High-pressure standing submersible motor winding wire assembly

A technology of submersible motor and winding wire, which is applied to electric components, shape/style/structure of winding conductors, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

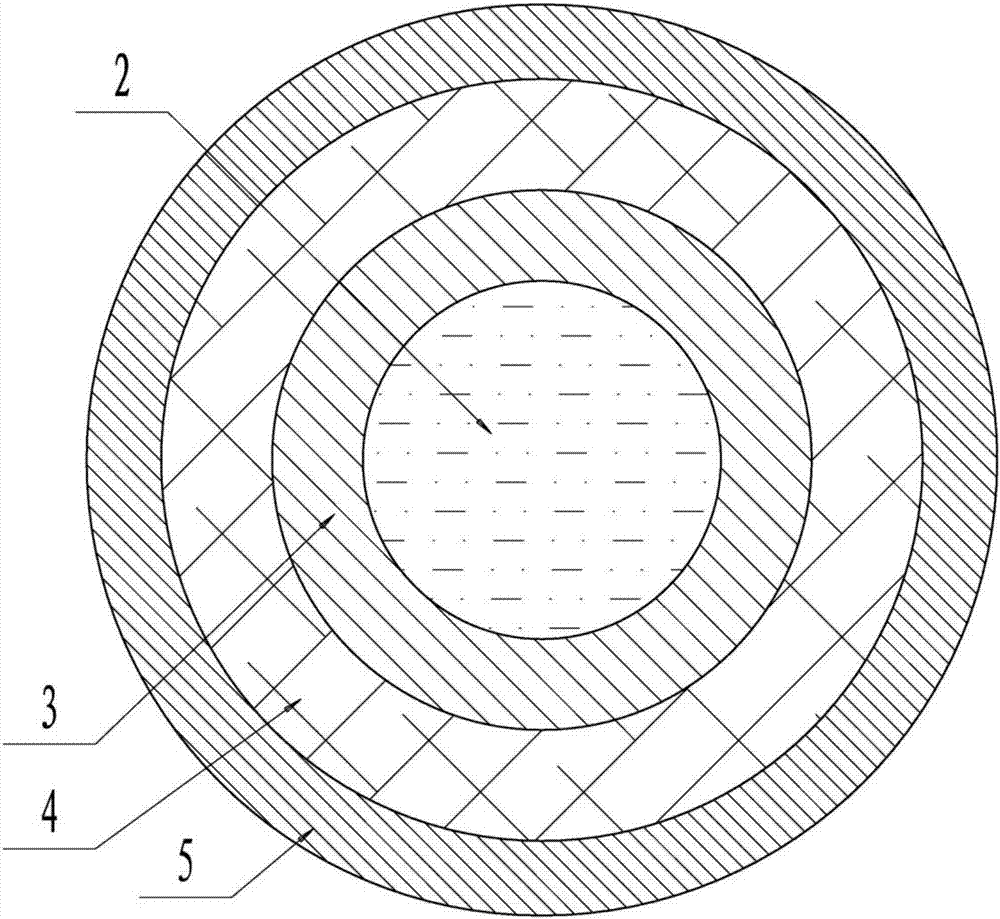

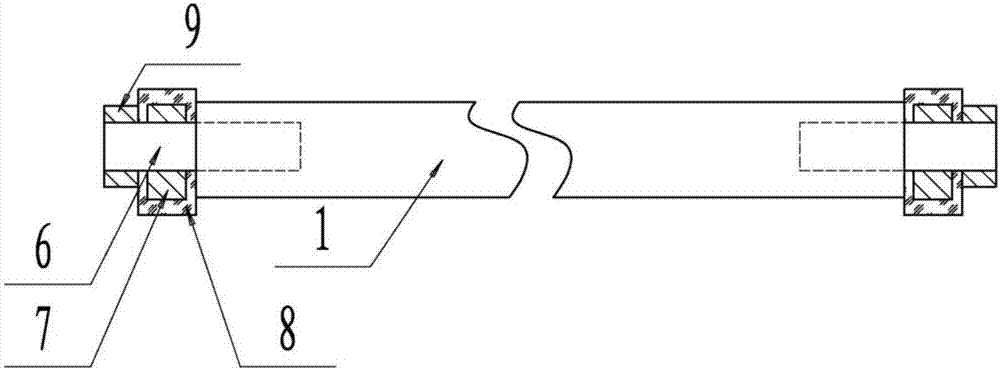

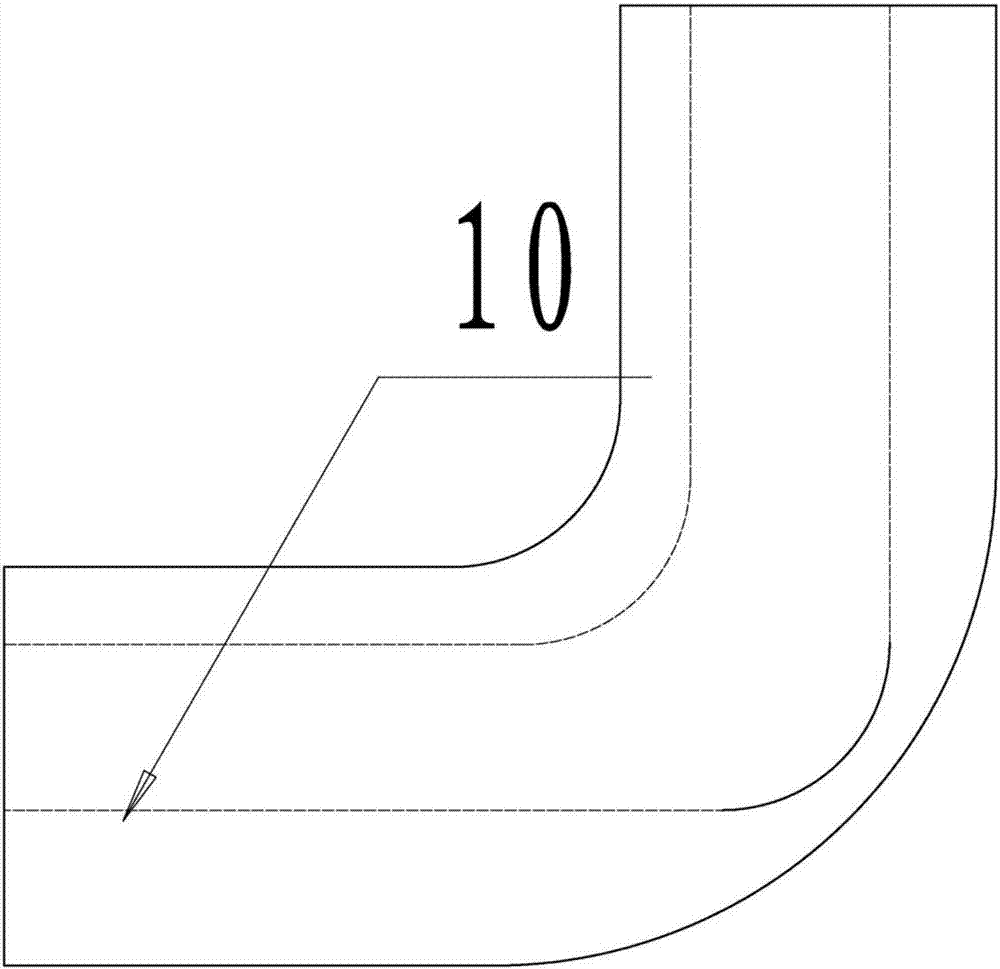

[0025] Such as Figure 1-3 As shown, the high-voltage submersible motor winding wire assembly of this embodiment includes a winding group 1; the winding group 1 includes a sealed heat-resistant hose sleeve 3 with a prefabricated length and wound in the motor; the sealed heat-resistant hose sleeve 3 is half Transparent platinum vulcanized silicone hose and other soft hoses. The high voltage is 10KV-100KV, or above 100kV.

[0026] A flexible metal conductor 2 is packaged in the sealed heat-resistant hose sleeve 3 .

[0027] According to the model of different motors, calculate the length of the heat-resistant hose sleeve 3 that needs to be wound, and after winding the heat-resistant hose sleeve 3, slowly inject the flexible metal conductor 2 from the lower port. The port is vacuumed.

[0028] In order to better prevent breakdown or damage to the conductor, an insulating layer 4 is set on the sealed heat-resistant hose sleeve 3 , and a sheath layer 5 is set on the insulating l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com