Solar cell back plane and preparation method thereof

A technology for solar cells and backplanes, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve problems such as difficulty in reaching the service life, and achieve the effects of low cost, stable backplane structure, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

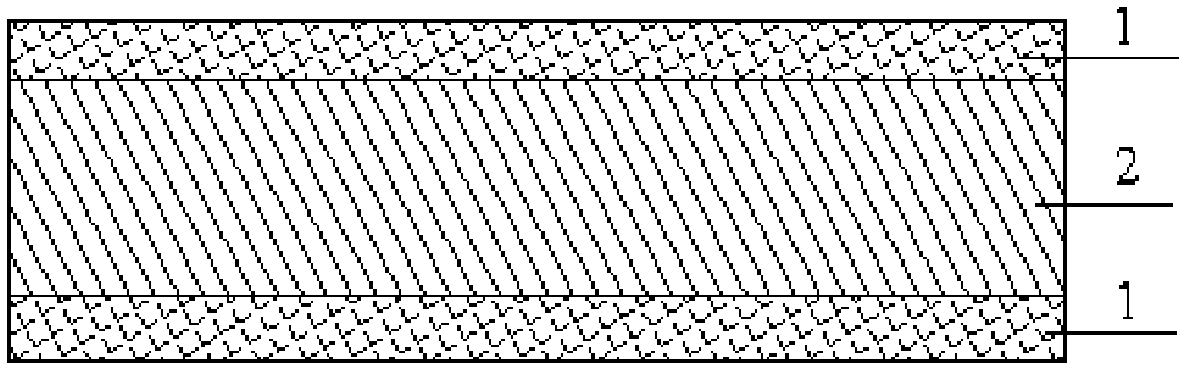

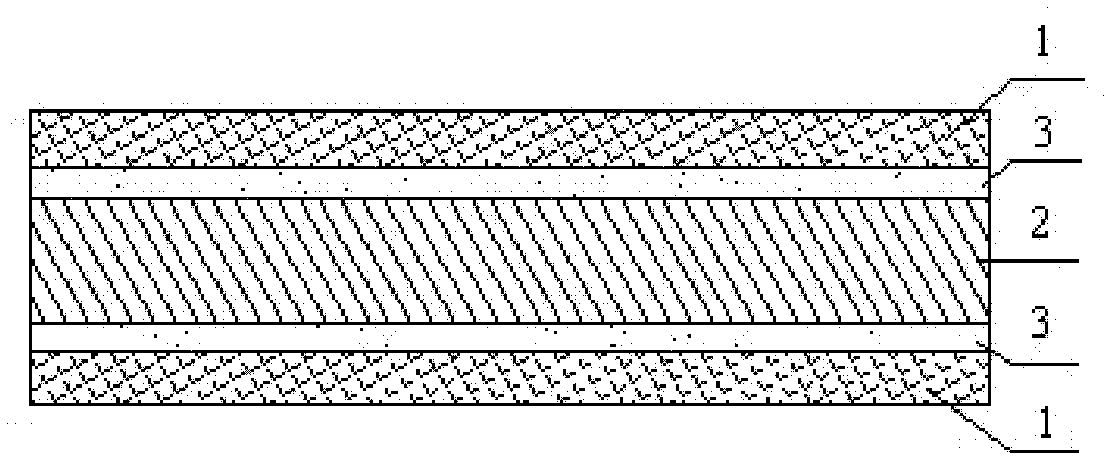

[0037] The preparation method of the solar battery back plate provided by the invention comprises the following steps:

[0038] (1) Using the extrusion casting method, a biaxially oriented polyester film is produced on a biaxially stretching machine. The temperatures of each section of the extruder are 180°C, 220°C, 275°C, 275°C, 275°C, and 280°C, respectively. The cooling drum speed is controlled at 30r / min, the cooling drum temperature is 60°C, and the temperature difference range is 1°C; the longitudinal stretching temperature is controlled between 90°C-120°C, the stretching ratio is controlled at 3.8-4.0, and the transverse stretching temperature is 120°C-140°C, the stretch ratio is controlled at 3.8-4.0, and the temperature error range is 0.5°C.

[0039] (2) The biaxially stretched polyester film obtained in step (1) is rolled and placed on the coating line for off-line coating. After the adhesive is coated on the upper and lower surfaces of the polyester film, the Heat ...

Embodiment 1

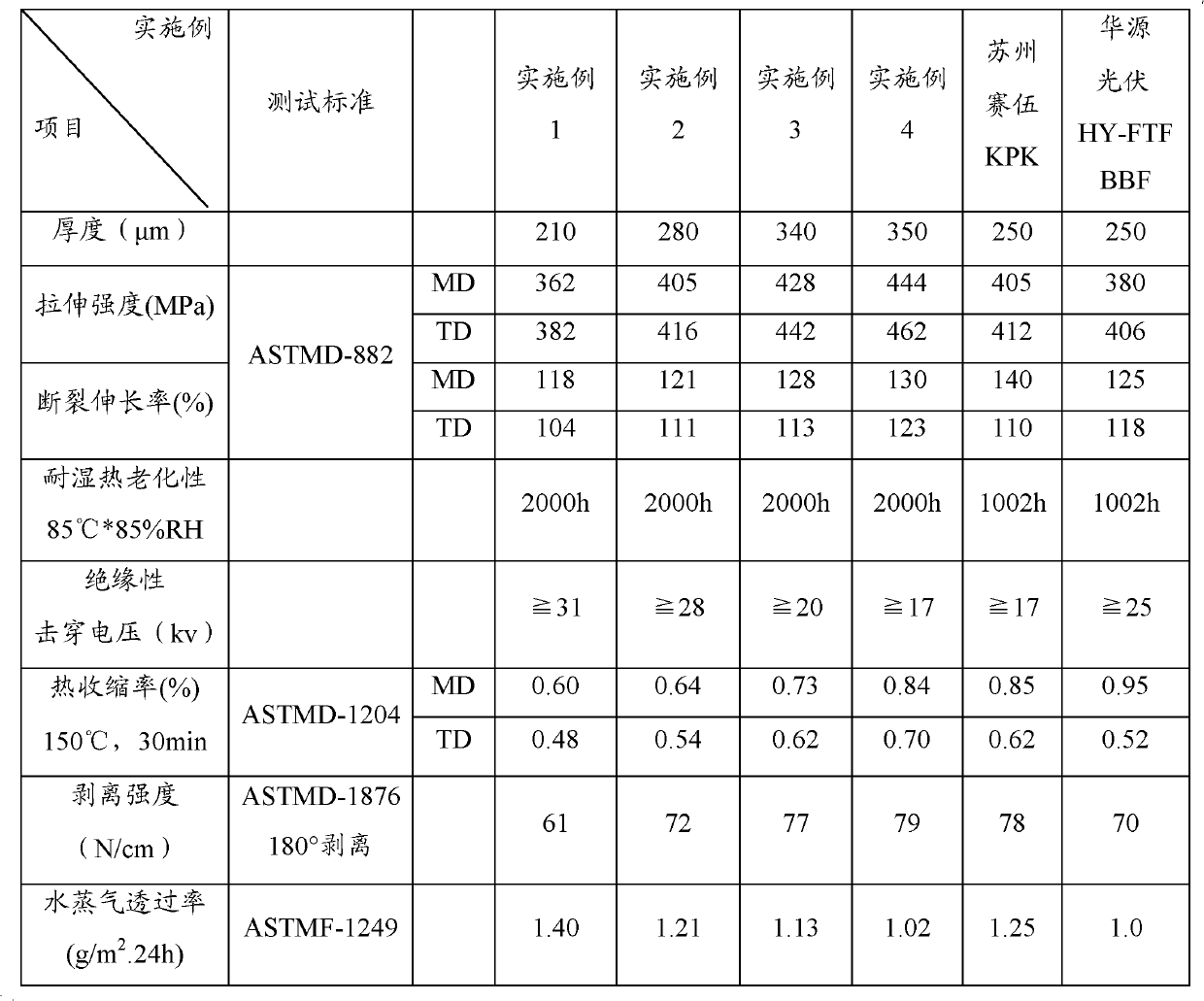

[0050] The solar backsheet was prepared according to the above method, wherein the thickness of the weather-resistant layer was 25 μm, the thickness of the structural reinforcement layer was 150 μm, and the thickness of the adhesive layer was 5 μm. The relevant properties of the obtained backsheet are shown in Table 1.

Embodiment 2

[0052] The solar backsheet was prepared according to the above method, wherein the thickness of the weather-resistant layer was 30 μm, the thickness of the structural reinforcement layer was 200 μm, and the thickness of the adhesive layer was 10 μm. The relevant properties of the obtained backsheet are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com