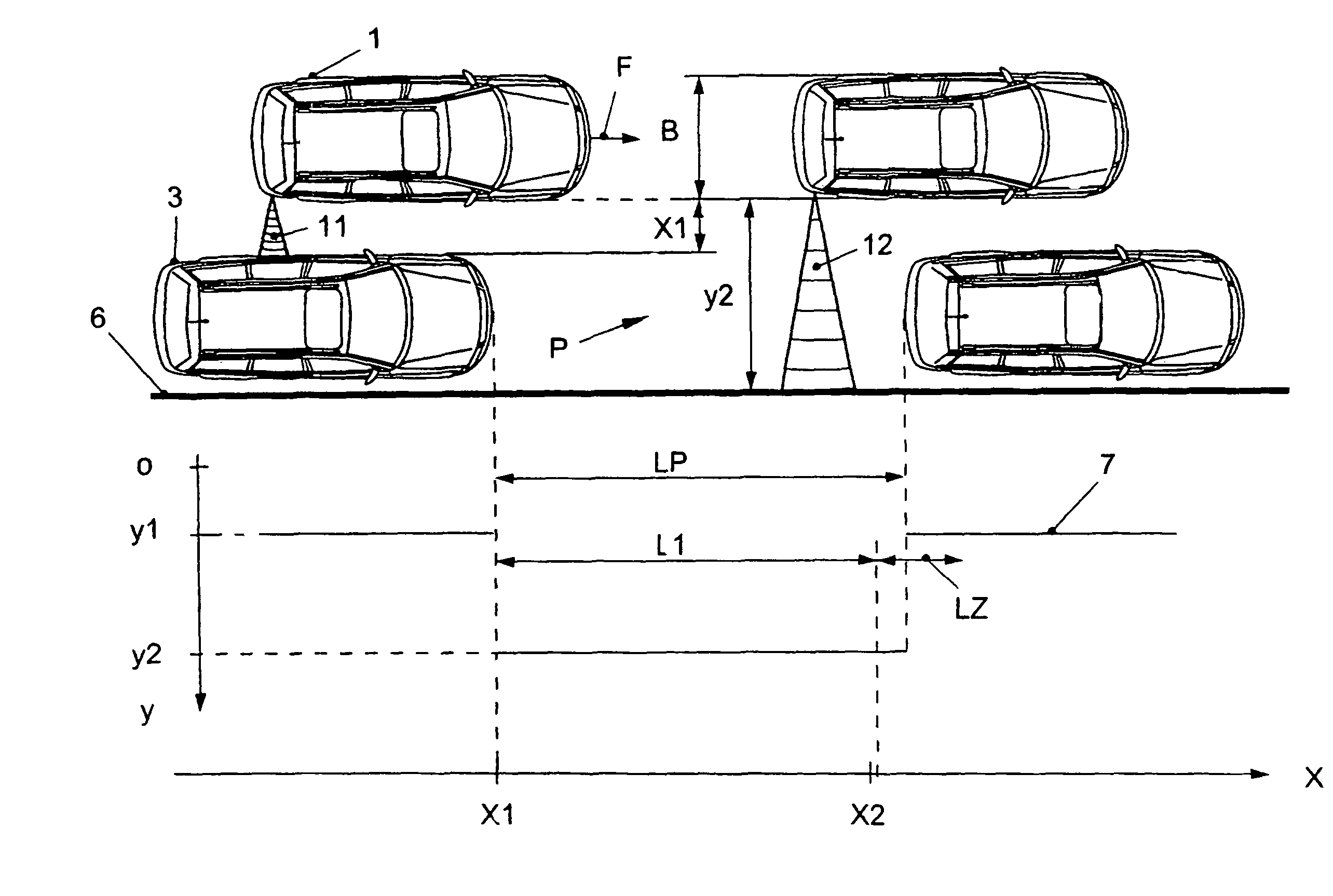

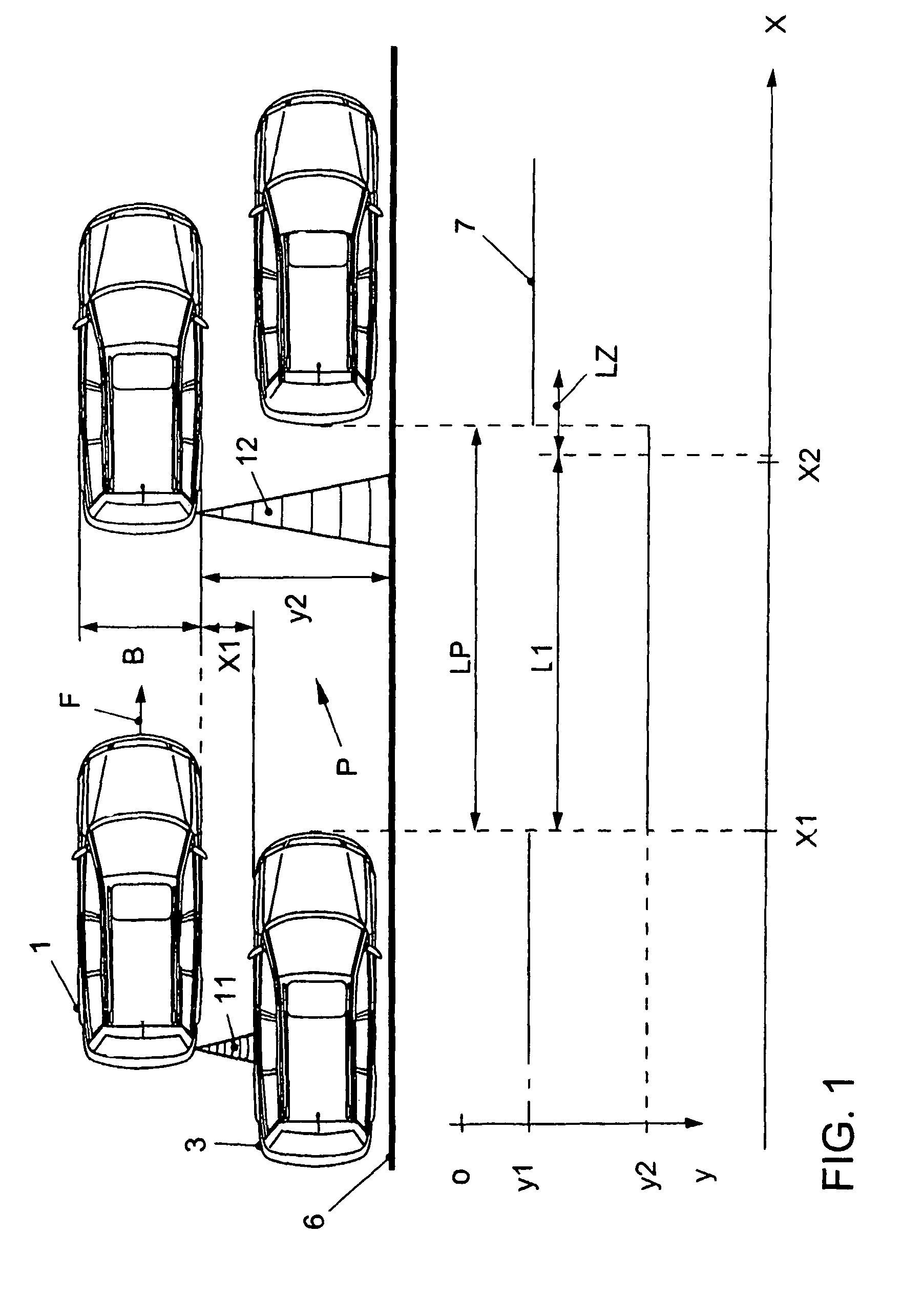

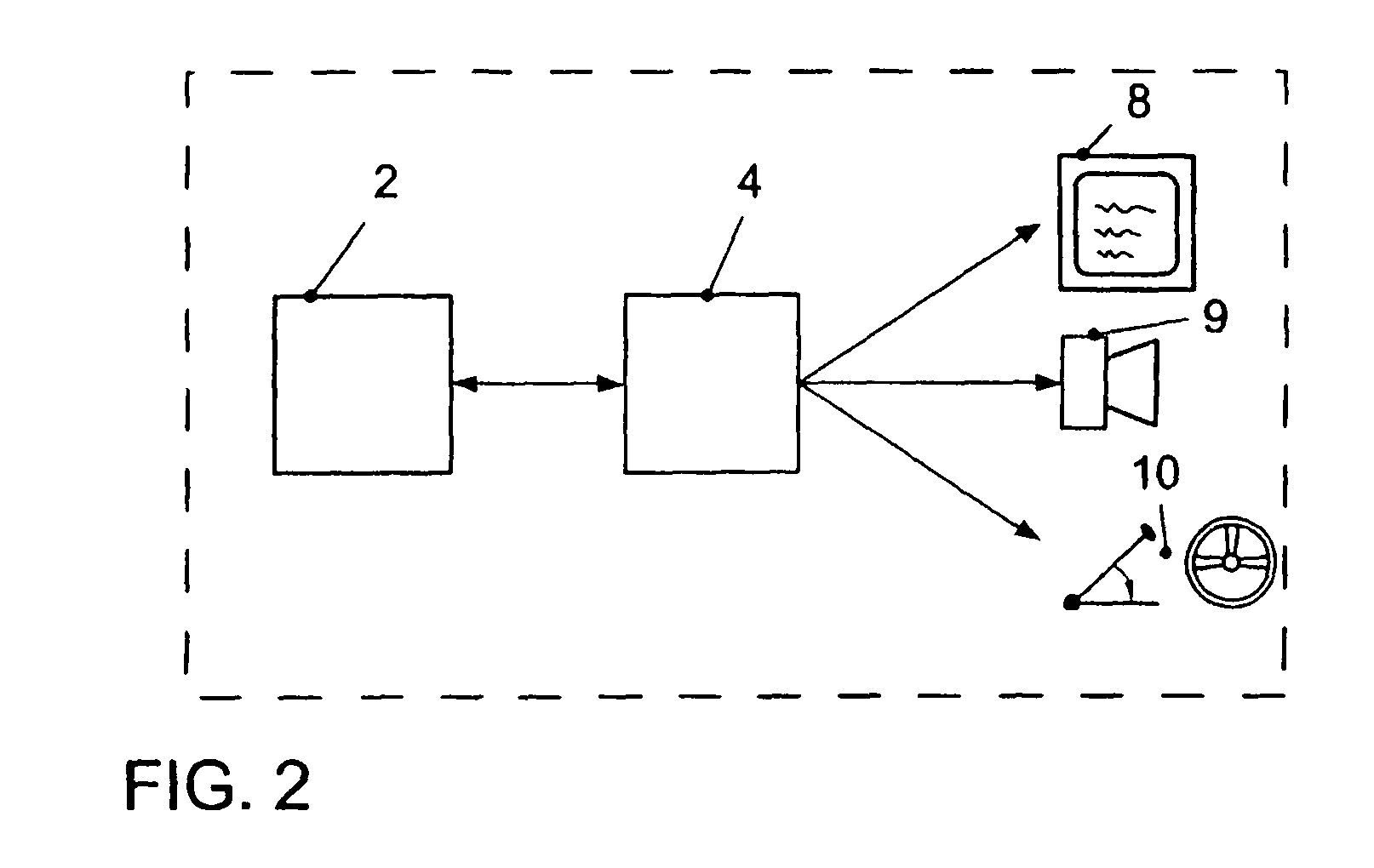

Device For A Motor Vehicle

ActiveUS20080033647A1Easy to measureRapid repetitionComplex mathematical operationsPosition/course control in two dimensionsEngineeringBiological activation

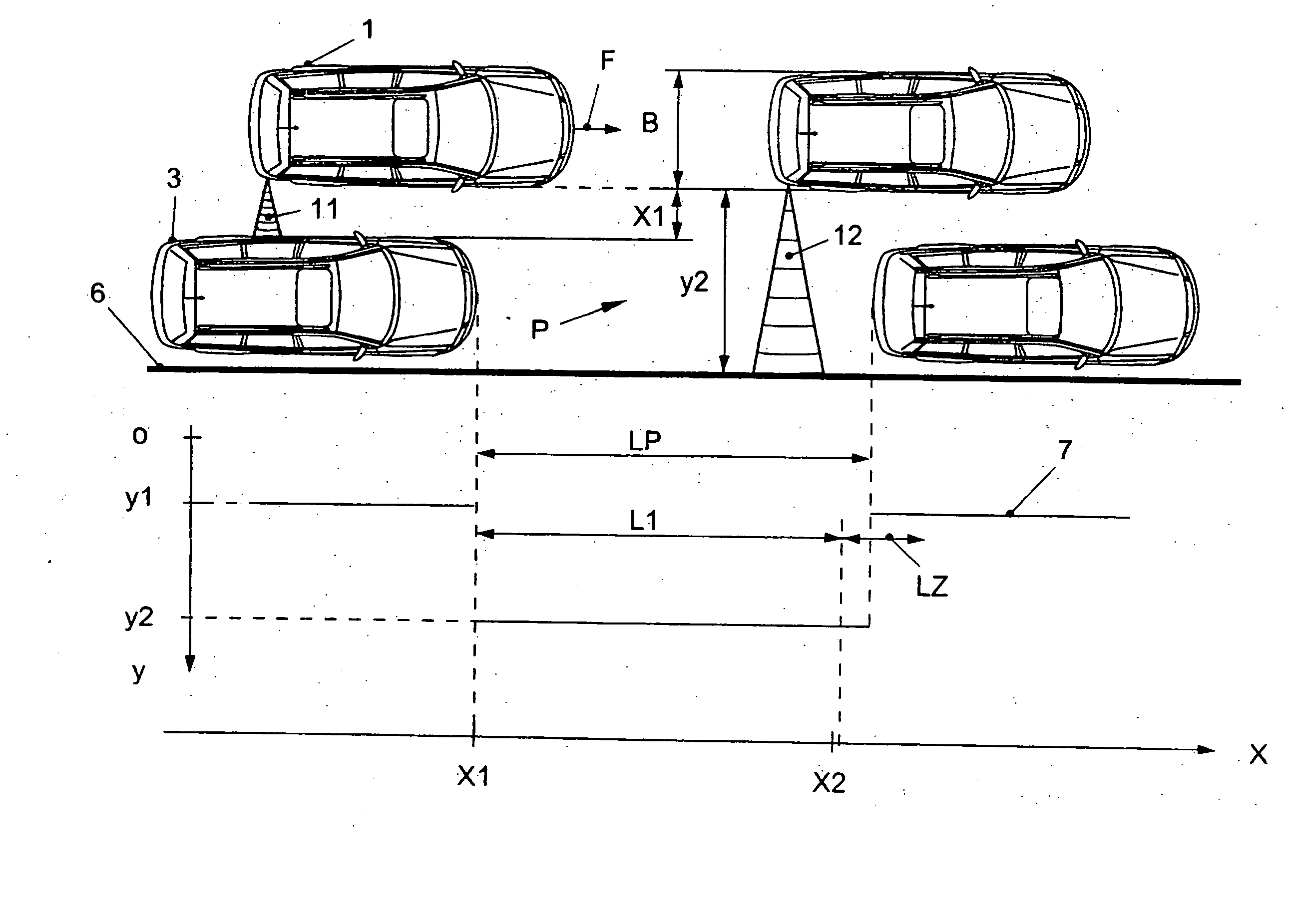

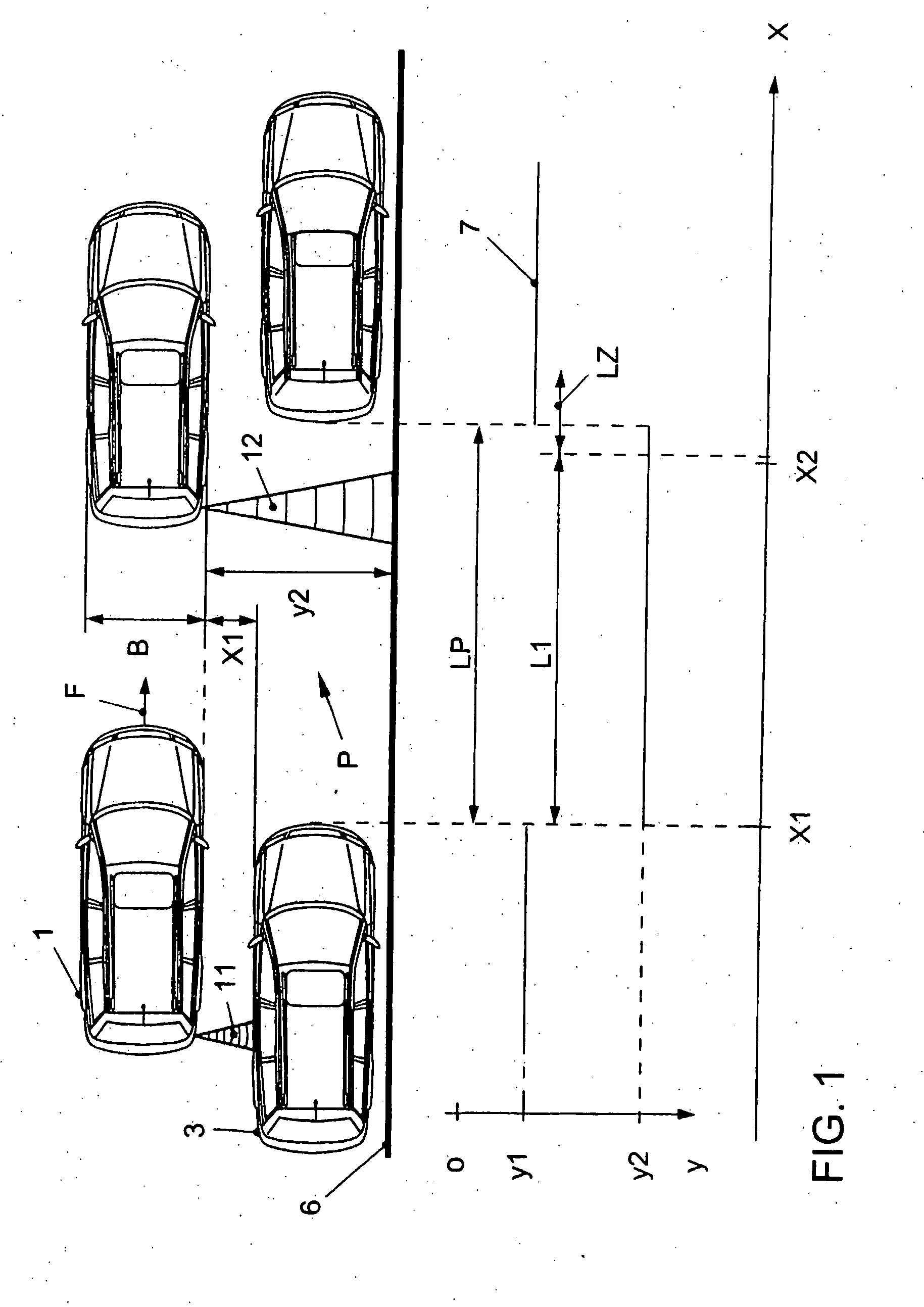

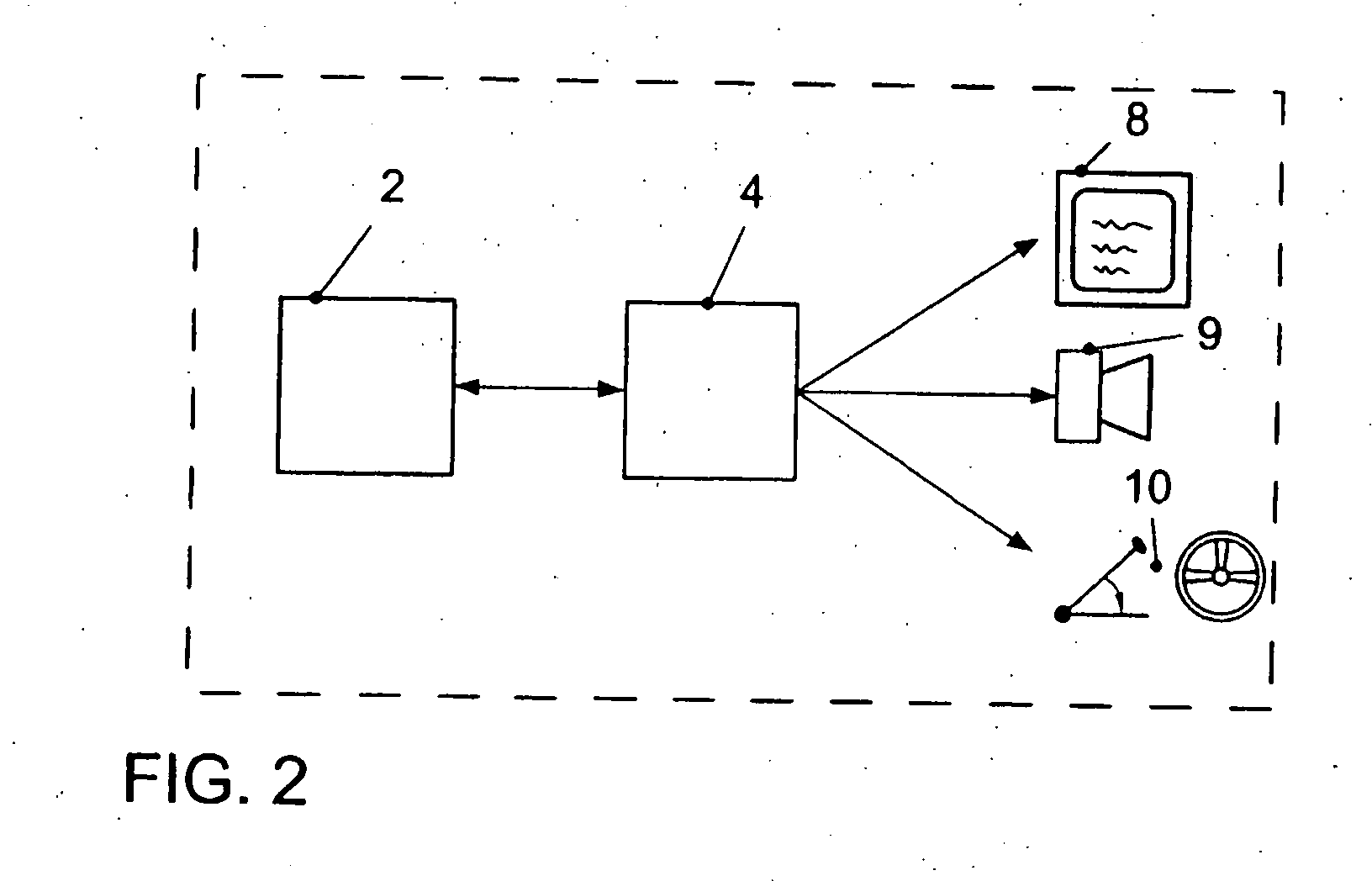

A device for a motor vehicle includes at least one distance sensor for recording a predominantly lateral clearance between the motor vehicle and objects, and a control device for controlling the distance sensor, the distance sensor emitting measuring signals during an activation time, and receiving measuring signal reflected by at least one object during a measurement receiving time. In the process, the measurement receiving time of the distance sensor is modifiable by the control device.

Owner:VOLKSWAGEN AG

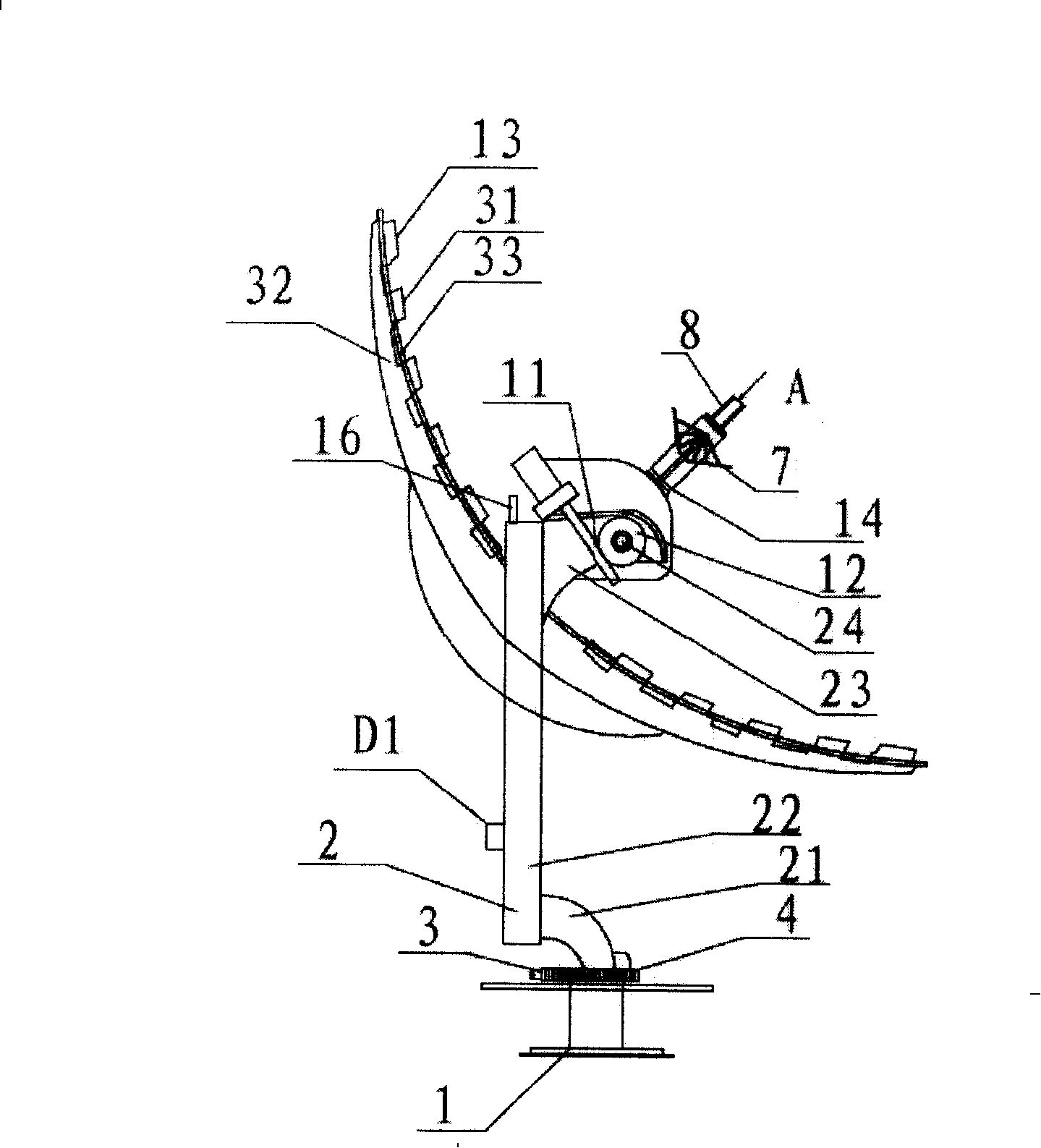

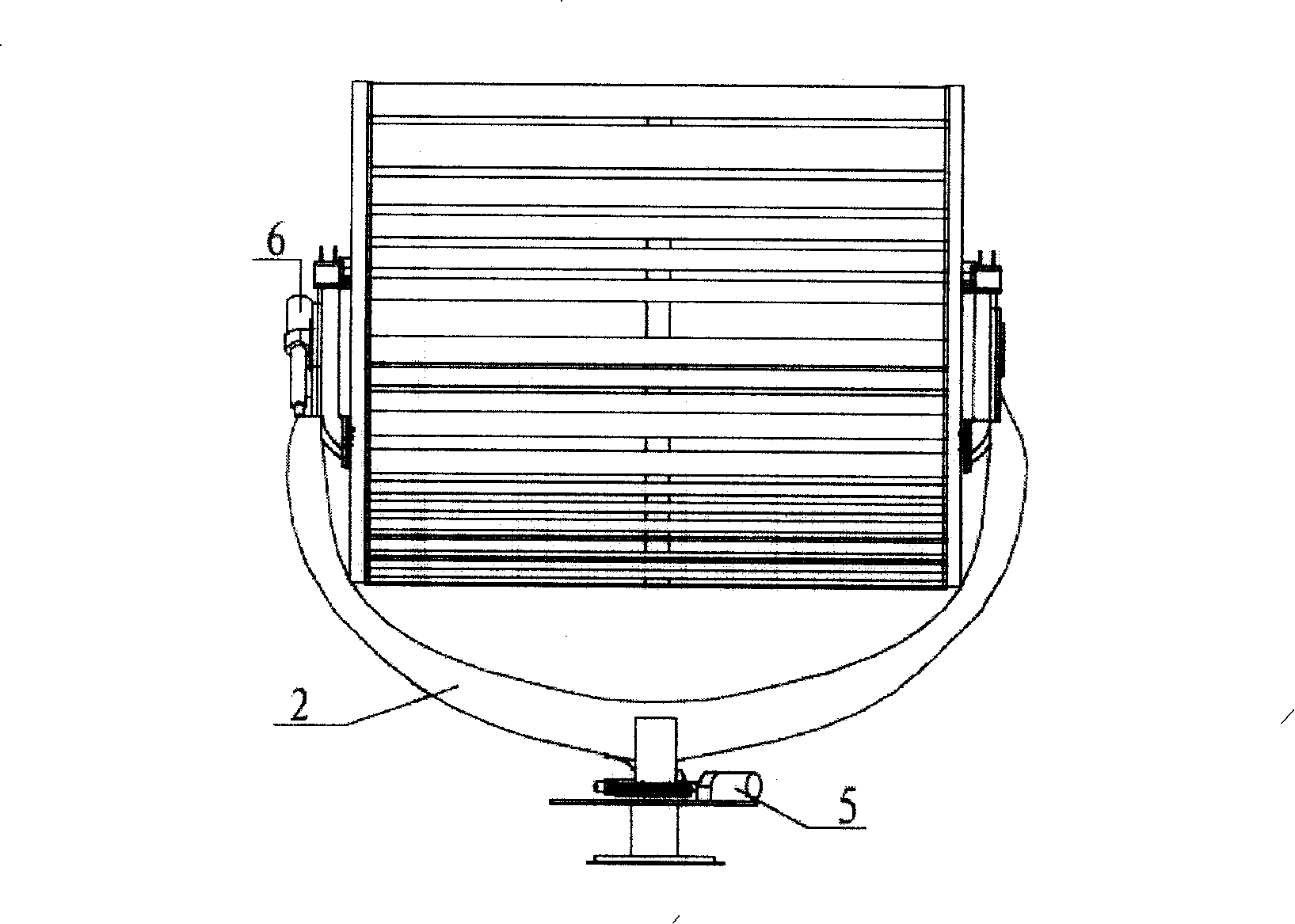

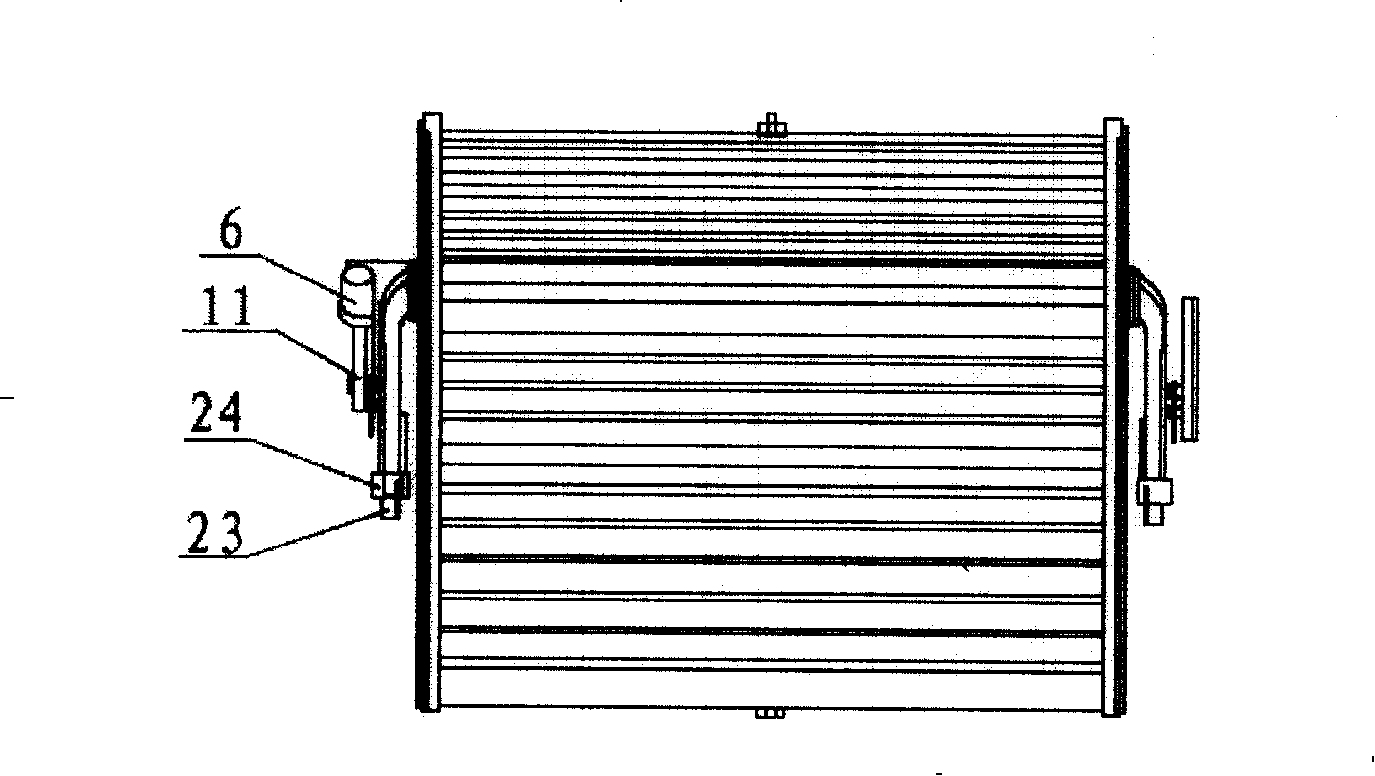

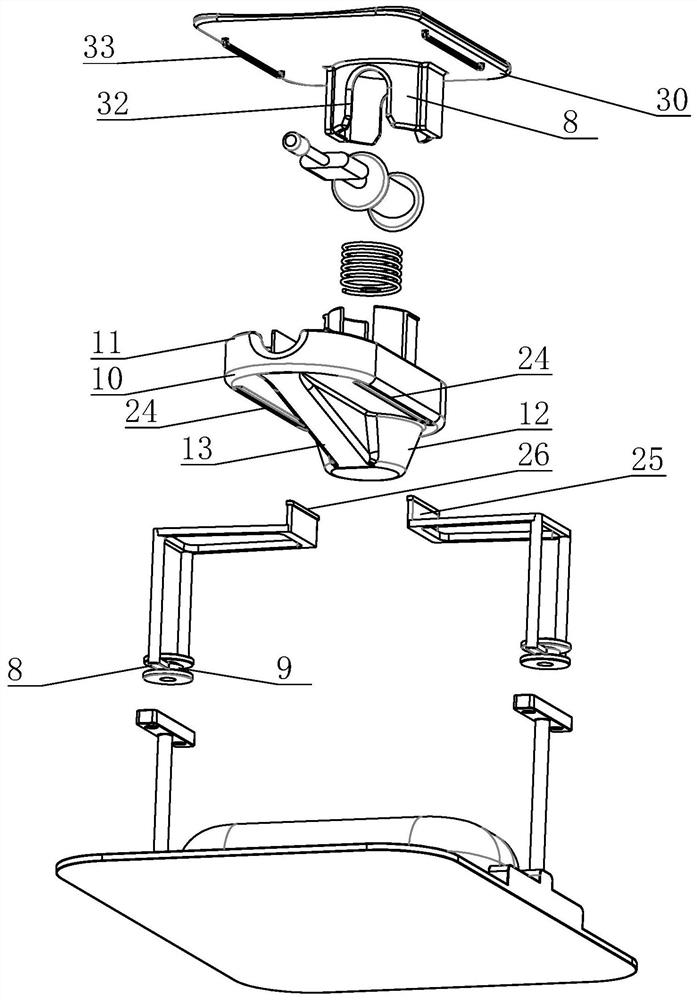

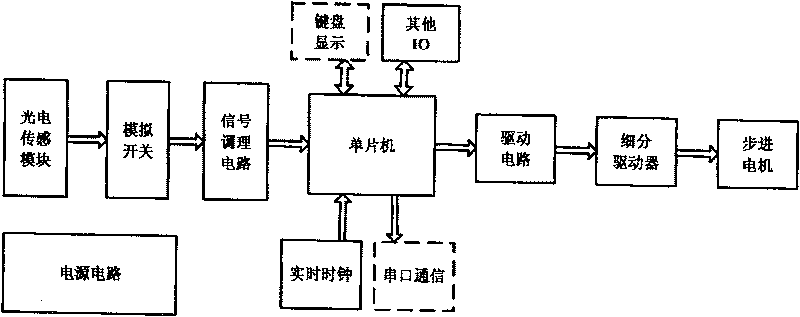

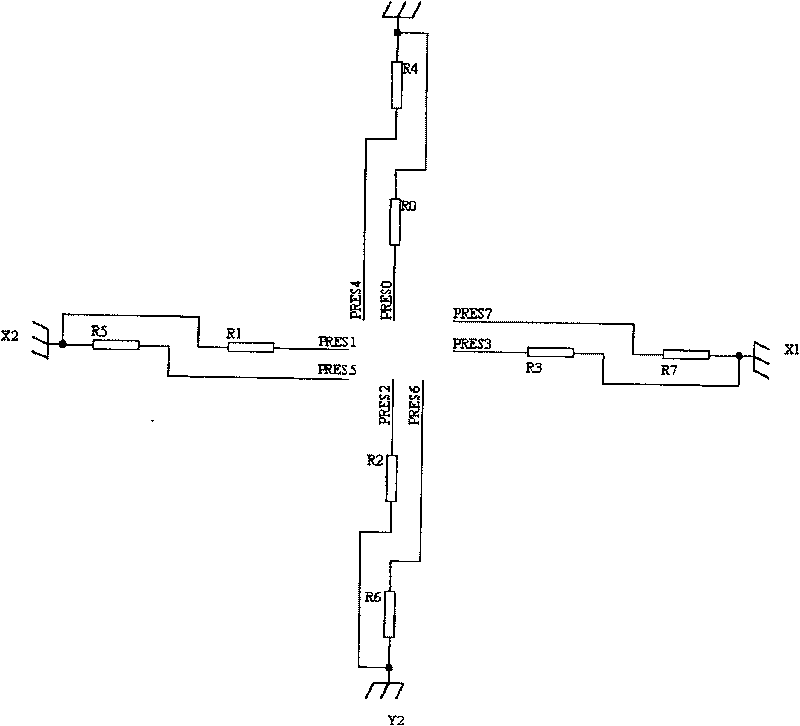

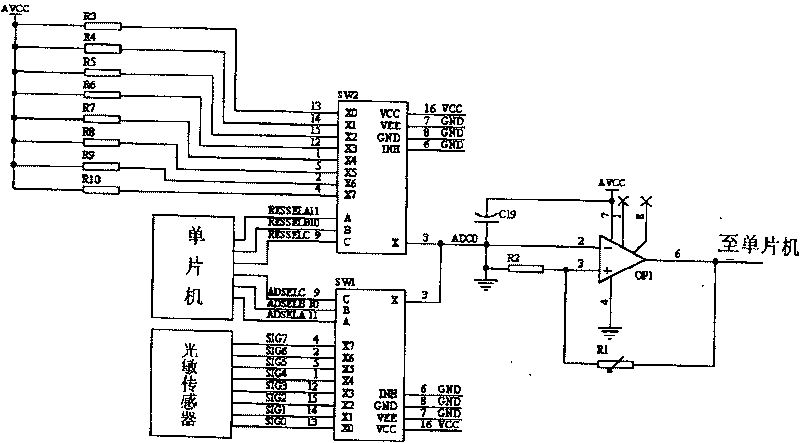

Automatic tracking type solar generator

InactiveCN101227158ALess power consumptionReduces power consumption and low cost compared to MCU trackersPhotovoltaic supportsMirrorsElectricitySolar generator

An automatic tracing type solar generator belongs to the technical field of solar electric power generation, which comprises a chassis, a supporting structure with a rotating shaft, a light concentrating thermal-collecting device, an accumulator, a driving device and an automatic tracing controlling device, wherein the supporting structure is connected on the chassis through a first driving device, the light concentrating heat-collecting device is mounted on the rotating shaft of the supporting structure and is connected with the supporting structure through a second driving device, the driving motor and the automatic tracing type controlling device of the two driving devices are electrically connected, and the light concentrating heat-collecting device is electrically connected with the accumulator. The invention has good property and long service life. The automatic tracing type lighting system combines input ends of four sensing devices to judge the position, which increases judging accuracy. The circuit is simple and reliable, power consumption is low, and cost is greatly reduced compared with a single-chip processer tracker. The invention effectively utilizes solar, which is nonpolluting, no discharging, saves energy and protects environment. A light collecting cover can automatically turnover upwards, has the function of snow resistance, rain resistance and automatic protection, and effectively protects the damage of a motor.

Owner:北京格物创道科技发明有限公司

Device for a motor vehicle

ActiveUS8244457B2Easy to measureRapid repetitionAnti-collision systemsEngine controllersMotorized vehicleDistance sensors

Owner:VOLKSWAGEN AG

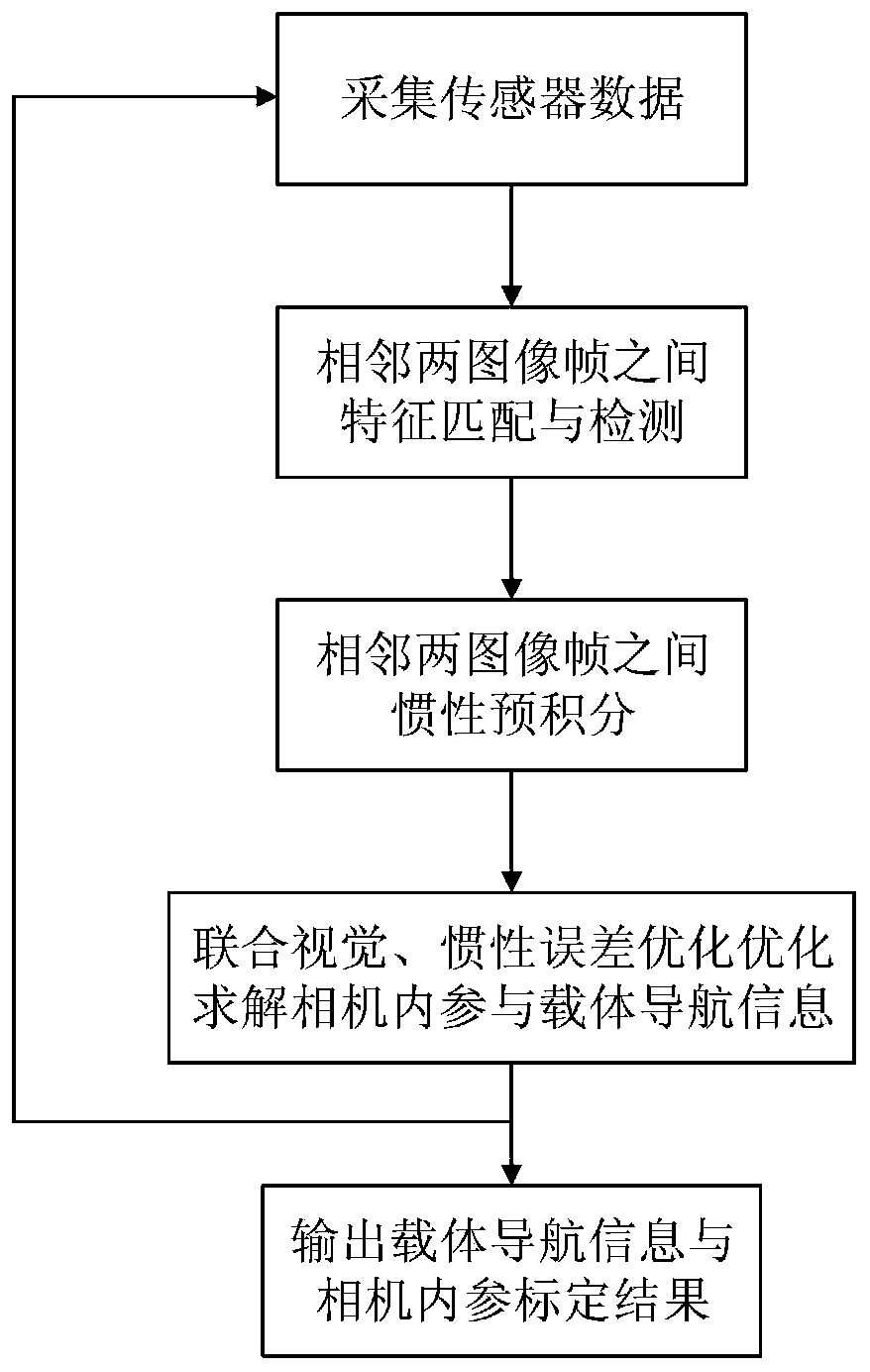

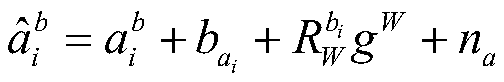

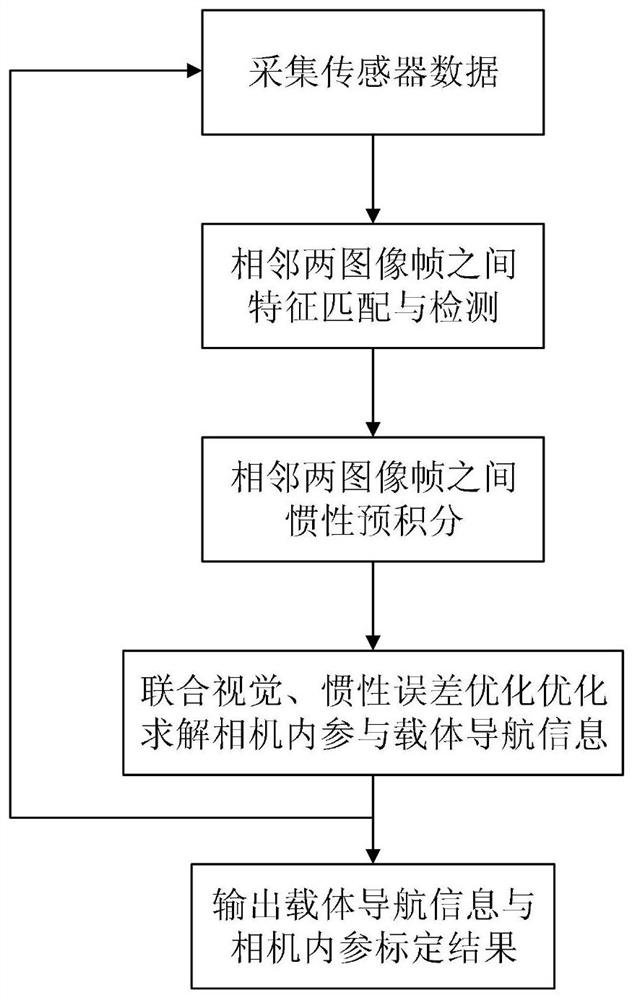

Visual/inertial integrated navigation method based on online calibration of camera internal parameters

ActiveCN111156997AResolved Accuracy DecreaseHigh precisionNavigation by speed/acceleration measurementsAccelerometer dataGyroscope

The invention discloses a vision / inertia integrated navigation method based on online calibration of camera internal parameters. The method comprises the steps of collecting visual sensor data S(k), accelerometer data and gyroscope data at the moment k, and performing feature matching and detection between two adjacent image frames by utilizing the visual sensor data S(k); carrying out pre-integration between two adjacent image frames by utilizing inertial sensor data; optimizing and solving carrier navigation information and camera internal parameters by combining a visual reprojection errorand an inertia pre-integration error; and outputting carrier navigation information and the camera internal parameters. According to the invention, the calibration of the camera internal parameters can be completed under the visual / inertial navigation framework, and the problem that the precision of the navigation system is reduced due to changes of the camera internal parameters can be effectively solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

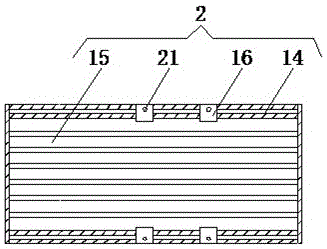

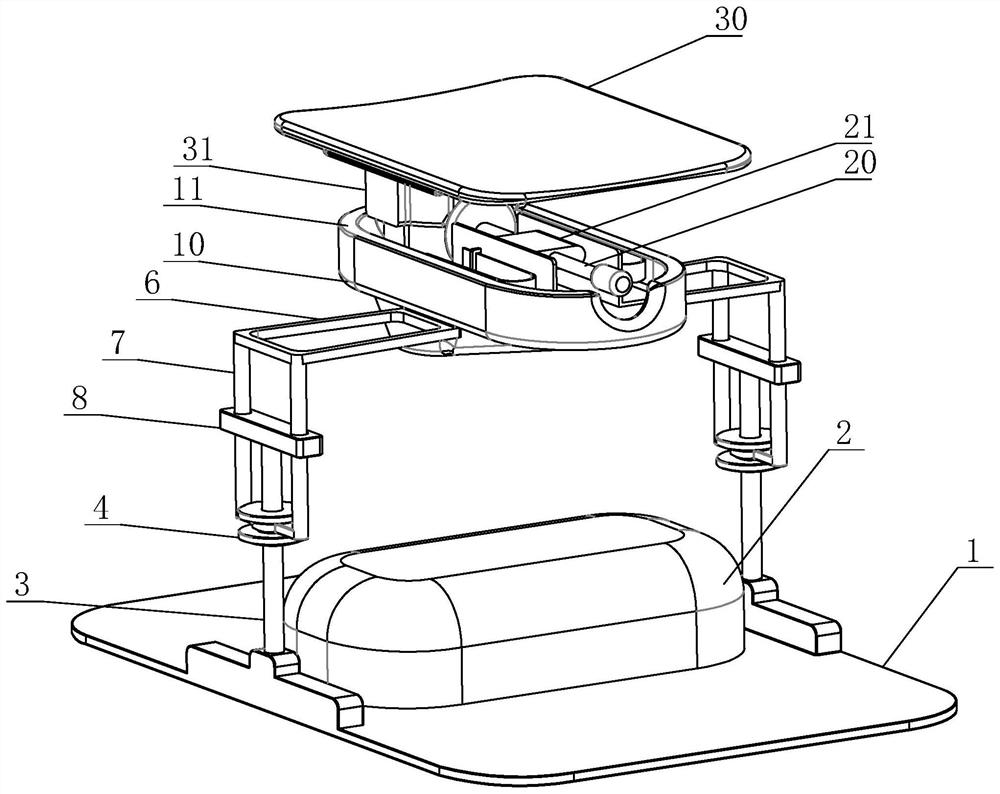

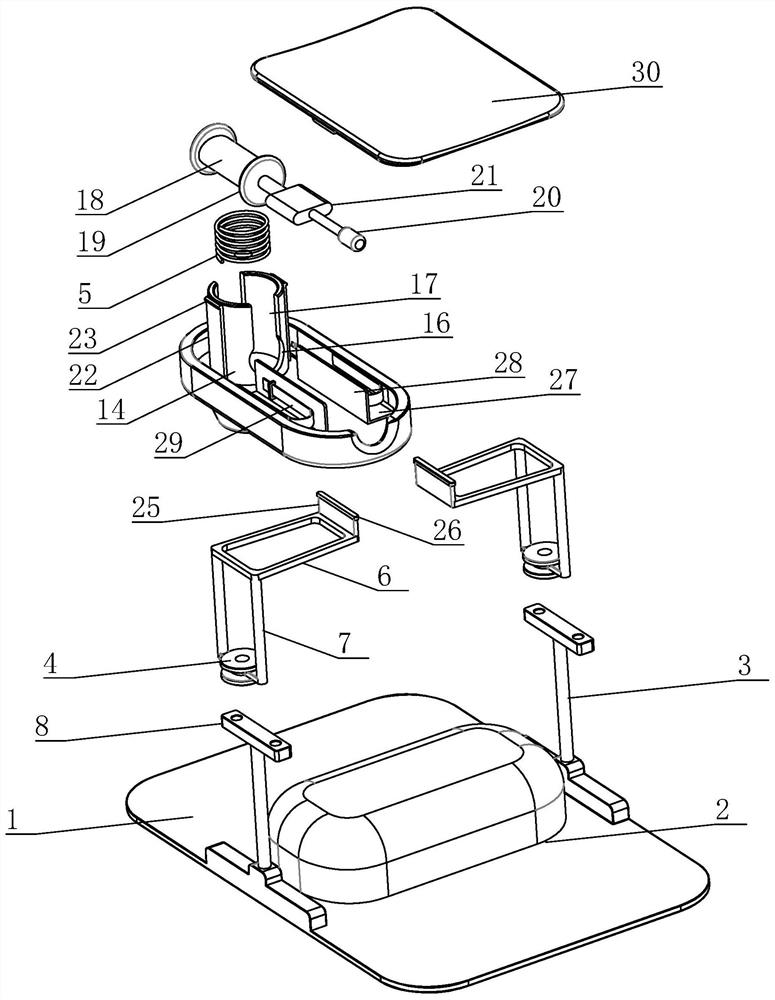

Foot measuring device and multi-dimensional foot feature analyzing system and method

ActiveCN110179468AGuaranteed accuracyResolved Accuracy DecreaseDiagnostic recording/measuringSensorsFeature extractionMeasurement device

The present invention discloses a foot measuring device and a multi-dimensional foot feature analyzing system and method. The multi-dimensional foot feature analyzing system comprises a foot measuringdevice, a connector and a terminal device; the foot measuring device is used for obtaining foot raw data, including point cloud data, RGB data, pressure distribution data and total pressure data; theconnector is respectively connected with the foot measuring device and the terminal device; the terminal device is used for calculating and visualizedly outputting multi-dimensional foot features, and the method comprises corresponding user operations, data interaction between the foot measuring device and the terminal device, fusing of the raw data collected by the foot measuring device and multi-dimensional foot feature extraction. The provided foot measuring device and the multi-dimensional foot feature analyzing system and method can acquire users' foot data in an open environment, analyze the multi-dimensional foot features quickly and efficiently, and provide automatic calibration of the foot measuring device.

Owner:福建双驰智能信息技术有限公司 +1

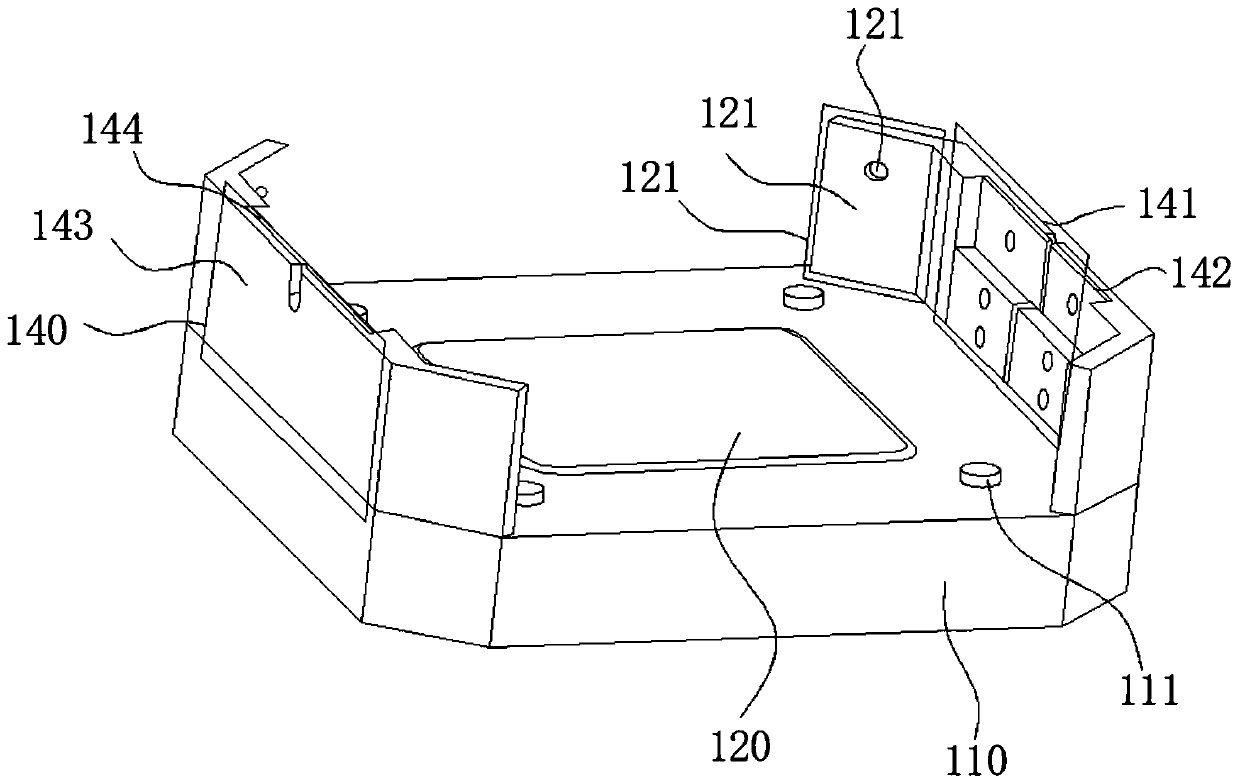

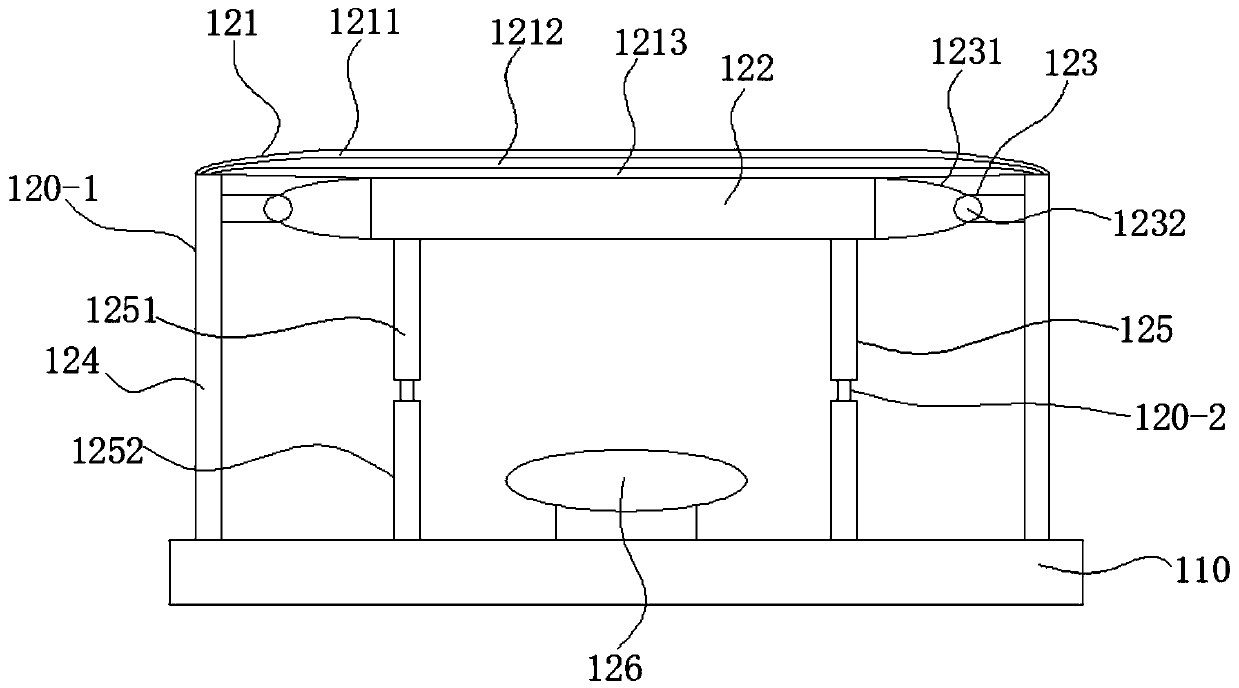

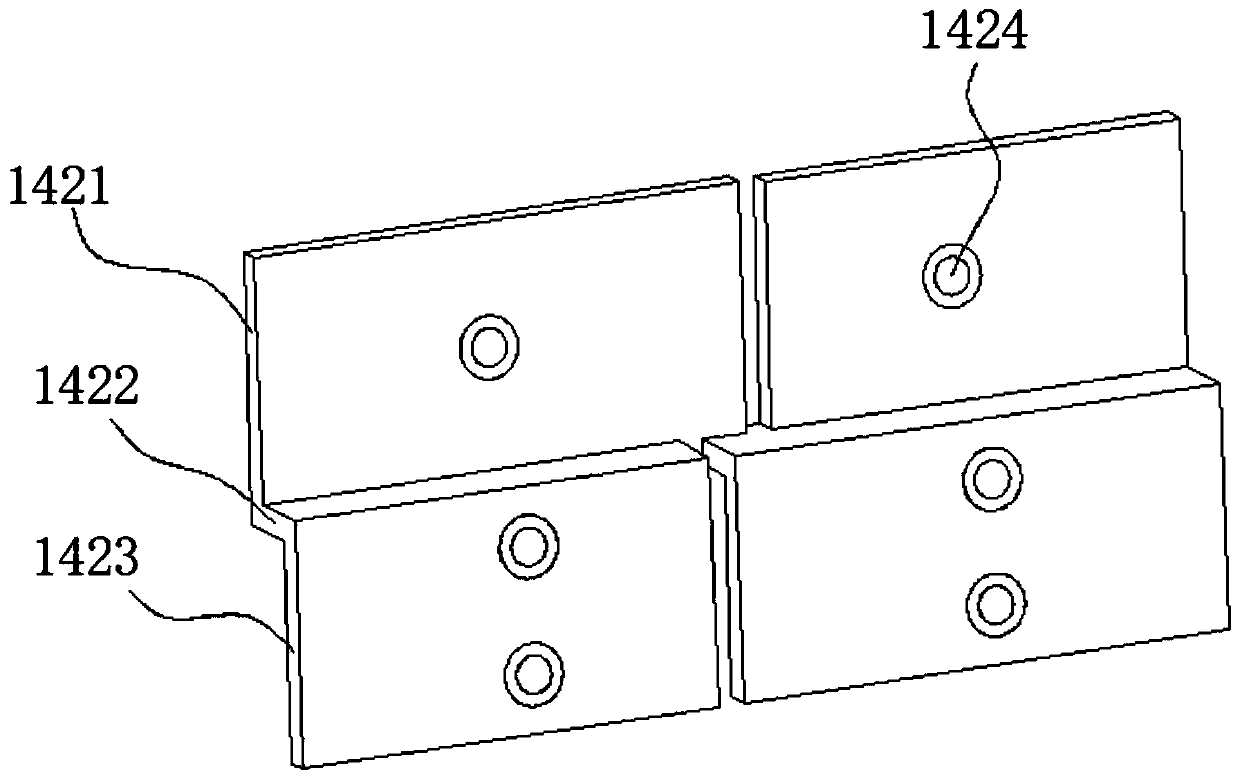

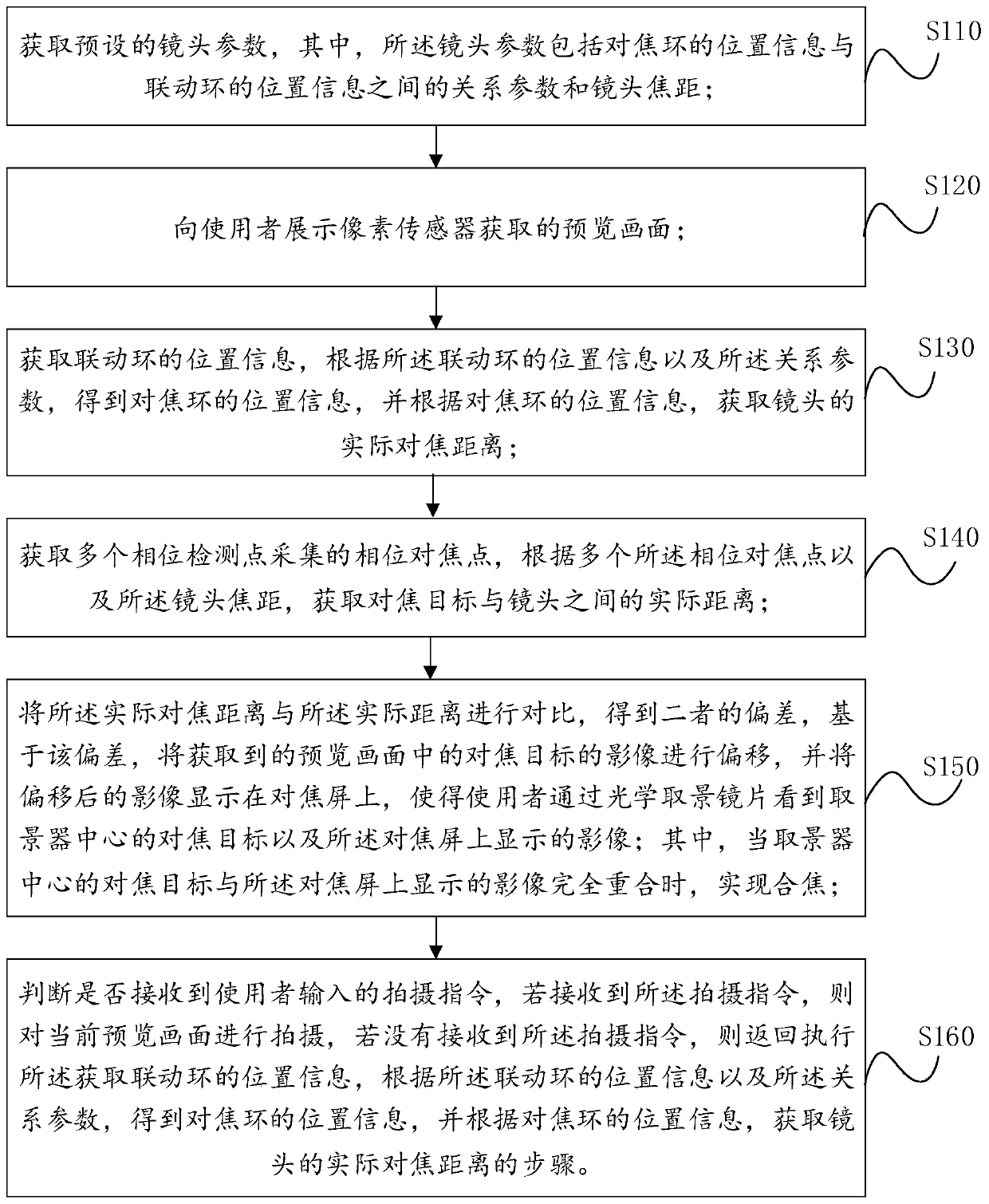

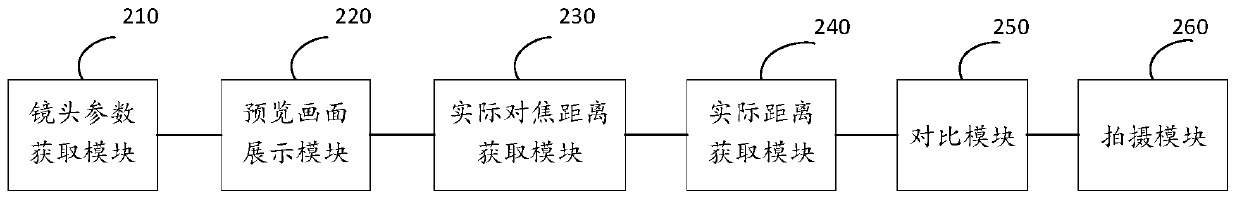

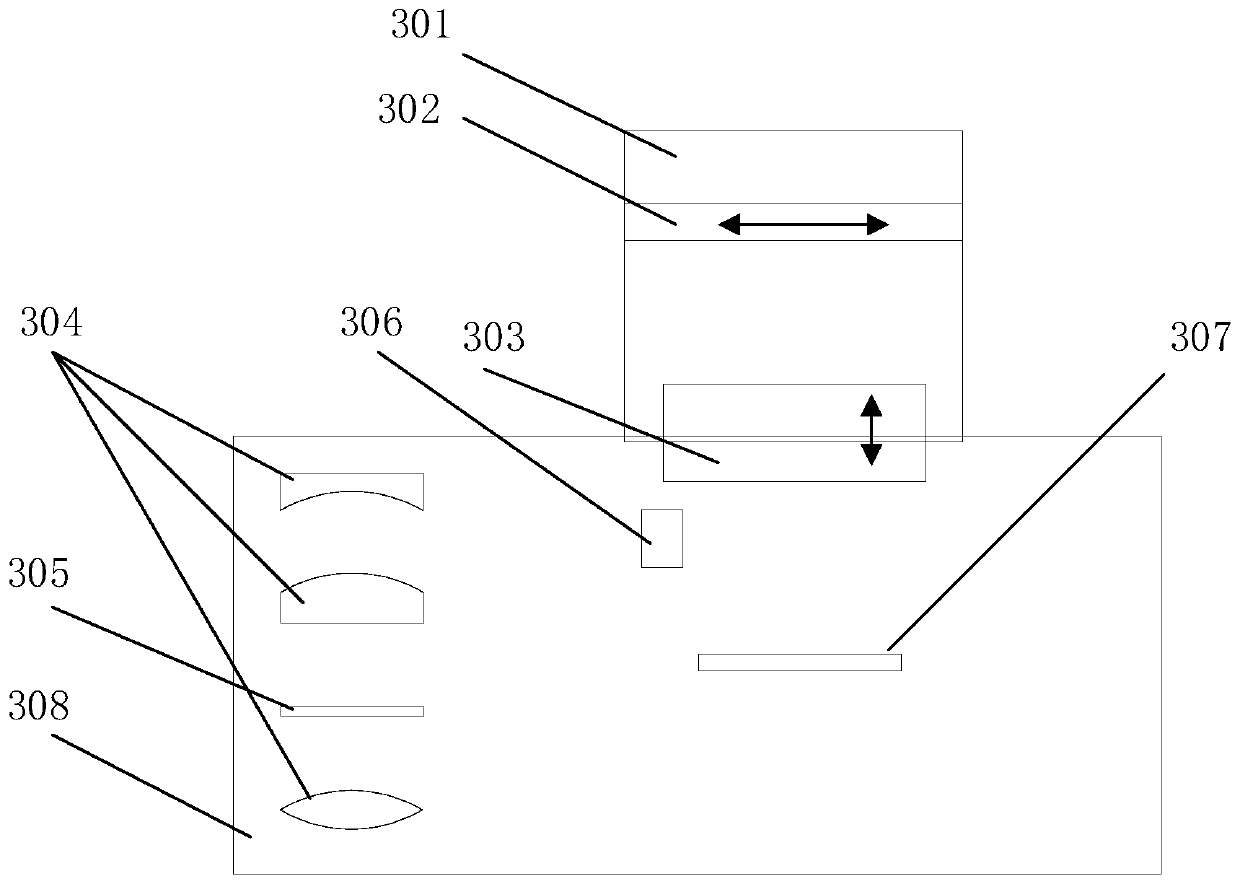

Manual focusing shooting method and device of exchangeable lens paraxial camera

ActiveCN111263059AEasy to operateResolve mismatchTelevision system detailsColor television detailsOphthalmologyComputer science

The embodiment of the invention discloses a manual focusing shooting method and device of an exchangeable lens paraxial camera. The method comprises the steps of acquiring preset lens parameters; displaying a preview image acquired by a pixel sensor to a user; obtaining the actual focusing distance of the lens according to the position information of a linkage ring and the lens parameters; obtaining the actual distance between a focusing target and the lens according to the phase focusing point and the lens focal length; according to the deviation between the actual focusing distance and the actual distance, deviating the image of the focusing target in a preview image and displaying on a focusing screen; judging whether a shooting instruction is received or not ; if the shooting instruction is received, shooting the current preview image ; and if the shooting instruction is not received, executing the step of obtaining the actual focusing distance of the lens according to the positioninformation of the linkage ring and the lens parameters again.

Owner:SHANGHAI SEAGULL DIGITAL CAMERA

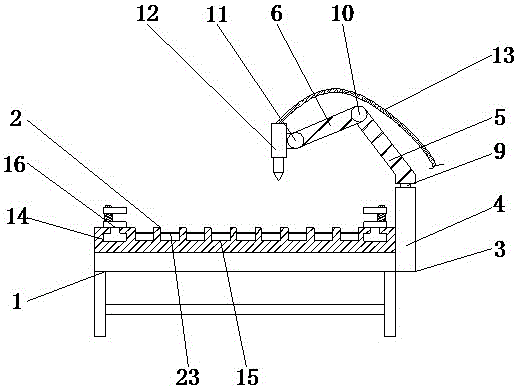

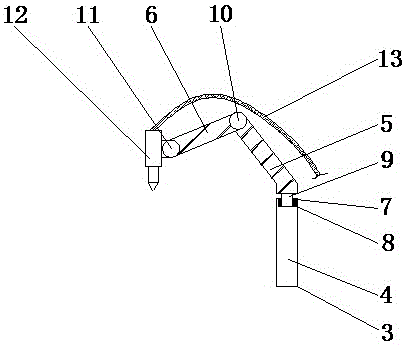

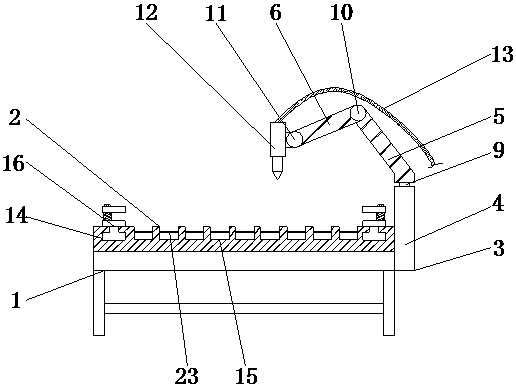

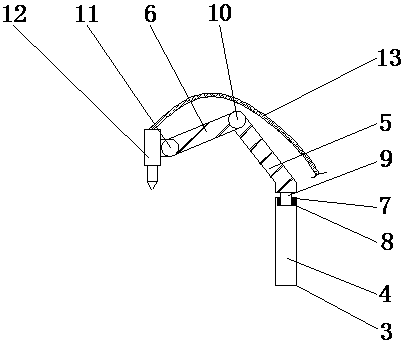

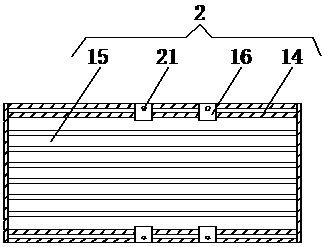

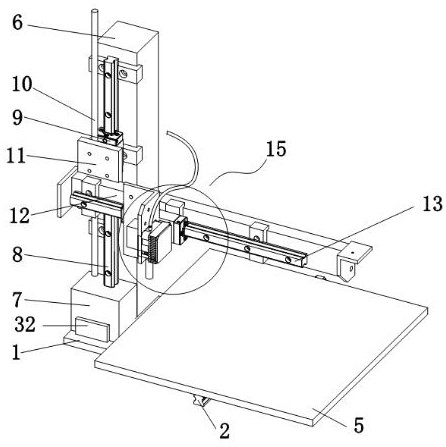

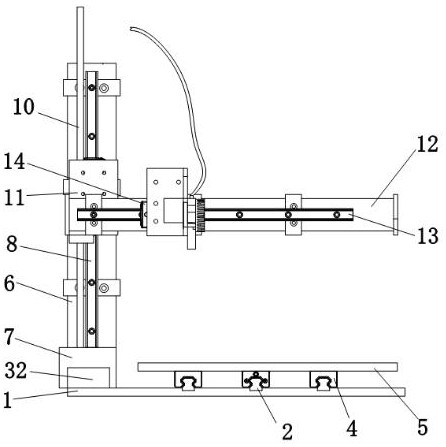

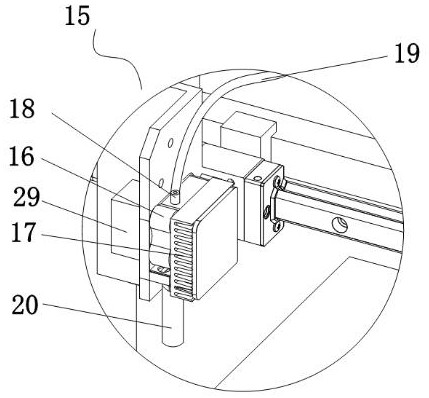

Flame cutting machine

InactiveCN106513918AEasy to cleanStrengthen the fixationGas flame welding apparatusEngineeringMechanical engineering

The invention discloses a flame cutting machine. The flame cutting machine comprises a base and a workbench. The bottom of the workbench is fixedly connected with the top of the base. A cutting device is fixedly mounted on one side face of the base. The cutting device comprises a fixing rod, a first connecting rod and a second connecting rod. A groove is formed in the top of the fixing rod. A bearing is arranged inside the groove. A rotating shaft is arranged at the bottom of the first connecting rod. One end of the rotating rod is movably connected with the top of the fixing rod through the bearing. One end of the first connecting rod is movably connected with one end of the second connecting rod through a first pin shaft. The other end of the second connecting rod is movably connected with one side face of a flame nozzle through a second pin shaft. An air inlet hose is arranged at the top of the flame nozzle. The two ends of the upper surface of the workbench are each provided with a slide rail. Water grooves are further formed in the upper surface of the workbench, wherein the water grooves are arrayed in an equally-spaced manner. The flame cutting machine is safe to use and convenient to clean, and cutting precision of the flame cutting machine is greatly improved.

Owner:WUXI DONGBEITANG YONGFENG RUBBER FACTORY

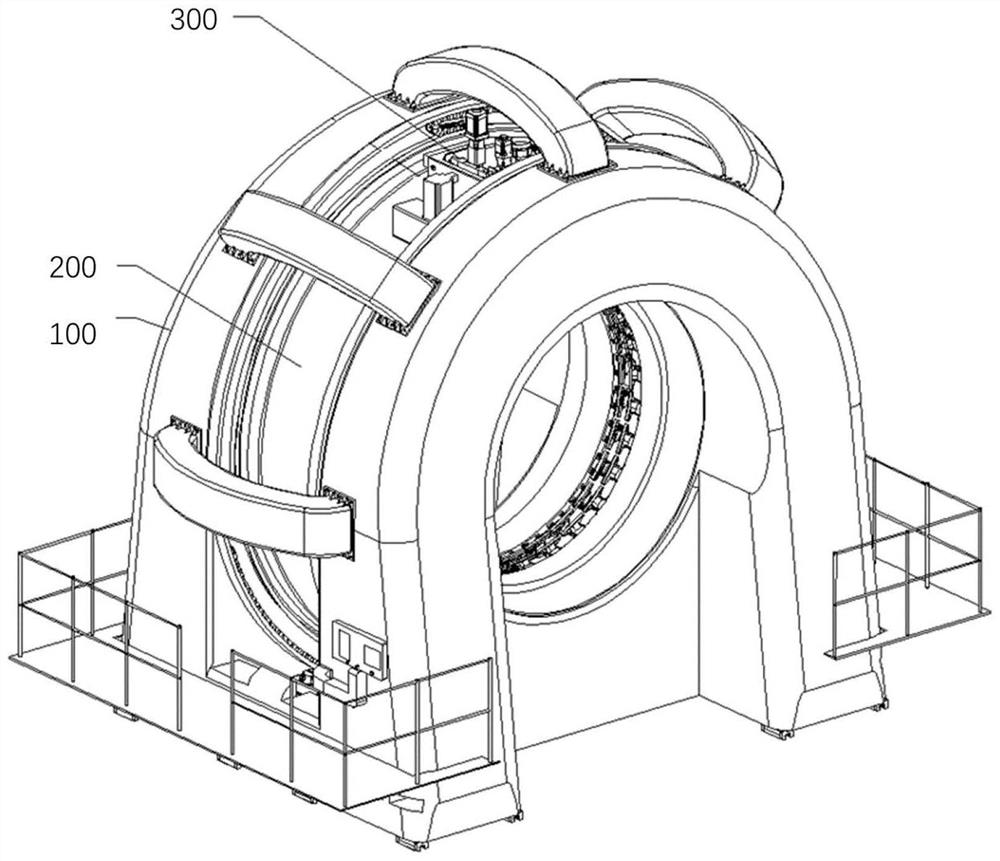

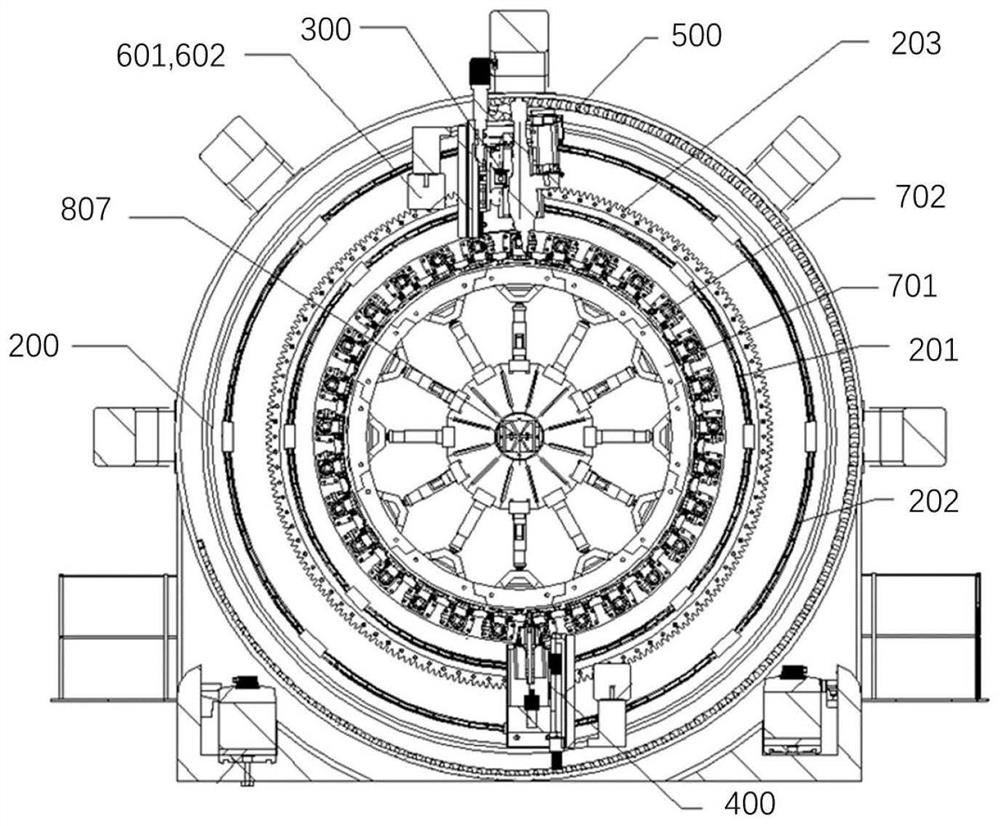

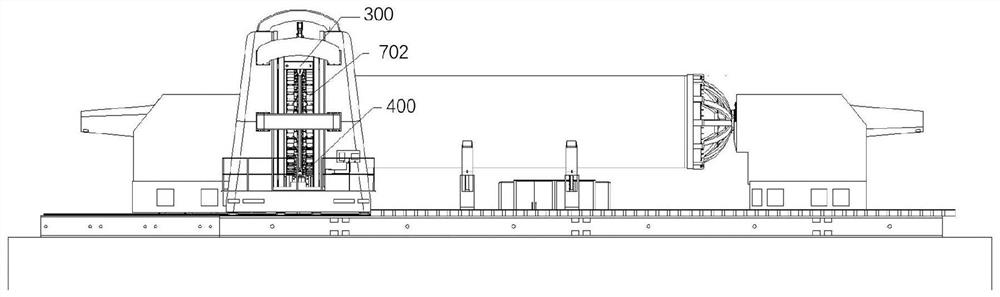

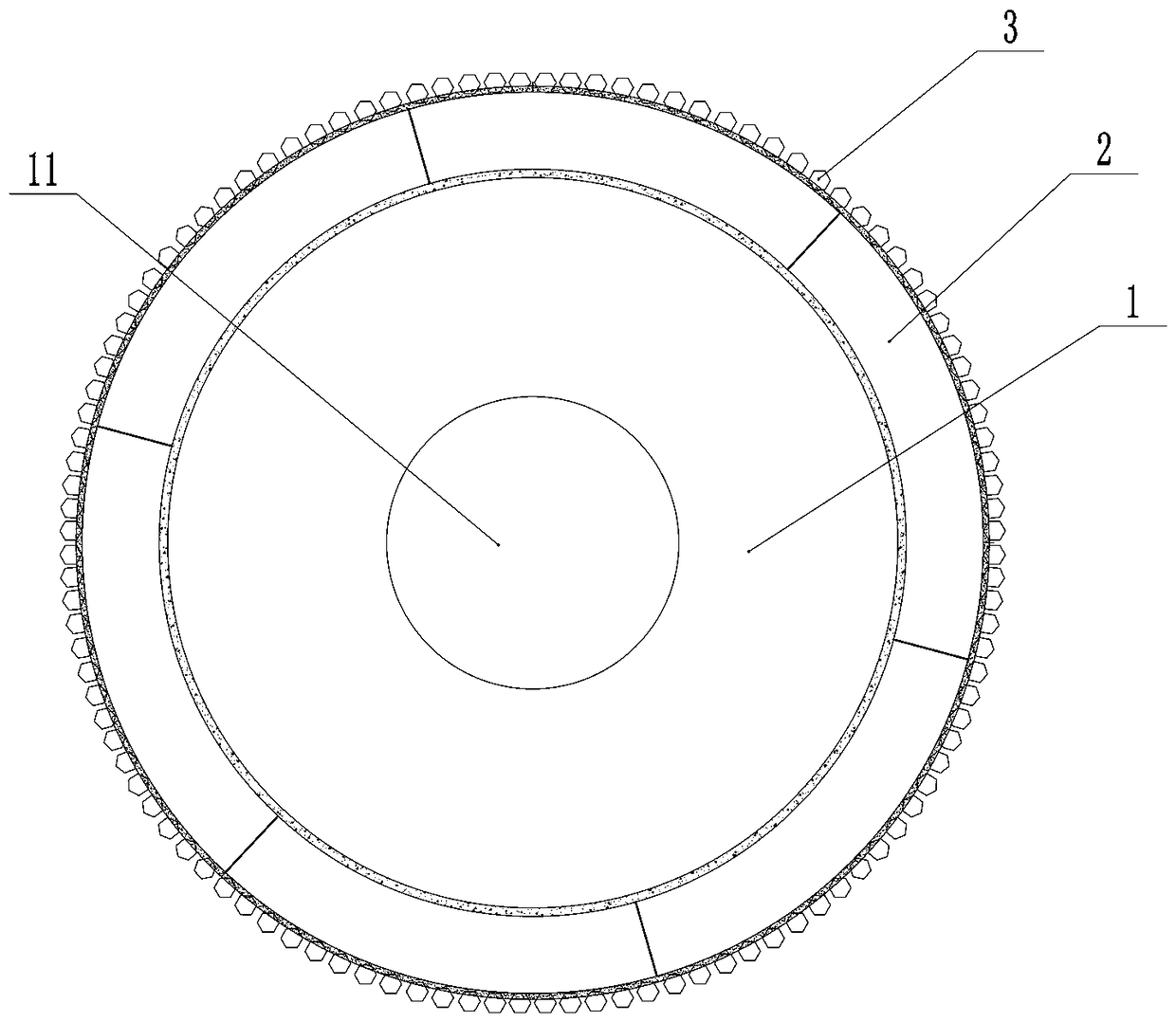

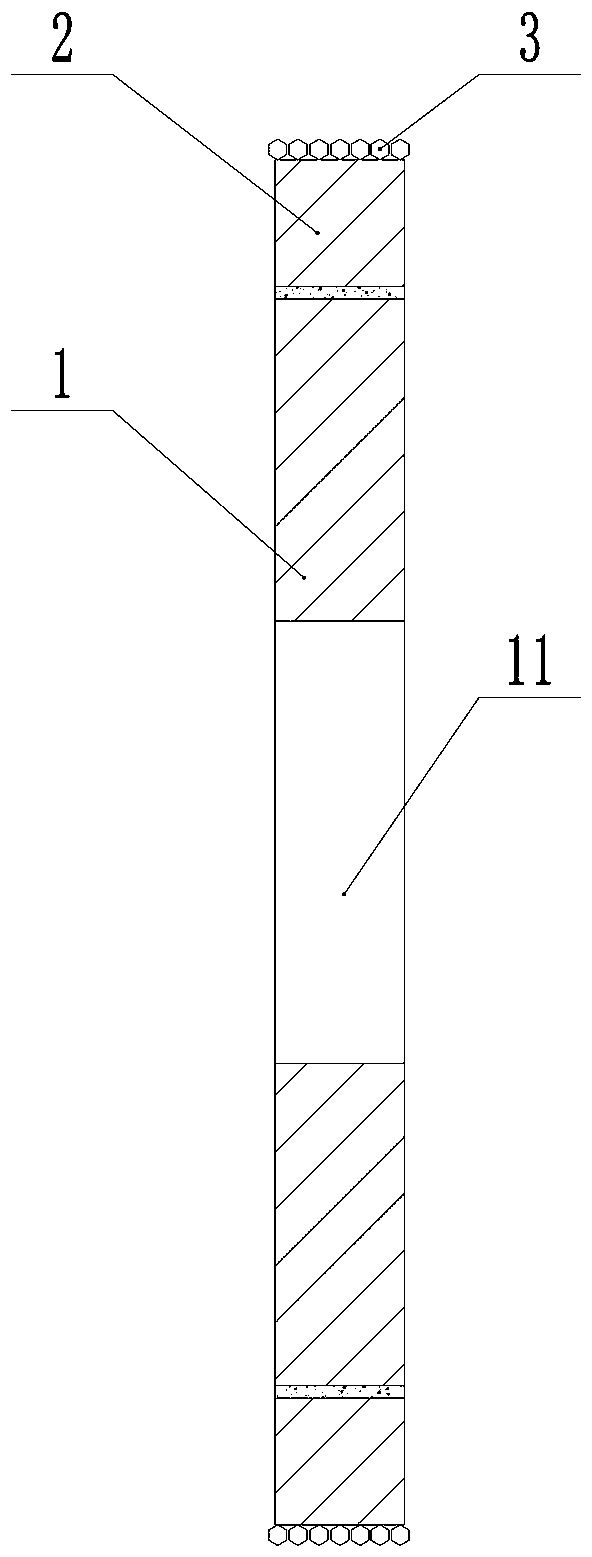

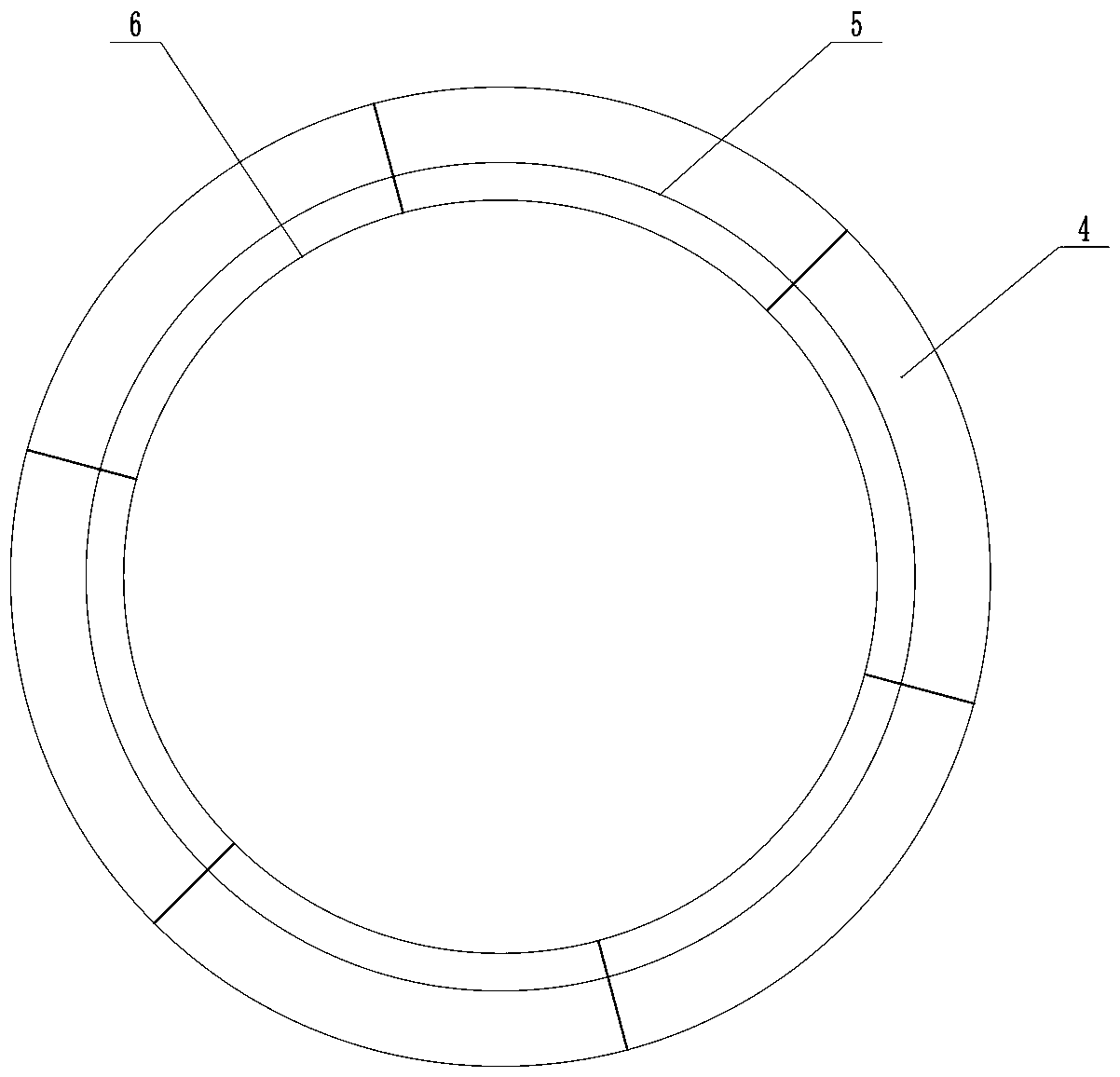

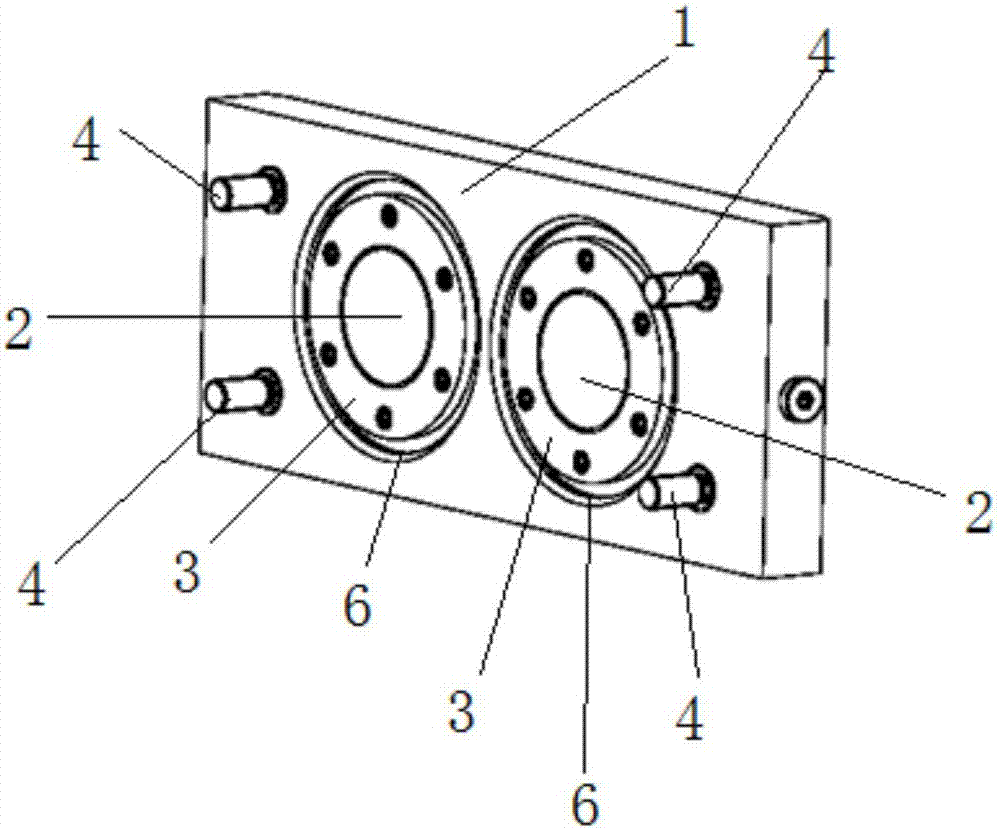

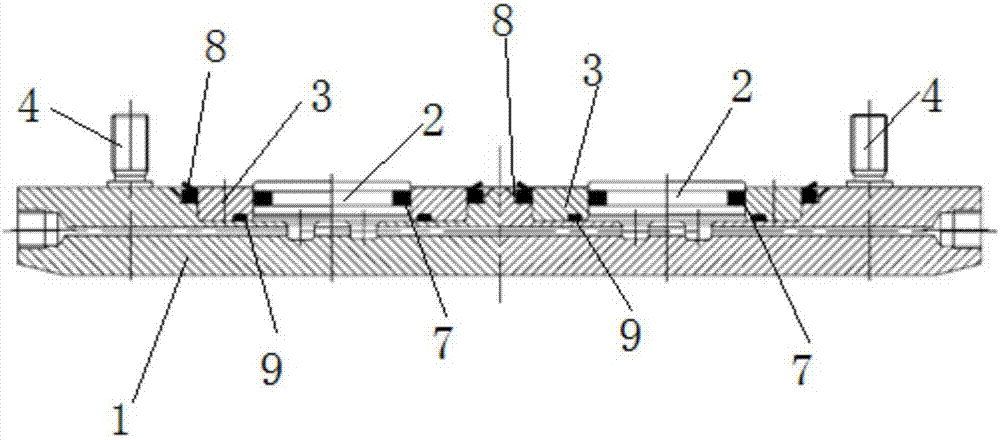

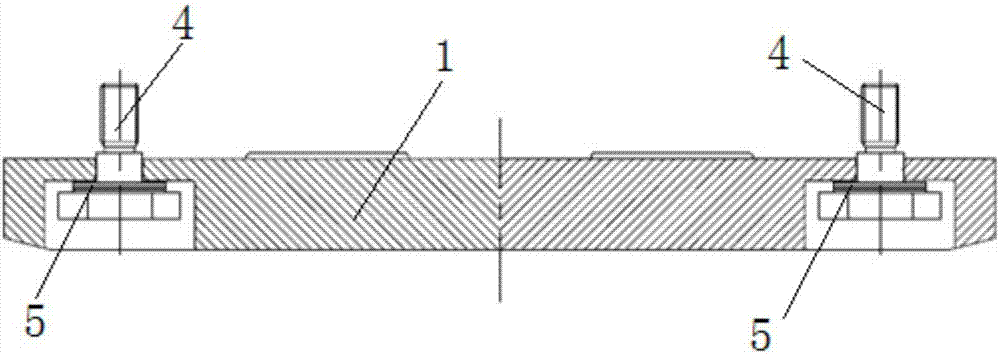

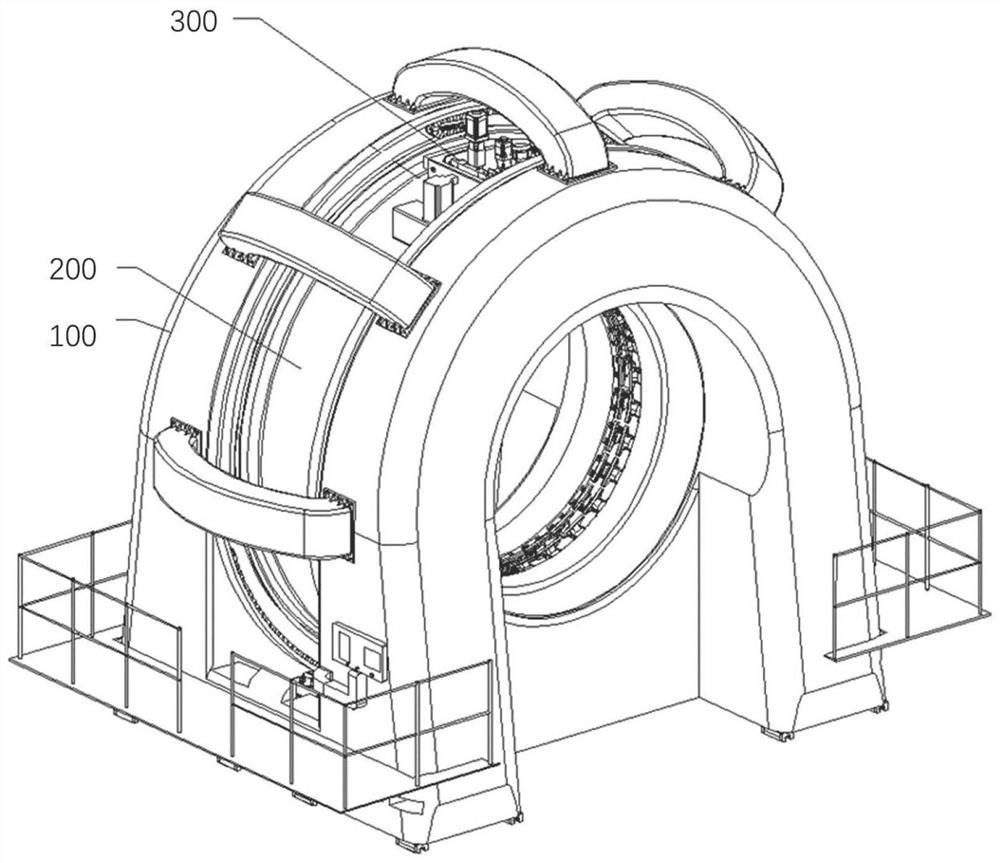

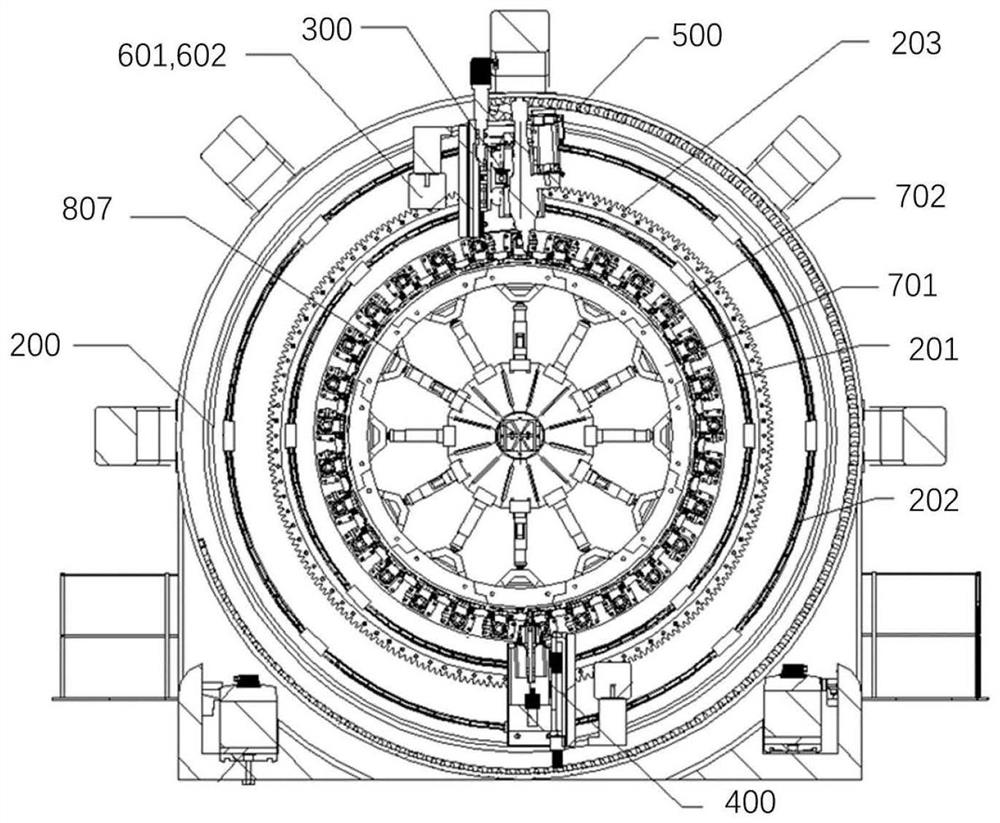

Friction stir welding device for welding storage tank of aerospace vehicle

ActiveCN112935523AResolved Accuracy DecreaseSolve the problem that the accuracy decreases after a long time of useOther manufacturing equipments/toolsNon-electric welding apparatusSlide platePortal frame

The invention provides a friction stir welding device for welding a storage tank of an aerospace vehicle. The friction stir welding device comprises a frame in a hollow portal frame form and used for fixedly arranging a to-be-welded storage tank, an annular sliding plate and a friction stir welding machine head. The annular sliding plate is a hollow circular sliding plate and is internally provided with a first annular guide rail, a second annular guide rail and an annular gear ring. The friction stir welding machine head is installed on the annular sliding plate and erected on the first annular guide rail and the second annular guide rail, and the friction stir welding machine head is driven on the annular gear ring to run around the first annular guide rail and the second annular guide rail so as to complete circumferential welding of the storage box to be welded. According to the device, the problem that the precision is reduced after the device is used for a long time due to large inertia caused by synchronous rotation is solved, and the practicability of the device is also improved.

Owner:BEIJING LANDSPACETECH CO LTD

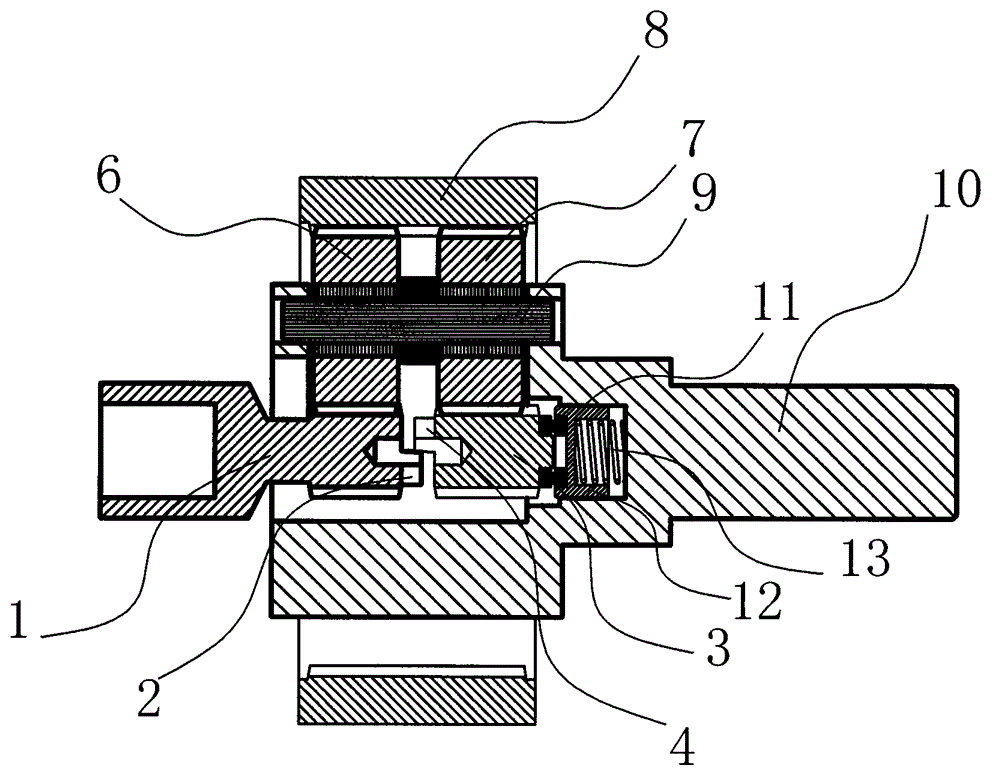

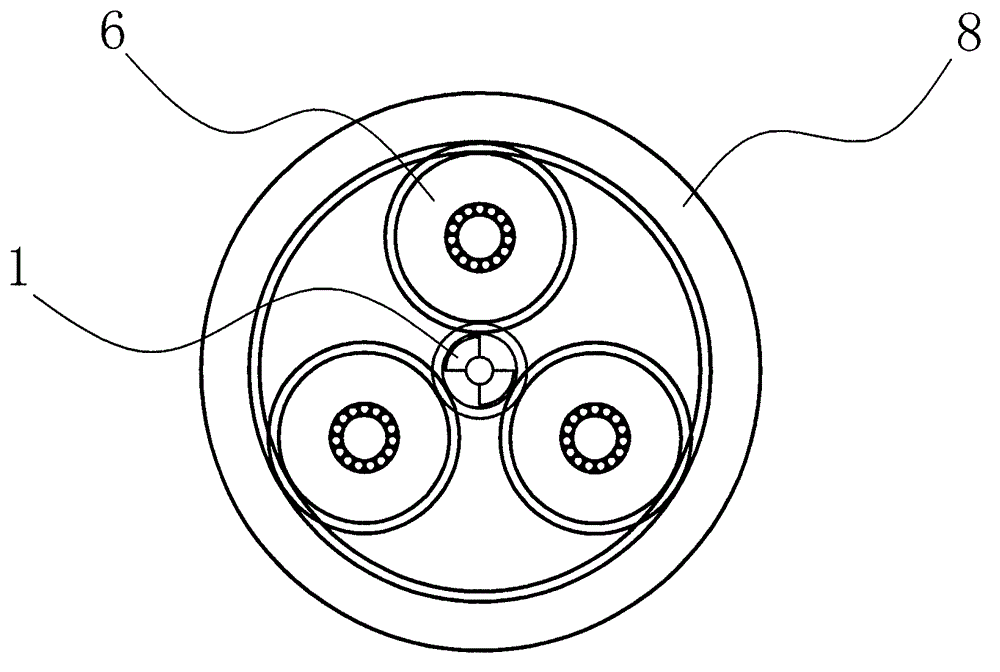

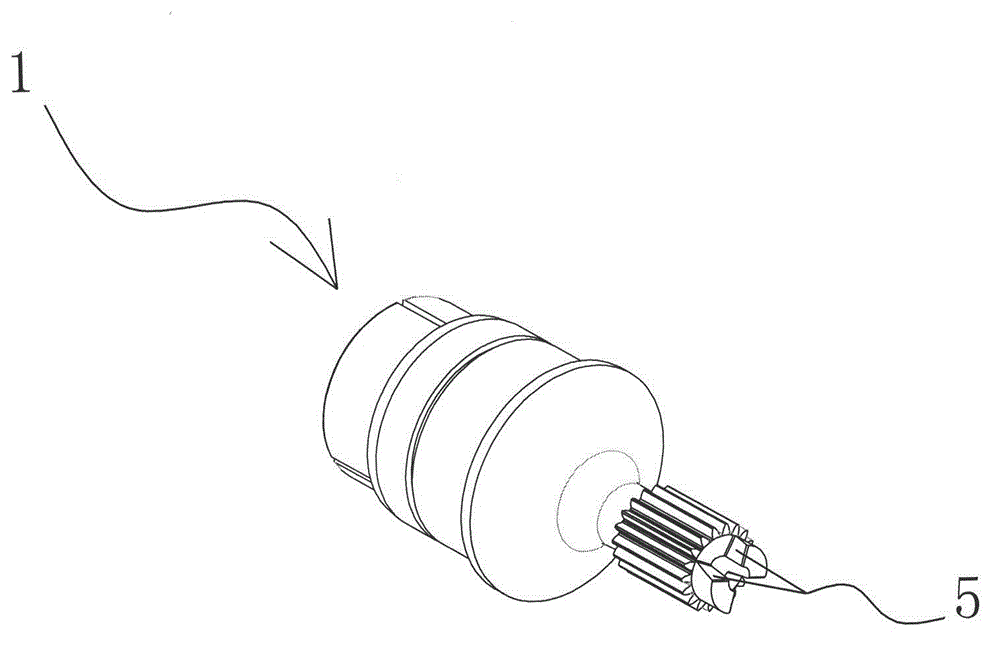

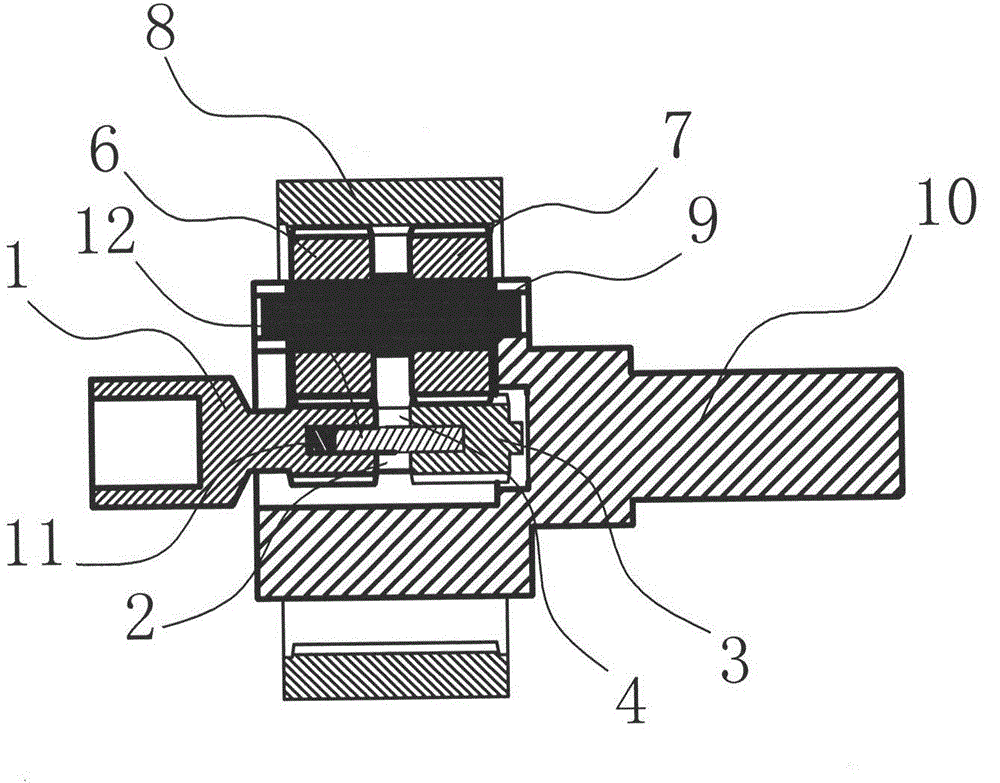

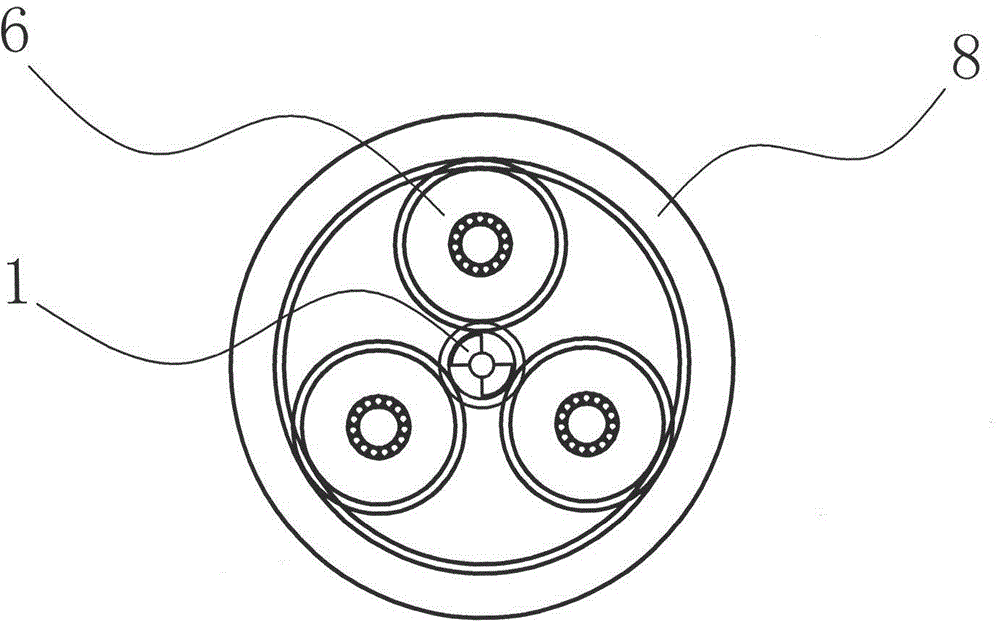

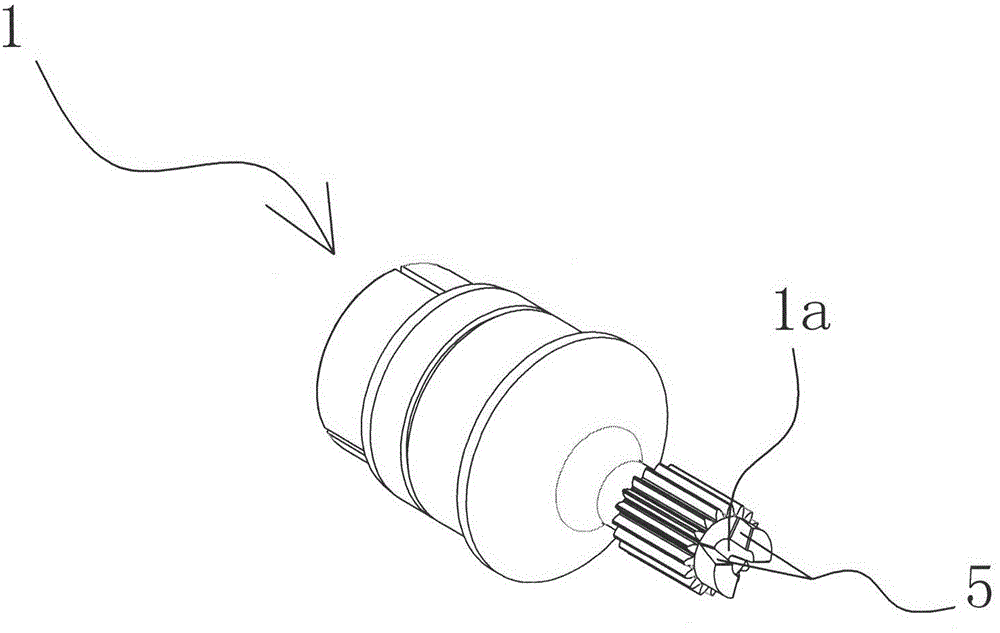

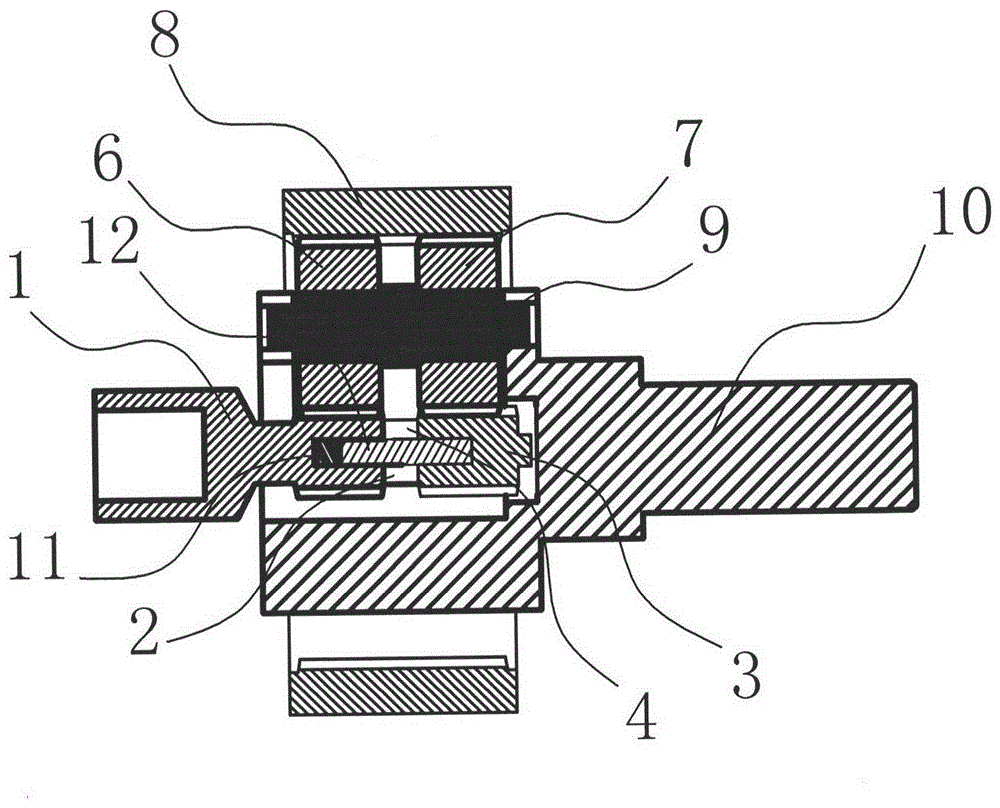

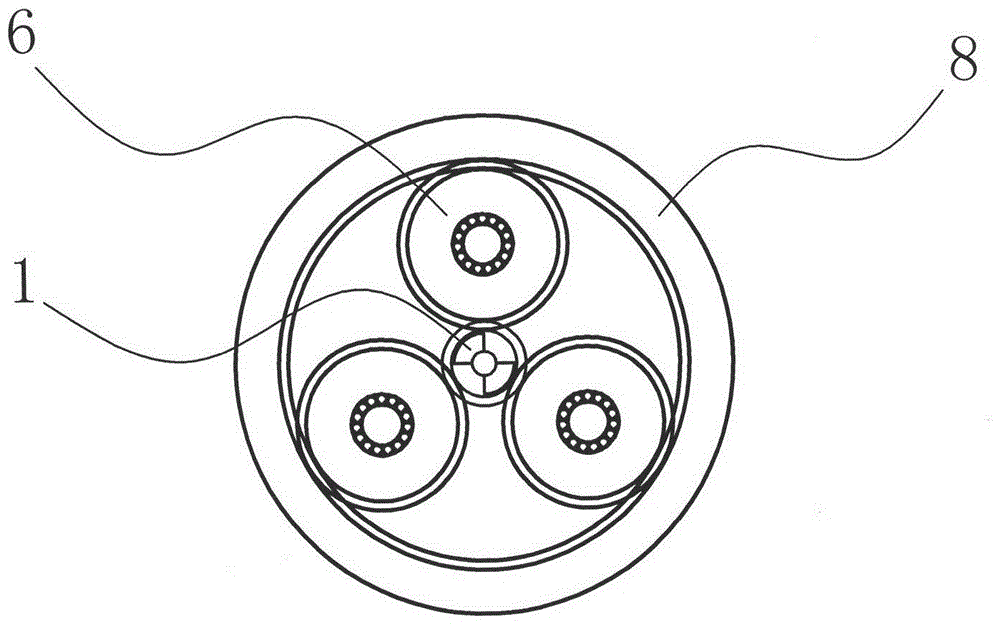

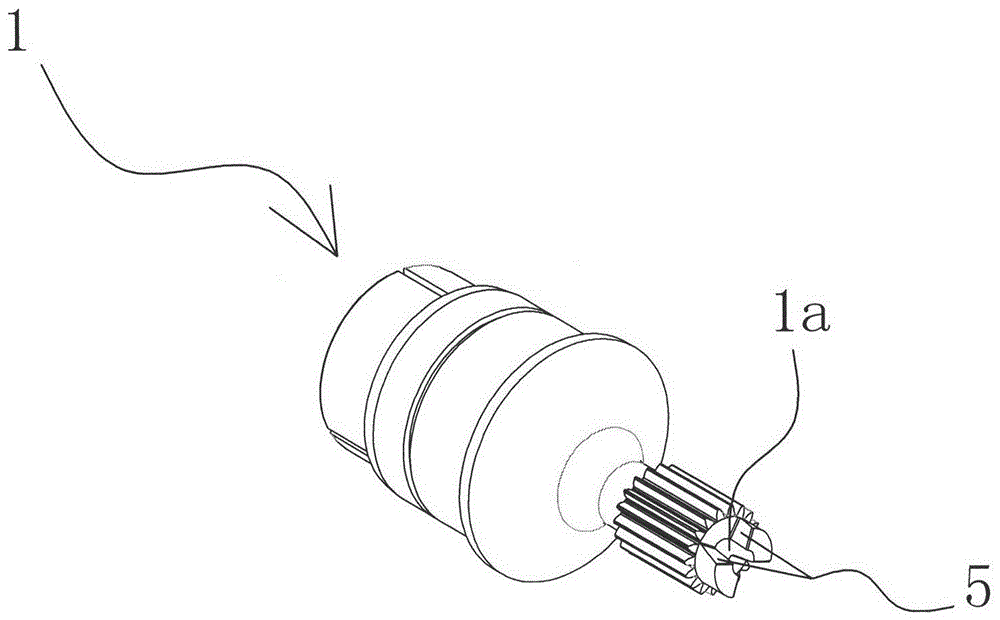

Planetary gear reducer

ActiveCN102865336BHigh transmission precisionResolved Accuracy DecreaseToothed gearingsGearing detailsGear wheelReducer

Owner:ZHEJIANG SANKAI MECHANICAL & ELECTRICAL

Planet gear reducer

ActiveCN102878250AHigh transmission precisionResolved Accuracy DecreaseToothed gearingsGearing detailsReducerAngle alpha

The invention provides a planet gear reducer, belongs to the technical field of machinery, and solves the problem that transmission precision of the existing planet gear reducer is reduced due to abrasion of the planet gear reducer after long-term operation. The planet gear reducer comprises an output planet carrier, an inner gear ring, a sun gear A, a sun gear B and a plurality sets of planet gear structures. Each set of planet gear structure comprises a planet gear shaft, a planet gear A and a planet gear B. The sun gear A and the sun gear B are provided with a spline A and a spline B respectively. Both the spline A and the spline B are provided with a plurality of connecting ends. A gap is reserved between each two adjacent connecting ends. Each connecting end is provided with a helical surface with a helical angle alpha. The sun gear A is provided with a first inner hole. A pressure spring is mounted in the first inner hole. The planet gear reducer is capable of compensating abrasion so as to improve transmission precision.

Owner:ZHEJIANG SANKAI MECHANICAL & ELECTRICAL

Single-layer high-precision brazed superabrasive grinding wheel and manufacturing method thereof

ActiveCN108857940AHigh precisionImprove manufacturing precisionBonded abrasive wheelsGrinding devicesAdhesiveThermal deformation

The invention provides a single-layer high-precision brazed superabrasive grinding wheel and a manufacturing method thereof. The grinding wheel comprises a metallic basic body, and multiple metallic embedded blocks adhere to the peripheral face of the metallic basic body and are sequentially spliced to form an annular structure; abrasive layers are brazed on the peripheral faces of all the metallic embedded blocks respectively. The manufacturing method includes the steps that 1, female die blocks are manufactured; 2, an inner shape face is machined; 3, abrasive particles are fixed through electroplating or with high-temperature adhesive; 4, the metallic embedded blocks are manufactured; 5, high-temperature brazing is performed; 6, criterion alignment is performed; 7, a metallic matrix is bonded; 8, the metallic matrix is machined; 9, a female die and an electroplating layer or a high-temperature glue layer are removed. With the method, influences on thermal deformation of the basic body of the grinding wheel can be effectively reduced during high-temperature brazing, then the manufacturing precision of the grinding wheel is ensured, and the single-layer high-precision brazed superabrasive grinding wheel is easily applied and popularized in the field of precision machining.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

A kind of flame cutting machine

The invention discloses a flame cutting machine. The flame cutting machine comprises a base and a workbench. The bottom of the workbench is fixedly connected with the top of the base. A cutting device is fixedly mounted on one side face of the base. The cutting device comprises a fixing rod, a first connecting rod and a second connecting rod. A groove is formed in the top of the fixing rod. A bearing is arranged inside the groove. A rotating shaft is arranged at the bottom of the first connecting rod. One end of the rotating rod is movably connected with the top of the fixing rod through the bearing. One end of the first connecting rod is movably connected with one end of the second connecting rod through a first pin shaft. The other end of the second connecting rod is movably connected with one side face of a flame nozzle through a second pin shaft. An air inlet hose is arranged at the top of the flame nozzle. The two ends of the upper surface of the workbench are each provided with a slide rail. Water grooves are further formed in the upper surface of the workbench, wherein the water grooves are arrayed in an equally-spaced manner. The flame cutting machine is safe to use and convenient to clean, and cutting precision of the flame cutting machine is greatly improved.

Owner:WUXI DONGBEITANG YONGFENG RUBBER FACTORY

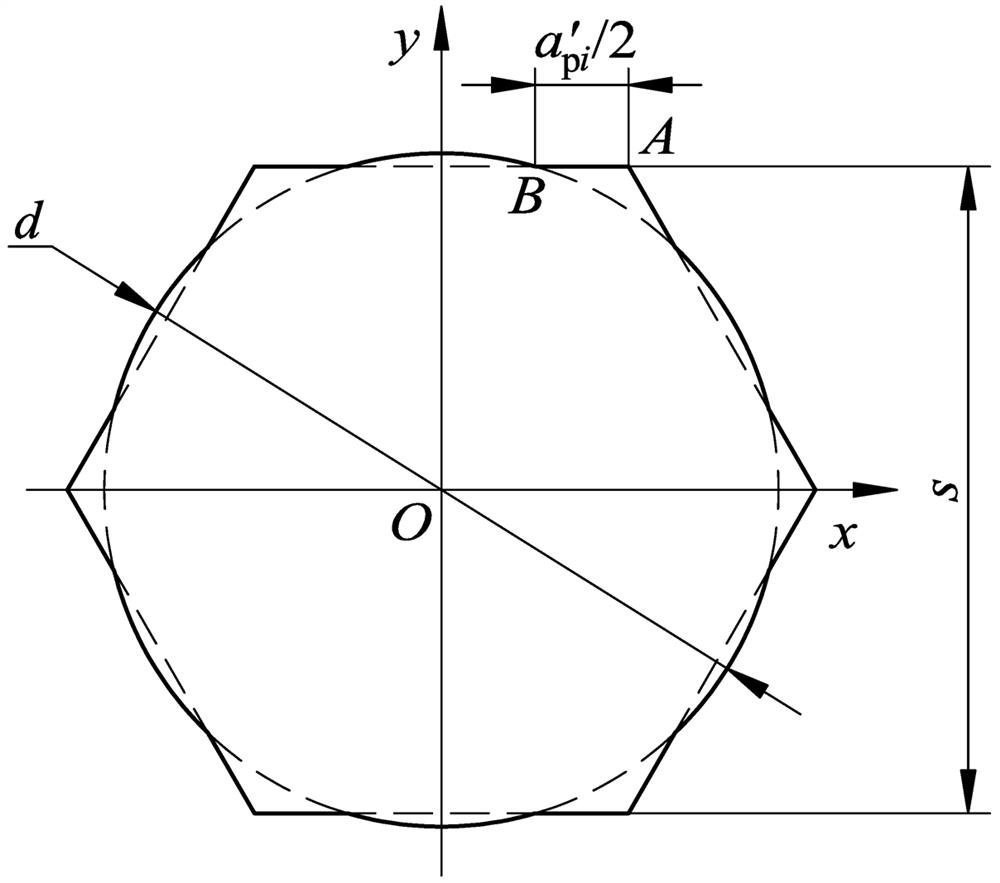

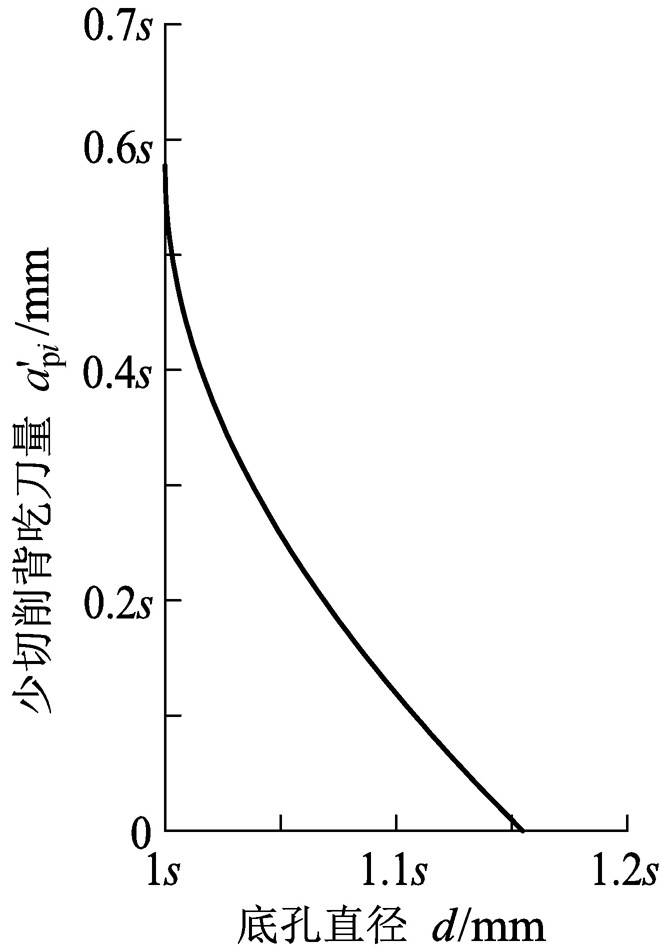

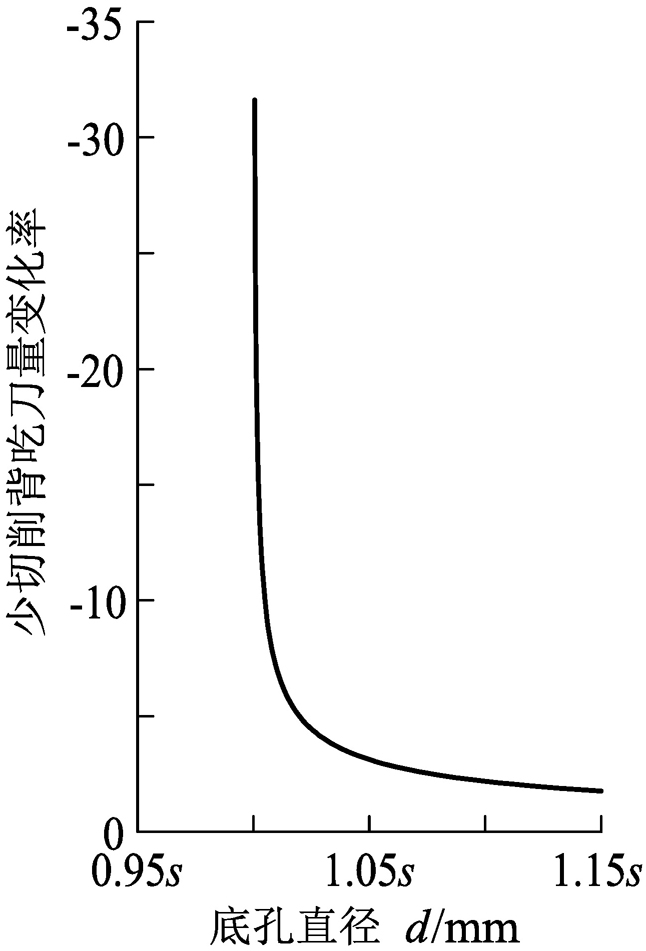

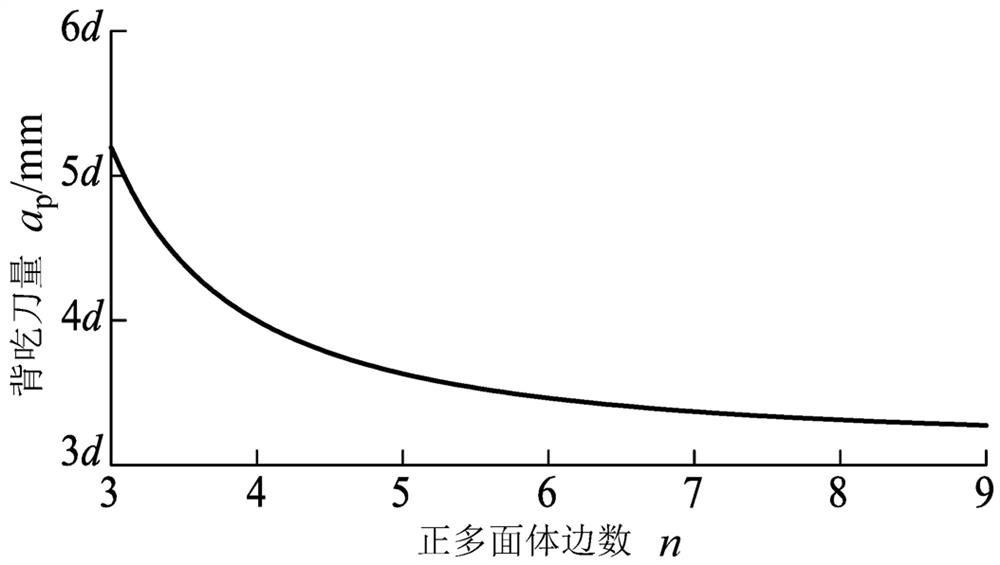

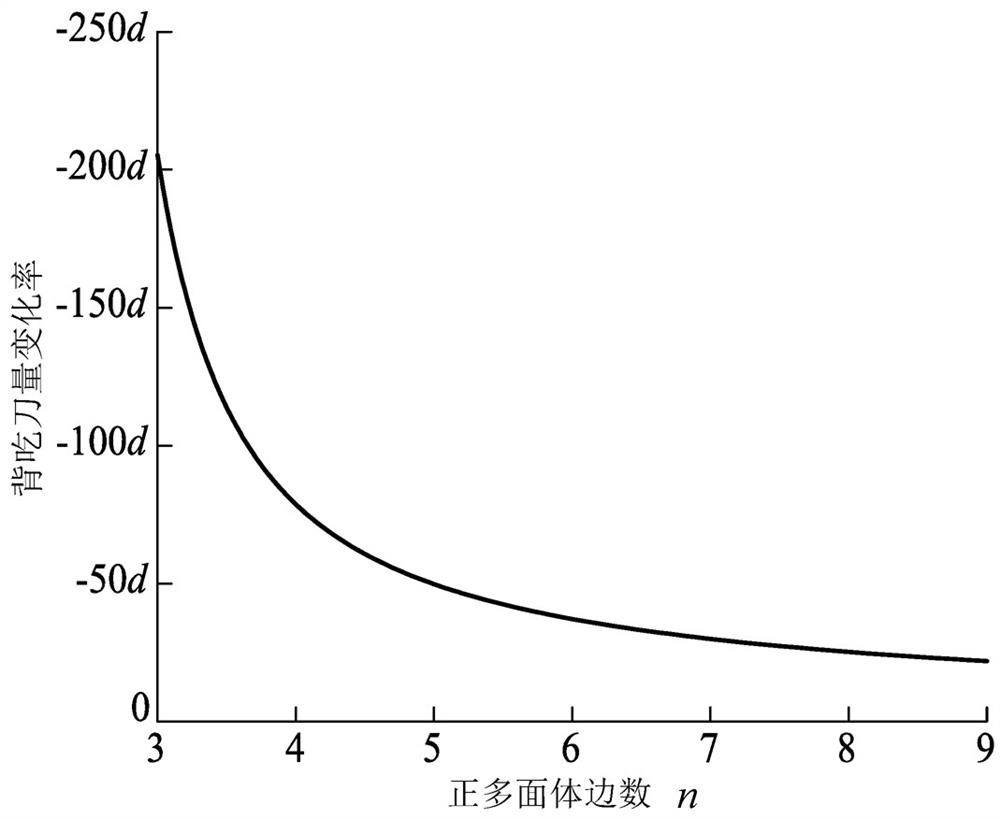

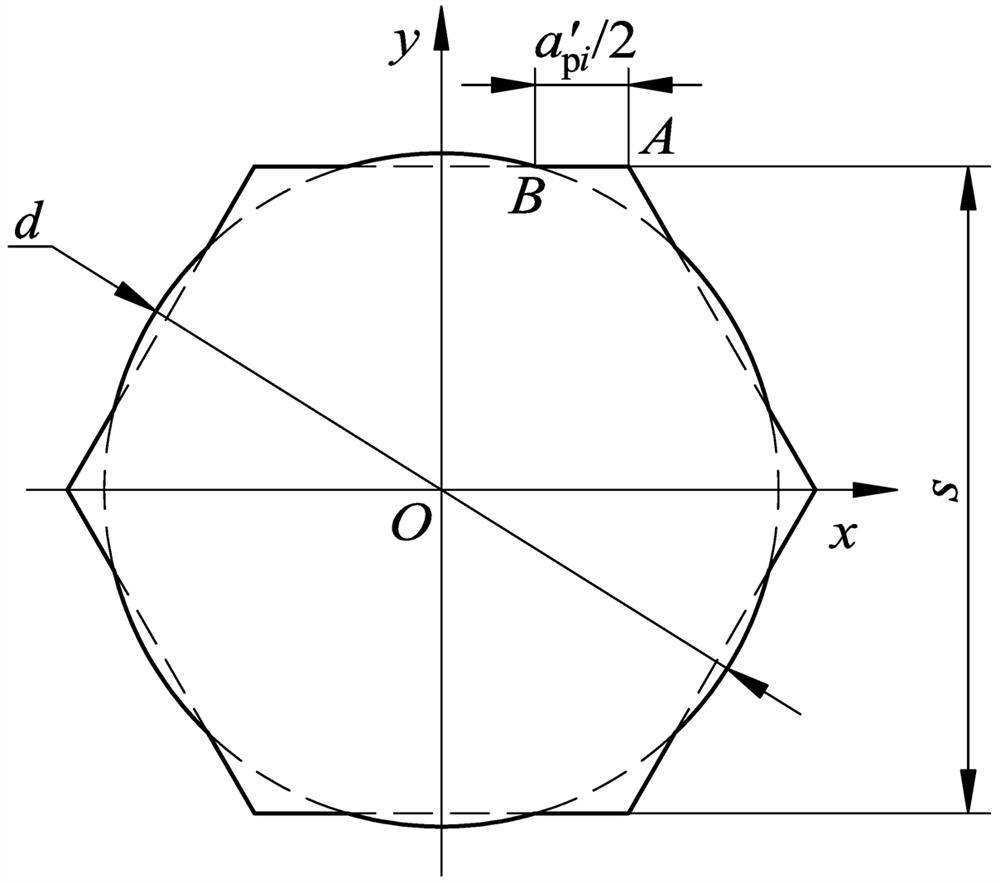

Inner hexahedron punching manufacturing method

PendingCN112001049AAvoid interferenceReduce back biteGeometric CADSpecial data processing applicationsPunchingBack cutting

The invention discloses a few-cutting manufacturing method for an inner hexahedron. The method comprises the steps that firstly, the back engagement of the cutting edge is reduced by enlarging a prefabricated bottom hole, so that the purpose of reducing cutting force is achieved, then the change characteristic of the method is analyzed by establishing a small-cutting-amount model, the minimum backengagement of the cutting edge during manufacturing is determined according to the manufacturing error standard of an inner hexahedron and a wrench, and finally the reasonable back cutting depth andthe diameter of a prefabricated bottom hole are controlled in an amplification coefficient or optimization coefficient mode according to loads. A few-cutting manufacturing method is adopted for machining the inner hexahedron, on the premise that the using performance of the inner hexahedron is guaranteed, the cutting force is reduced, precision reduction caused by too large punching force is eliminated, interference on the strength design of parts is avoided, and meanwhile manufacturing energy consumption is reduced.

Owner:SUZHOU SABO IND DESIGN

Method for improving FSS laser etching machining precision on surface of antenna reflector

ActiveCN110253151AResolved Accuracy DecreaseImprove test efficiencyLaser beam welding apparatusLaser etchingMachining

The invention relates to a method for improving FSS laser etching machining precision on the surface of an antenna reflector, and belongs to the technical field of antenna reflector FSS machining. According to the method, design profile data for laser etching are corrected by using actually-measured profile data of the antenna reflector for the first time, namely, the actually-measured profile data are converted into the same coordinate system as the design profile data for comparison analysis, the design profile data for laser etching are corrected according to errors, so that the subsequent antenna surface FSS laser etching processing precision is improved. The dimension precision and relative position precision of an antenna reflector surface FSS oscillator graph manufactured through the method are both superior to 15 microns.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Rolling mill supporting roller hydraulic lining plate assembly and application method thereof

PendingCN107282640AResolved Accuracy DecreaseEffectively adjust the gapMetal rolling stand detailsRolling equipment maintainenceSlide plateRolling mill

The invention discloses a rolling mill supporting roller hydraulic lining plate assembly which comprises a lining plate body. Two pistons are arranged in the center of the lining plate body. The outer portion of each piston is coaxially connected with a press ring in a sleeved manner. Screws are arranged at the four vertexes of the lining plate body correspondingly. A disc spring is arranged between a screw head of each screw and the corresponding press ring. The invention further discloses an application method of the lining plate assembly. The rolling mill supporting roller hydraulic lining plate assembly solves the problem that at present, a rolling mill supporting roller bearing pedestal copper sliding plate is worn seriously, and consequently the precision of a rolling mill is reduced.

Owner:MCC SFRE HEAVY IND EQUIP

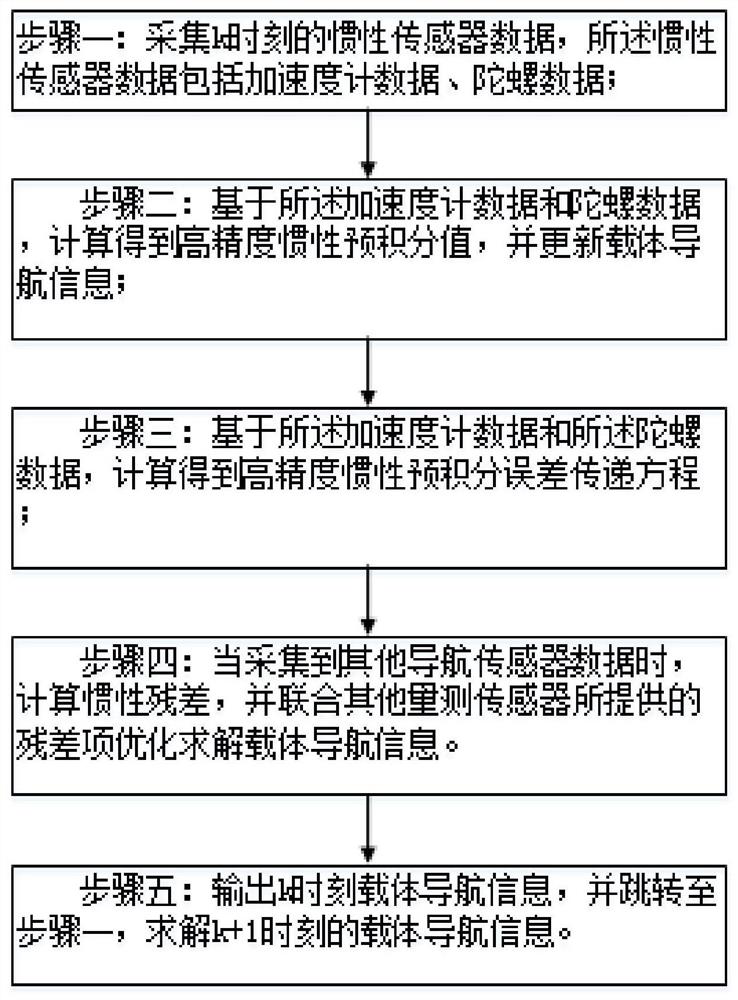

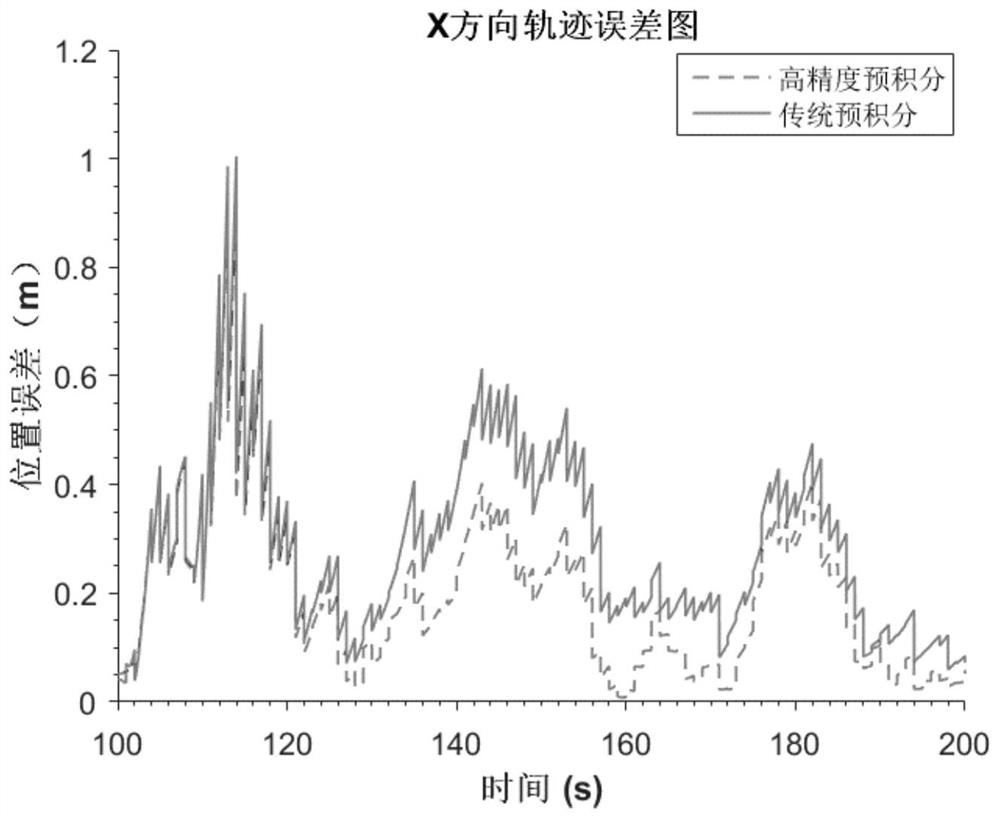

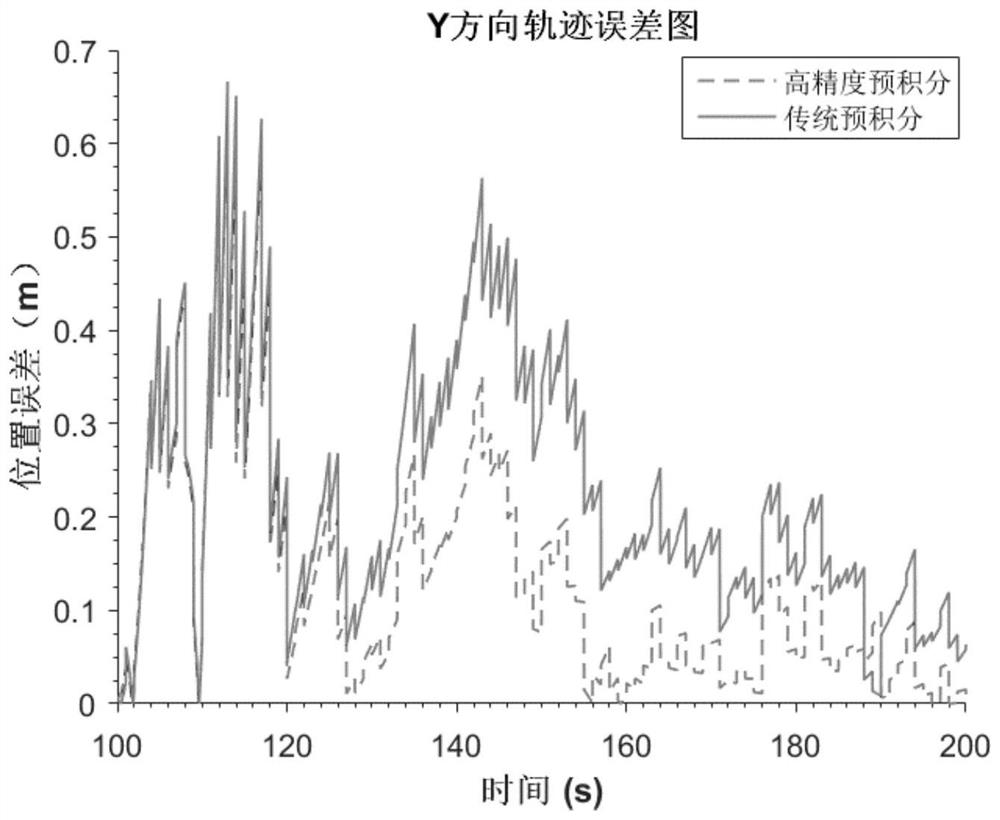

Factor graph integrated navigation method based on high-precision inertial pre-integration

PendingCN113175933AResolved Accuracy DecreaseNavigational calculation instrumentsNavigation by speed/acceleration measurementsAlgorithmClassical mechanics

The invention discloses a factor graph integrated navigation method based on high-precision inertial pre-integration, which comprises the following steps of modeling the earth rotation angular rate and the influence of the rotation angular rate of a navigation system and an earth coordinate system caused by carrier motion into a traditional inertial pre-integration model, simultaneously considering the influence of an earth reference ellipsoid, and calculating to obtain a high-precision inertia pre-integration error transfer equation. On the basis, navigation information output by the IMU is fused with navigation information provided by other measurement sensors through an optimization theory based on a factor graph model. Optimization solution is then carried out to obtain the navigation information of the carrier. The method can effectively solve the problem that the precision of the navigation system is reduced due to the fact that a traditional factor graph integrated navigation system based on an inertia pre-integration method is inaccurate in modeling of inertia output information, and can be applied to various factor graph integrated navigation systems based on high-precision inertial devices.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

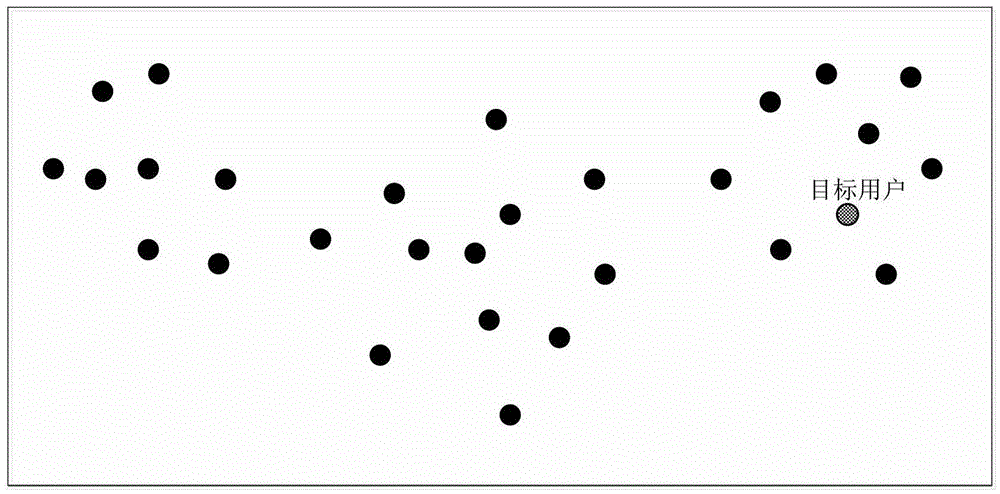

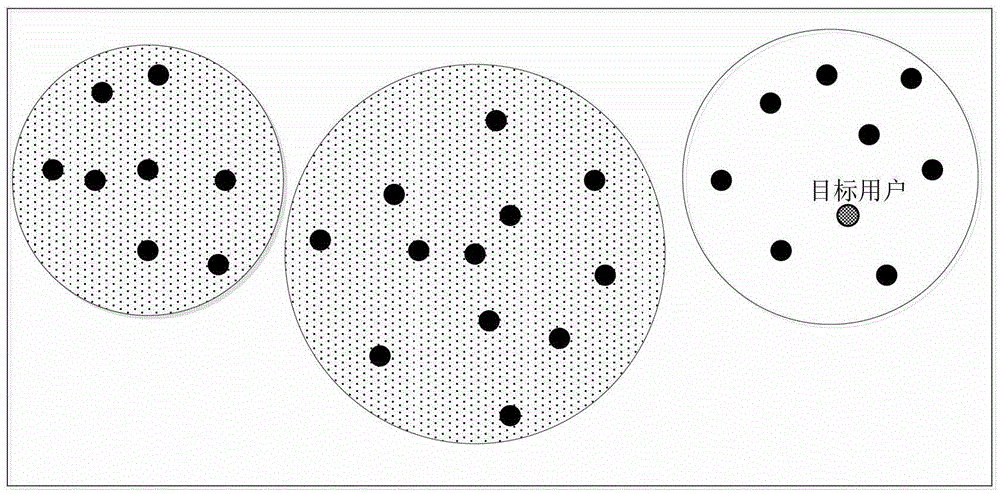

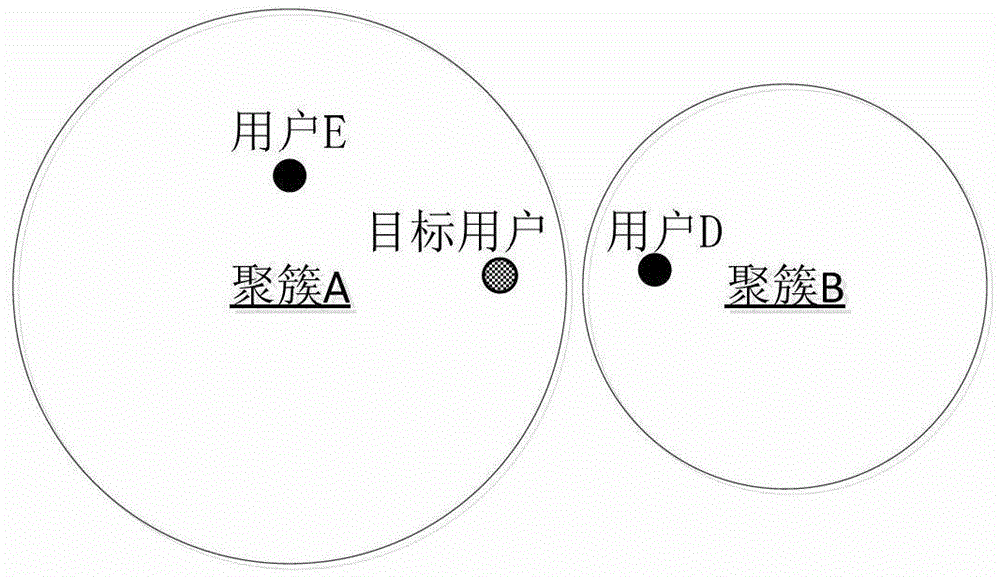

A personalized recommendation method and system based on user group relevance

ActiveCN103077220BResolved Accuracy DecreaseHigh precisionSpecial data processing applicationsCluster algorithmInternet communication

The invention relates to the field of internet communication, and discloses a user group correlation degree-based personalized recommendation method, which comprises the following steps of: A, clustering users by using a clustering algorithm; B, judging distance from a target user to a cluster edge, executing a step C when the distance is greater than a given threshold value, otherwise executing B-1, calculating correlation degree between a cluster of the target user and other clusters, B-2, combining previous r clusters related with the cluster of the user, B-3, searching n closest neighbors in the combined cluster, and further executing a step D; C, searching n closest neighbors in the cluster of the target user; D, predicting a grading value of a related product according to grade of the closest neighbor on the product; and E, selecting the previous m products to be recommended to the user according to the level of a predicted grading value. The invention also discloses a user group correlation degree-based personalized recommendation system. According to the method and the system, the accuracy for personalized recommendation can be effectively improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

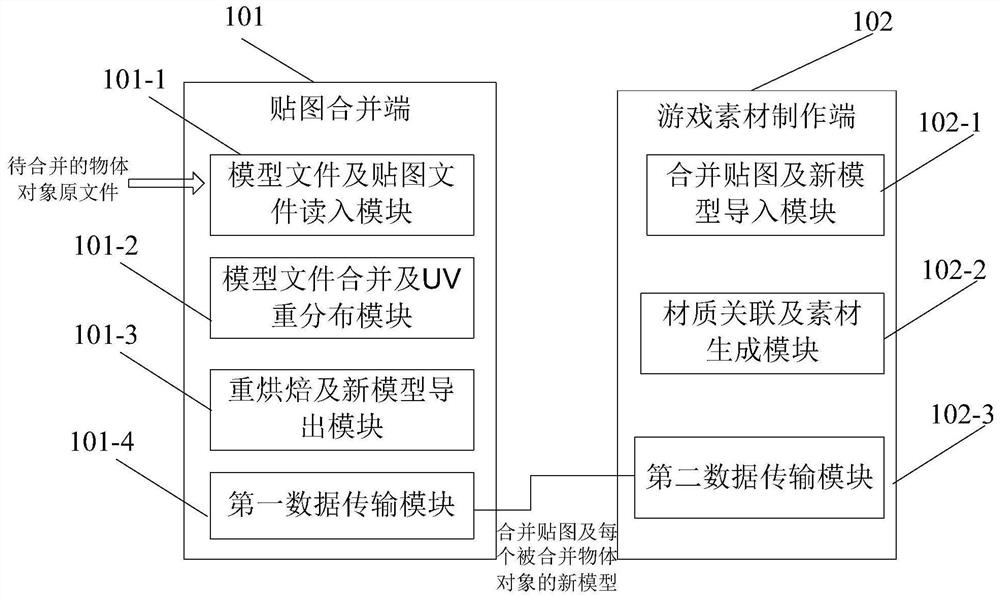

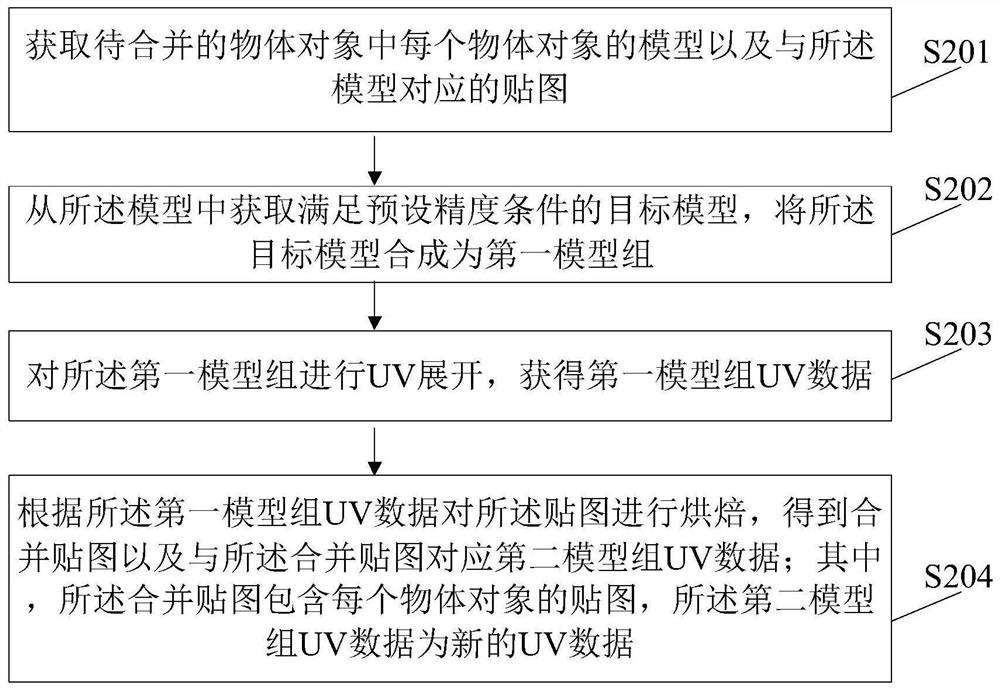

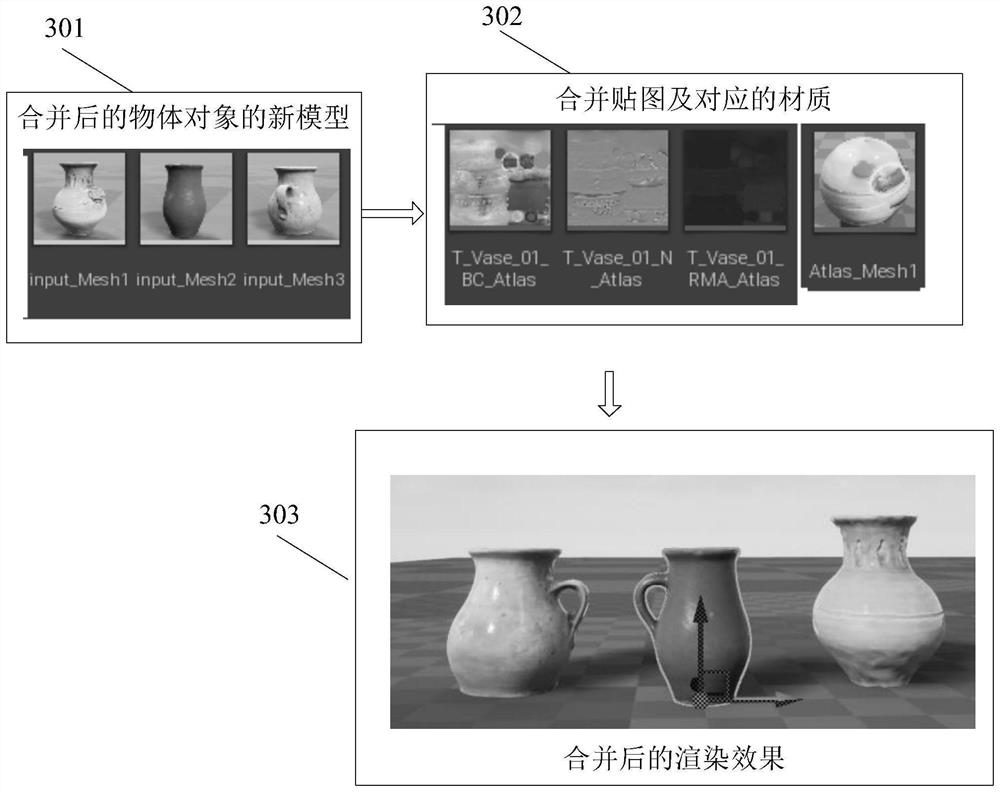

Map processing and game material generation method and device

PendingCN114359460ASolve the problem of not being able to move anymoreGuaranteed accuracyVideo games3D-image renderingAlgorithmSimulation

The invention discloses a chartlet processing and game material generation method and device. The map processing method comprises the following steps: acquiring a model of each object in to-be-merged objects and a map corresponding to the model; obtaining target models meeting a preset precision condition from the models, and synthesizing the target models into a first model group; performing UV expansion on the first model group to obtain UV data of the first model group; baking the chartlet according to the first model group UV data to obtain a combined chartlet and second model group UV data corresponding to the combined chartlet; wherein the merged map comprises a map of each object, and the UV data of the second model group are new UV data. According to the game material generation method, the combined chartlet and the corresponding model are adopted to generate game materials. By adopting the method, the problem that the precision of each model is reduced after the chartlets are merged is solved, and the rendering efficiency of the game materials in the game is improved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

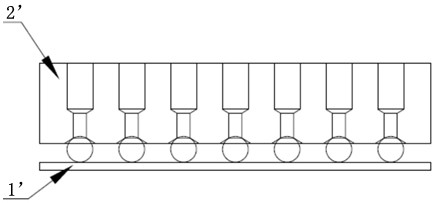

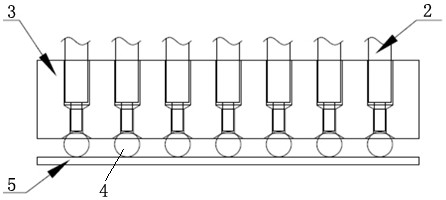

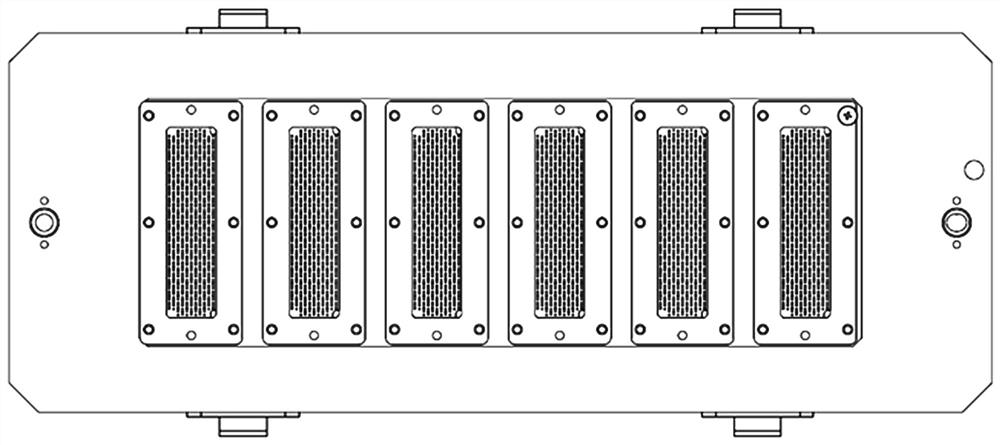

Ejector pin type ball mounting jig

PendingCN114783902AAvoid the situation of not detaching from the ball planting fixtureResolved Accuracy DecreaseSolid-state devicesSemiconductor/solid-state device manufacturingElectric machinerySolder ball

The invention discloses an ejector pin type ball mounting jig which comprises a ball mounting jig body, a pin plate and ejector pins, the pin plate is additionally arranged above the ball mounting jig body, the ejector pins are fixed in the pin plate, a plurality of pin holes corresponding to the ejector pins are formed in the ball mounting jig body, a ball suction hole is formed in the head of the ball mounting jig body, and the position of each ejector pin corresponds to the hole position of the ball suction hole. And the ejector pin moves up and down in the ball suction hole and is used for ejecting and separating the solder balls in the ball mounting jig. Lifting of the needle plate is controlled through an air cylinder or a motor. The needle plate is additionally arranged above the ball mounting jig, lifting is controlled through the air cylinder or the motor, the tin balls are ejected out through the ejector pins in the needle plate, the situation that part of the tin balls are not separated from the ball mounting jig is avoided, the part, matched with the ejector pins, in the ball mounting jig is made of steel instead of graphite materials, and the problem that the precision is reduced due to abrasion in graphite holes is solved.

Owner:SHANGHAI TECHSENSE CO LTD

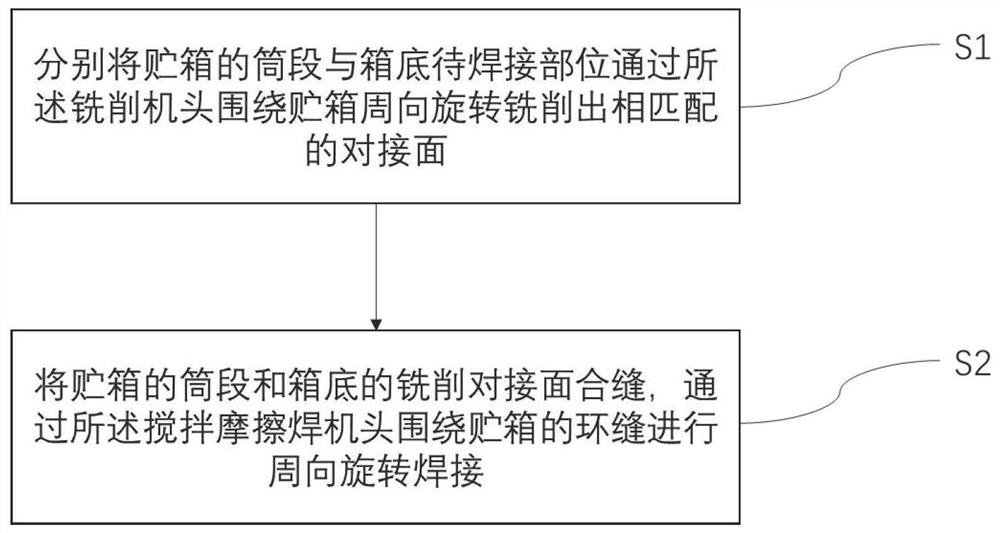

A welding method for a friction stir welding device of an aerospace vehicle tank

ActiveCN112935524BResolved Accuracy DecreaseResolve synchronizationOther manufacturing equipments/toolsNon-electric welding apparatusFriction weldingFriction stir welding

The invention provides a welding method for a friction stir welding device of a storage tank of an aerospace vehicle. The friction stir welding device of the storage tank of an aerospace vehicle includes a friction stir welding head and a milling head. The method includes: step S1, respectively milling the barrel section of the storage tank and the part to be welded at the bottom of the tank through the milling head around the circumferential direction of the storage box to mill out a matching butt joint surface; step S2, milling the barrel section of the storage box and the The milled butt joint surfaces of the bottom of the tank are seamed, and the friction stir welding head is used to perform circumferential rotation welding around the circumferential seam of the storage tank. The method solves the problem that the accuracy of the device decreases after a long service time due to the large inertia caused by the synchronous rotation, and improves the practicability of the device.

Owner:GUIZHOU AEROSPACE TIANMA ELECTRICAL TECH

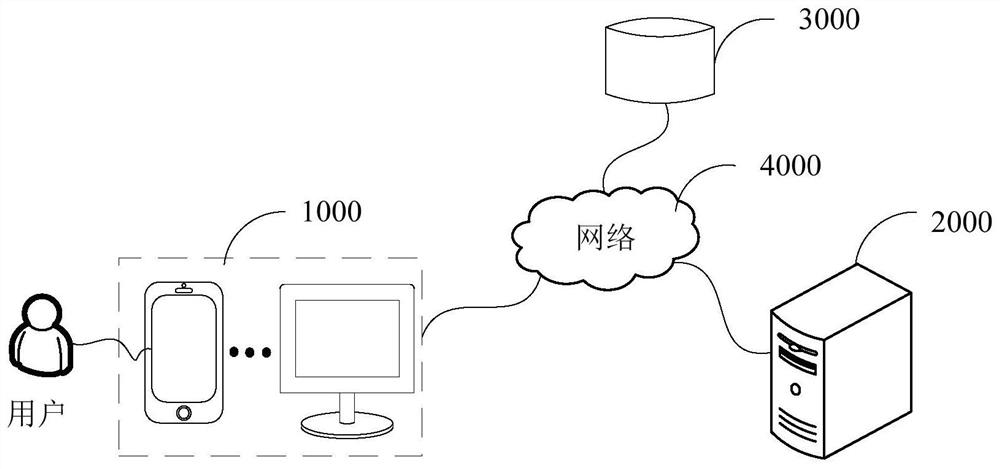

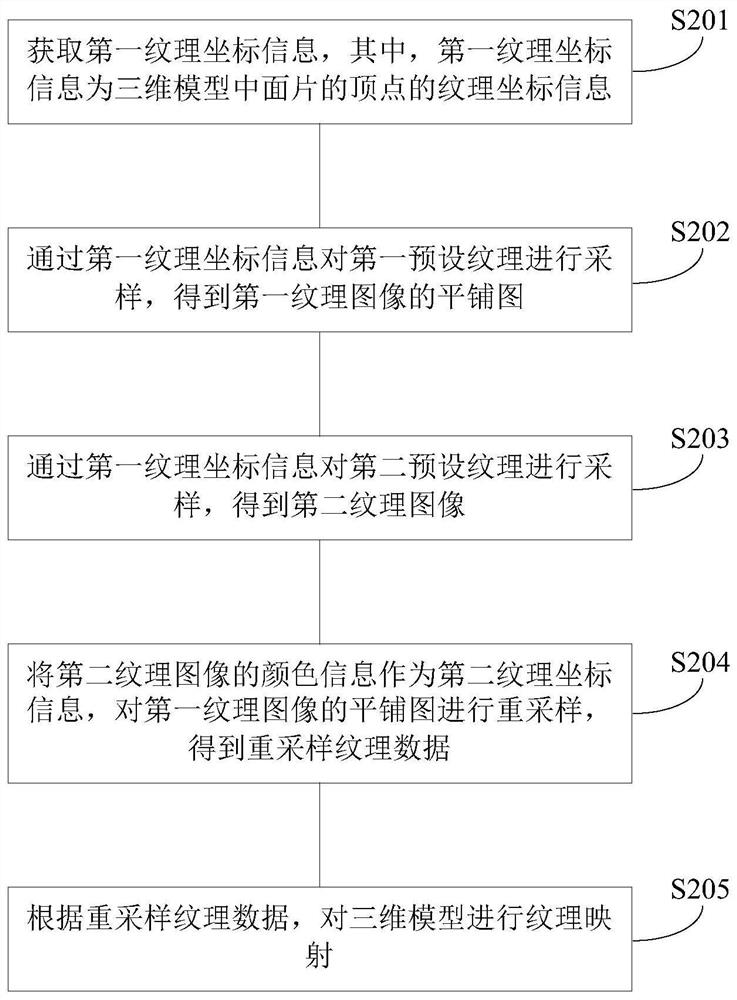

Texture mapping method and device of three-dimensional model, storage medium and computer equipment

PendingCN112802172AResolved Accuracy DecreaseDoes not affect accuracy3D-image rendering3D modellingComputer visionThree dimensional model

The embodiment of the invention discloses a texture mapping method and device of a three-dimensional model, a storage medium and computer equipment. The method comprises the steps of obtaining first texture coordinate information which is texture coordinate information of vertexes of patches in the three-dimensional model; sampling a first preset texture through the first texture coordinate information to obtain a tiled image of the first texture image; sampling a second preset texture through the first texture coordinate information to obtain a second texture image; taking the color information of the second texture image as second texture coordinate information, and resampling the tiled image of the first texture image to obtain resampled texture data; and performing texture mapping on the three-dimensional model according to the resampled texture data. According to the technical scheme of the invention, even if the vertexes of the three-dimensional model patch are few, the precision of texture mapping is still not affected, so that the problem that the precision of texture mapping is reduced when the vertexes of the three-dimensional model patch are insufficient is well solved.

Owner:NETEASE HANGZHOU NETWORK

a 3d printer

ActiveCN112959659BHigh transmission accuracyImprove bearing capacityManufacturing heating elements3D object support structuresComputer printingSolenoid valve

Owner:SHENZHEN ATOMSTACK TECH CO LTD

A planetary gear reducer

ActiveCN102878250BHigh transmission precisionResolved Accuracy DecreaseToothed gearingsGearing detailsGear wheelReducer

The invention provides a planet gear reducer, belongs to the technical field of machinery, and solves the problem that transmission precision of the existing planet gear reducer is reduced due to abrasion of the planet gear reducer after long-term operation. The planet gear reducer comprises an output planet carrier, an inner gear ring, a sun gear A, a sun gear B and a plurality sets of planet gear structures. Each set of planet gear structure comprises a planet gear shaft, a planet gear A and a planet gear B. The sun gear A and the sun gear B are provided with a spline A and a spline B respectively. Both the spline A and the spline B are provided with a plurality of connecting ends. A gap is reserved between each two adjacent connecting ends. Each connecting end is provided with a helical surface with a helical angle alpha. The sun gear A is provided with a first inner hole. A pressure spring is mounted in the first inner hole. The planet gear reducer is capable of compensating abrasion so as to improve transmission precision.

Owner:ZHEJIANG SANKAI MECHANICAL & ELECTRICAL

Comprehensive auxiliary device for cardiac interventional therapy

InactiveCN111281572BQuality improvementReduce shakingDiagnosticsSurgeryPostoperative complicationRat heart

The invention discloses a comprehensive auxiliary device for cardiac interventional therapy, and mainly relates to the field of cardiac interventional therapy devices. It includes an adjustable frame that can be lifted and lowered, and a pressing mechanism that is slidingly connected to it is detachably provided on the adjusting frame. The mechanism is also provided with a supporting plate, and the elastic force of reverse separation is obtained by compressing the spring between the supporting plate and the pressing mechanism, and the elastic force is controllable to trigger. The beneficial effect of the present invention is that it can assist the support of the doctor's hand during the operation and the compression of the puncture site after the operation, which helps to improve the quality of the operation and reduce the complications after the operation.

Owner:中国人民解放军总医院第八医学中心

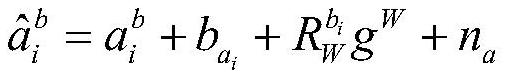

A Vision/Inertial Integrated Navigation Method Based on Online Calibration of Camera Intrinsic Parameters

ActiveCN111156997BResolved Accuracy DecreaseHigh precisionNavigation by speed/acceleration measurementsAccelerometer dataComputer graphics (images)

The invention discloses a visual / inertial combined navigation method based on camera internal reference online calibration, the steps are: collecting visual sensor data S(k), accelerometer data and gyroscope data at time k and using the visual sensor data S(k) to perform adjacent Feature matching and detection between two image frames; use inertial sensor data and pre-integrate between two adjacent image frames; combine visual reprojection error and inertial pre-integration error to optimize and solve carrier navigation information and camera internal parameters; output carrier navigation information and camera intrinsics. The invention can complete the calibration of the internal parameters of the camera under the visual / inertial navigation framework, and can effectively solve the problem of the decrease of the precision of the navigation system caused by the change of the internal parameters of the camera.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

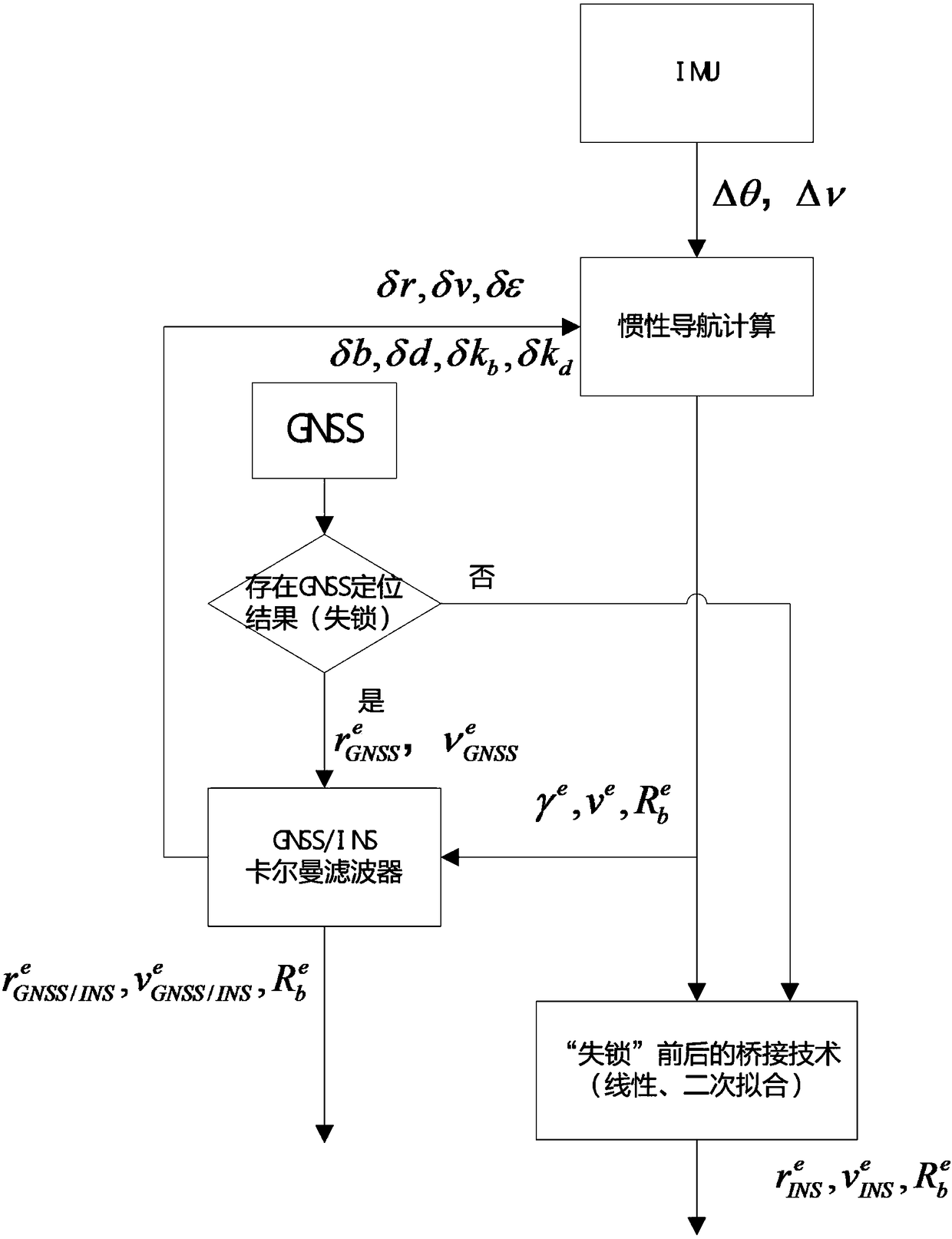

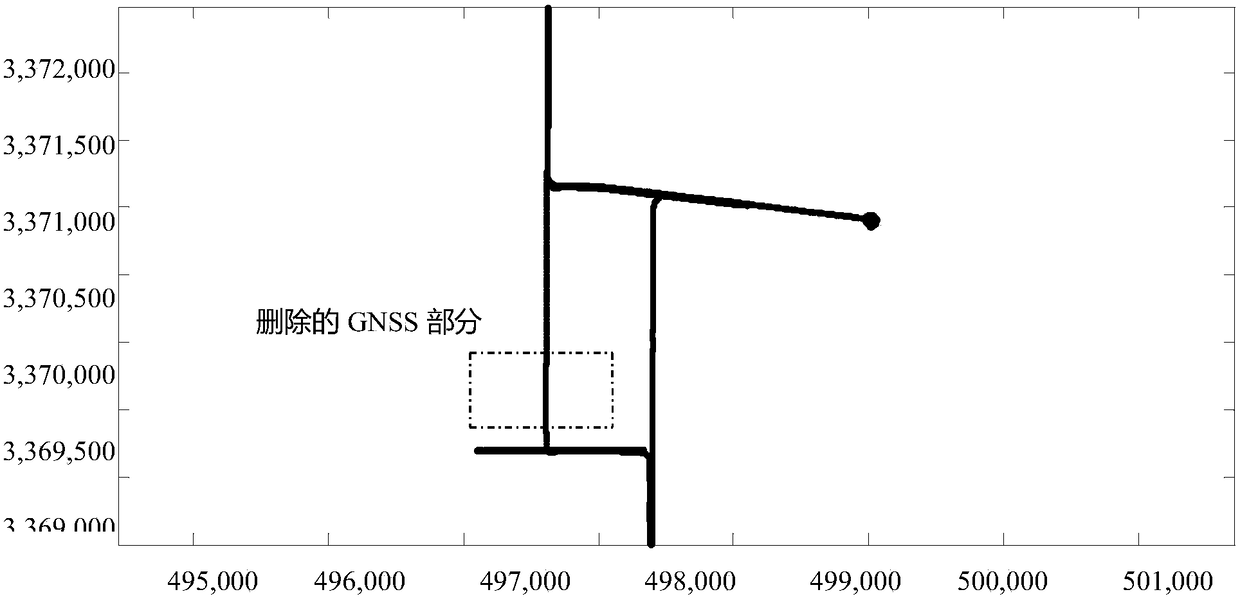

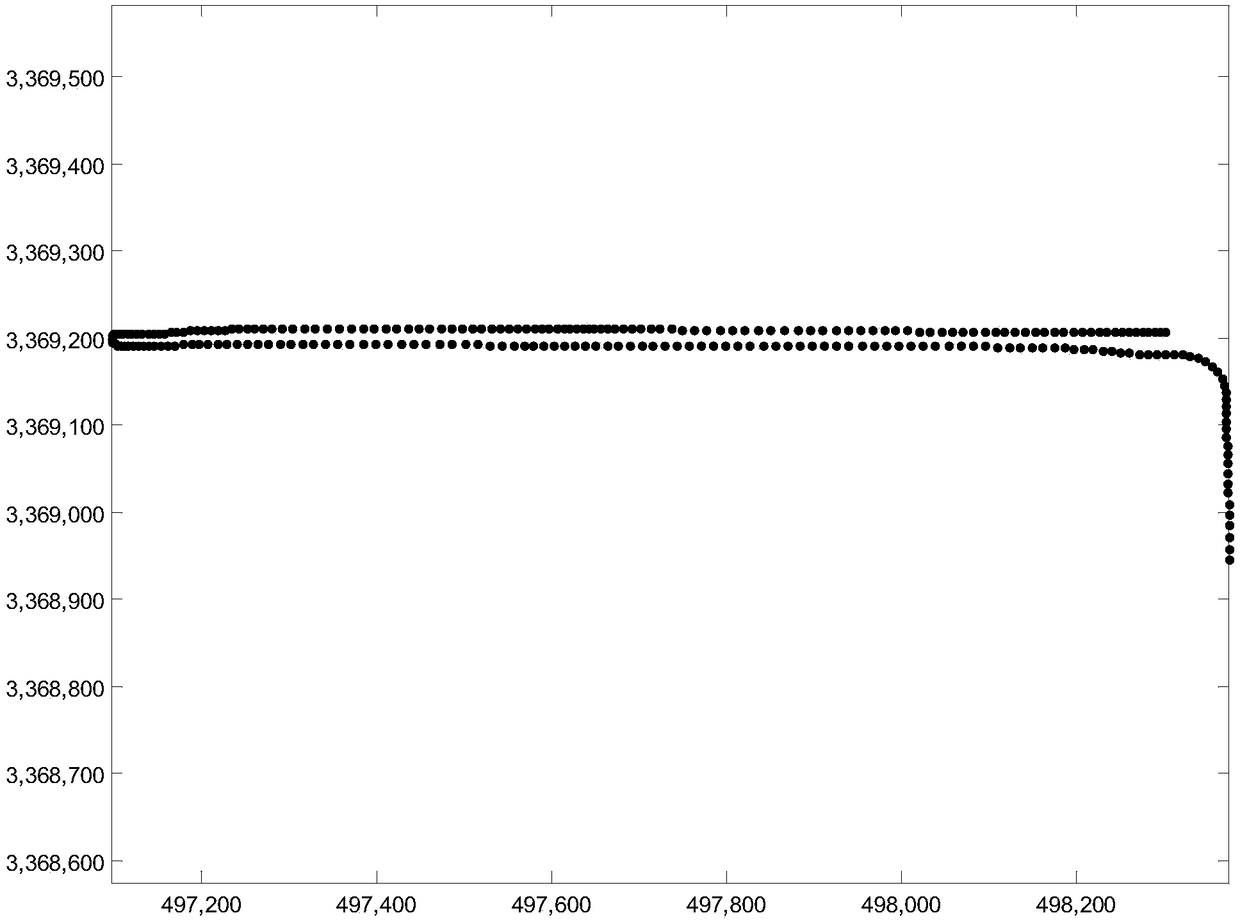

A bridging method in gnss-ins combination

ActiveCN105698790BContinuous high-precision steady-state outputSmooth high precision steady state outputNavigation by speed/acceleration measurementsMarine navigationKalman filter

The invention discloses a bridging method for GNSS-INS combination. The bridging method includes the steps that firstly, a position quantity at the centimeter level is figured out according to a carrier phase observed value; secondly, if no GNSS positioning result exists, INS self-contained navigation calculation is conducted; thirdly, if a GNSS positioning result exists, a GNSS-INS filter is started, the difference of position quantities obtained in the first step and the second step forms a measured value of extended Kalman filtering, compensation quantities of all state quantities are worked out, and the state quantity of a correction system is updated. The bridging method unitedly solves the problem of jittering existing in a positioning result in normal GNSS continuous observation and the problem of system precision reduction caused by GNSS lock-losing, and has the advantages of being high in adaptability, stability and precision.

Owner:WUHAN GEOSUN NAVIGATION TECH CO LTD

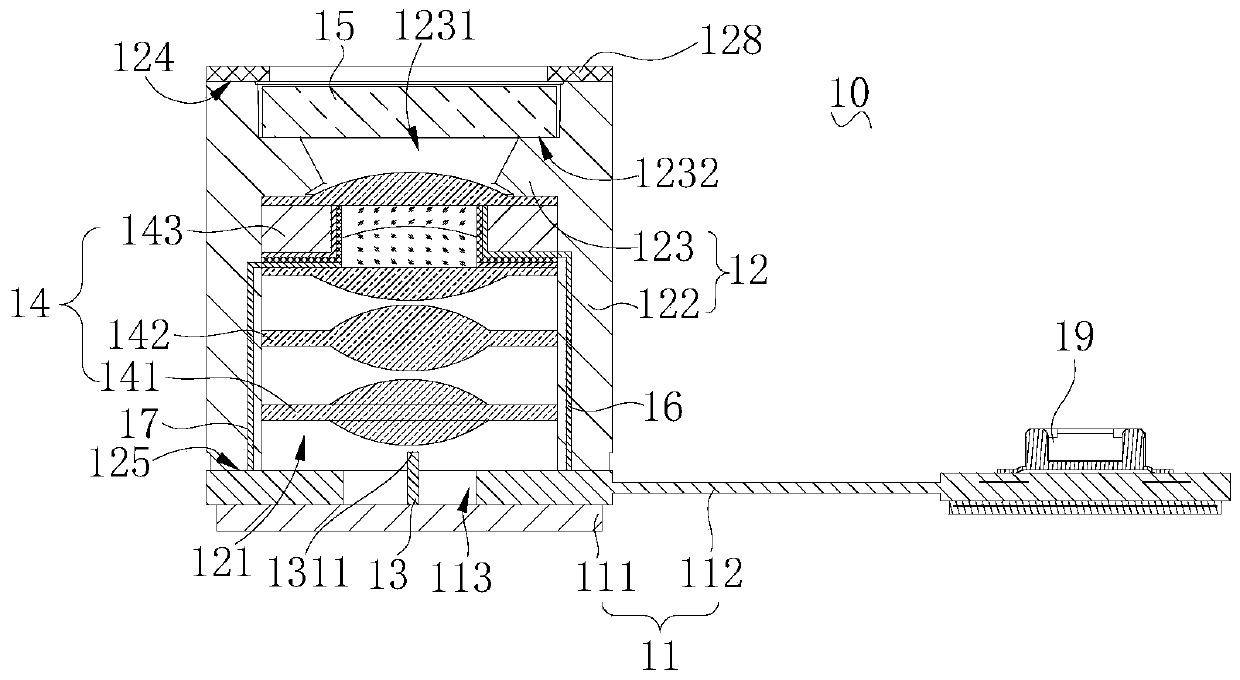

Structured light projector, image acquisition structure and electronics

ActiveCN108490631BImprove temperature driftSmall temperature driftOptical elementsEngineeringDiffraction optics

The present invention discloses a structured light projector. The structured light projector comprises a substrate module, a lens cone, a light source, a collimation element and a diffraction opticalelement. The lens cone comprises a lens cone side wall, and the lens cone side wall and the substrate module commonly form a holding cavity. The light source is arranged on the substrate module and isconfigured to emit a laser. The collimation element is configured to collimate the laser and comprises a plurality of lenses which are arranged on a light-transmitting light path of the light sourceand comprising at least one first-class lens, at least one second-class lens with glass materials and at least one liquid-state lens, and the at least one liquid-state lens can change the focal lengthunder the action of the voltage. The diffraction optical element is installed on the lens cone. The present invention further discloses an image obtaining structure and an electronic device. A mode for combination of the lenses is employed to improve the problem of generation of a temperature excursion phenomenon, the feature of small temperature excursion of the glass materials of the second-class lens is employed to reduce the temperature excursion, and the at least one liquid-state lens is employed to change the focal length to solve the problem of reducing the laser pattern accuracy.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Internal polyhedron manufacturing method based on punching and cutting process

The invention relates to an internal polyhedron manufacturing method based on a punching and cutting process. The method comprises the following steps of optimally using a normal hexahedron to transfer a torque; then reducing back engagement of a cutting edge by enlarging a prefabricated bottom hole so as to achieve a purpose of reducing the cutting force; then establishing a less cutting model toanalyze a change characteristic of the method; then determining the minimum back engagement of the cutting edge according to a manufacturing error standard of the normal hexahedron and a wrench; andfinally, controlling the reasonable back engagement of the cutting edge and the diameter of the prefabricated bottom hole by way of an amplified coefficient or a preferred coefficient according to thesize of a load. Machined by adopting the normal hexahedron and combining with a less cutting manufacturing method, on the premise of guaranteeing the service performance, the cutting force is reduced, precision reduction due to large punching and cutting forces is eliminated, interference to strength design of a part is avoided, and meanwhile, the manufacturing energy consumption is reduced.

Owner:SUZHOU SABO IND DESIGN

A method of improving the processing precision of fss laser etching on the surface of antenna reflector

ActiveCN110253151BResolved Accuracy DecreaseImprove test efficiencyLaser beam welding apparatusLaser etchingMechanical engineering

The invention relates to a method for improving the processing precision of FSS laser etching on the surface of an antenna reflector, and belongs to the technical field of FSS processing of antenna reflectors. The method of the present invention proposes for the first time the use of the antenna reflector measured surface data to correct the design surface data for laser etching, that is, the measured surface data is converted into the same coordinate system as the design surface data for comparative analysis, and the laser is corrected according to the error. The design surface data is used for etching, so as to improve the subsequent processing accuracy of FSS laser etching on the surface of the antenna. The size accuracy and relative position accuracy of the FSS oscillator pattern on the surface of the antenna reflector manufactured by this method are better than 15 μm.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Solar automatic tracking circuit

InactiveCN1928460BResolved Accuracy DecreaseImprove judgment accuracySolar heating energySolar heat collector controllersMicrocontrollerMathematical model

The invention relates to an automatic solar tracking circuit, belonging energy technique area, comprising photosensitive sensor, which provides location sensing signal for the whole circuit; power supply circuit, which provides regulated DC power supply for the whole circuit; signal conditioning circuit which selects-pass and enlarges sensing signal imported by photosensitive sensor; real-time clock circuit, which provides precise time scale for the whole circuit and inputting for math model built by single chip microprocessor; single main circuit, which is the core of the whole circuit, processes position and time signals input and sends control signal to driving circuit. Driving circuit drives motor to revise position. In the invention judgment precision is improved largely by judging position with time and senor inputting. The problem that precision of photosensitive sensing module is decreased because temperature changes, is solved by setting multilevel conditioning circuit in thewhole circuit.

Owner:宁波新亚机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com