A radiation cooling coating with long afterglow luminescence performance and its preparation method

A long afterglow luminescence and radiation cooling technology, applied in luminescent paints, coatings, climate sustainability, etc., can solve the problems of single color, reduce the energy of radiation cooling layer, and change the luminous color, so as to improve the cooling efficiency and improve Luminous efficiency and the effect of improving radiation cooling power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

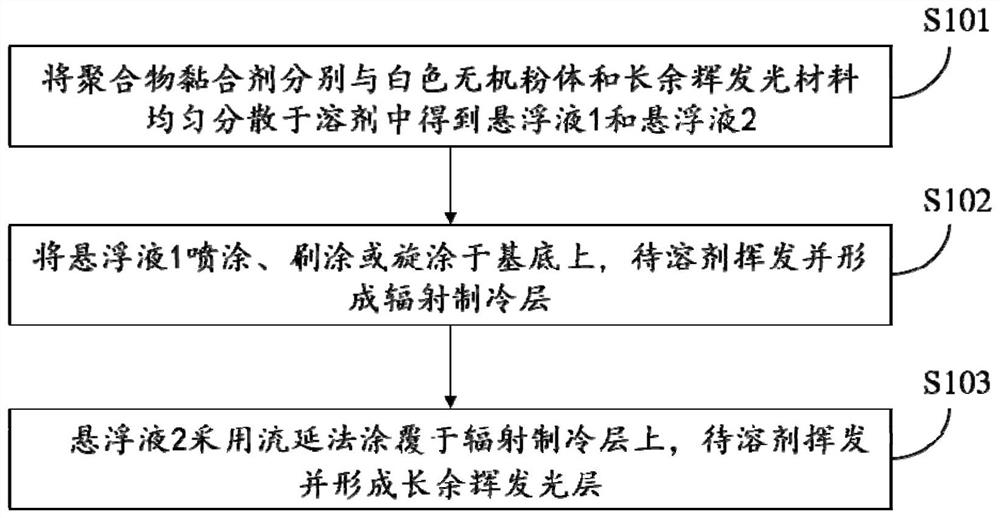

[0042] see figure 2 , figure 2 It is a flow chart of a preparation method of a radiation refrigeration coating with long afterglow luminescence provided by the present invention, such as figure 2 As shown, the preparation method includes:

[0043] S101: uniformly dispersing the polymer binder, the white inorganic powder and the long afterglow luminescent material in a solvent to obtain suspension 1 and suspension 2;

[0044] S102: spraying, brushing or spin-coating the suspension 1 on the substrate, and waiting for the solvent to volatilize and form a radiation refrigeration layer;

[0045] S103: Coat the suspension 2 on the radiation refrigeration layer by a casting method, and wait for the solvent to volatilize to form a long afterglow luminescent layer.

[0046] In some embodiments, the method for uniform dispersion is treatment in a homogenizer for 30 minutes. The solvent is one or both of water, ethanol, toluene and acetone. The solvent volume fraction in the susp...

Embodiment 1

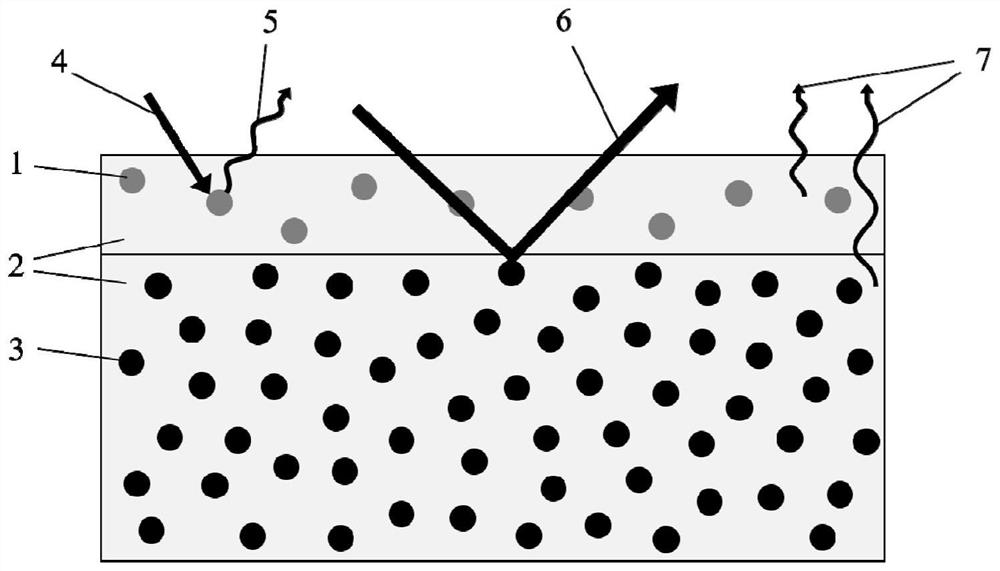

[0050] The long afterglow light-emitting layer in the coating described in this embodiment includes (SrAl 2 O 4 :Eu 2+ ,Dy 3+ ) and PMMA, the radiative cooling layer includes BaSO 4 and PVB. Among them, (SrAl 2 O 4 :Eu 2+ ,Dy 3+ ) with an average particle size of 0.1 μm, BaSO 4 The average particle size is 0.5 μm, tested with BaSO alone 4 The reflectance of the powder in the visible light band is 0.97. The thickness of the radiation cooling layer is about 500 μm, and the thickness of the long afterglow light-emitting layer is about 1 μm.

[0051] The coating preparation process is as follows: According to BaSO 4 : The mass ratio of PVB was 15:1, and it was mixed into the solvent, and then treated with a homogenizer for 30 min to obtain a uniform suspension 1. The volume fraction of the solvent in the suspension is 80%; the solvent is ethanol. The suspension 1 was sprayed on a glass plate with a spray gun, and was left to dry naturally at room temperature for 3 hou...

Embodiment 2

[0055] The long afterglow light-emitting layer in the coating described in this embodiment includes (Sr 2 MgSi 2 O 7 :Eu 2+ ,Dy 3+ ) and PMMA, the radiative cooling layer includes TiO 2 and TPX. Among them, (Sr 2 MgSi 2 O 7 :Eu 2+ ,Dy 3+ ) with an average particle size of 0.1 μm, TiO 2 The average particle size is 0.5 μm. The thickness of the radiation cooling layer is about 500 μm, and the thickness of the long afterglow light-emitting layer is about 2 μm.

[0056] The coating preparation process is as follows: According to TiO 2 : The mass ratio of TPX was 10:1, and it was mixed into the solvent, and then treated with a homogenizer for 30 min to obtain a uniform suspension 1. The volume fraction of the solvent in the suspension is 80%; the solvent is 50% water and 50% ethanol. The suspension 1 was sprayed on a glass plate with a spray gun, and was left to dry naturally at room temperature for 3 hours to form a radiation refrigeration layer with a thickness of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com