Sponge city semi-permeable road structure using original road structure

A road structure and sponge city technology, applied in roads, roads, waterway systems, etc., can solve the problems of destroying urban traffic, public facilities, high reconstruction costs, and long construction periods, so as to enhance stability and reduce the release of dirty impurities , Improve the effect of setting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

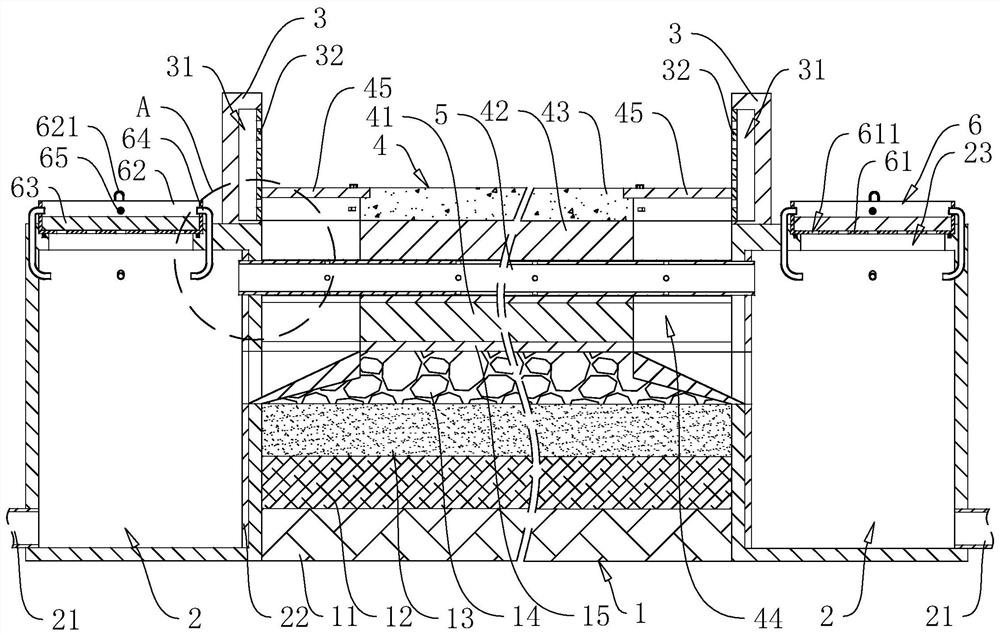

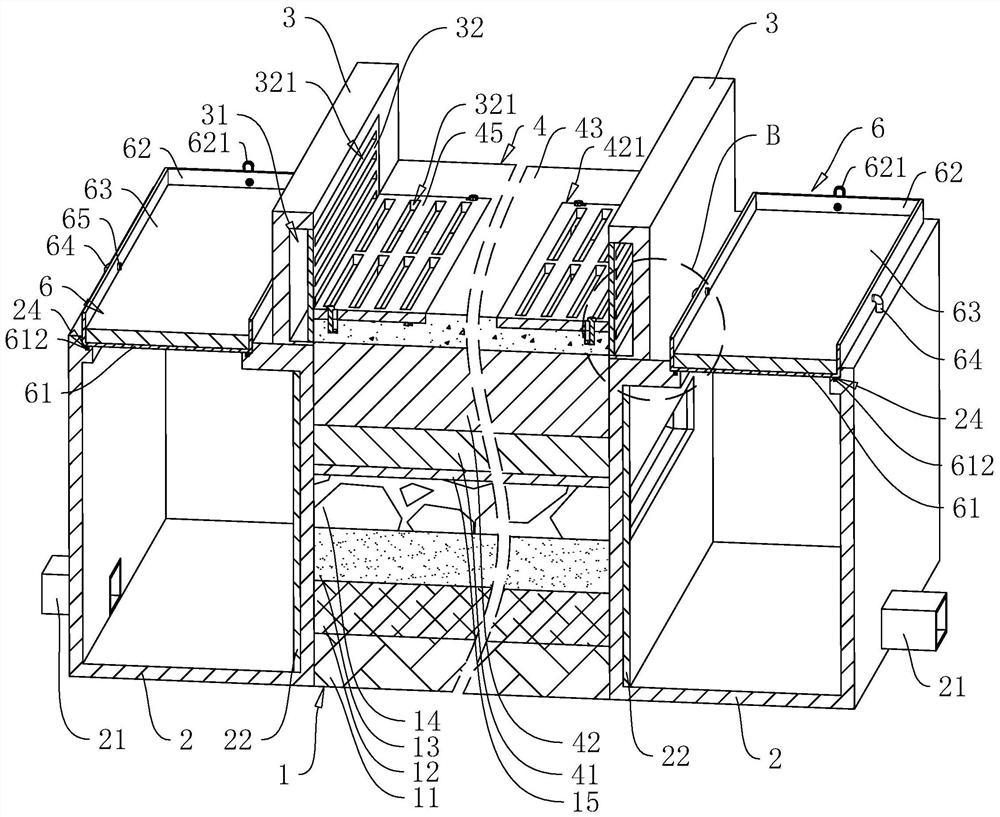

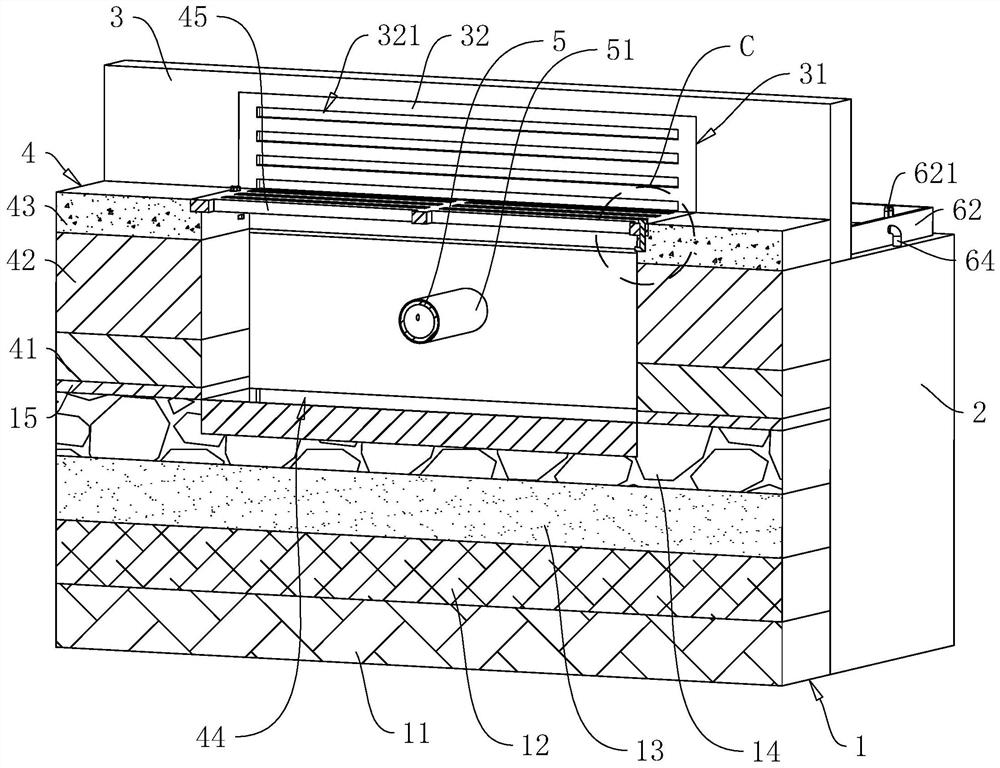

[0037] Attached to the following Figure 1-6 This application will be described in further detail.

[0038] The embodiment of the present application discloses a semi-permeable road structure in a sponge city using the original road structure. refer to figure 1 and figure 2 , The sponge city semi-permeable road structure using the original road structure, including the original roadbed 1, the original roadbed 1 includes a plain soil layer 11, a natural graded gravel layer 12, a lime soil layer 13 and an anti-folding cement concrete layer 14 in order from bottom to top , the top surface of the original roadbed 1 is pre-laid with a layer of waterproof mortar protective layer 15.

[0039] refer to figure 1 and figure 2 , the two sides of the original roadbed 1 in the extension direction are respectively provided with drainage and storage blind ditch 2, and the side of the drainage and storage blind ditch 2 away from the original roadbed 1 is connected with a discharge pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com