Patents

Literature

64results about How to "Good support and protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

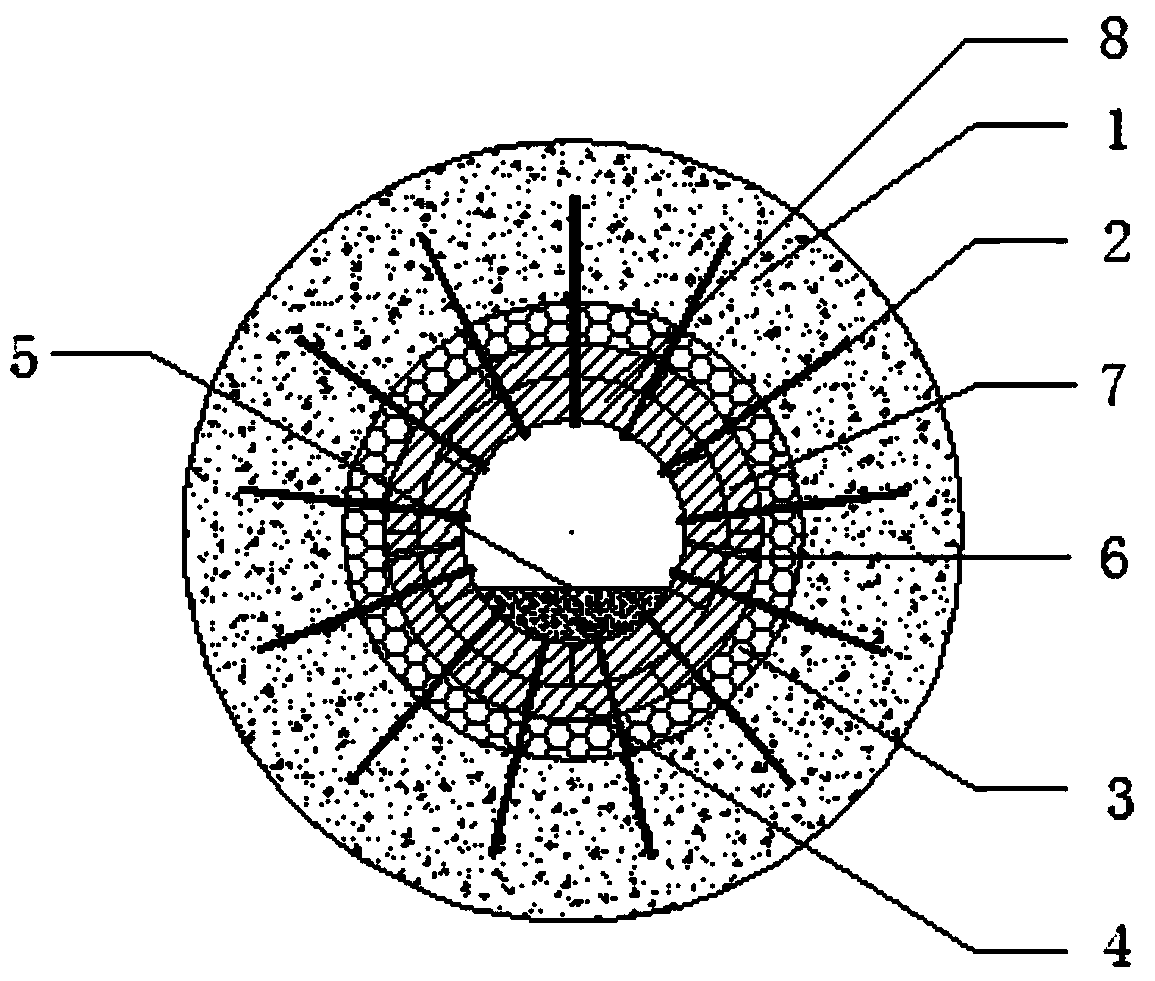

Fault-passing roadway waterproof damping and shock-resisting coupling support method

ActiveCN103912292AMaintain pressure resistanceImprove stress resistanceUnderground chambersTunnel liningGlass fiberCoupling

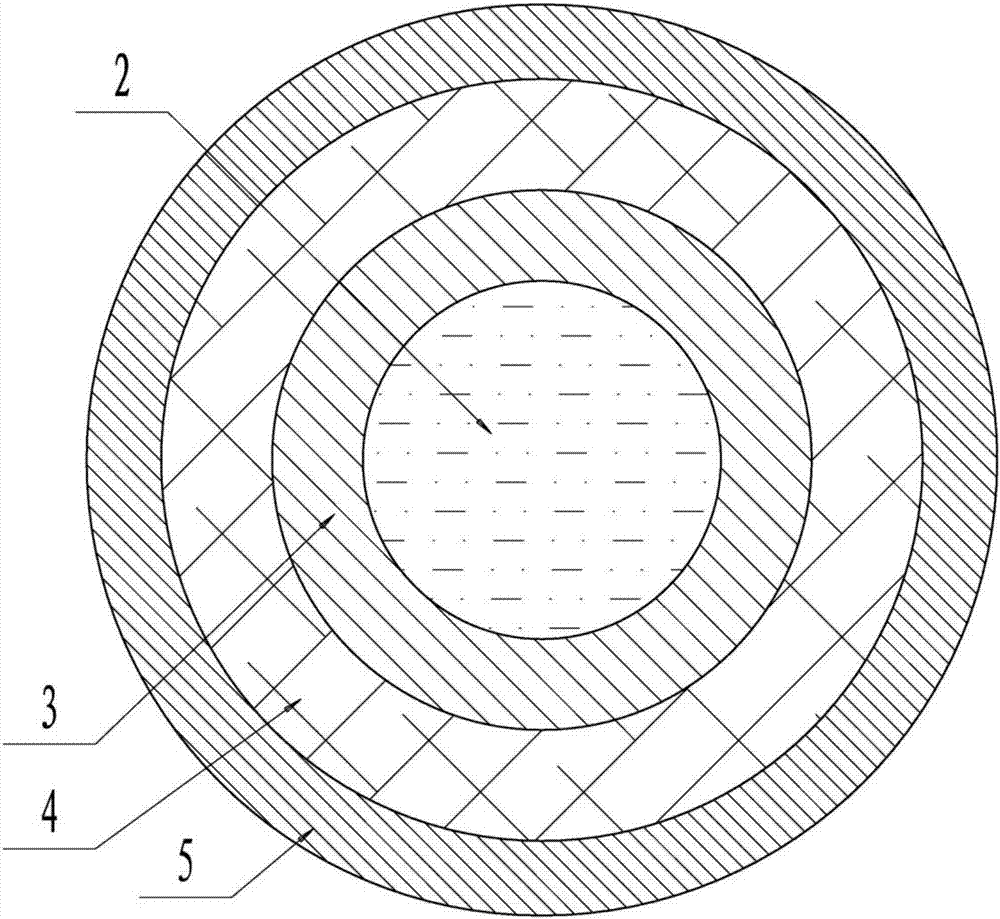

The invention belongs to the technical field of mining shock-resisting supporting and particularly relates to a fault-passing roadway waterproof damping and shock-resisting coupling support method. The fault-passing roadway waterproof damping and shock-resisting coupling support method includes sequentially setting a surrounding rock plastic ring, a damping support ring and two layers of tiles from surrounding rocks of the fault to a roadway, forming the surrounding rock plastic ring by the surrounding rocks in an artificial blasting manner, and paving cement-based glass fibers on the inner surface of the surrounding rock plastic ring to form the damping support ring; paving two layers of the tiles on the inner surface of the damping support ring, wherein the tiles on the outer layer is outer waterproof tiles, and the tiles on the inner layer are inner tiles; enabling an anchorage rod to be perpendicular to the outlines of the tiles and sequentially penetrate the tiles, the damping support ring and the middle of the surrounding rock plastic ring to form a fixed coupling, and paving ballasts on the ground of the roadway and the upper surfaces of the tiles. By the method, support intensity is high, buffering and damping and shock resistance are high, and waterproof effect is good.

Owner:LIAONING TECHNICAL UNIVERSITY

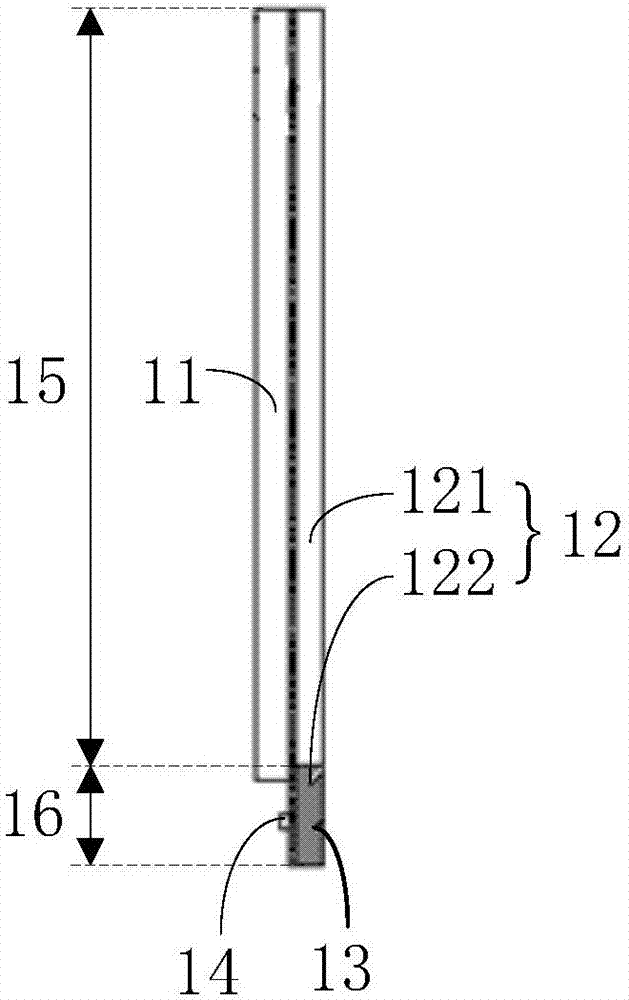

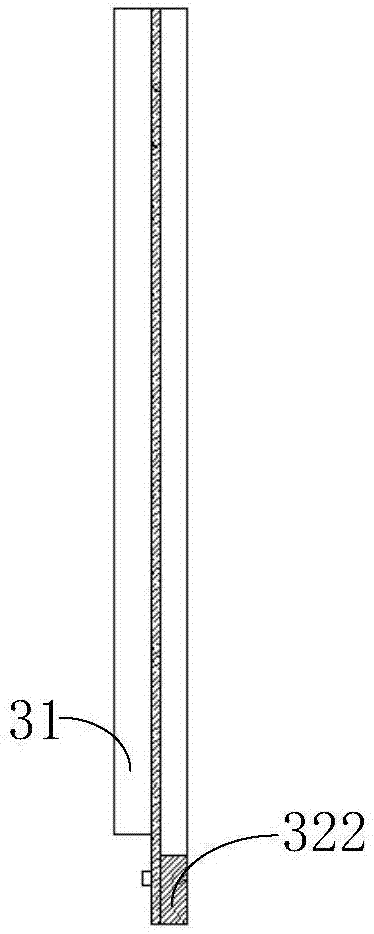

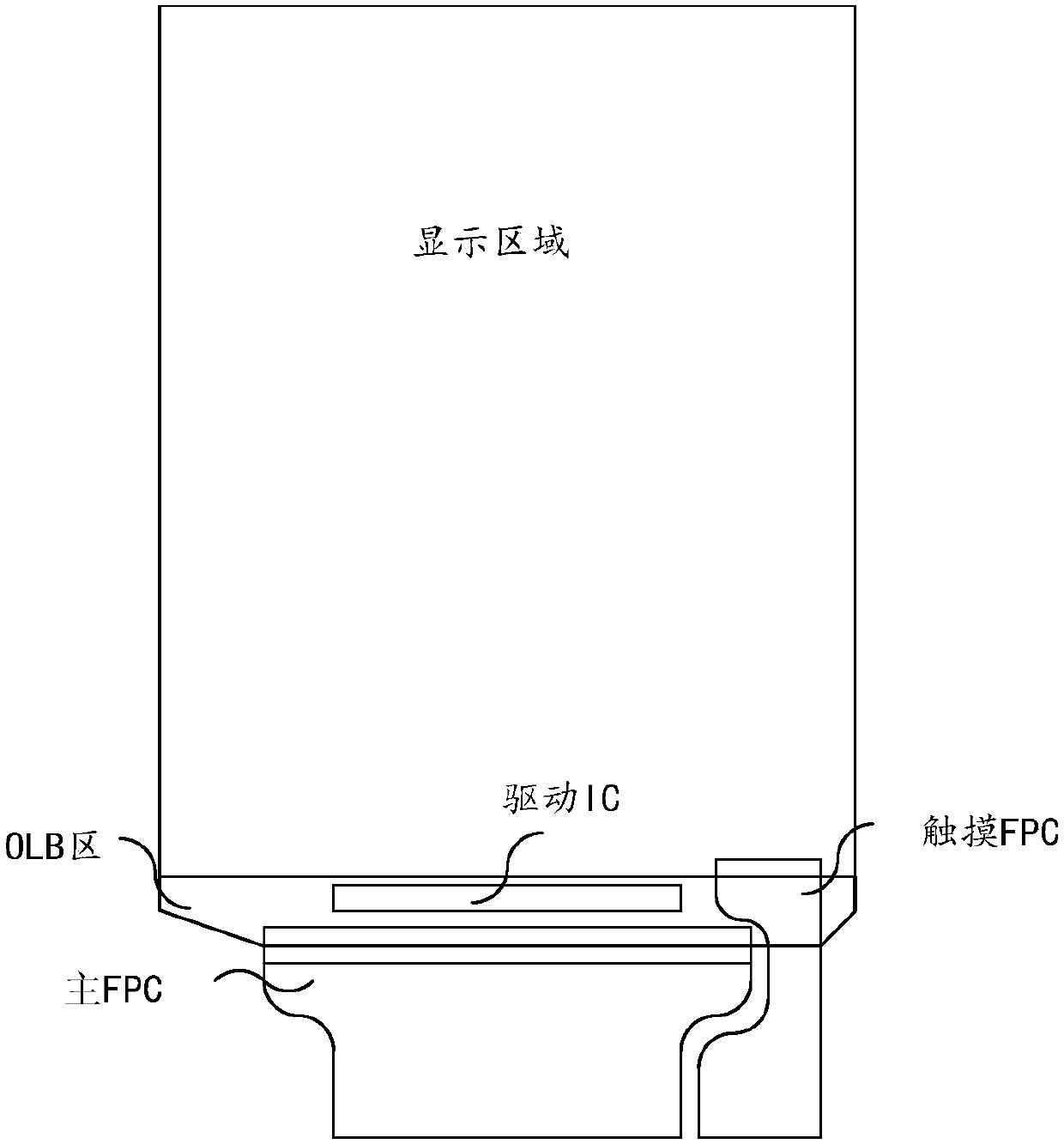

Display panel

InactiveCN107479236AAvoid breakage damageSolve technical problems that are prone to cracking and damageSolid-state devicesNon-linear opticsComputer science

The invention provides a display panel. The display panel comprises a first substrate, an array substrate and a luminous display layer; the array substrate comprises a base layer and a plastic base material layer which is arranged on the base layer and used for arranging a pixel unit and driving a chip; the array substrate comprises a display area corresponding to the first substrate and a driving area arranged at one side of the display area; the base layer of the array substrate of the display area is a glass substrate, and the base layer of the array substrate of the diving area is a reinforcement plate. According to the display panel, by means of the reinforcement plate, the array substrate of the area corresponding to a driving chip can be subjected to good support protection, and then the phenomenon that the glass substrate of the display panel is broken and damaged is prevented.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

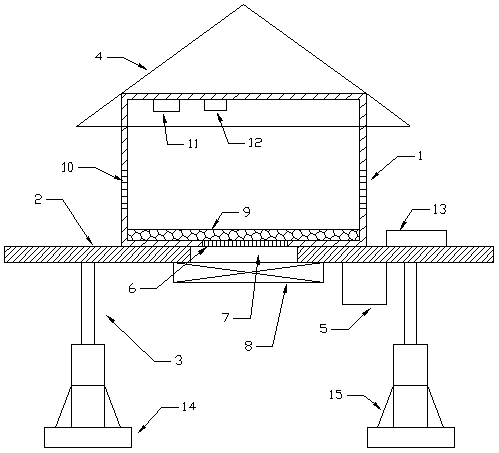

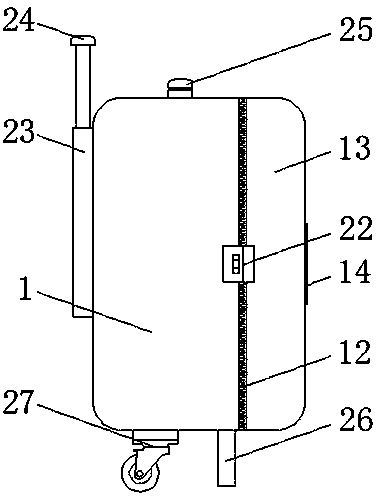

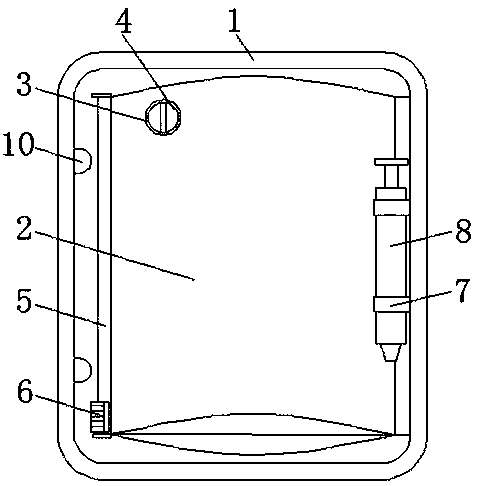

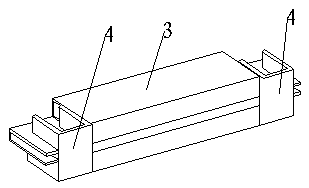

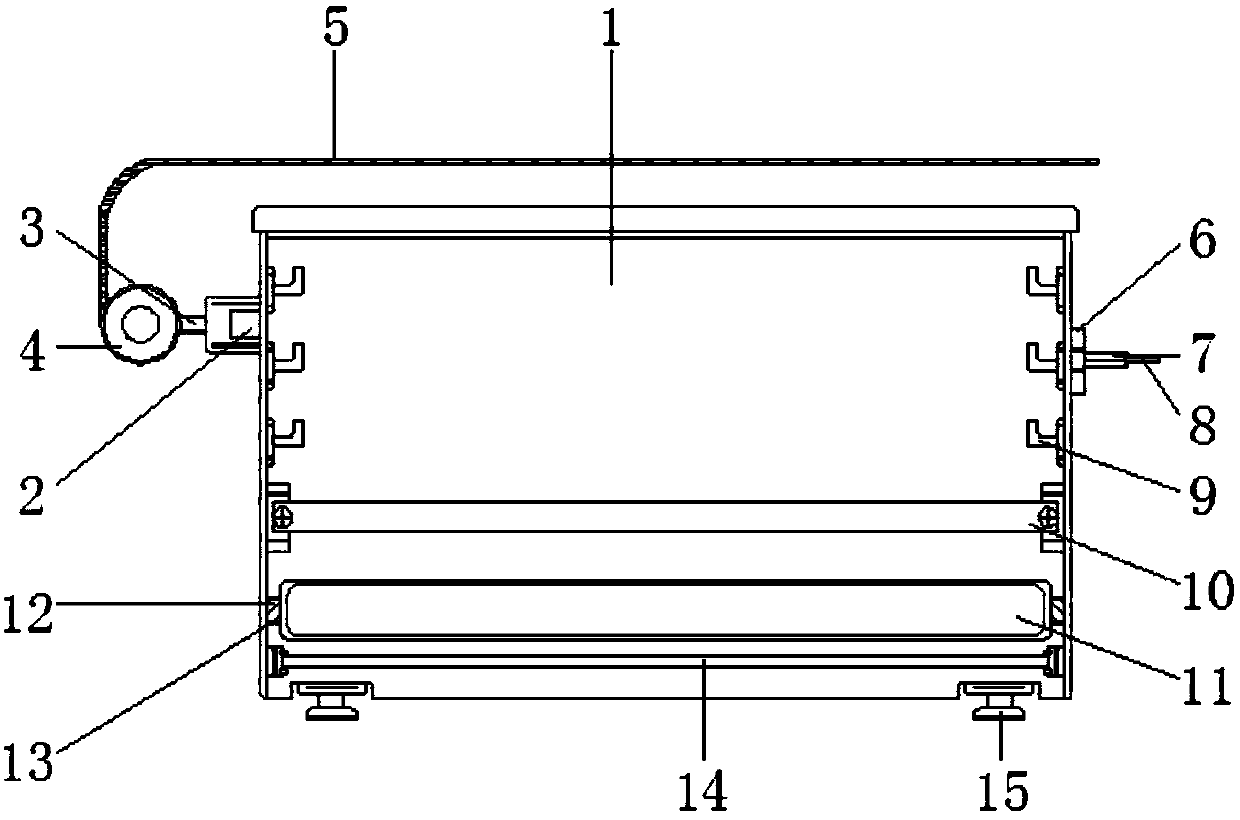

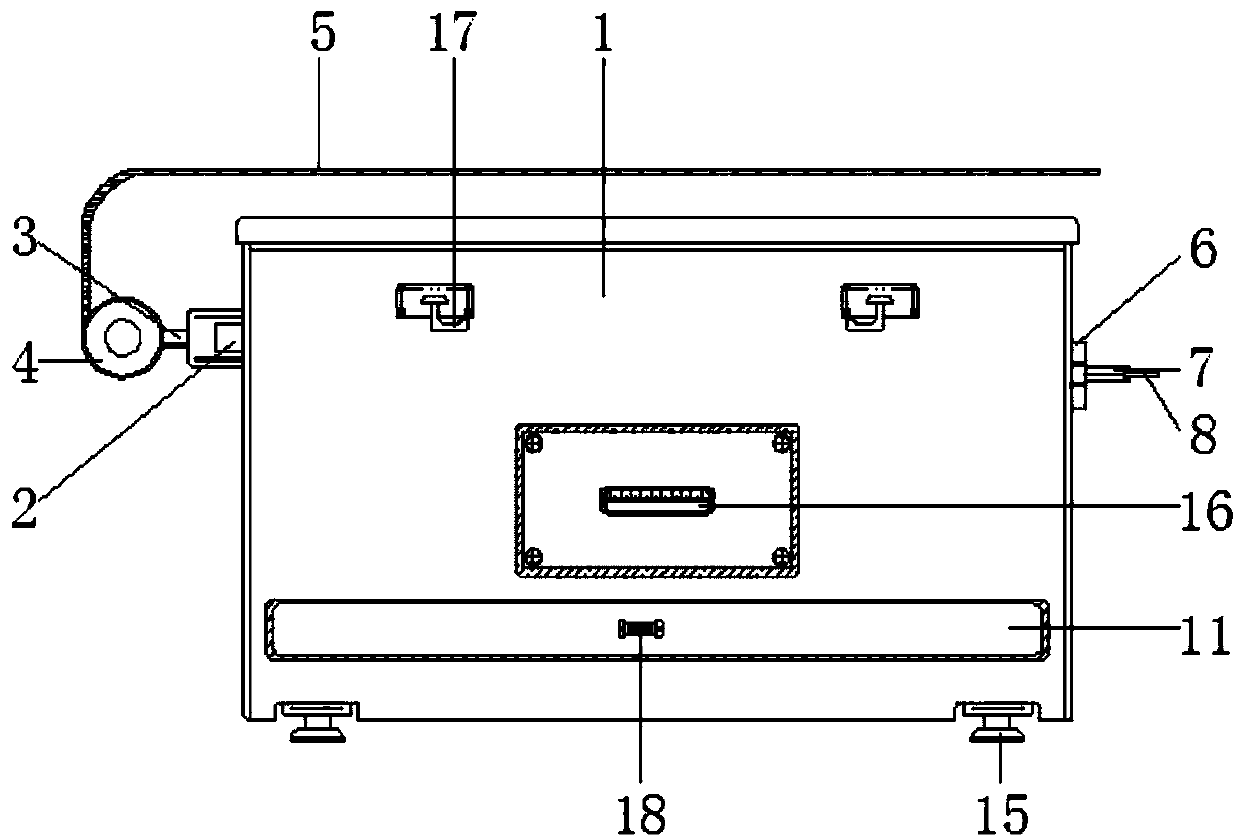

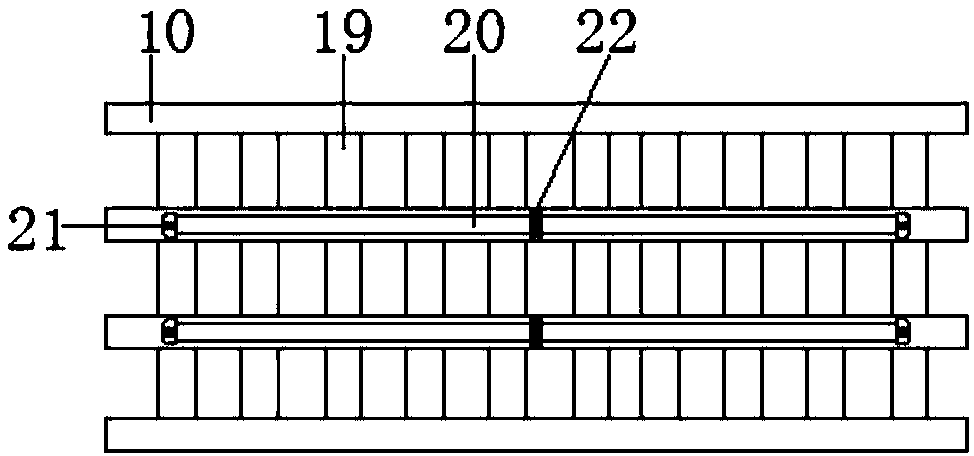

Multifunctional novel bee keeping box

InactiveCN108552082APlace flatAvoid harmAgriculture and animal husbandary industryBeehivesElectricityMoisture absorption

The invention discloses a multifunctional novel bee keeping box, which comprises a bee keeping box body, wherein the bee keeping box body is arranged on a supporting plate; the bottom of the supporting plate supports an electric cylinder; the top of the bee keeping box body is provided with a solar panel; a bottom plate of the bee keeping box body is provided with a reticular cooling plate; the supporting plate which just faces the cooling plate is provided with a cooling hole; the cooling hole is provided with an exhaust fan installed on the supporting plate; the bottom of the bee keeping boxbody is provided with a moisture absorption box; the side wall of the bee keeping box body is provided with a plurality of air holes. According to the multifunctional novel bee keeping box, temperature and humidity in the bee box can be effectively controlled, a warm and comfortable living environment is provided for bees, meanwhile, the bee box can be conveniently fixedly placed, and therefore,the bee box can be stably placed so as to bring convenience for the bees to produce honey; meanwhile, electric equipment can be supplied with electricity through solar energy, resources can be effectively utilized, and are saved, and the multifunctional novel bee keeping box has complete functions and is suitable for being practically used.

Owner:中江县仕兴养蜂专业合作社

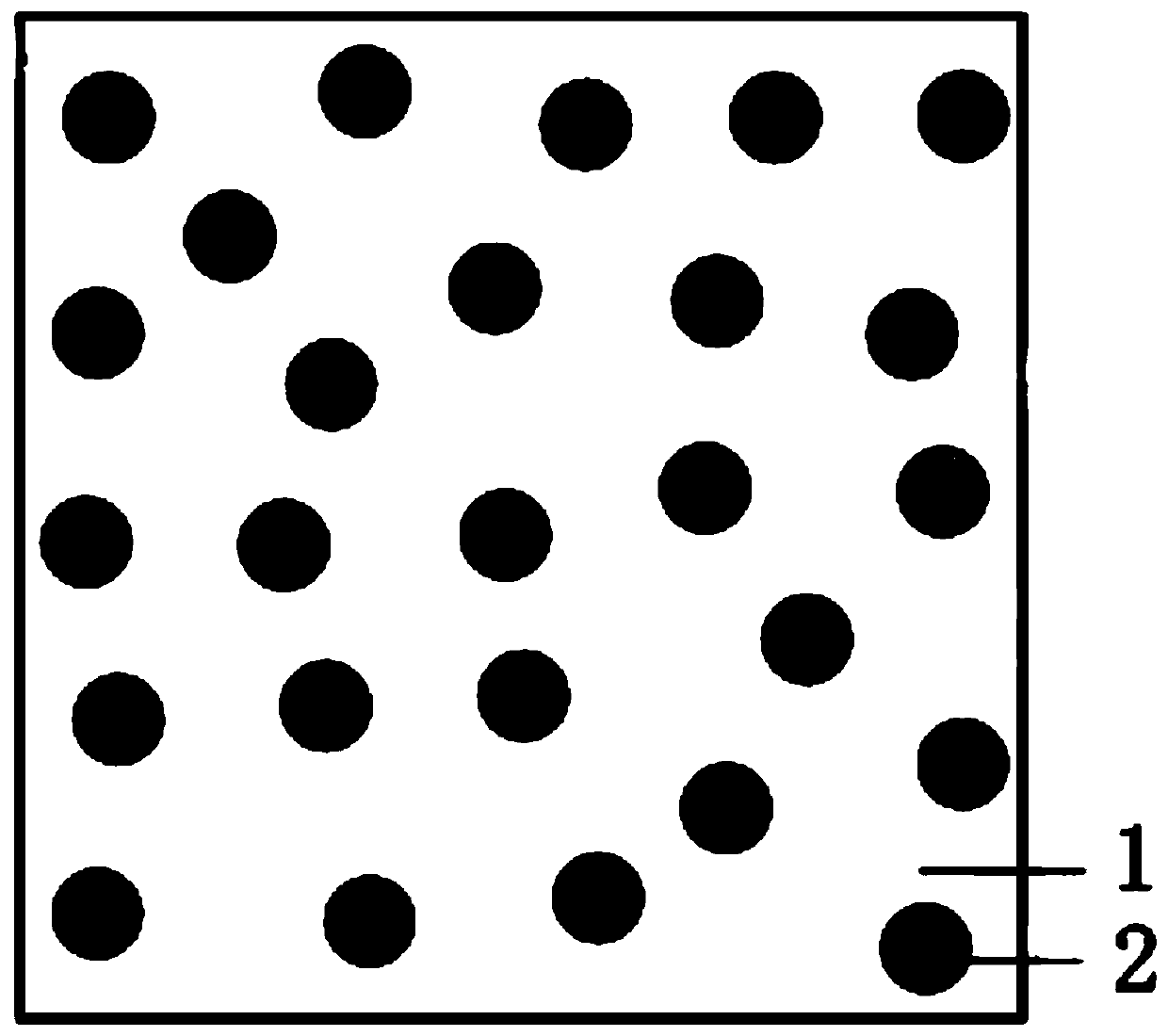

Titanium/titanium carbide core-shell structure reinforced aluminum matrix composite material and preparation method thereof

The invention discloses a titanium / titanium carbide core-shell structure reinforced aluminum matrix composite material. The material is composed of pure aluminum or aluminum alloy matrix and a titanium / titanium carbide core-shell particle reinforced phase. According to the reinforced phase, titanium serves as the core, a titanium carbide ceramic layer serves as a shell, and the dimensions of titanium carbide particles inside the shell change in a gradient manner. The invention further discloses a preparation method of the titanium / titanium carbide core-shell structure reinforced aluminum matrix composite material. According to the titanium / titanium carbide core-shell structure reinforced aluminum matrix composite material, the toughness of the composite material is improved because of thehigh-toughness titanium core, the strength of the composite material is improved because of the titanium carbide ceramic layer with the high volume fraction, and therefore, the aluminum matrix composite material has the high strength and the good toughness at the same time.

Owner:XIAN UNIV OF TECH

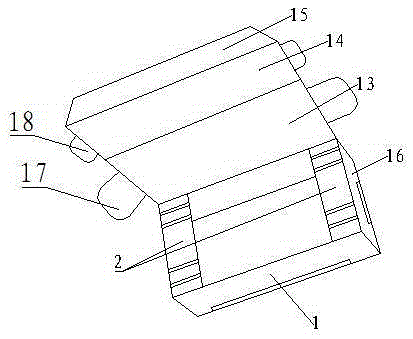

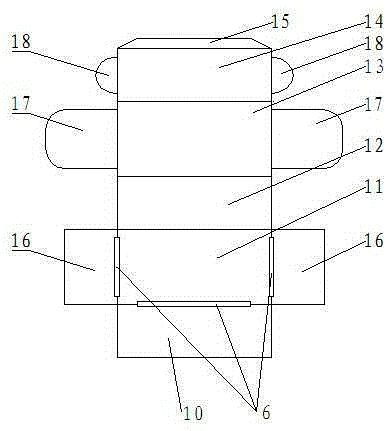

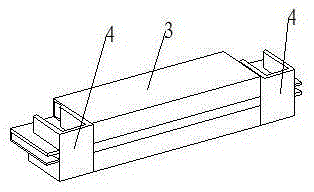

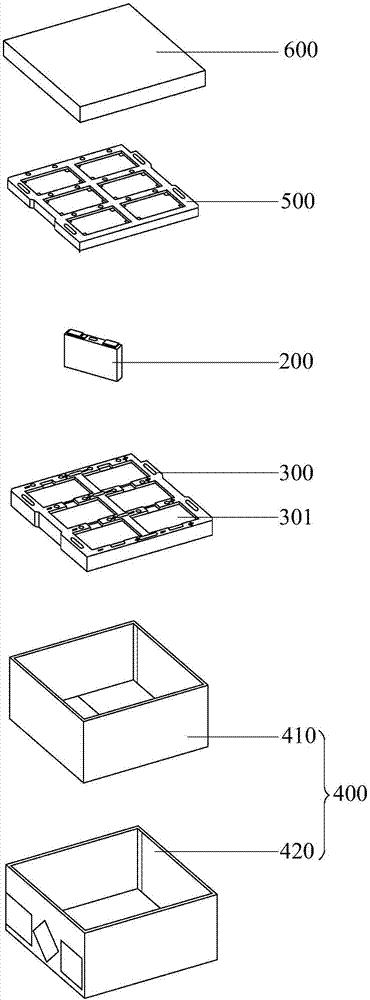

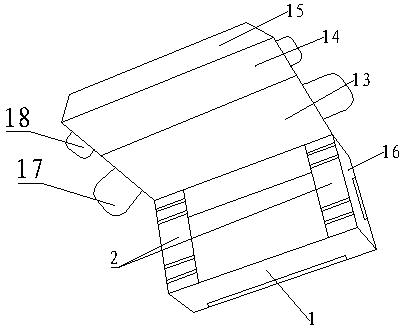

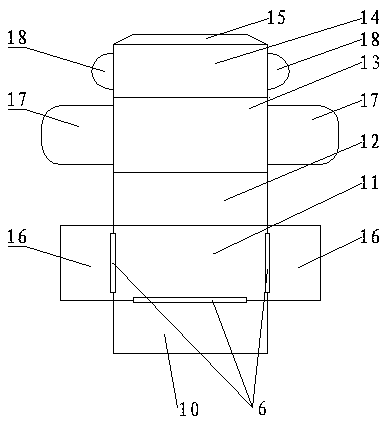

Reusable flat electronic product packaging box and making method thereof

InactiveCN105346799AWith buffer distanceEasy to splitPackage recyclingPackaging vehiclesLearning machineMechanical engineering

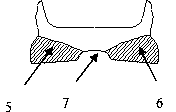

The invention relates to a reusable flat electronic product packaging box and a making method thereof. The packaging box comprises an outer box body and two support pads used for supporting two end parts of the flat electronic product, wherein each support pad is formed by a buffer body and two mortise locks; the buffer body is formed by a center plate and two folded parts; each folded part is formed by a first folded plate, a second folded plate, a third folded plate, a fourth folded plate, a fifth folded plate, a sixth folded plate and a seventh folded plate; one side of the first folded plate is vertically connected with one side of the center plate; the first folded plate, the second folded plate, the third folded plate, the fourth folded plate and the fifth folded plate are vertically folded in sequence; and the folding direction of the second folded plate is opposite to the direction of the center plate, so that the second folded plate and the center plate are respectively located at the upper end face and the lower end face of the first folded plate. According to the invention, the mortise locks are inserted to two ends of the buffer body, thus avoiding the phenomenon of sliding of a product in a clearance between two folded parts. The packaging box is suitable for packaging electronic products such as an English learning machine, material utilization rate is improved, and paper waste rate is reduced.

Owner:LUOYANG INST OF SCI & TECH

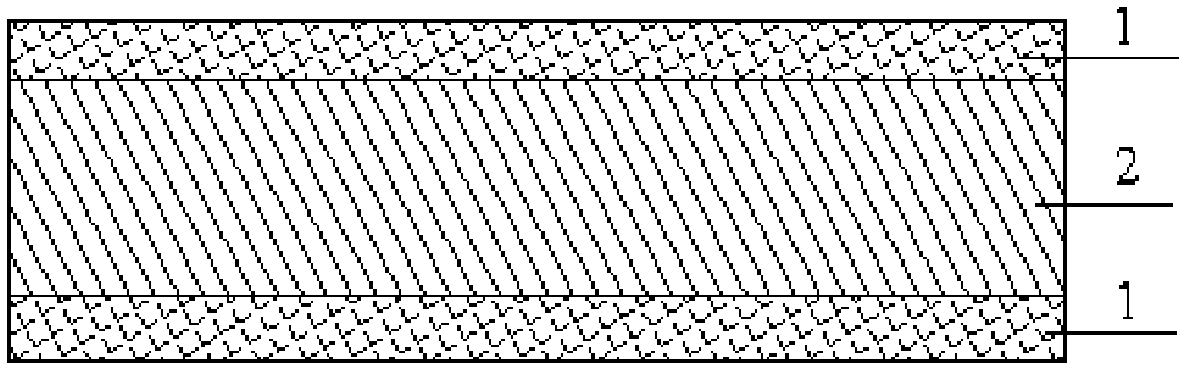

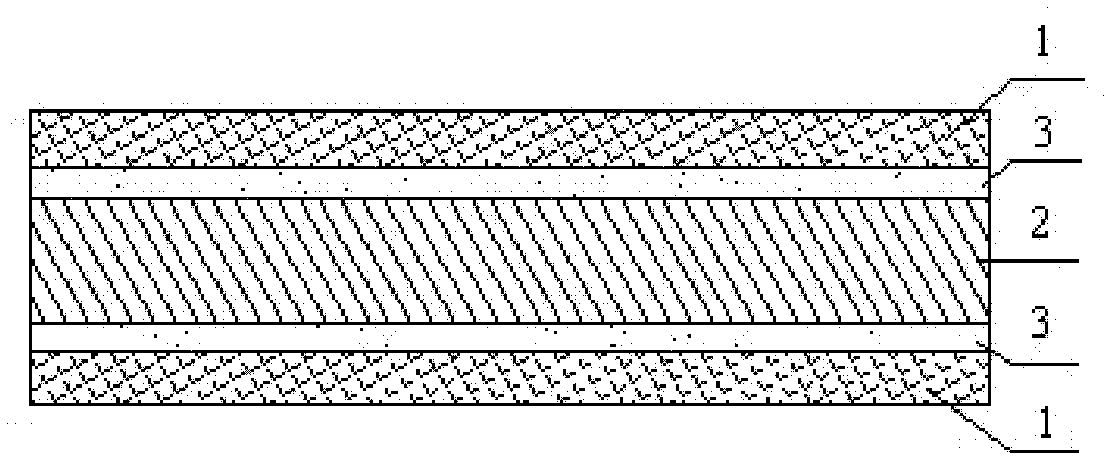

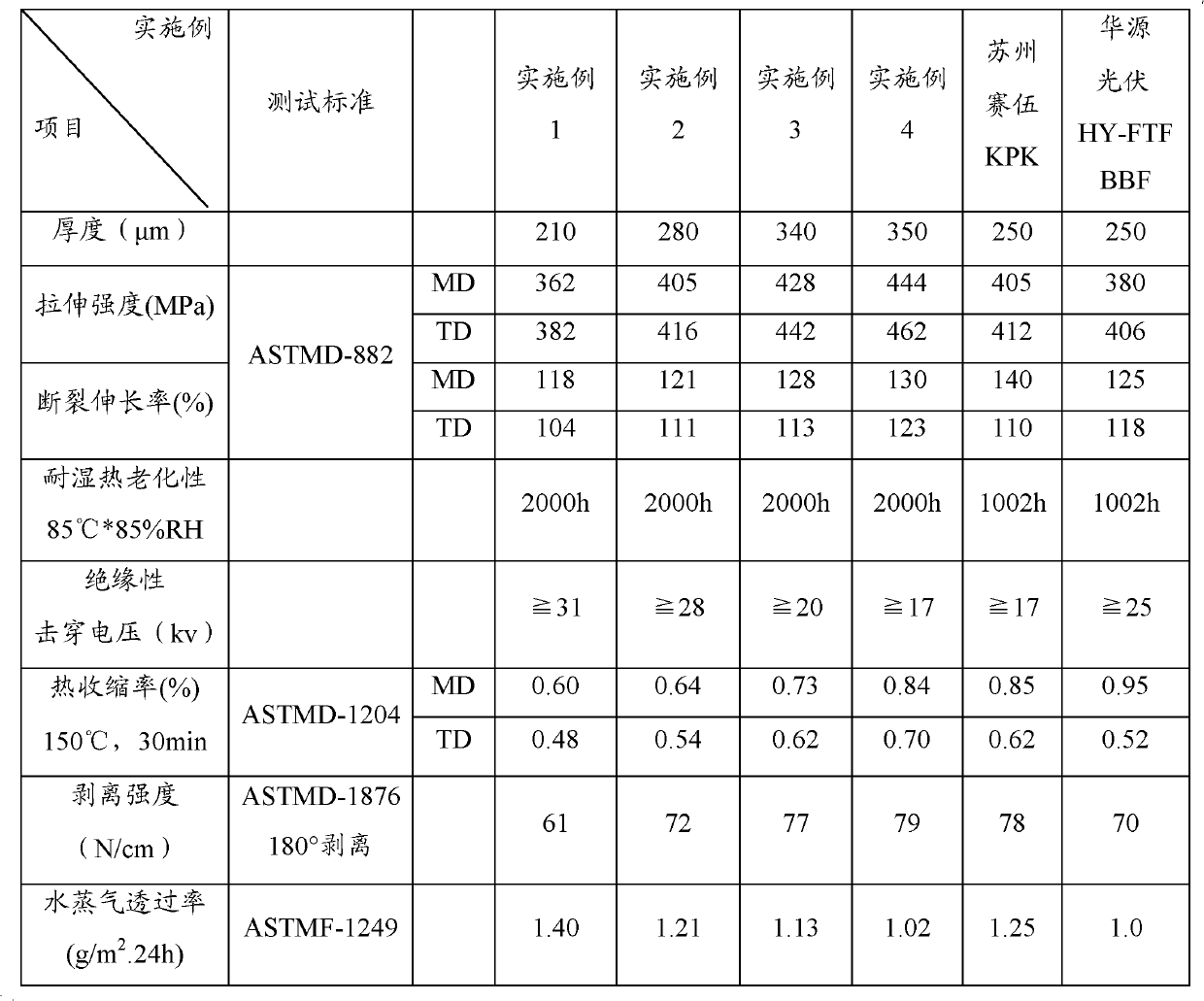

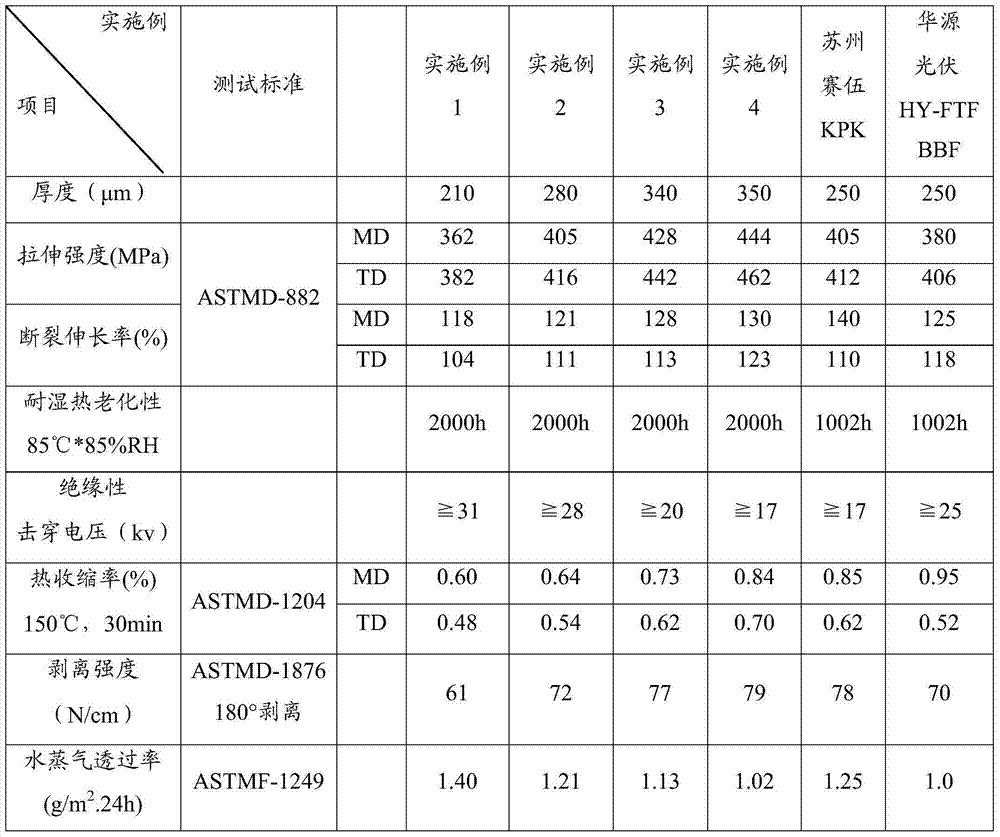

Solar cell back plane and preparation method thereof

ActiveCN102610679ALow costImprove mechanical propertiesSynthetic resin layered productsPhotovoltaic energy generationPolyetherimideWeather resistance

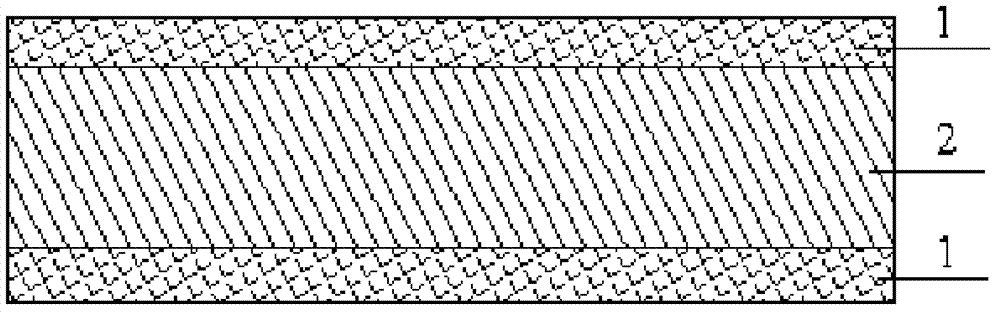

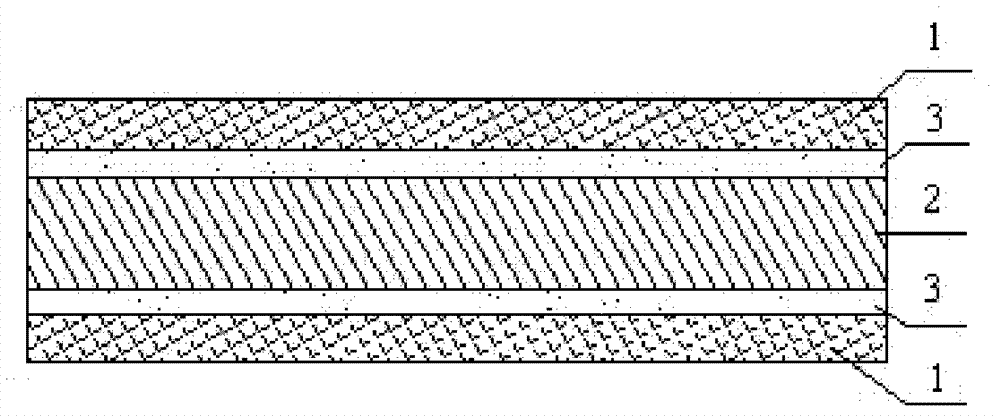

The invention provides a solar cell back plane and a preparation method of the solar cell back plane, belonging to the technical field of the solar photovoltaic cells. According to the invention, weather resistance of the solar cell back plane can be further improved and service life of the solar cell back plane can be prolonged. The solar cell back plane provided by the invention comprises a weather resistance layer and a structure enhancement layer, the weather resistance layer is made of polyetherimide; the structure enhancement layer is provided with the weather resistance layer on two sides. The solar cell back plane is characterized of simple structure, normal materials, excellent performance, simple technology for preparation method and simple operation.

Owner:合肥长阳新材料科技有限公司

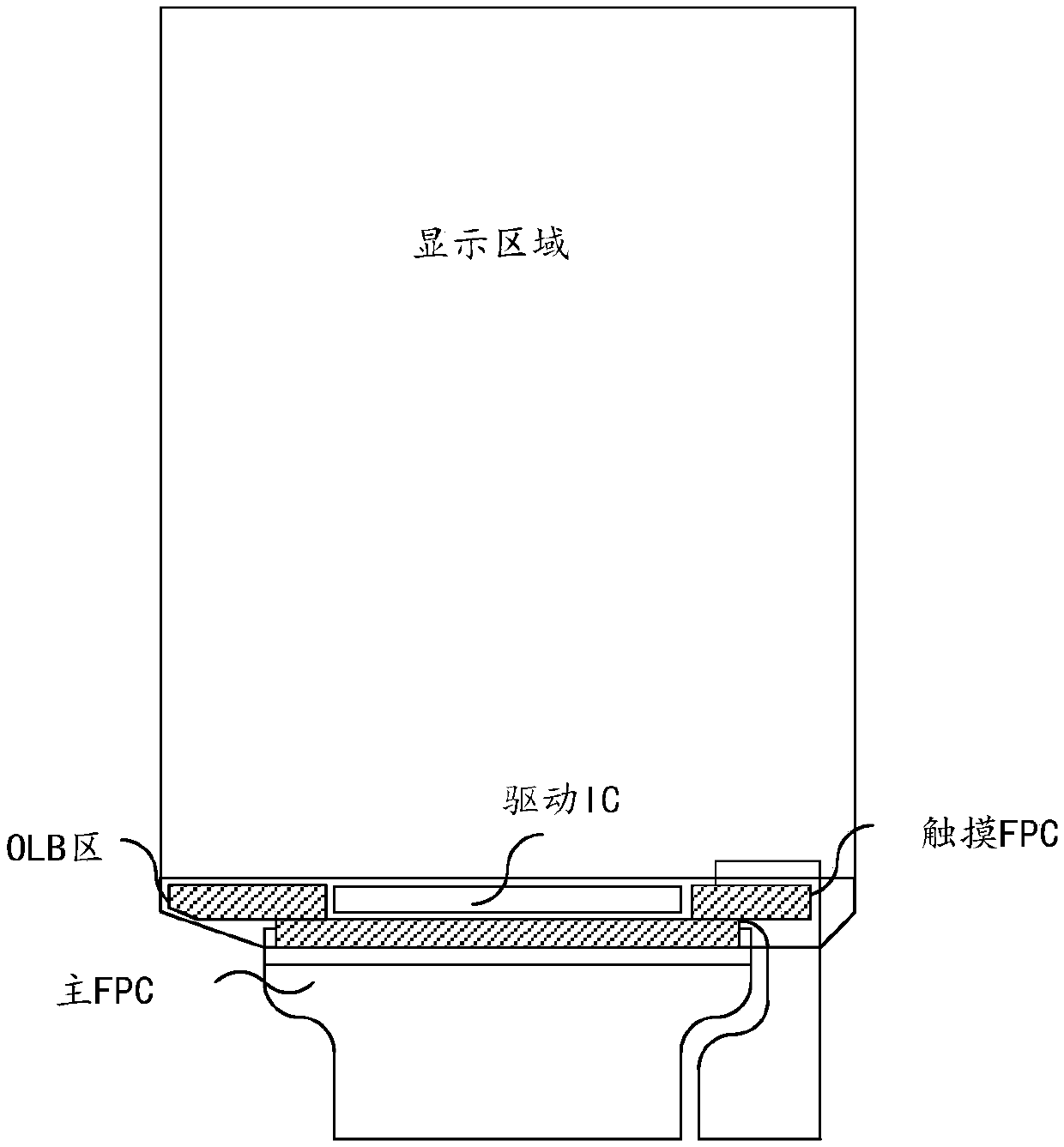

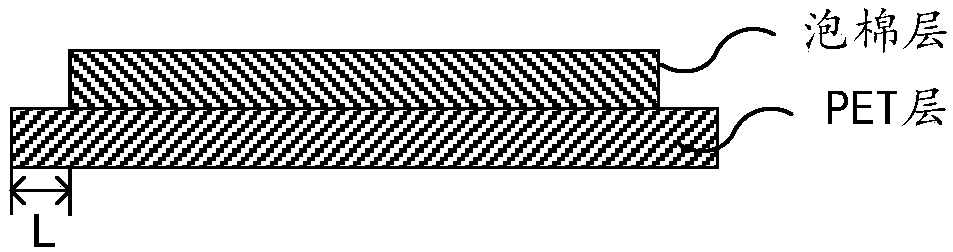

AMOLED light-emitting panel and display device

ActiveCN109659331AImprove structural strengthIssues Affecting Display PerformanceSolid-state devicesSemiconductor devicesDisplay deviceEngineering

The embodiment of the invention discloses an AMOLED light-emitting panel and a display device. The AMOLED light-emitting panel comprises a display area and an OLB area located at one side of the display area, the OLB area is internally provided with a drive IC, at least one side of the drive IC is provided with a buffer structure formed by stacking a PET layer and a foam layer located at the upperportion of the PET layer. The buffer structure arranged at least one side of the drive IC in the OLB area is formed by stacking the PET layer and the foam layer located at the upper portion of the PET layer, the materials of the PET layer are hard, the materials of the foam layer are soft, the PET layer in the buffer layer can have a certain support protection effect for the OLB area, the foam layer can have a good buffer protection effect for the OLB area to effectively enhance the structural strength of the AMOLED light-emitting panel and avoid the problem that the display performance of the AMOLED light-emitting panel is influenced due to crack or fracture of the OLB area when the AMOLED light-emitting panel is impacted so as to effectively improve the usage performances of the AMOLEDlight-emitting panel.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

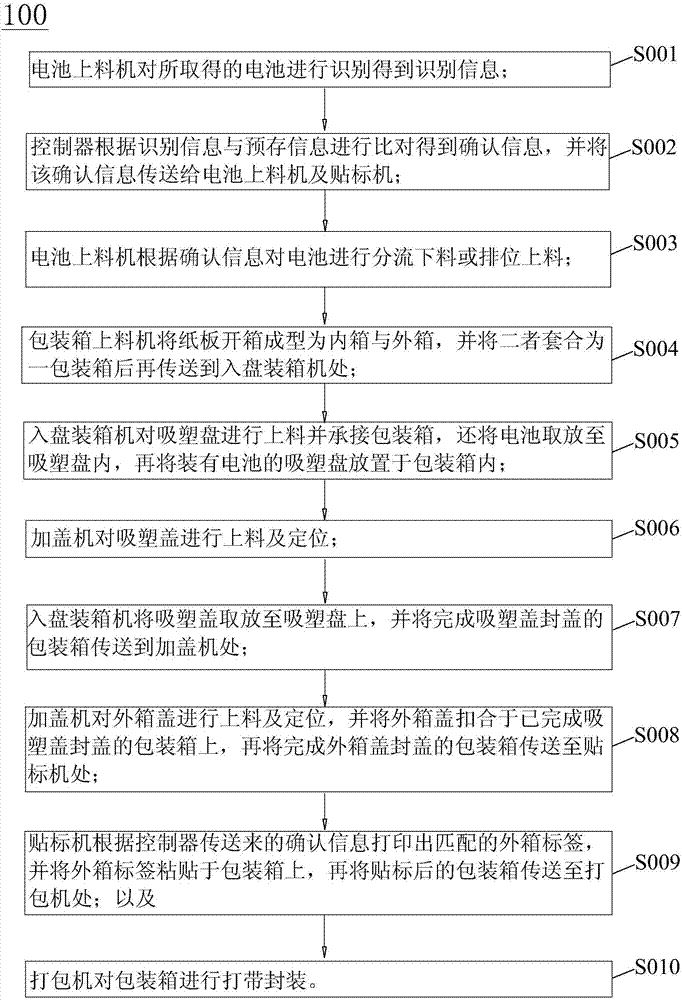

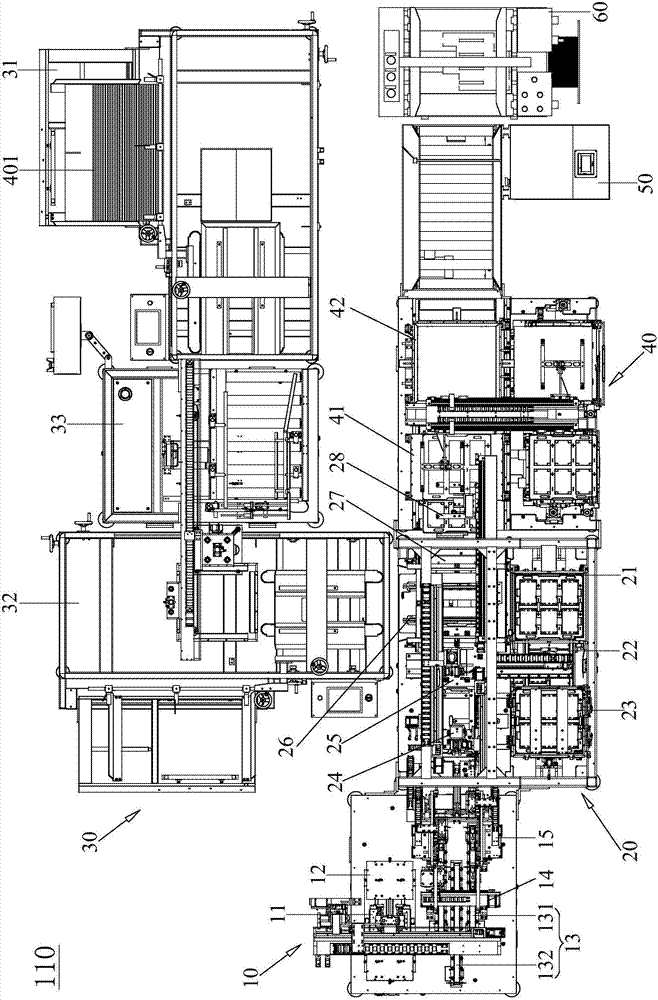

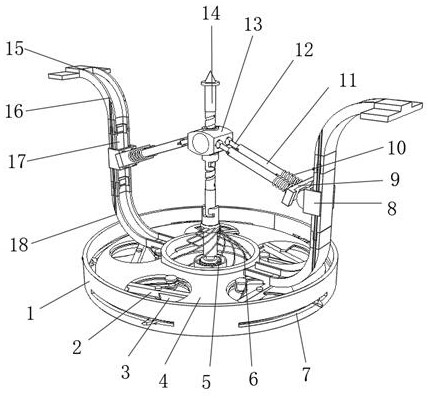

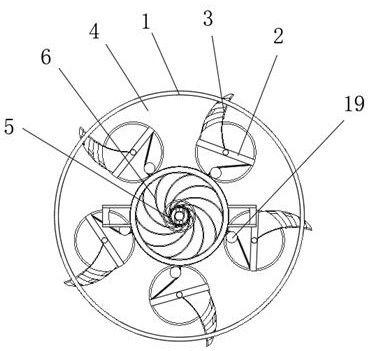

Battery packaging method

ActiveCN106976580AAchieve high integrationEliminate packaging errorsIndividual articlesPackaging machinesCardboardElectrical battery

The invention discloses a battery packaging method. The method comprises the steps that identification information is obtained by identifying batteries on a battery feeder; confirmation information is transmitted to the battery feeder and a labeling machine by a controller according to the identification information; distribution offline or arrangement feeding is conducted on the batteries by the battery feeder; paperboards are unpacked by a packaging box feeder to form an inner box body and an outer box body, and the inner box body and the outer box body are nested into the packing box; the batteries are taken and put into a plastic tray by a tray feeding boxing machine, and the plastic tray is arranged in the packing box; a plastic cover is fed and positioned by a cover adding machine; the plastic cover is taken and put on the plastic disc by the tray feeding boxing machine, and then the packing box covered with the plastic cover is conveyed to the cover adding machine; an outer box cover is fed and positioned by the cover adding machine, the outer box cover is bucked to the packaging box sealed with the plastic cover, and then the packaging box sealed with the outer box cover is conveyed to the labeling machine; and labeling is conducted by the labeling machine, and packaging is conducted by the packaging machine. The battery packaging method is high in degree of automation, high in efficiency and capable of lowering the cost effectively.

Owner:DONGGUAN WORLD PRECISION MACHINERY

Deep foundation pit supporting and protecting system for building construction

The invention belongs to the technical field of building construction, and particularly relates to a deep foundation pit supporting and protecting system for building construction. The following scheme is provided for the problems that the labor intensity of workers is high, no main structure or main supporting point exists, the supporting and protecting effect is poor, and the safety of the workers is low. The deep foundation pit supporting and protecting system comprises a base, wherein a bottom plate is fixedly connected to the inner wall of the bottom end of the base; the inner wall of the bottom end of the bottom plate is connected with a motor through rivets; one end of an output shaft of the motor is connected with a threaded rod through a coupler; the outer wall of the bottom end of the threaded rod is sleeved with a sleeve; ten to twelve steel wire ropes distributed at equal intervals are arranged on the outer wall of the bottom end of the sleeve; the outer wall of the bottom end of the bottom plate is movably connected with an annular plate; and four to six connecting ropes distributed at equal intervals are arranged on the outer wall of the annular plate. The mounting and dismounting process is simple, the labor intensity of the workers is high, the supporting structure is stable, the supporting and protecting effect is good, the safety of the workers is high, and the using efficiency of the deep foundation pit supporting and protecting system is improved.

Owner:何焕

Aluminum alloy shell for electronic product

InactiveCN108315609AImprove aestheticsImprove gripAnodisationMetal casingsUltimate tensile strengthCeramic membrane

The invention belongs to the technical field of metal processing and particularly relates to an aluminum alloy shell for an electronic product. The aluminum alloy shell material is prepared from the following components by proportion: 4 to 8 percent of Mg, 0.5 to 0.9 part of Cu, 0.6 to 0.9 part of Fe, 0.3 to 0.7 part of Si, 0.4 to 0.6 part of Ca, 0.1 to 0.2 part of Zr, 0.2 to 0.3 part of Mn, 0.1 to 0.2 part of Cr, 0.05 or less than 0.05 percent of Ti, 0.02 or less than 0.02 percent of B, 0.01 or less than 0.01 percent of V and the balance of aluminum and unavoidable impurities. A preparation method of the shell comprises the following technical process: firstly, smelting and molding an aluminum alloy; secondly, carrying out hot processing on the aluminum alloy; thirdly, carrying out metalprocessing on the shell; fourthly, plating the shell. The aluminum alloy shell produced by the technology has the advantages of good thermal conductivity, good structural strength, good processing characteristics and excellent surface hardness and scratch resistance; in addition, due to the existence of a surface ceramic membrane, the shell has good anti-oxidation properties, good aesthetic feeling and good gripping hand feel.

Owner:HEFEI TONGYOU ELECTRONICS TECH CO LTD

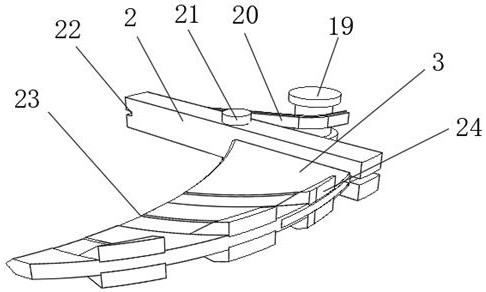

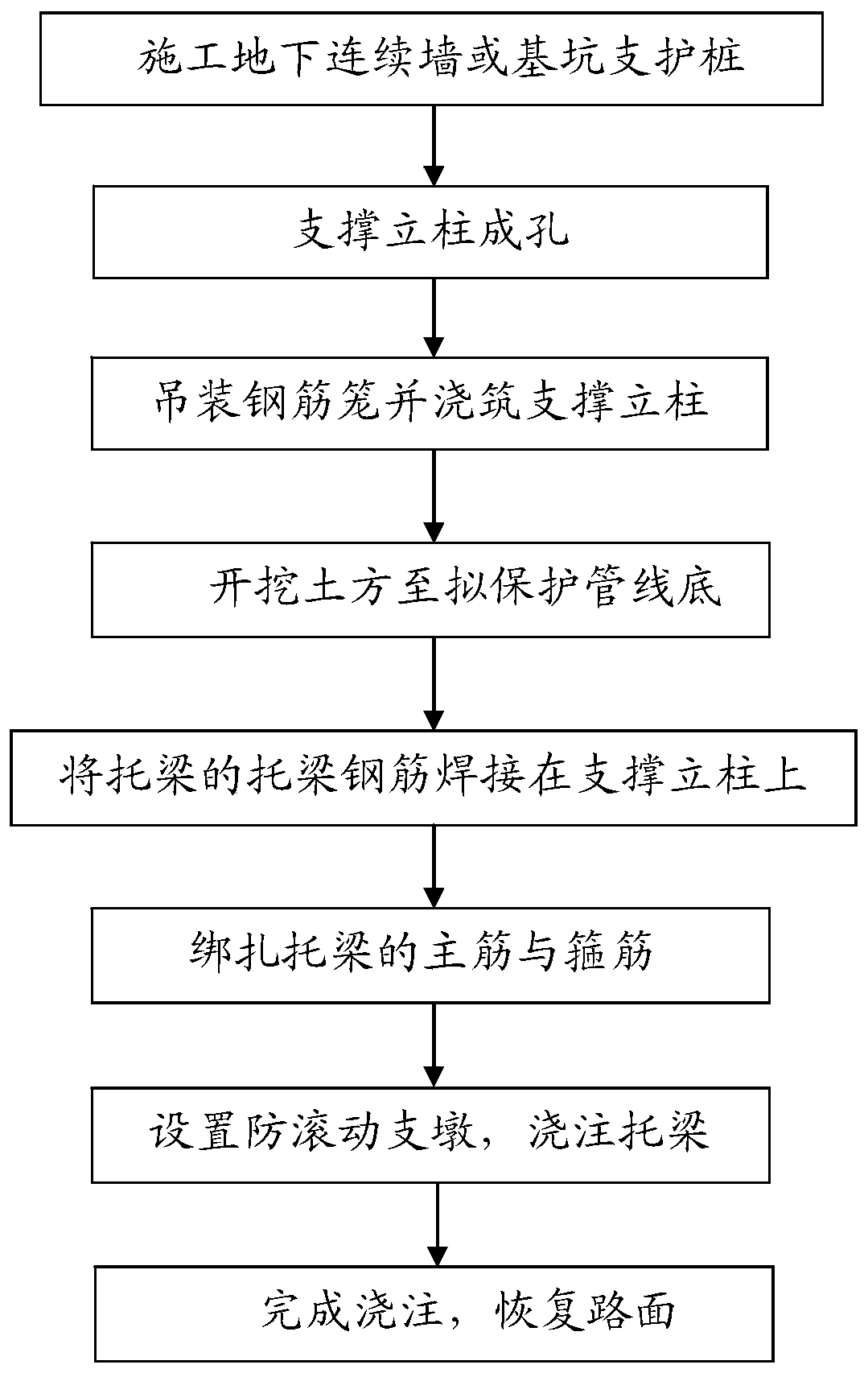

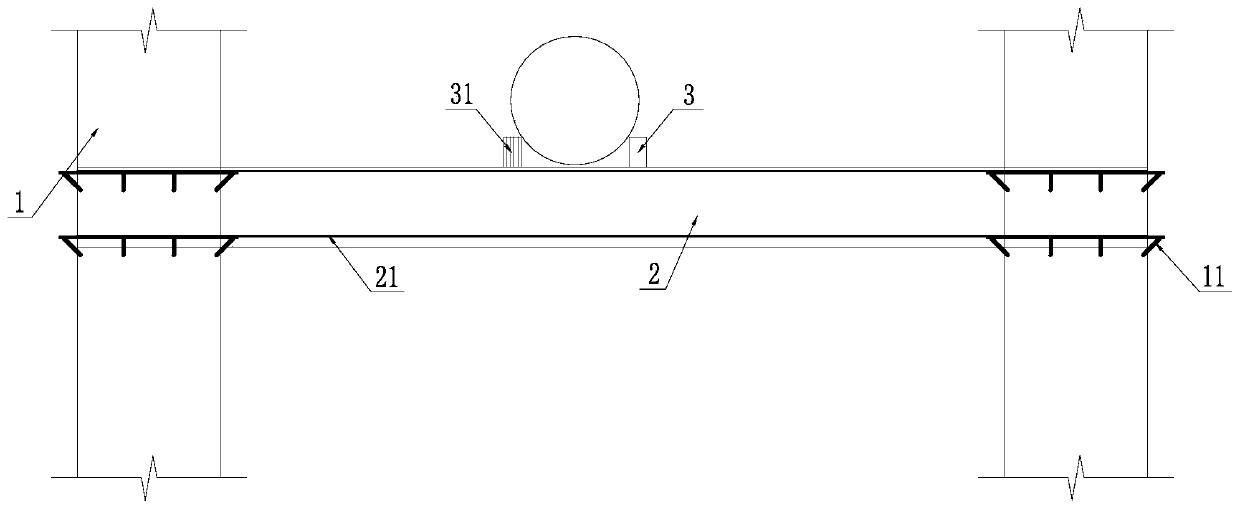

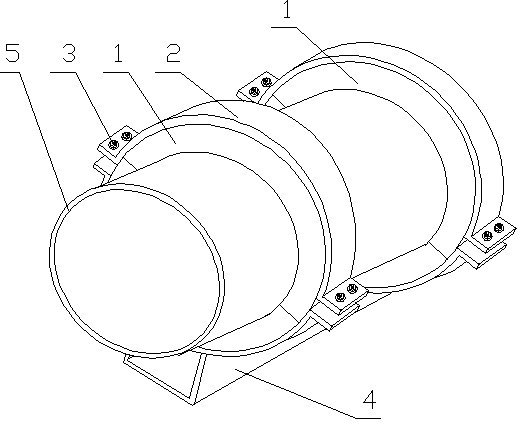

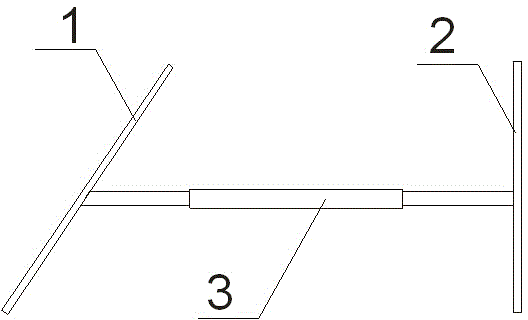

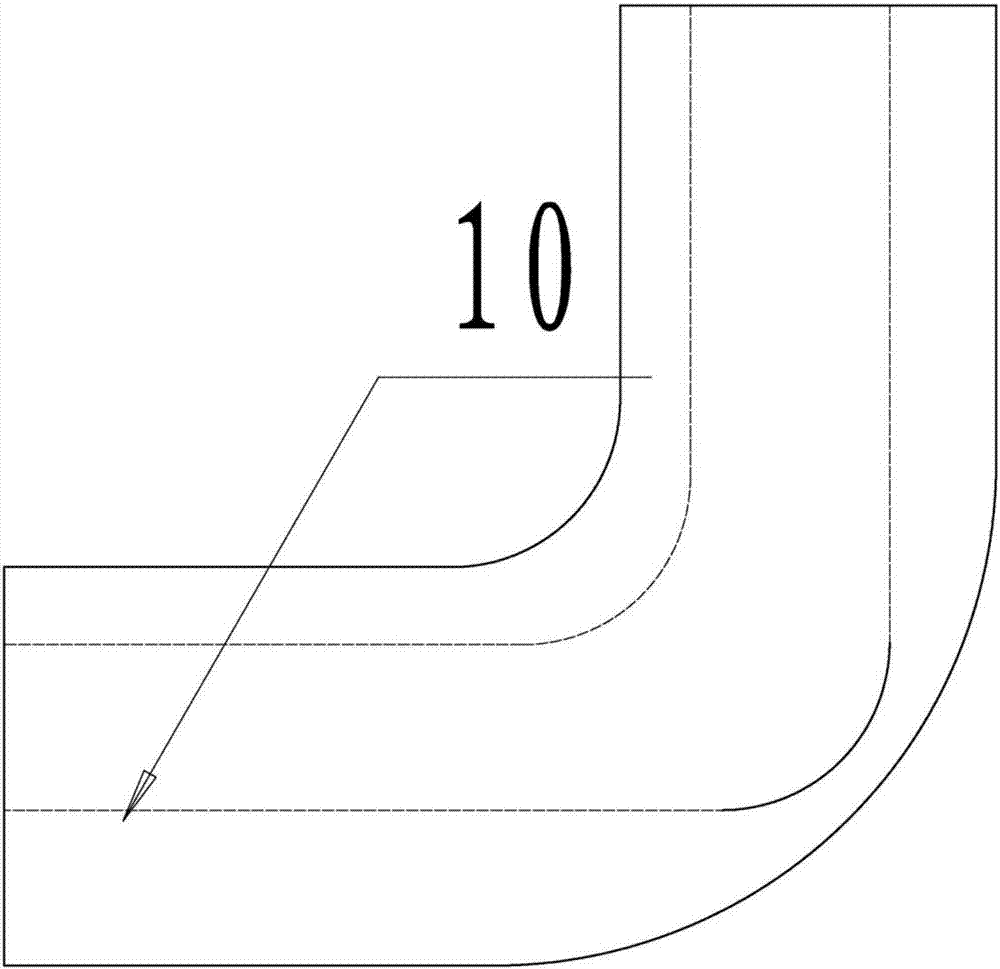

Method and structure for protecting pipeline in situ by using reinforced concrete joist

PendingCN110344440ASimple processSimple structureArtificial islandsUnderwater structuresButtressLine tubing

The invention discloses a method and a structure for protecting a pipeline in situ by using a reinforced concrete joist. A protection process has the following steps: firstly, constructing a underground diaphragm wall or a foundation pit support pile; secondly, poring support columns; thirdly, hoisting a reinforcement cage and pouring the support columns; fourthly, excavating an earthwork to the bottom of a pipeline to be protected; fifthly, welding reinforcement of the joist to the support columns; sixthly, binding main reinforcement and stirrups of the joist; seventhly, arranging anti-rolling buttresses and pouring the joist; and eighthly, completing the pouring and recovering a pavement. The method for protecting the pipeline in situ by using the reinforced concrete joist is used to protect the pipeline in situ, which is simple in process and operation, saves a construction period, reduces the construction cost, and makes the protection more concise and in place. The structure for protecting the pipeline in situ by using the reinforced concrete joist is formed by combining the joist with the anti-rolling buttresses and carrying out support pouring through the support columns. The structure has the advantages of simple structure, stable support and good support and protection effects.

Owner:SHENZHEN INVESTIGATION & RES INST

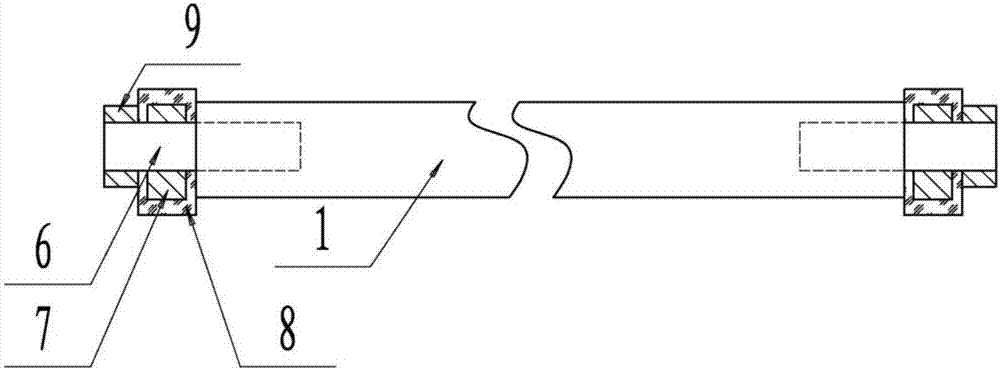

High-strength magnesium steel heat-insulating material, preparation method thereof and heat-insulating block made of high-strength magnesium steel heat-insulating material

InactiveCN102093028AGood support and protectionAging resistantThermal insulationPipe protection by thermal insulationChemical industryThermal insulation

The invention relates to a high-strength magnesium steel heat-insulating material, a preparation method thereof and a heat-insulating block made of the high-strength magnesium steel heat-insulating material, belonging to the technical field of chemical industry. The high-strength magnesium steel heat-insulating material is mainly used for support and heat insulation of pipelines and equipment. The high-strength magnesium steel heat-insulating material is prepared from the following components in parts by weight: 4000-4500 parts of magnesium oxide, 2500-3000 parts of magnesium chloride, 5-10 parts of ferrous sulfate, 5-10 parts of trisodium phosphate, 5-10 parts of oxalic acid and 2800-3300 parts of glass fiber. The invention has favorable functions of supporting and protecting pipelines and equipment, and has the characteristics of low coefficient of heat conductivity, favorable thermal-insulation effect, aging resistance, water resistance, corrosion resistance, heat resistance, fire resistance, no toxicity and no smell.

Owner:陈品山

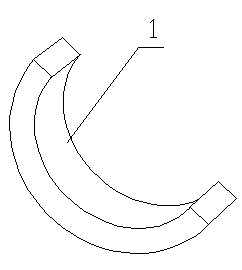

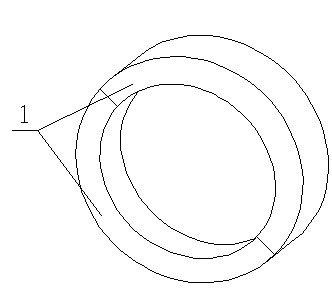

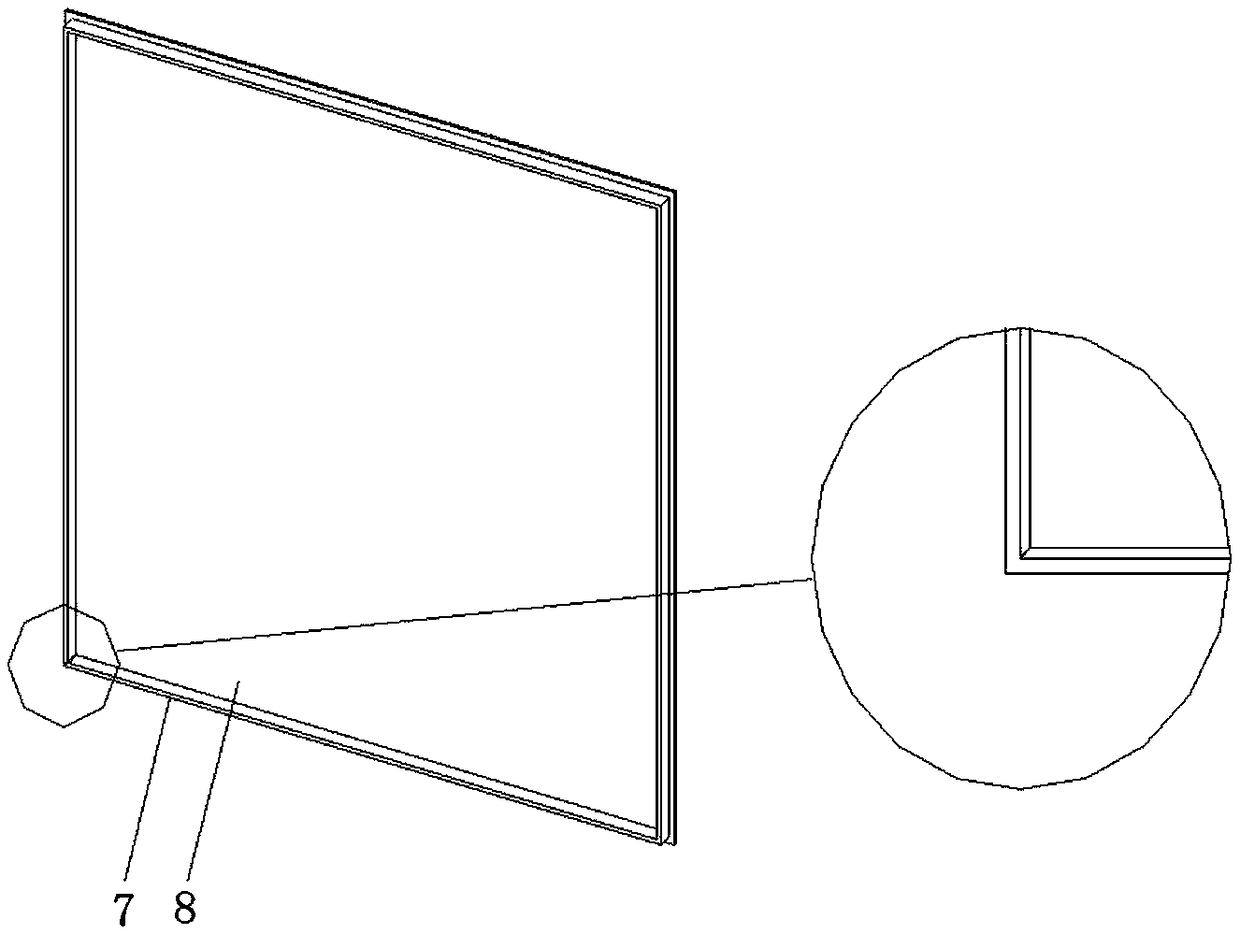

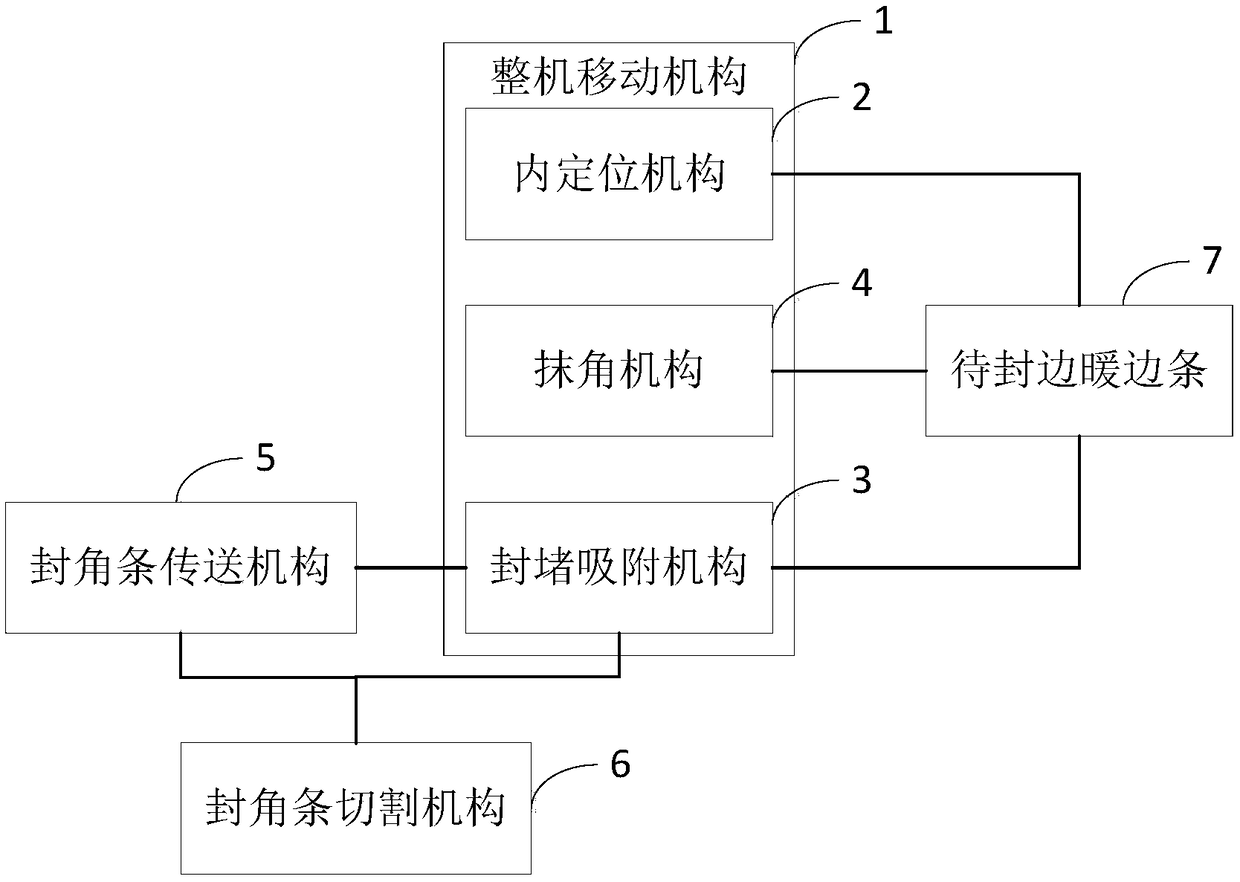

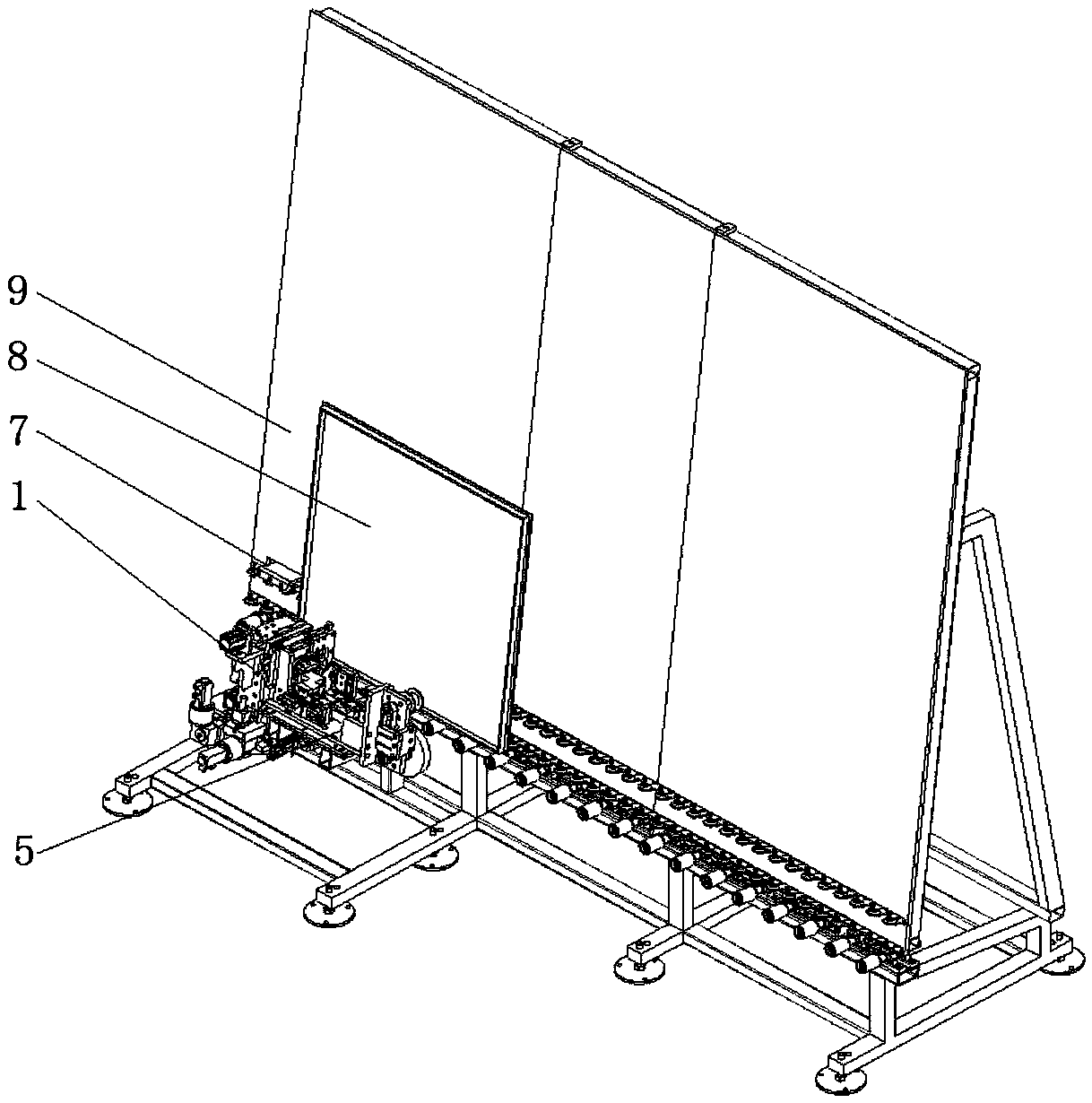

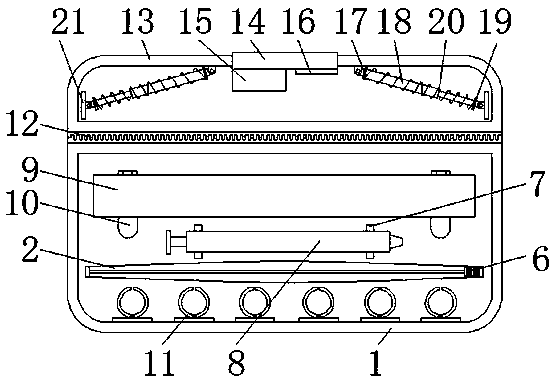

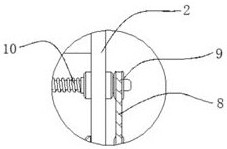

Angle part edge sealing machine for warm edge strip

ActiveCN108409165AImprove efficiencyQuality improvementGlass reforming apparatusPhotovoltaic energy generationEngineeringEdge banding

The invention discloses an angle part edge sealing machine for a warm edge strip. The angle part edge sealing machine comprises a complete machine moving mechanism, an inner positioning mechanism, a blockage absorption mechanism, an angle erasing mechanism, an angle seal strip conveying mechanism and an angle seal strip cutting mechanism, wherein the angle part edge sealing machine for the warm edge strip is used for supporting and protecting foot parts of the warm edge strip through an inner positioning stopper block in the inner positioning mechanism so as to avoid the phenomenon that the warm edge strip is ejected aslant in an edge sealing process; angle seal strips which are cut are adhered to angle positions of the warm edge strip through the blockage absorption mechanism; the angle seal strips are rolled and pressed through an angle erasing wheel so as to realize angle erasing and edge sealing operations. In addition, the angle seal strip conveying mechanism and the angle seal strip cutting mechanism are also arranged, so that a set of full automatic processes including stripping, conveying, cut-off and adhesion on the rolled edge sealing strip can be formed, so that the edgesealing efficiency and quality of the warm edge strip are greatly improved; therefore, for the characteristic of the foot part positions of the warm edge strip, the edge sealing processing on the angle parts of the warm edge strip is automatically realized, the edge sealing efficiency is improved, the effect is better, and the precision is higher.

Owner:TENON BEIJING EQUIP

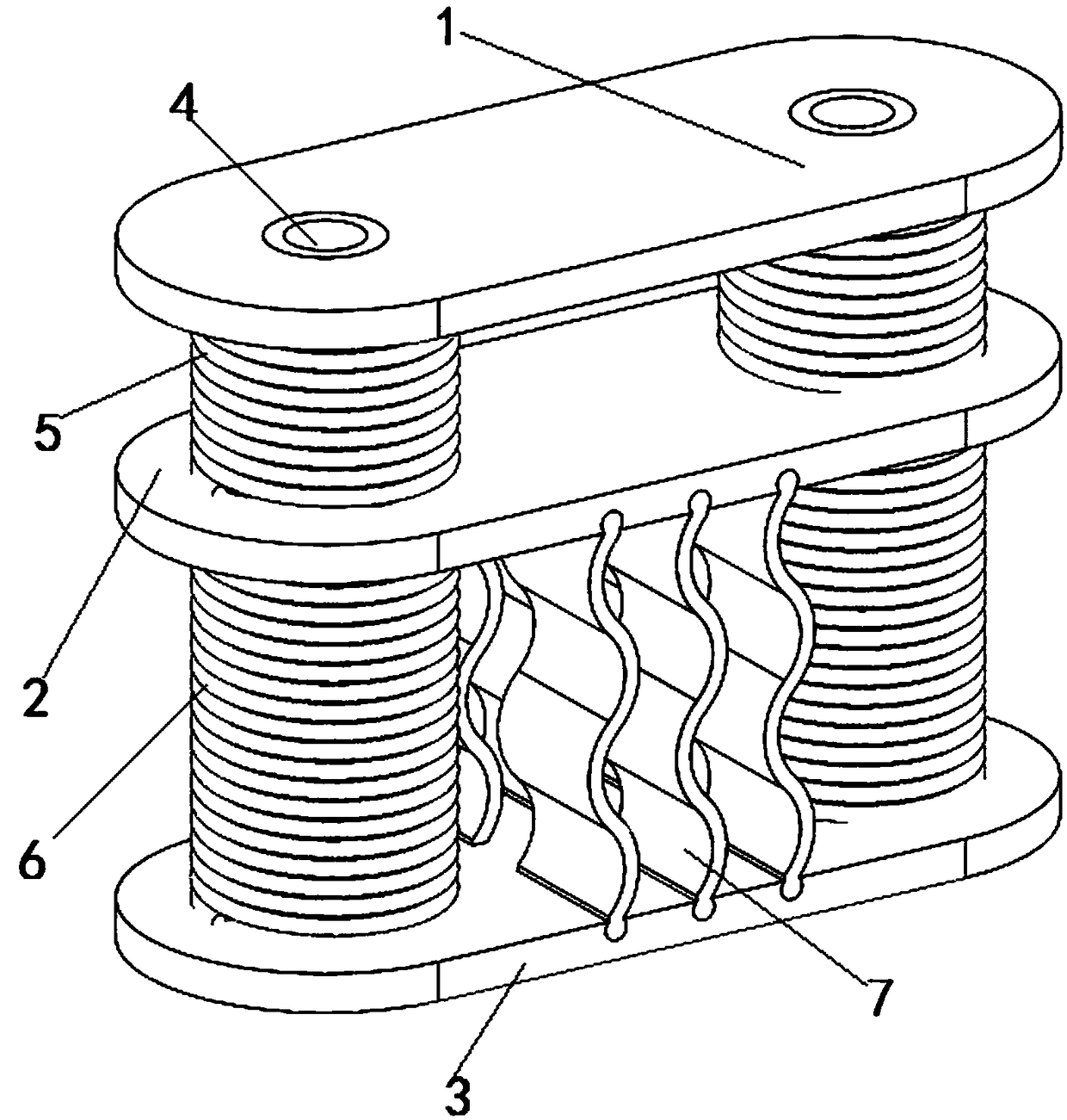

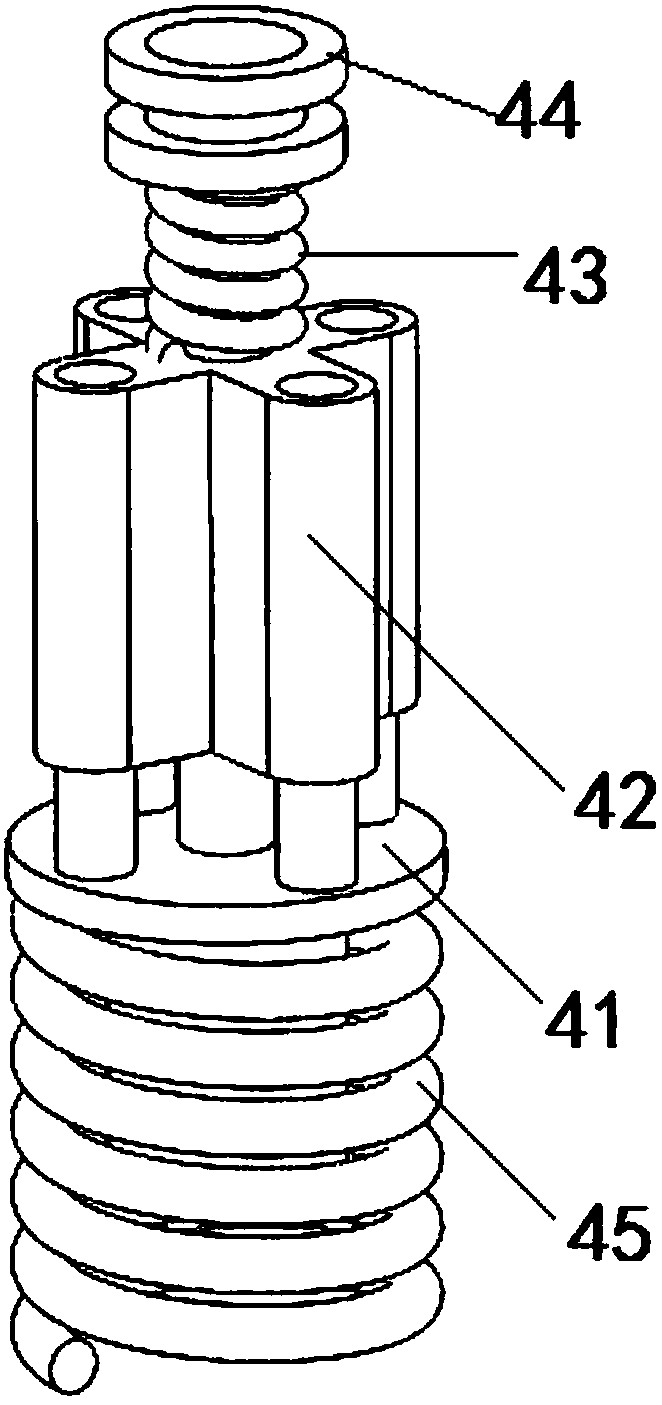

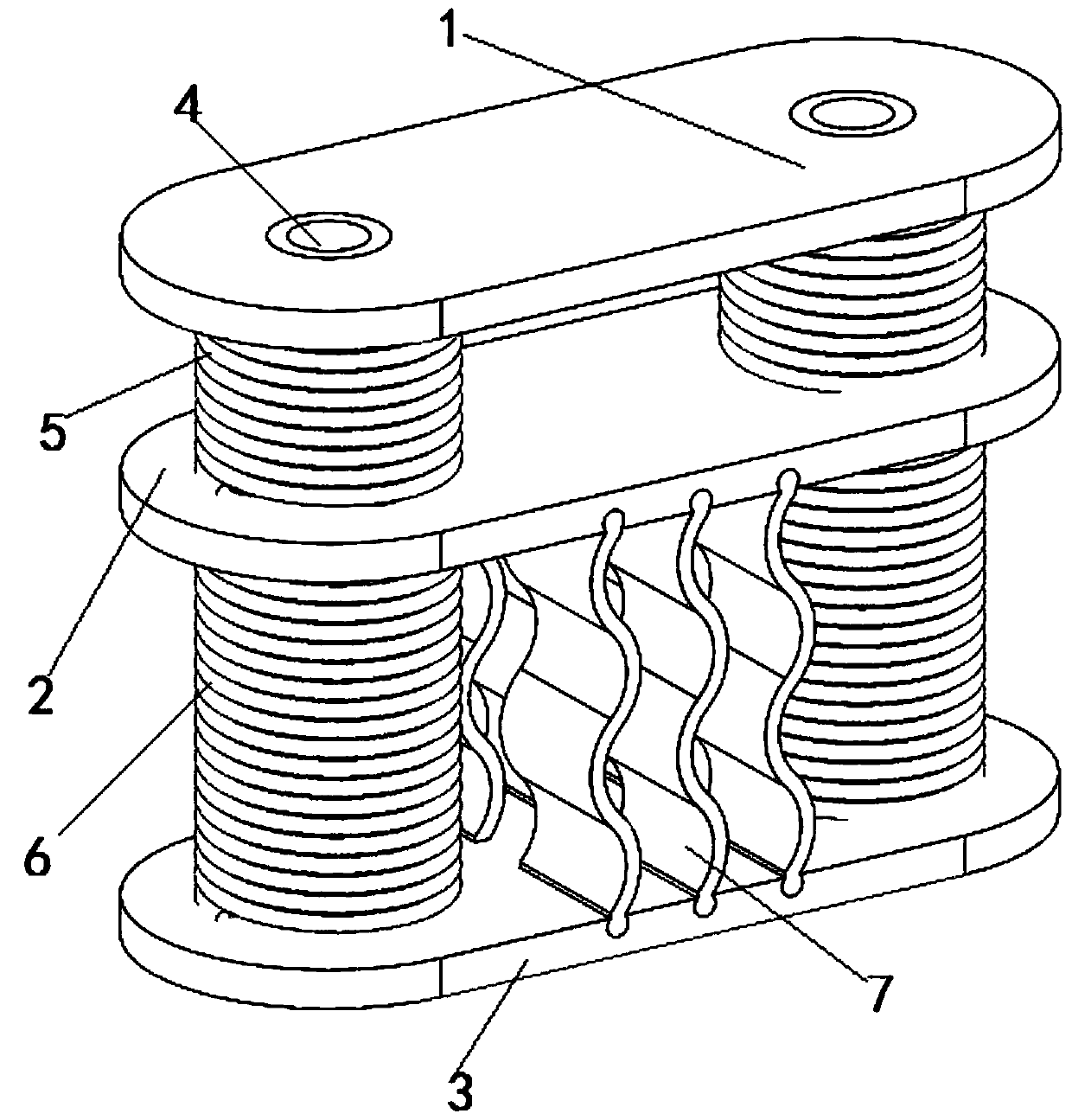

Cosmetic package protection device

ActiveCN108482863ATransportation safetyStable supportContainers to prevent mechanical damageProtection mechanismEngineering

The invention discloses a cosmetic package protection device. The cosmetic package protection device comprises a supporting top plate, a middle transition plate and a bottom mounting plate, wherein the supporting top plate, the middle transition plate and the bottom mounting plate are sequentially mounted from top to bottom in the vertical direction. Two first buffer springs are symmetrically mounted between the supporting top plate and the middle transition plate. Two second buffer springs are symmetrically mounted between the middle transition plate and the bottom mounting plate. Two bufferprotection mechanisms are symmetrically mounted at the left end and the right end of the middle transition plate. Corrugated rubber plates are vertically mounted on the front side and the back side ofthe bottom of the middle transition plate in the linear direction. According to the cosmetic package protection device, through the structural design of the supporting top plate, the middle transition plate, the bottom mounting plate and the two buffer protection mechanisms, good supporting and protection effects can be achieved in the cosmetic package transportation process; multi-buffering canbe achieved, the cosmetic package protection device can also be well protected, and it is ensured that cosmetics are safely transported for a long distance under a complex road condition; and the cosmetic package protection device has high application and popularization value.

Owner:浙江大洪包装科技股份有限公司

Portable roadblock for roads and bridges based on municipal construction

ActiveCN112195814AEasy to carryStable supportTraffic signalsRoad signsArchitectural engineeringStructural engineering

Owner:安徽良策建工集团有限公司

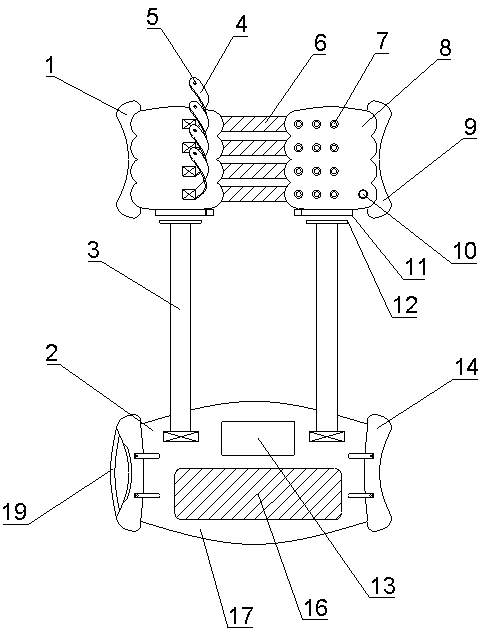

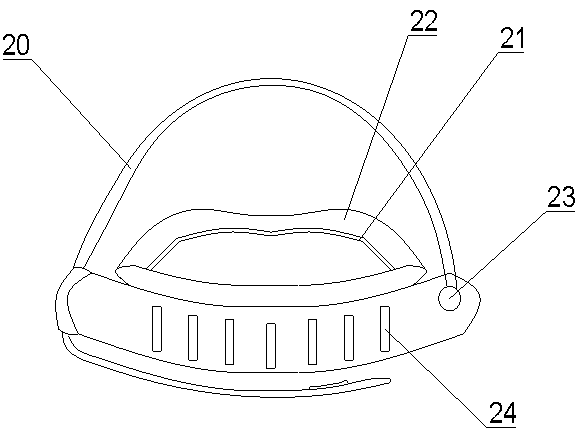

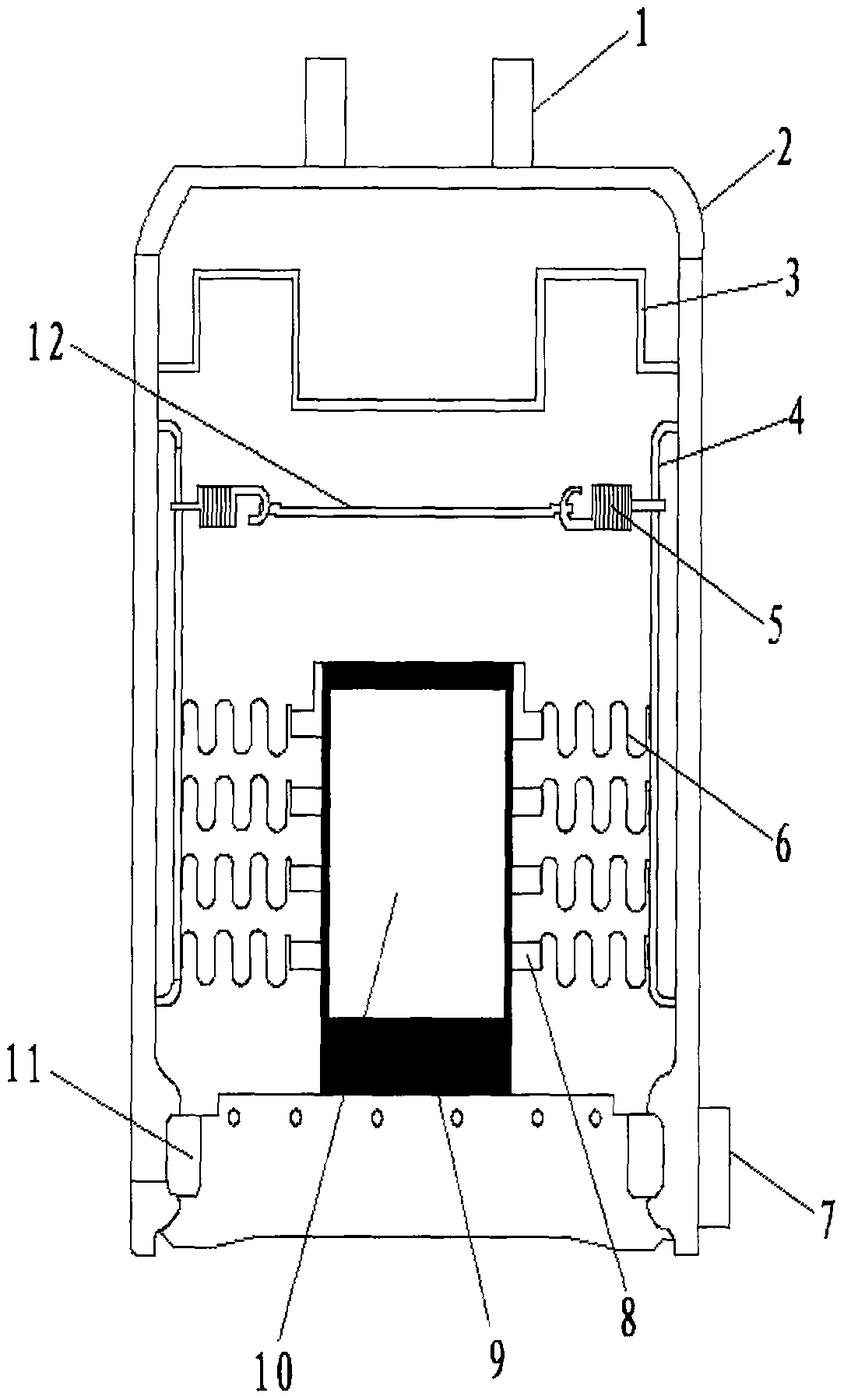

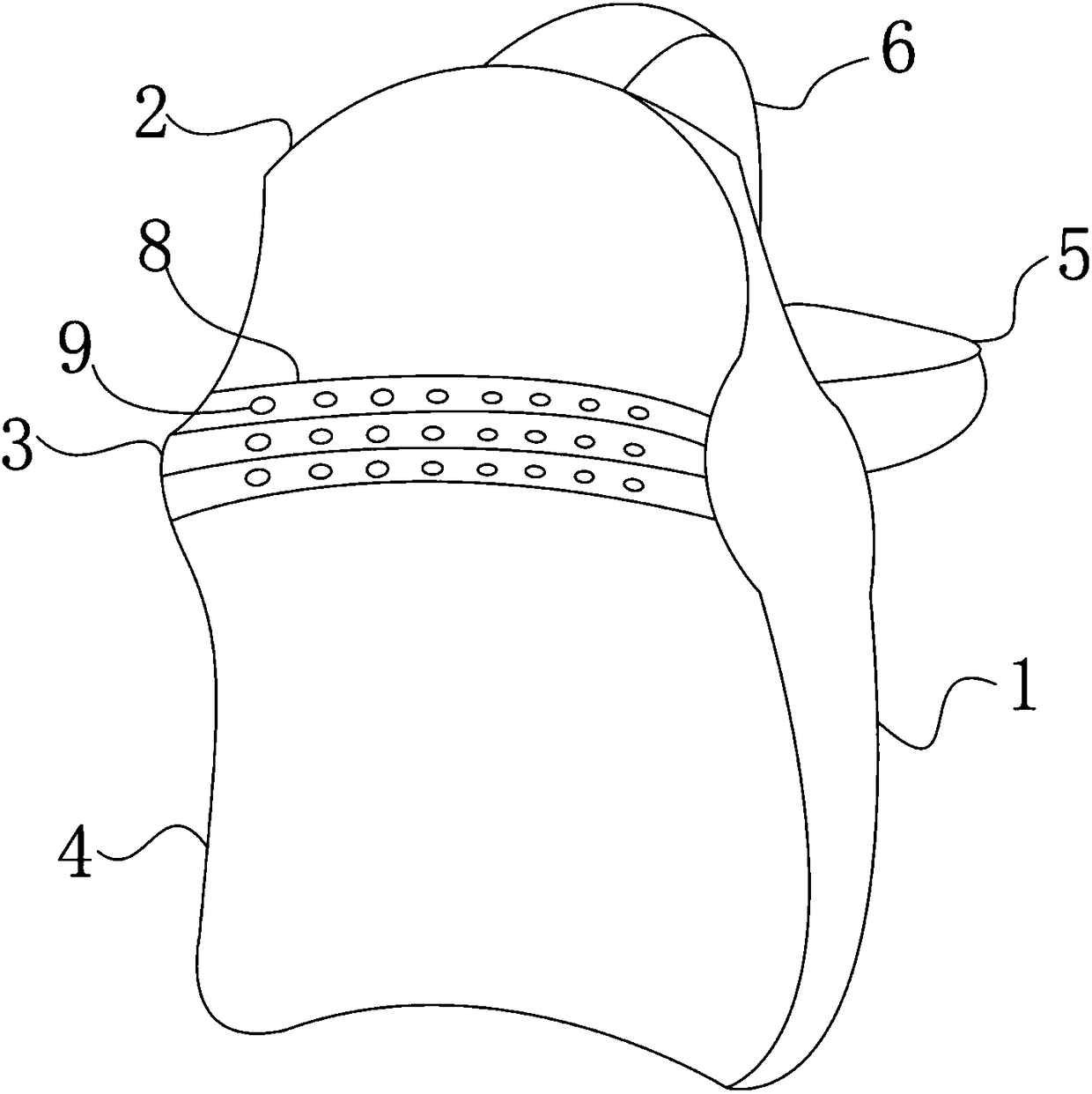

Multifunctional cervical vertebra and lumbar vertebra traction apparatus

The invention discloses a multifunctional cervical vertebra and lumbar vertebra traction apparatus. The apparatus comprises a cervical vertebra traction part and a lumbar vertebra traction part; the cervical vertebra traction part comprises a first external protection plate and an air bag; the first external protection plate is divided into a left part and a right part, and a rotary part is arranged at one end of the first external protection plate; the air bag is arranged on the inner wall of the first external protection plate; the air bag is in an annular opening shape; an elastic belt is arranged at an opening of the air bag; tying belts are arranged on the back of the air bag, and son buckles are arranged on the tying belts; a plurality of mother buckles are arranged on the air bag; an installation part is arranged on the lumbar vertebra traction part, and second external protection plates are arranged on the two sides of the installation part; a fixing part is arranged on the second external protection plate on one side, and a gap is formed between the fixing part and the corresponding second external part; a winder is arranged on the second external protection plate on the other side; a locking belt is arranged on the winder; connection belts are arranged on the installation part, and clamping pins are arranged at the tops of the connection belts. The cervical vertebra and lumbar vertebra traction apparatus can be in combined use or in separated use, is convenient to dismantle and install and has a better ventilation effect.

Owner:王虎林

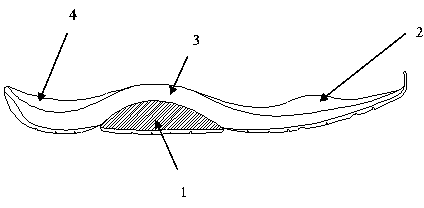

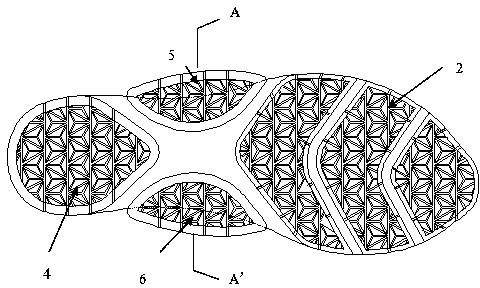

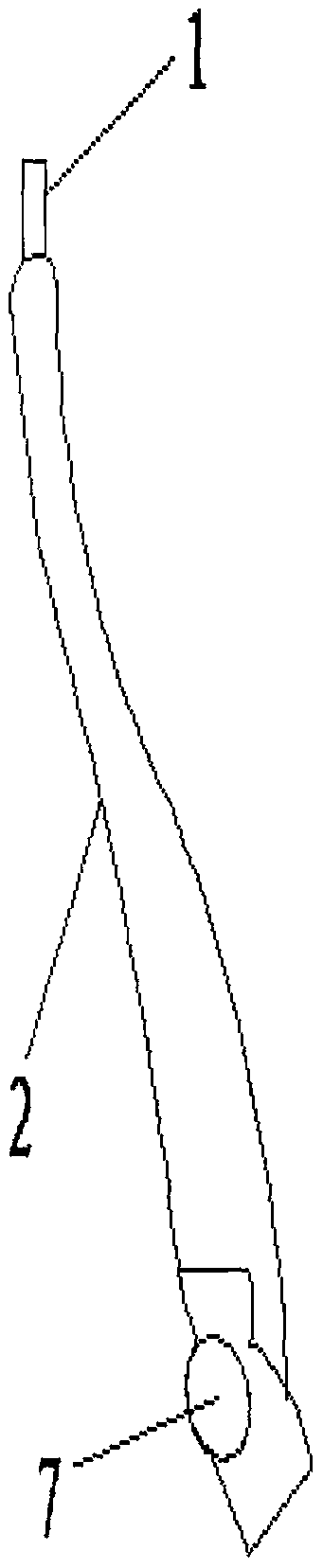

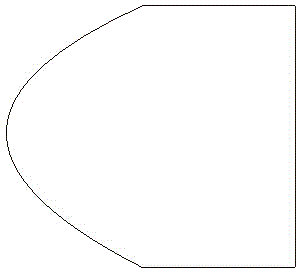

Sole and shoe

ActiveCN103349397AGood support and protectionLess discomfortSolesUpperPhysical medicine and rehabilitationEngineering

The invention provides a sole. The sole comprises a front foot portion, a foot arch portion and a heel portion, wherein the foot arch portion is in an arch shape, and a foot arch protection unit which provides bearing protection for the foot arch is arranged on the foot arch portion. The invention further provides a shoe including the sole. The sole solves the problem that an existing sole can not provide good bearing protection for the foot arch. The sole can provide good bearing protection for the foot arch, and the uncomfortable feelings of the foot arch produced when a user walks or does sports are reduced.

Owner:MAOTAI FUJIAN SOLES CO LTD

Solar cell back plane and preparation method thereof

ActiveCN102610679BLow costImprove mechanical propertiesSynthetic resin layered productsPhotovoltaic energy generationPolyetherimideWeather resistance

The present invention relates to the technical field of solar photovoltaic cells, in particular to a solar cell back plate and a preparation method thereof. In order to further improve the weather resistance of the solar cell back plate and prolong its service life, the present invention provides a solar cell back plate and its Preparation. The solar battery back sheet provided by the present invention includes a weather-resistant layer and a structural reinforcement layer, and the material of the weather-resistant layer is polyetherimide; both sides of the structural reinforcement layer are provided with weather-resistant layers. The solar battery back plate has simple structure, easy-to-obtain material, excellent performance, simple preparation method and process, and is easy to operate.

Owner:合肥长阳新材料科技有限公司

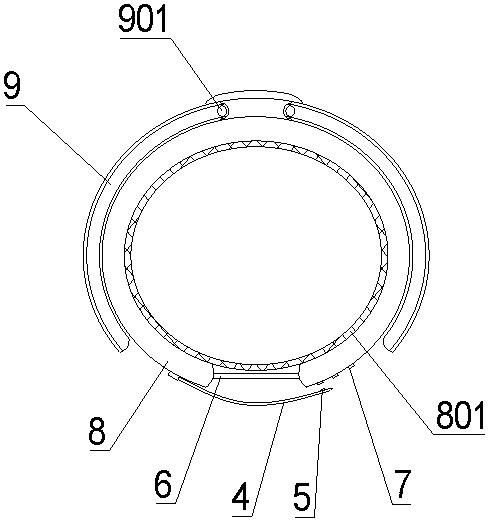

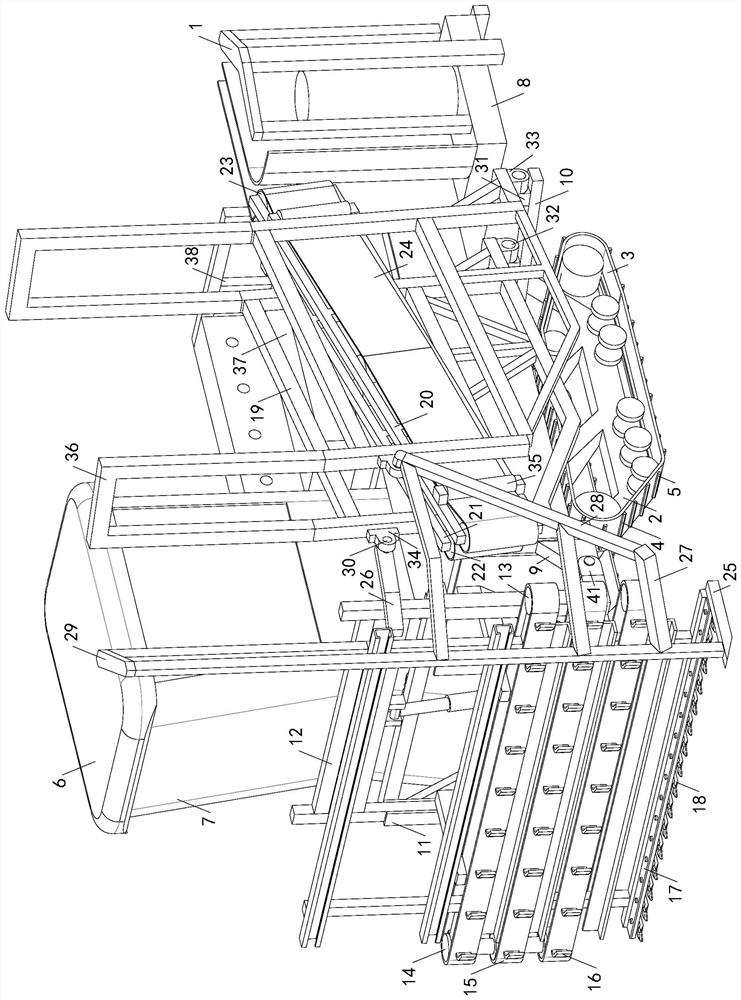

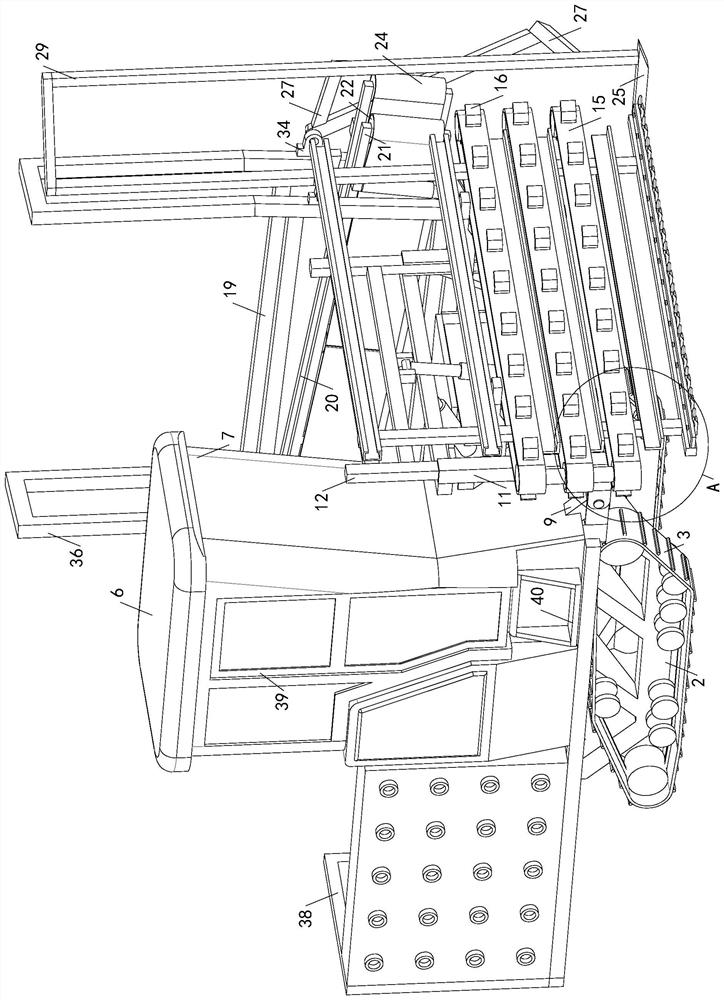

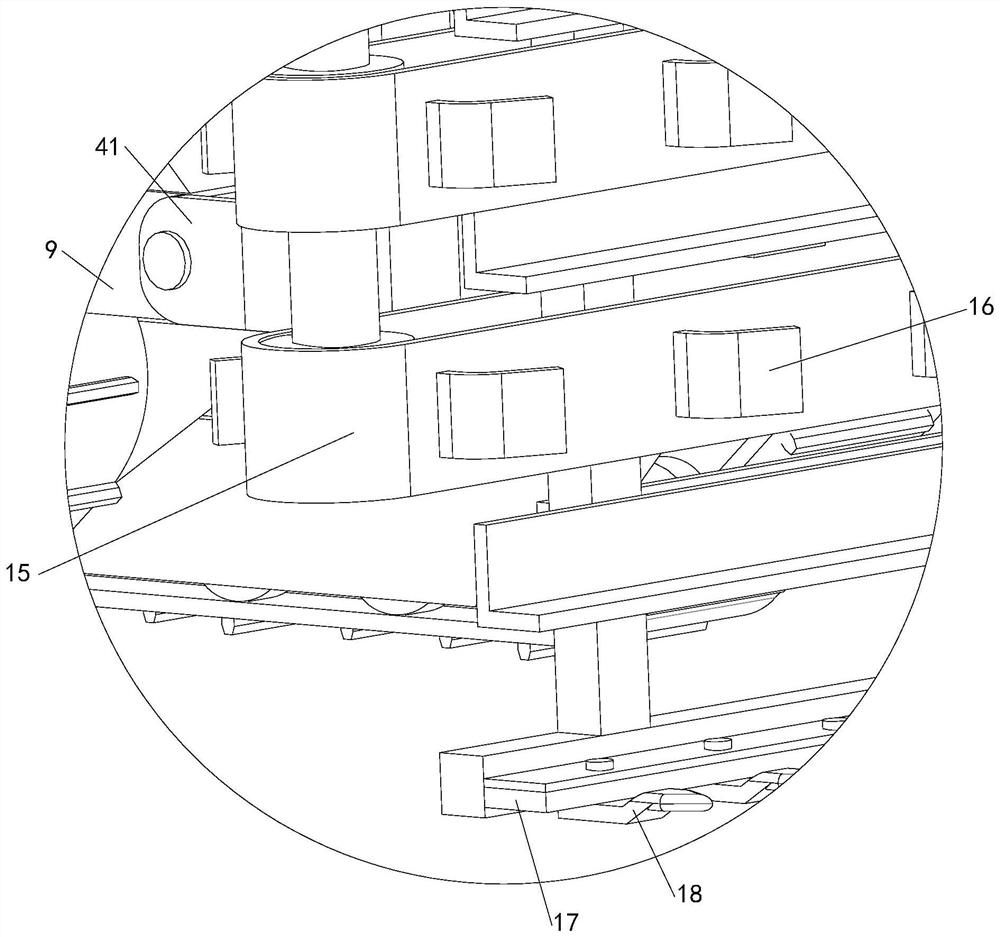

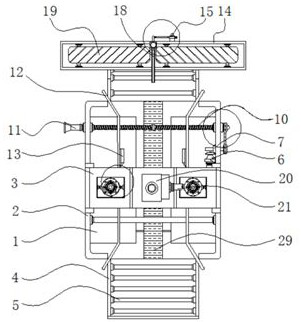

Reed combine harvester

The invention relates to the technical field of reed cutting, airing and bundling, and provides a reed combine harvester which is good in maneuvering performance, good in applicability, good in driving comfort, small in reed breaking phenomenon in the conveying process, small in influence on subsequent reed bundling, high in operation efficiency and good in use coupling performance and comprises a bundling mechanism and a power vehicle body. A crawler belt is installed on the power vehicle body, a plurality of long anti-slip strips and a plurality of short anti-slip strips are arranged on the crawler belt and alternately arranged at intervals, a driving shed is installed on the power vehicle body, an annular observation window is installed on the driving shed, and a driving system is installed in the driving shed. The power vehicle body is fixedly connected with an installation table, a suspension frame and a supporting rod, the bundling mechanism is installed on the installation table, the suspension frame is connected with a lifting frame through a header frame, a main hydraulic cylinder is installed between the header frame and the power vehicle body, and an auxiliary hydraulic cylinder is installed between the lifting frame and the header frame.

Owner:天津泓城农业机械有限公司

Multifunctional trunk

The invention discloses a multifunctional trunk which comprises a trunk box, wherein one side of the inner wall of the trunk box is fixedly connected with a compression bag; an air exhaust hole is formed in the surface of the compression bag; the surface of the air exhaust hole is in threaded connection with a hole cover; a bag mouth is formed in one side of the compression bag; a bag sealer is arranged on the surface of the bag mouth; and a fixing clamp is fixedly connected to one side of the inner wall of the trunk box. The invention relates to the technical field of trunks. The multifunctional trunk disclosed by the invention has a function of compressing clothes, the space occupied by the cloth is greatly reduced, and the clothes are not disordered during traveling. Moreover, the restarticles can be put into storage boxes to be classified, so that the articles can be conveniently arranged and classified, and fragile and easily damaged articles can be prevented from being extruded.Therefore, the space inside the trunk is subjected to maximized utilization, and the trunk can be kept neat and attractive. Moreover, the trunk has solar charging and GPS (Global Position System) positioning functions, is environmentally friendly and saving in energy and has strong safety performance.

Owner:金妙英

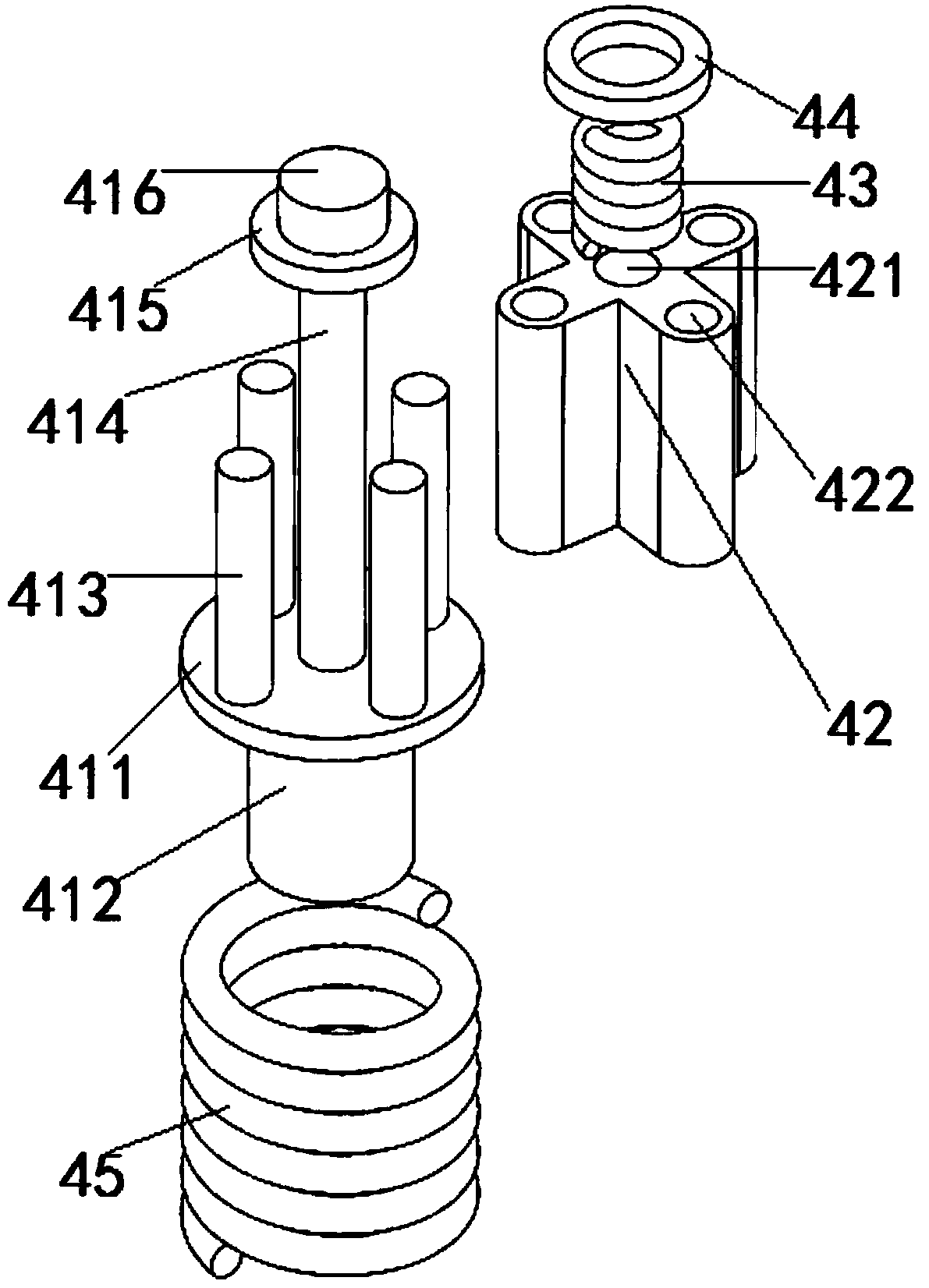

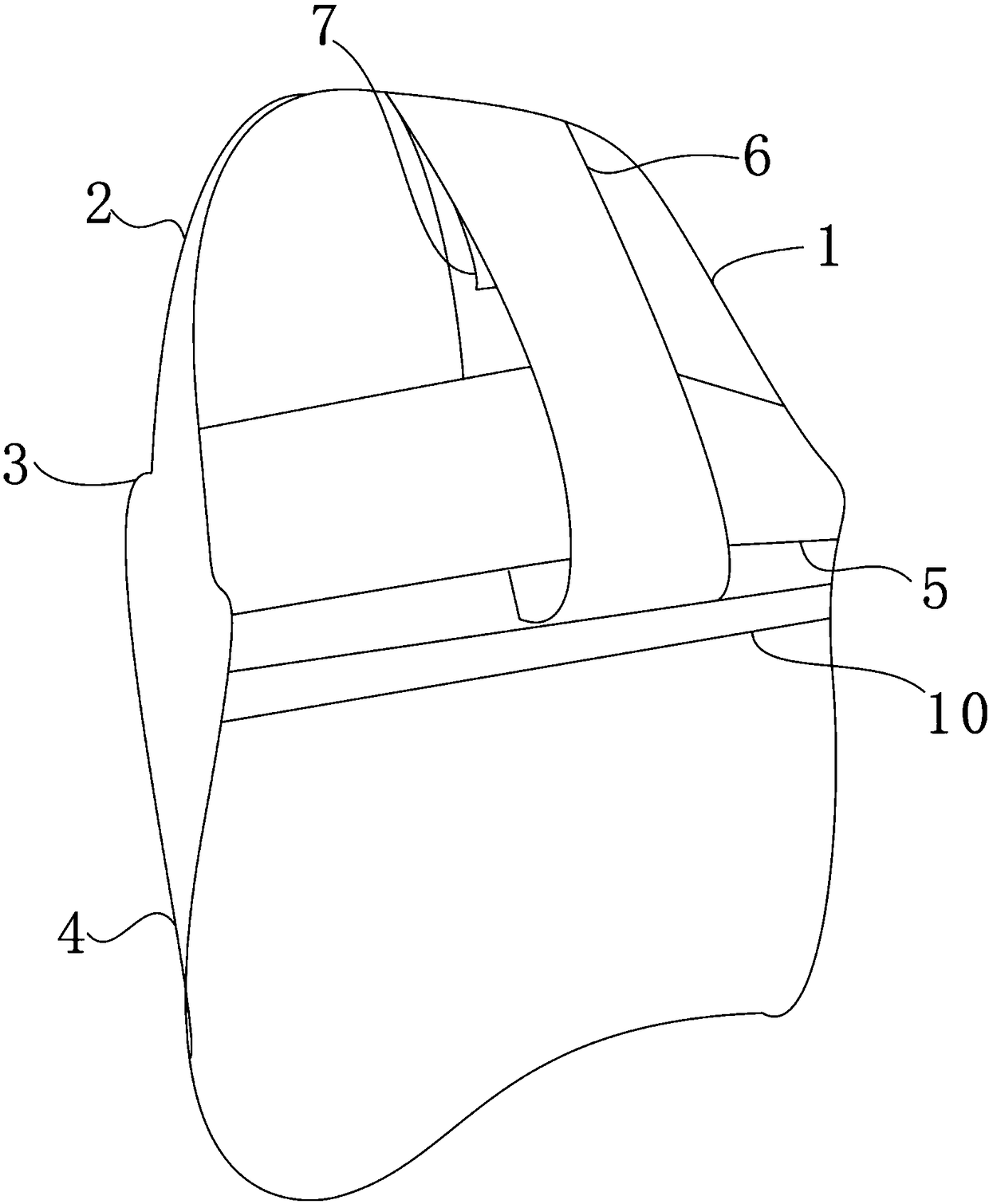

Automobile front seat backrest frame manufacturing method

InactiveCN109278608AConform to the physiological curveImprove comfortBack restsSeat framesEngineeringMechanical engineering

The invention discloses an automobile front seat backrest frame manufacturing method. A backrest frame is included, and a main pipe is arranged at the top end of the backrest frame; a transverse support steel wire is arranged on the upper part of the backrest frame; the two sides of the backrest frame are provided with brackets, a transverse support rod is arranged between the brackets, and the two ends of the transverse support rod are connected to the brackets through tension springs; a waist support plate is arranged on the lower part of the backrest frame, and a backrest bin is arranged inthe middle of the waist support plate; the two sides of the waist support plate are provided with connecting frames, the connecting frames are connected with one ends of S-shaped springs, and the other ends of the S-shaped springs are connected with the brackets; the bottom end of the backrest frame is provided with a rotating shaft, and one end of the rotating shaft is provided with an angle adjusting knob. The automobile front seat backrest frame manufacturing method aims at improving the comfort degree of passengers, and the backrest bin in the waist support plate on the lower part of thebackrest frame can increase the thickness of the backrest waist through filling, which accords with the physiological curve of the human body, and brings better riding experience.

Owner:赵一领

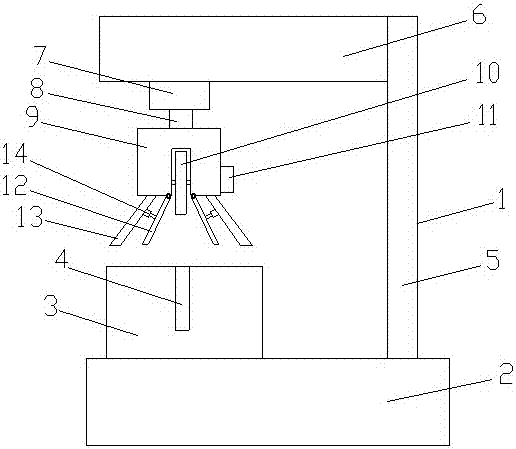

Wood board cutting device with two-stage protection boards for protecting cutting head

InactiveCN107309973AGood support and protectionPlay the role of sticking and anti-scatteringProfiling/shaping machinesWood working safety devicesEngineeringDisc cutter

The invention discloses a wood board cutting device installed with a two-level guard plate to protect a cutting head. A support frame is provided, and a horizontal boom frame is horizontally and horizontally extended from the upper end of the support frame. A pneumatic telescopic device is installed at the bottom of the front end of the horizontal boom frame. The lower end of the telescopic cylinder rod is fixedly connected to a cutting tool box, and the bottom of the cutting tool box is A cutting tool disk is installed on the box body, and the bottom ends of the cutting tool boxes on both sides of the cutting tool disk are installed with a first-level guard plate and a second-level guard plate. Hydraulic protection struts are connected between the guard plates, and an adhesive is also coated on the inner surface of the first-level guard plate. In the above manner, the present invention can perform stable and safe cutting work as a wood board cutting device.

Owner:无锡凯皓科技有限公司

A moisture-proof intelligent part size detection and classification device

ActiveCN109225911BPrevent fallingGood support and protectionSortingTransmission beltStructural engineering

The invention relates to a moisture-proof intelligent parts size detection and classification device, comprising a base, a feeding port and a support column. The upper end of the base is connected with brackets on both sides, and the base and the bracket are welded, and the feeding ports are distributed Rolling rods are arranged in the middle of both ends of the base, and the inner side of the feeding port is provided with rolling rods, the pillars are installed on both sides of the lower end of the base, and the pillars and the base are welded. In the present invention, through the setting of the feeding port and the rolling rod, the rolling rods are evenly distributed on the inner side of the feeding port at equal distances, and the feeding port and the base are distributed at the same level. When the workpiece is put into the feeding port, the user By pushing the workpiece, the workpiece slides from the top of the roller bar to the rear end and falls into the second conveyor belt. At the same time, the distance between the roller bar and the roller bar is guaranteed to be between 3cm and 5cm, preventing some smaller workpieces from directly passing through the gap. fall into the ground.

Owner:常州市工业互联网研究院有限公司 +1

Self-adaptive shoe stretcher

The invention discloses a self-adaptive shoe stretcher. The self-adaptive shoe stretcher comprises a front support, a rear support and a flexible telescoping rod, the front support is made of an elastic plastic sheet, and the rear support is made of a vertical hard supporting plate with a C-shaped cross section; the flexible telescoping rod with one end connected with one side of the plastic sheet and the other end connected with the inner side of the supporting plate is arranged horizontally. The self-adaptive shoe stretcher is capable of automatically adapting to shoes in various sizes and shapes, so that the shoe stretcher is higher in adaptability to better meet demands of people.

Owner:CHONGQING YUEFA COMMODITY

A reusable flat electronic product packaging box and manufacturing method thereof

InactiveCN105346799BWith buffer distanceEasy to splitPackage recyclingPackaging vehiclesLearning machineEngineering

The invention relates to a reusable flat electronic product packaging box and a making method thereof. The packaging box comprises an outer box body and two support pads used for supporting two end parts of the flat electronic product, wherein each support pad is formed by a buffer body and two mortise locks; the buffer body is formed by a center plate and two folded parts; each folded part is formed by a first folded plate, a second folded plate, a third folded plate, a fourth folded plate, a fifth folded plate, a sixth folded plate and a seventh folded plate; one side of the first folded plate is vertically connected with one side of the center plate; the first folded plate, the second folded plate, the third folded plate, the fourth folded plate and the fifth folded plate are vertically folded in sequence; and the folding direction of the second folded plate is opposite to the direction of the center plate, so that the second folded plate and the center plate are respectively located at the upper end face and the lower end face of the first folded plate. According to the invention, the mortise locks are inserted to two ends of the buffer body, thus avoiding the phenomenon of sliding of a product in a clearance between two folded parts. The packaging box is suitable for packaging electronic products such as an English learning machine, material utilization rate is improved, and paper waste rate is reduced.

Owner:LUOYANG INST OF SCI & TECH

Household and automatic covering type heater

InactiveCN107842903AImprove heating effectStable supportHeating fuelLighting and heating apparatusEngineeringHeat distribution

The invention relates to a household and automatic covering type heater. The household and automatic conveying type heater comprises a heater body, a rotating shaft and a heating pipe. The left side of the heater body is provided with a connection block, the left side of the connection block is provided with a first connection rod, the left side of the first connection rod is provided with a storage rotary table, and the storage rotary table is provided with a covering mat. The rotating shaft is arranged on the right wall of the heater body, the right side of the rotating shaft is provided with a second connection rod, and the right side of the second connection rod is fixedly provided with a wire clamping block. The inner wall of the heater body is fixedly provided with first hooks, a transverse rod is arranged below the first hooks, a dust collection plate is arranged below the transverse rod, and the outer side of the dust collection plate is fixedly provided with a sliding block. The household and automatic covering type heater has the beneficial effects that the covering mat is arranged and can cover the legs of a user well during heating, and therefore the dissipation of heatis avoided.

Owner:陈程丽

Bidirectional fixation vehicle memory headrest

InactiveCN109419241AImprove comfortPromote blood circulationPillowsElectrotherapyBlood circulationHuman health

The invention relates to a vehicle memory headrest, and especially relates to a bidirectional fixation vehicle memory headrest. The memory headrest includes a pillow body; the back of the headrest issimultaneously provided with a transverse elastic band and is also provided with a vertical fixing band; a bidirectional fixation mode is adopted to ensure that the headrest does not move, and the comfort level of usage is improved; the pillow body is divided into a headrest part, a neck pillow part and a shoulder guard part, which can provide good support and protection for head, neck and shoulder; and the neck pillow part is provided with filling bulge ribs filled with tourmaline stones, far infrared rays and negative ions generated by the tourmaline stones are utilized to promote blood circulation of the human body, the air quality inside a vehicle is improved, thereby alleviating human body fatigue, and human health is promoted.

Owner:TIANJIN ZHONGJIAN GUOKANG NANO TECH

A cosmetic packaging protection device

ActiveCN108482863BTransportation safetyStable supportContainers to prevent mechanical damageProtection mechanismEngineering

The invention discloses a cosmetic package protection device. The cosmetic package protection device comprises a supporting top plate, a middle transition plate and a bottom mounting plate, wherein the supporting top plate, the middle transition plate and the bottom mounting plate are sequentially mounted from top to bottom in the vertical direction. Two first buffer springs are symmetrically mounted between the supporting top plate and the middle transition plate. Two second buffer springs are symmetrically mounted between the middle transition plate and the bottom mounting plate. Two bufferprotection mechanisms are symmetrically mounted at the left end and the right end of the middle transition plate. Corrugated rubber plates are vertically mounted on the front side and the back side ofthe bottom of the middle transition plate in the linear direction. According to the cosmetic package protection device, through the structural design of the supporting top plate, the middle transition plate, the bottom mounting plate and the two buffer protection mechanisms, good supporting and protection effects can be achieved in the cosmetic package transportation process; multi-buffering canbe achieved, the cosmetic package protection device can also be well protected, and it is ensured that cosmetics are safely transported for a long distance under a complex road condition; and the cosmetic package protection device has high application and popularization value.

Owner:浙江大洪包装科技股份有限公司

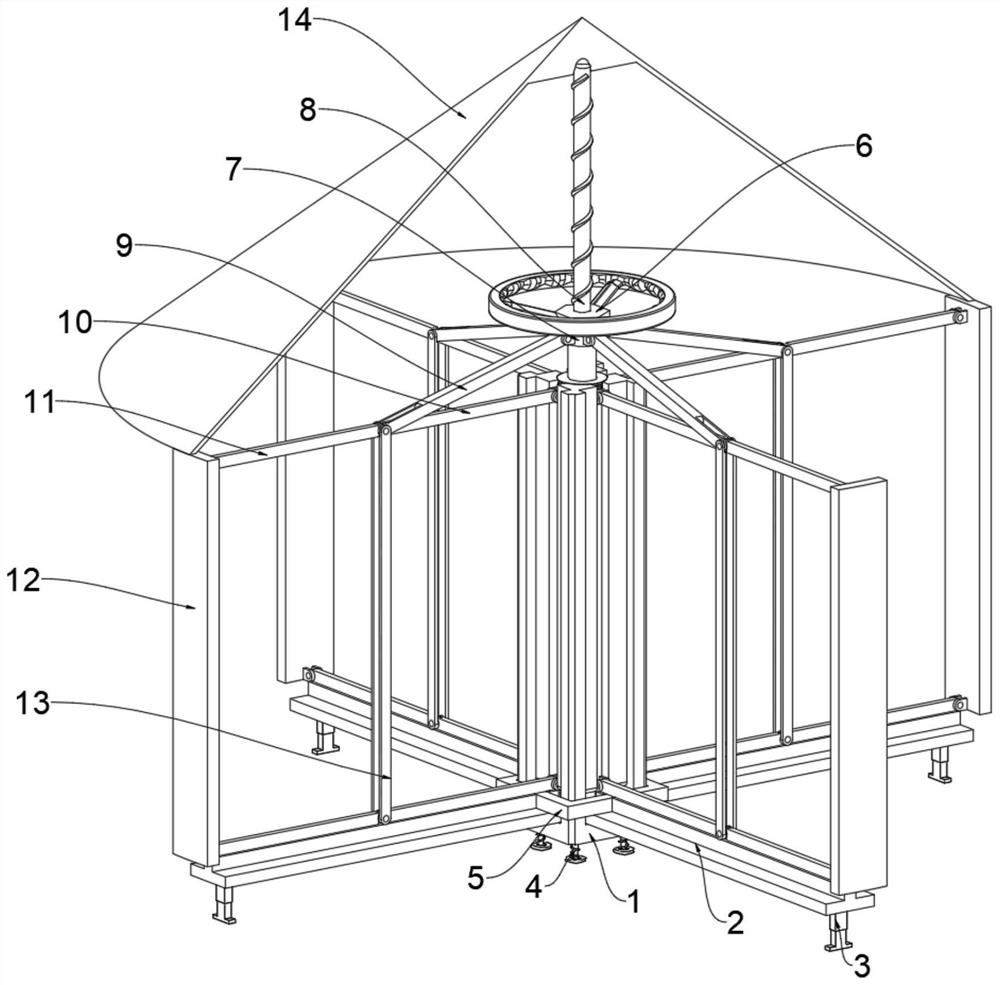

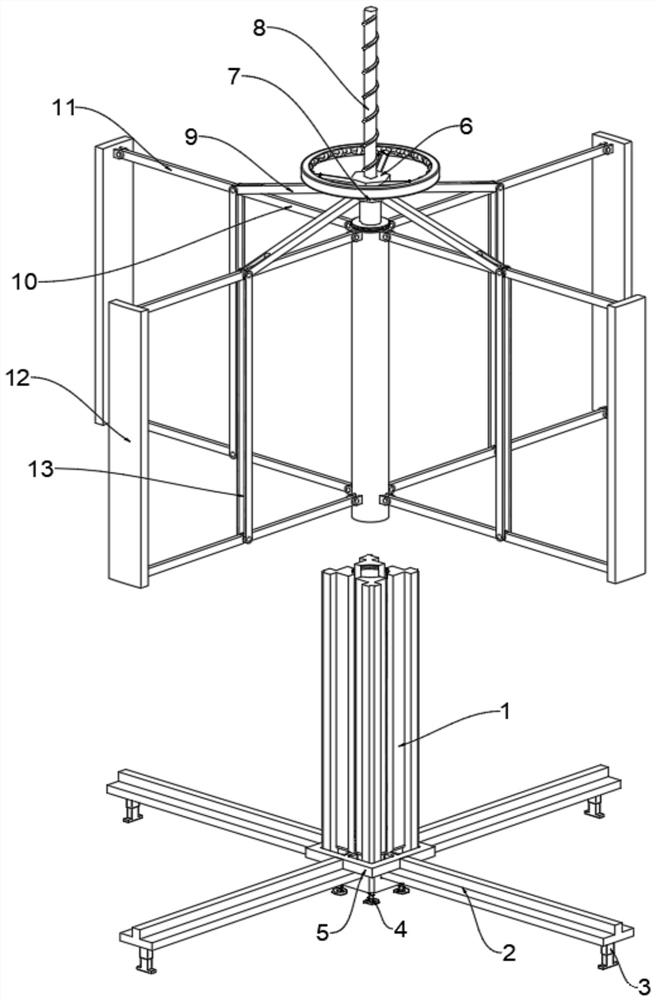

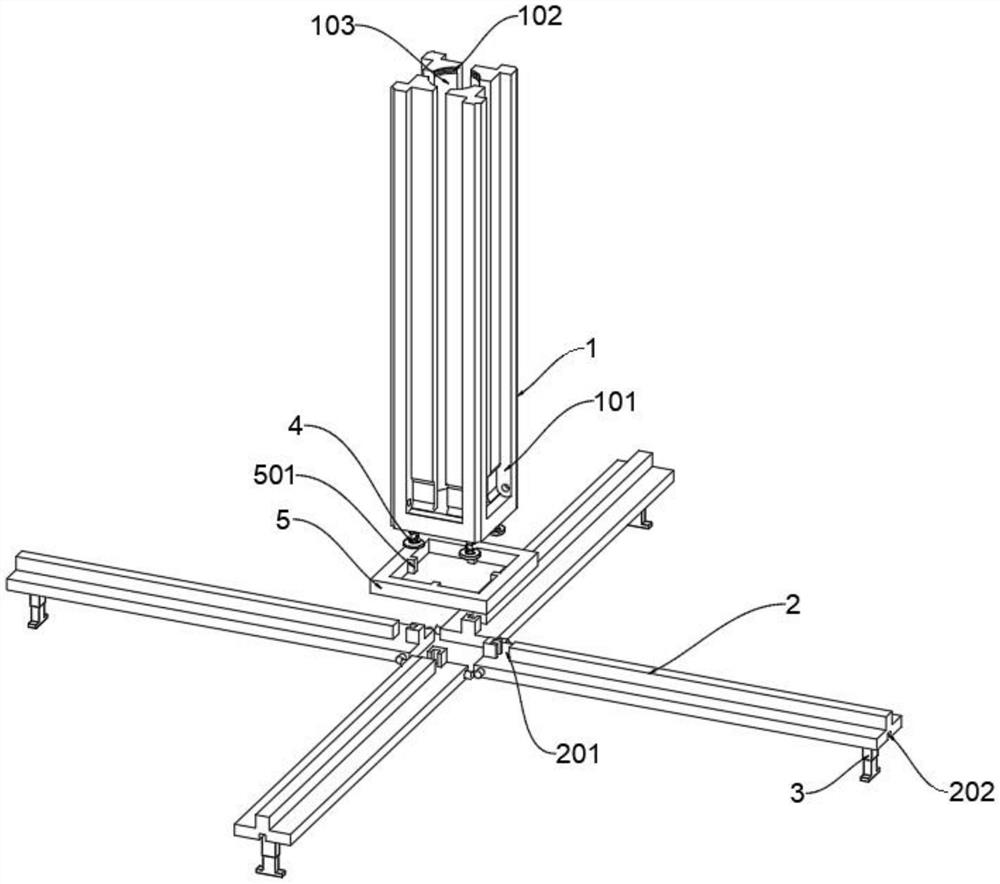

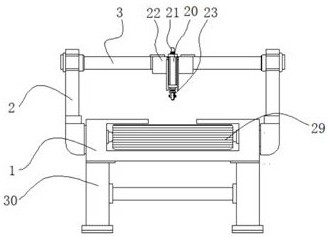

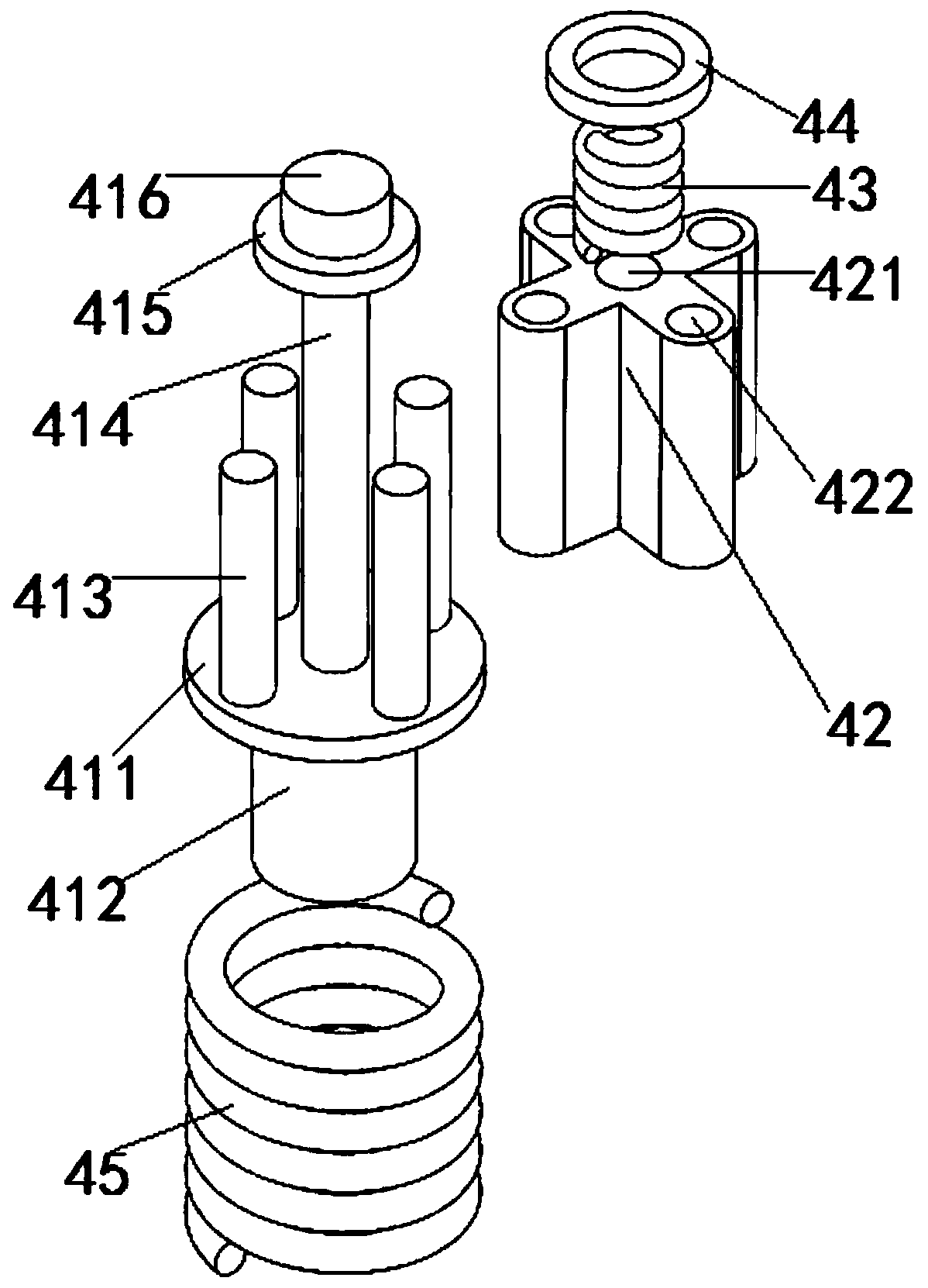

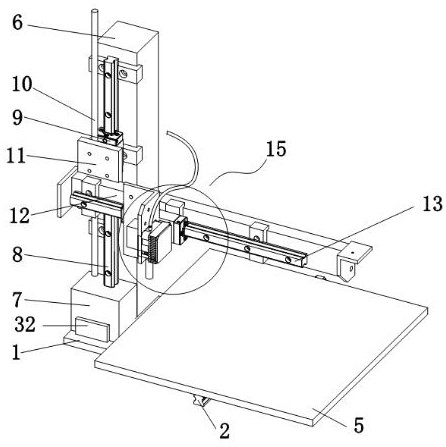

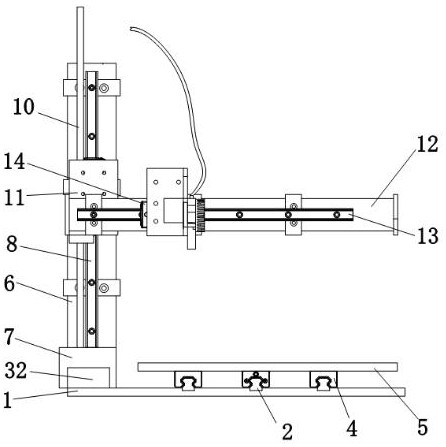

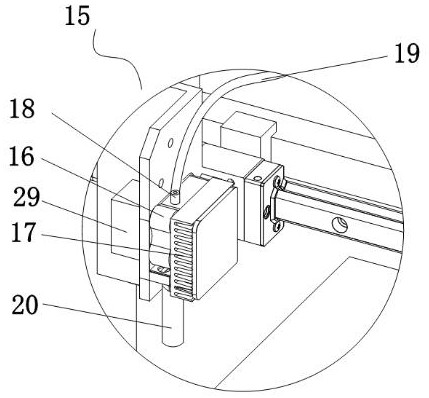

a 3d printer

ActiveCN112959659BHigh transmission accuracyImprove bearing capacityManufacturing heating elements3D object support structuresComputer printingSolenoid valve

Owner:SHENZHEN ATOMSTACK TECH CO LTD

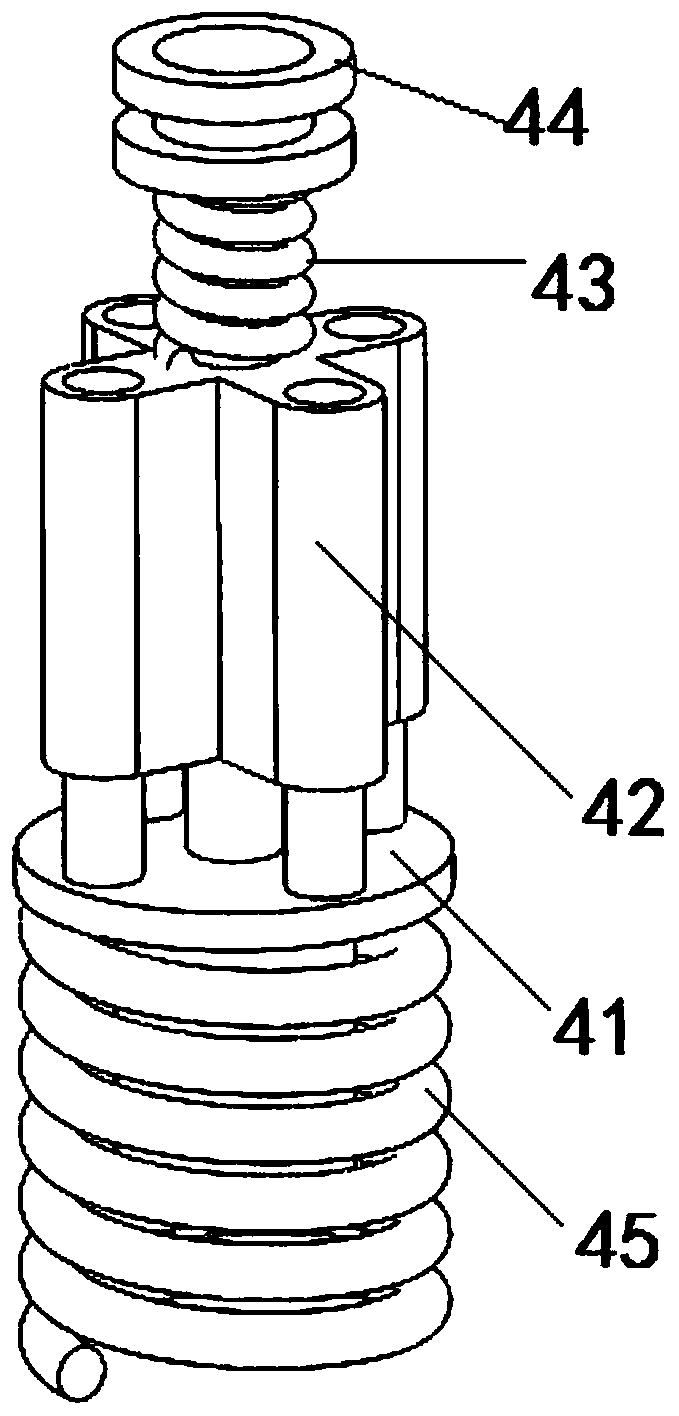

High-pressure standing submersible motor winding wire assembly

InactiveCN107294246APrevent outflowImprove conductivitySupports/enclosures/casingsWindings conductor shape/form/constructionHigh pressureElectrical conductor

The invention relates to a high-pressure standing submersible motor winding wire assembly, comprising a winding group. The winding group comprises a sealed heat-standing soft tube sleeve pre-fabricated and wound in the motor and a soft metal conductor packaged in the sealed heat-standing soft tube sleeve. As a further improvement in the above technical scheme, an insulation layer is sleeved on the sealed heat-standing soft tube sleeve, and a protection sleeve layer is sleeved on the insulation layer. The two ends of the sealed heat-standing soft tube sleeve are provided with conductive joints in connection with the soft metal conductor. According to the invention, the assembly is reasonably designed with a compact structure and can be used conveniently.

Owner:HEBEI GUOQIAN WIRES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com