High-strength magnesium steel heat-insulating material, preparation method thereof and heat-insulating block made of high-strength magnesium steel heat-insulating material

A heat-insulating material and high-strength technology, applied in the direction of protecting pipelines, heat exchange equipment, and heat preservation through heat insulation, can solve the problems of reducing the economic benefits of enterprises, increasing the heat loss of the conveying pipe network, and increasing the production cost, and achieve good results. Support protection, low thermal conductivity, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

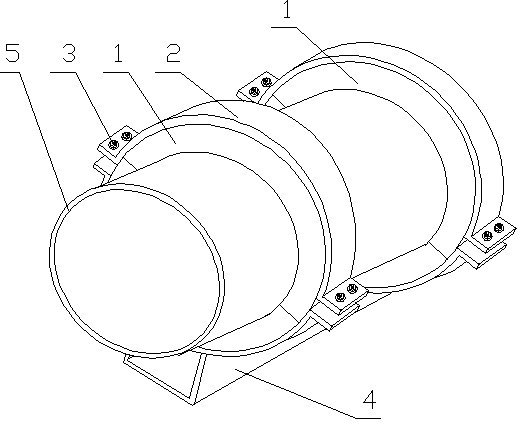

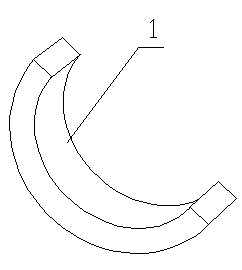

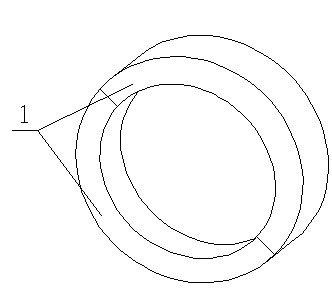

Image

Examples

Embodiment 1

[0023] The formula of this embodiment is: magnesia 1.5kg, magnesium chloride 1kg, ferrous sulfate 3g, trisodium phosphate 3g, oxalic acid 3g, glass fiber 1.075kg, wherein magnesia should meet the regulation of standard JC / T 449, magnesium chloride should meet the standard According to the provisions of QB / T 2605, the glass fiber should meet the provisions of the standard WB / T 1036.

[0024] The production method of this embodiment: first mix and stir water with ferrous sulfate, trisodium phosphate, and oxalic acid, so that ferrous sulfate, trisodium phosphate, and oxalic acid are all dissolved in water; then add magnesium chloride for stirring, and then add magnesium oxide for Stir into a paste to form a magnesium steel coating; finally mix the magnesium steel coating with glass fiber, pour the mixed paste into a mold, and naturally solidify and form.

[0025] The above steps have different requirements for the temperature of the mixture when stirring at different temperatures...

example 1

[0049] Example 1: The length is 500mm, the inner diameter is 200mm, the thickness is 60mm, and the service temperature is 300°C, No. 300 hydrophobic tube and shell product.

[0050] Marked as: High Strength Magnesium Steel Thermal Insulation Material 300GZ 500×Φ200×60 Q / HYS 005.

example 2

[0051] Example 2: No. 400 non-hydrophobic curved plate product with a length of 400mm, an inner diameter of 500mm, and a thickness of 70mm.

[0052] Marked as: High Strength Magnesium Steel Thermal Insulation Material 400H 400×Φ600×70 Q / HYS 005.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com