Reed combine harvester

A combine harvester and reed technology, which is applied to harvesters, individual balers, agricultural machinery and implements, etc., can solve the problems of affecting reed baling, poor maneuverability, and low operating efficiency, and achieve good ground grip and Broaden the installation range and achieve good harvesting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

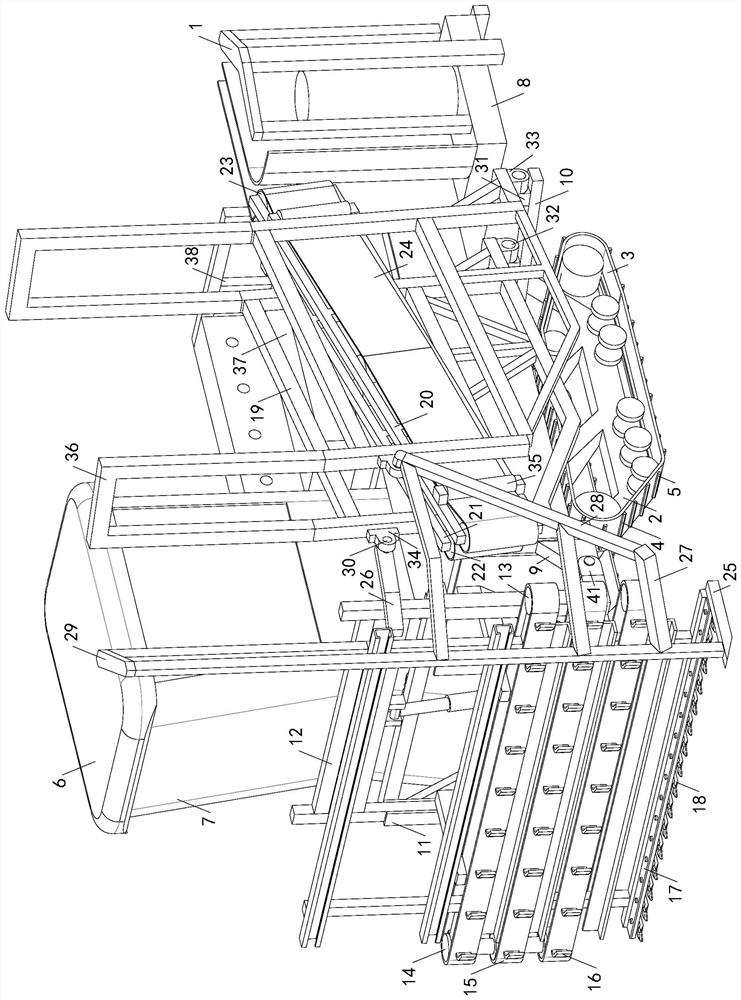

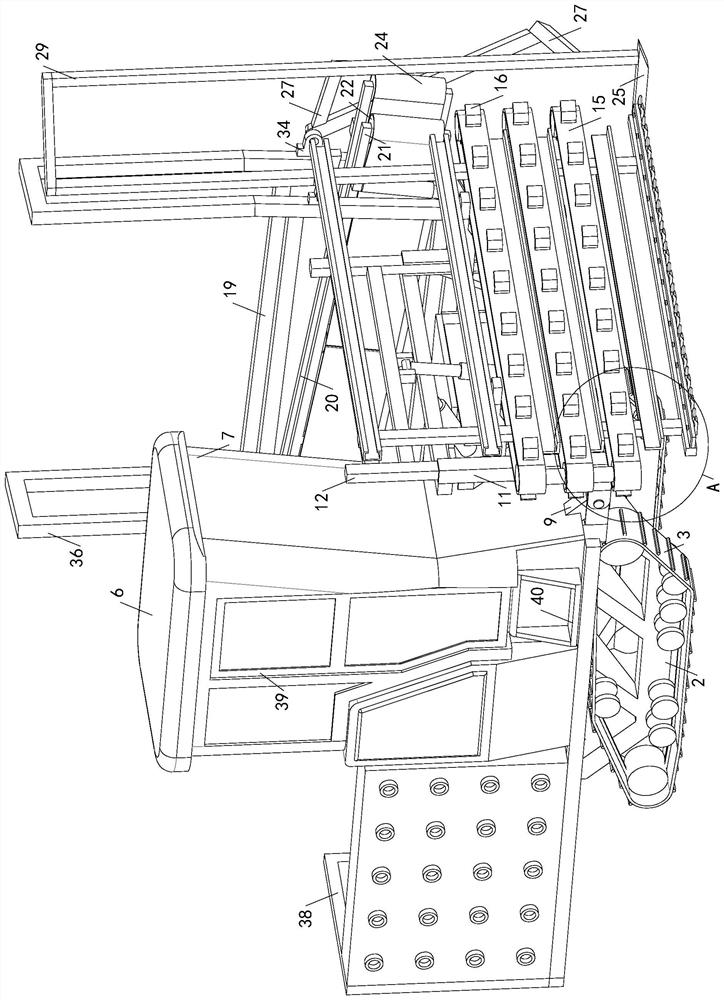

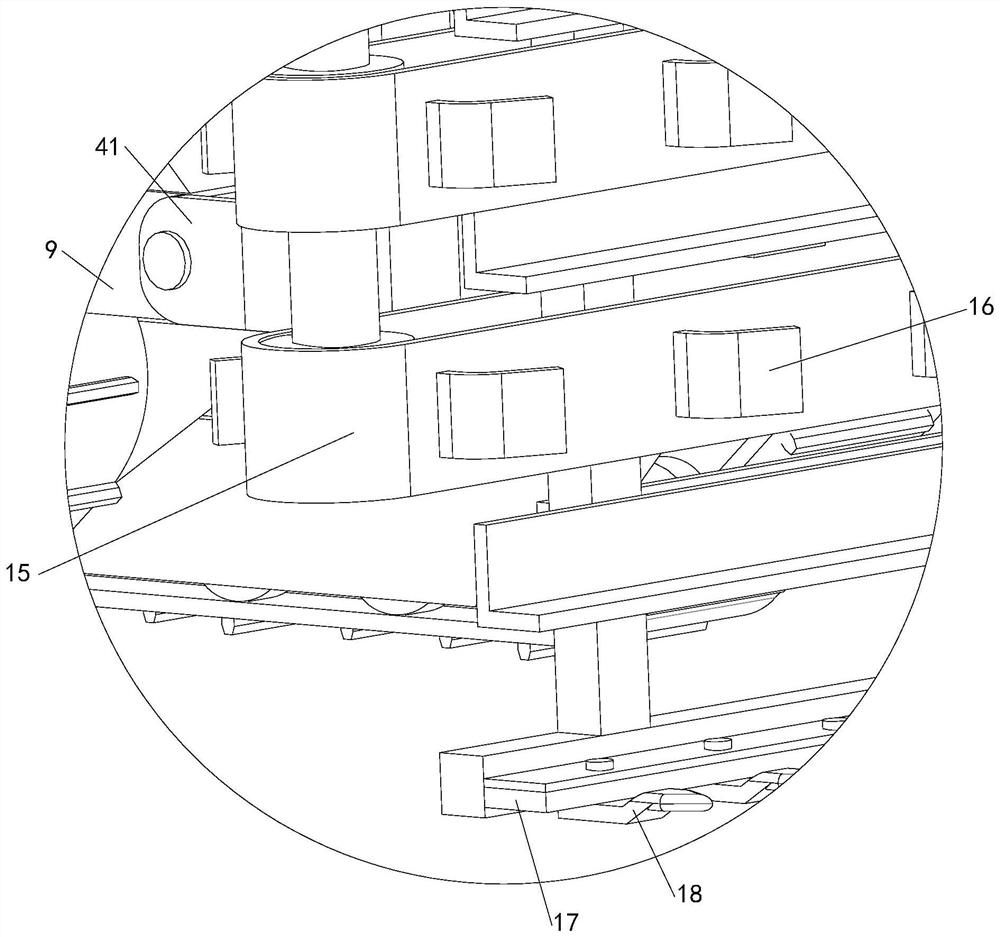

[0030] See Figure 1-5 A reed combined harvester, including the strapping mechanism 1, further comprising a power vehicle body 2, a power vehicle body 2 is attached to a track 3, and a plurality of long anti-slide strips 4 and a plurality of short anti-slide strips 5, more A long anti-slip strip 4 and a plurality of short anti-slide strips 5 are alternately arranged, and the coordination of the long anti-slide 4 and the short anti-slide strip 5 makes the track 3 and the ground grip effect, so that the power vehicle body 2 is improved. The motor performance of the walking portion is mounted on the power vehicle body 2. The driver's shed 6 is mounted on the driver's shed 6. The driving system is installed in the driver shed 6. The power vehicle body 2 is mounted for driving 6 control temperature. Temperature conditioning air conditioner 37 and sheet metal shield 38 for warming air conditioning 37, through the mounting of the power vehicle body 2 and the driver 6, facilitating the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com