Target material sputter coating device and use method thereof

A technology of sputtering coating and target materials, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc. It can solve the problems of affecting the processing quality of sputtering coating, falling off and breaking, etc., so as to improve the cleanliness and improve the The effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

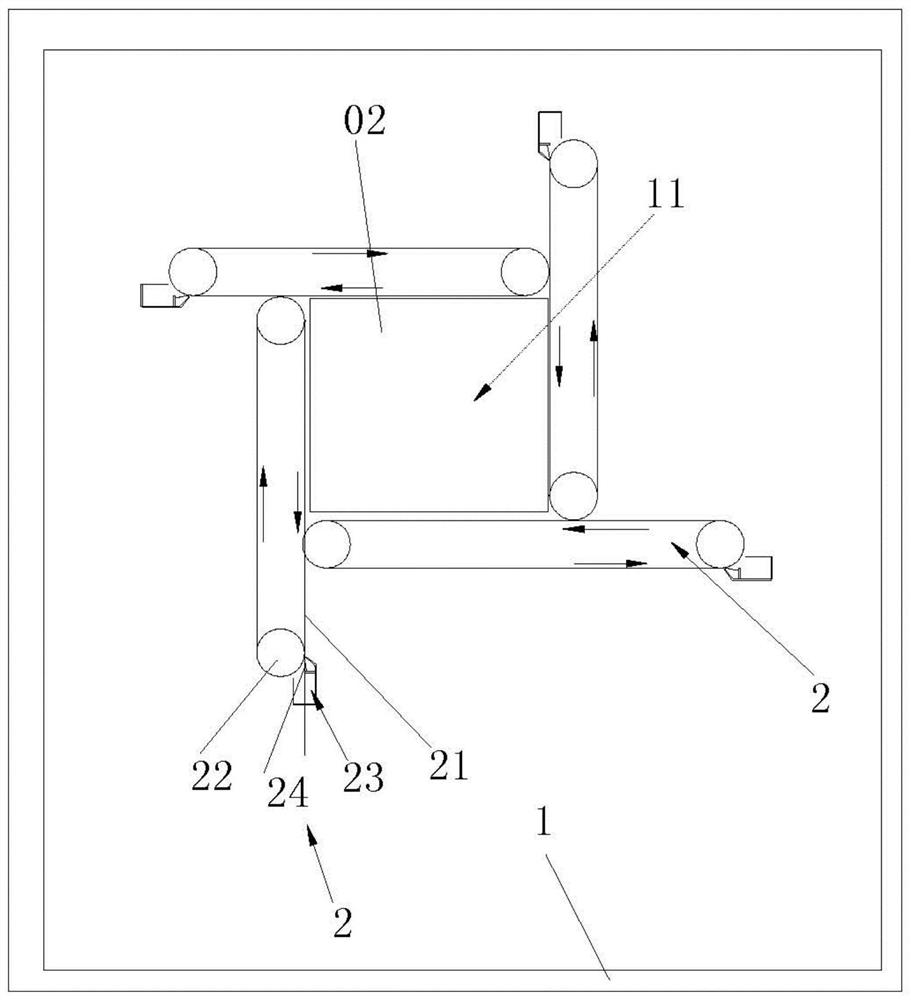

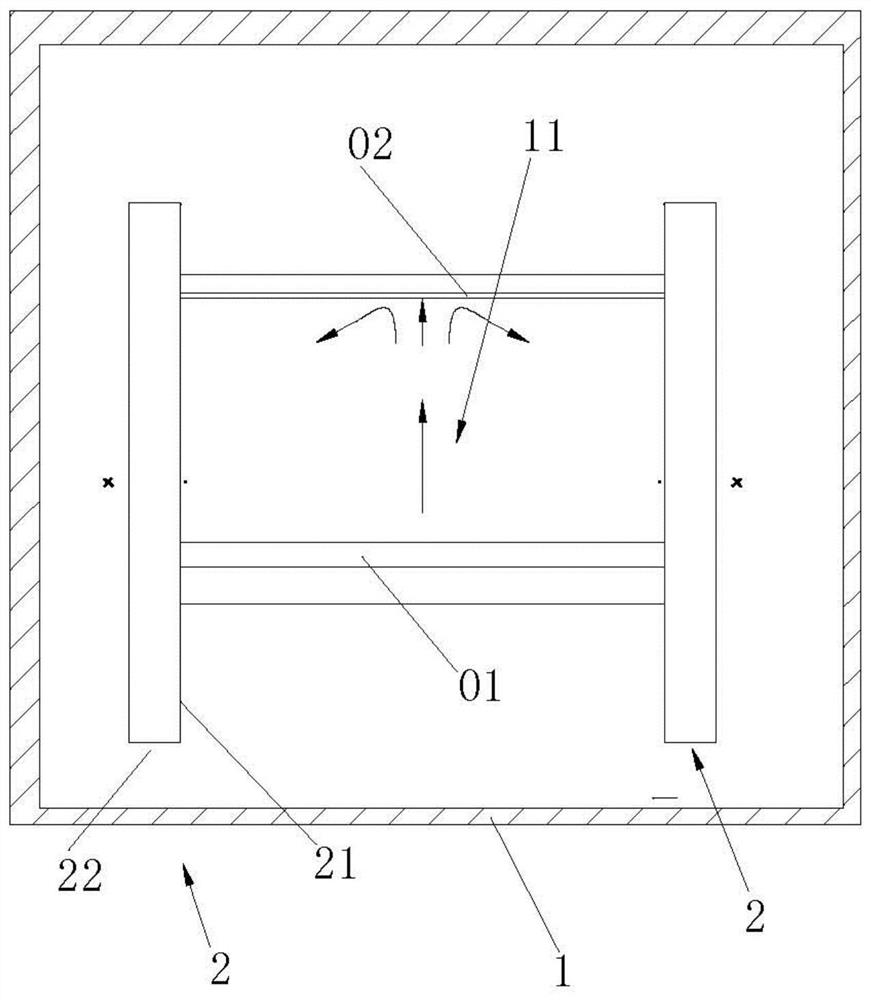

[0022] Such as figure 1 , figure 2 As shown, the target sputtering coating device of the present invention includes a sealed box 1, a negative pressure space is arranged in the sealed box 1, a coating chamber 11 is arranged in the negative pressure space, and a target material 01 base is arranged in the coating chamber 11. Seat and deposition base 02, the inner wall of the sealed box 1 is provided with a receiving cleaning device 2, the receiving cleaning device 2 includes a receiving conveyor belt 21, a target material scraping device and two rollers 22, and the two rollers 22 are rotatably installed In the inside of the sealed box 1, the two ends of the receiving conveyor belt 21 are respectively wrapped around two rollers 22; the receiving conveyor belt 21 is used to accept the particles flying to the inner wall of the sealed box 1; the target scraping device in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com