Fault-passing roadway waterproof damping and shock-resisting coupling support method

A technology of coupling support and roadway, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of equipment and personnel safety threats, reduce impact loads, and weak control forces of the two sides and the floor, so as to avoid casualties and Property loss, good support and protection, and the effect of improving material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is a detailed description of a water-proof, shock-absorbing, anti-scour coupling support method for a roadway crossing a fault in conjunction with the accompanying drawings and specific examples:

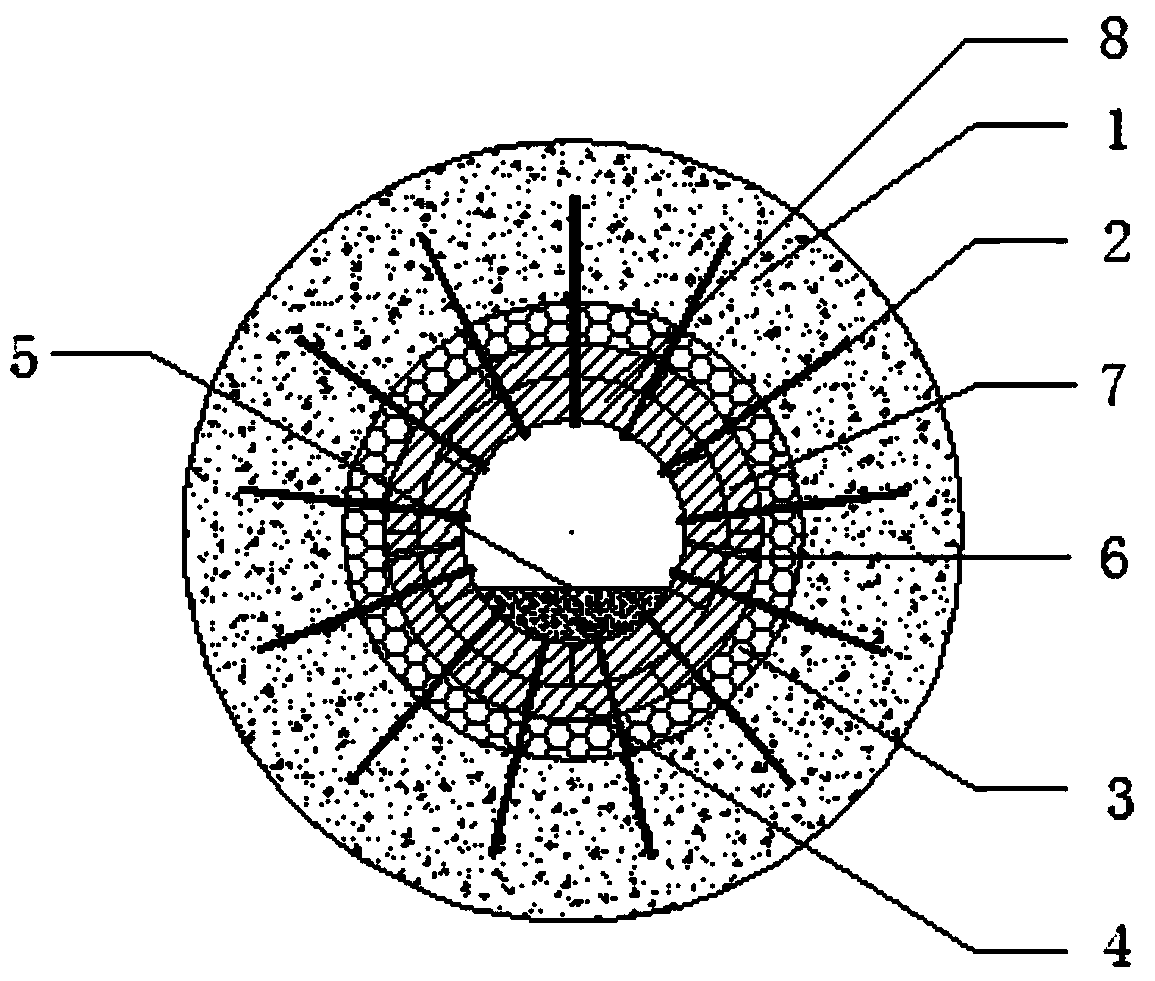

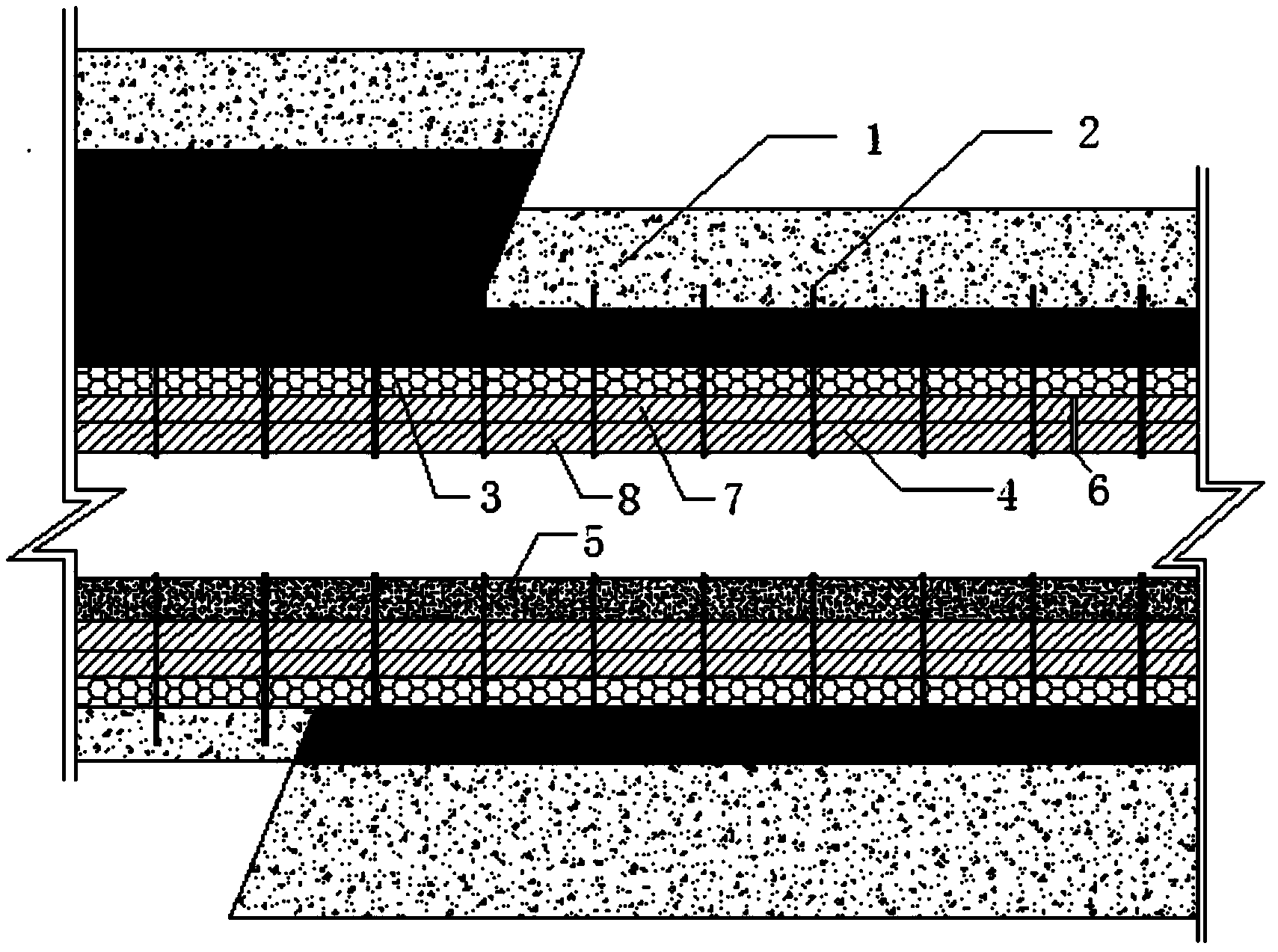

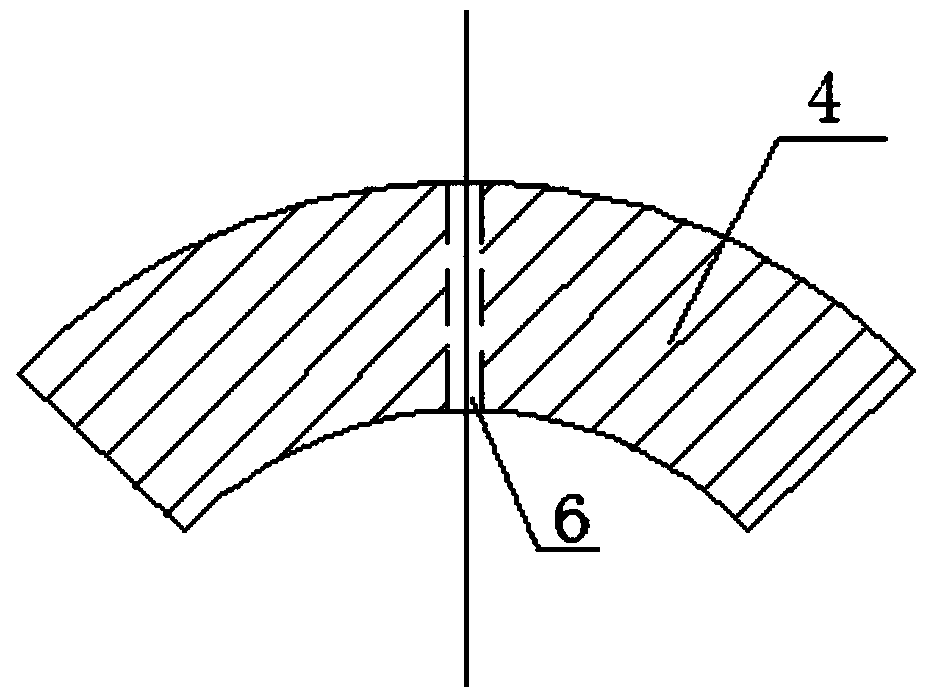

[0023] Such as figure 1 and figure 2 As shown, the support formed by a water-proof, shock-absorbing, and anti-scour coupling support method for a roadway crossing a fault according to the present invention is set up successively from the surrounding rock of the fault to the roadway. Sheet 4, the surrounding rock is artificially blasted to form a surrounding rock plastic ring 1, and the inner surface of the surrounding rock plastic ring 1 is laid with cement-based glass fiber to form a shock-absorbing support ring 3; the shock-absorbing support ring 3. Tiles 4 are laid on the inner surface. The tiles 4 are divided into two layers. The outer layer is the outer layer waterproof tile 7, and the inner layer is the inner layer tile 8; Tile 4, damping support ring 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com