An antifreeze type wind power device

A technology of wind power and windproof frame, which is applied in the direction of wind power generation, wind motor combination, wind engine consistent with the wind direction, etc., to achieve the effect of simple structure, long service life and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

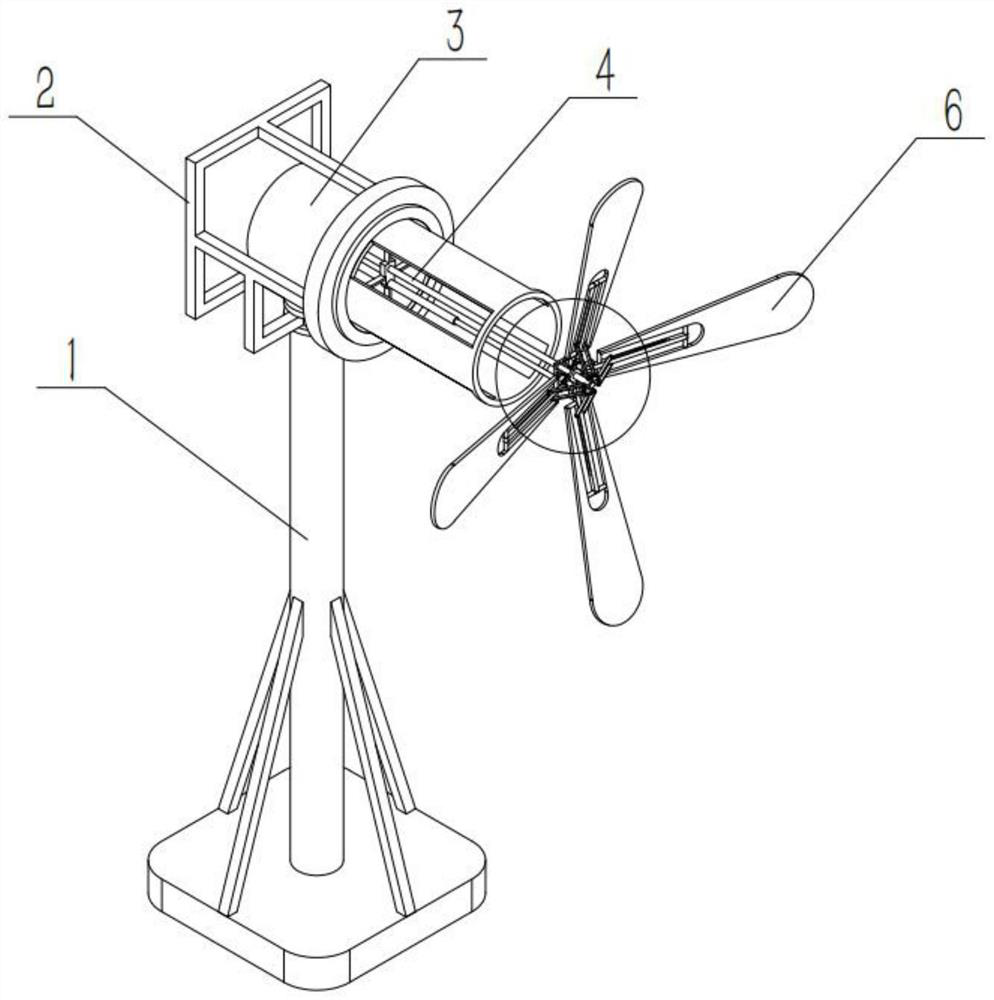

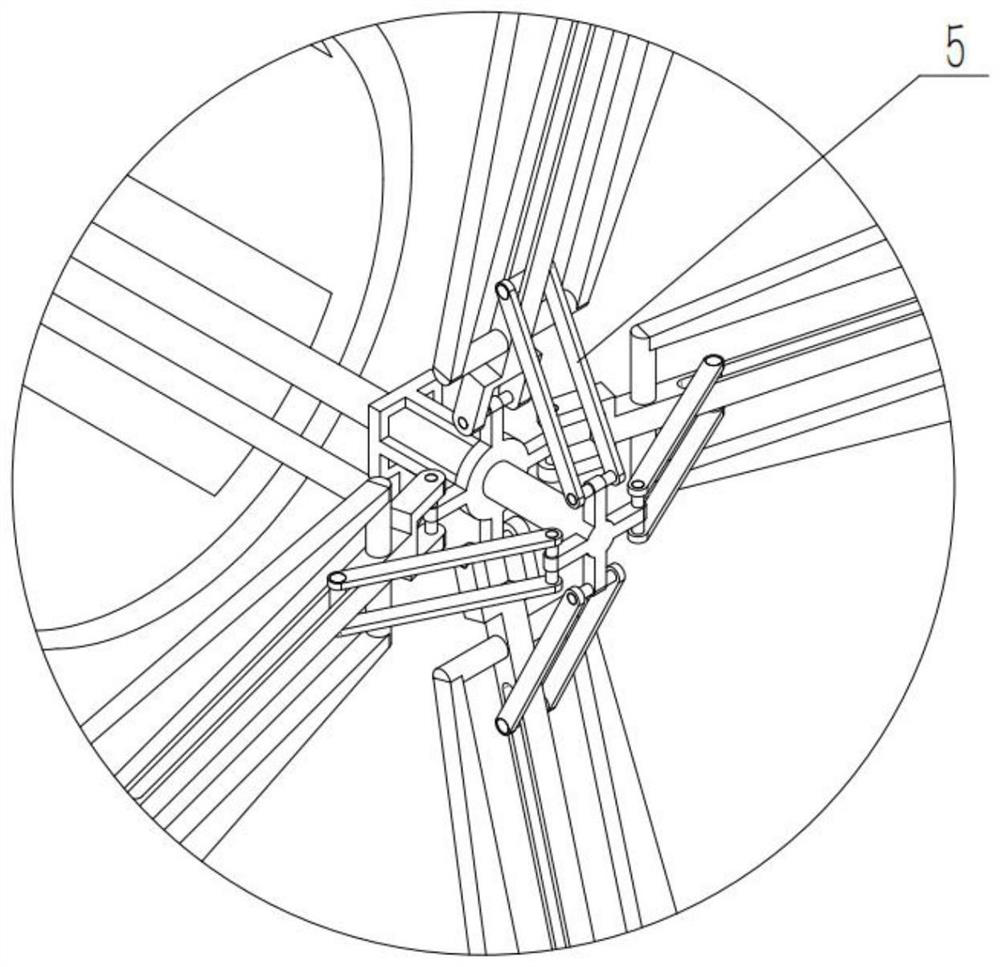

[0030] Such as Figure 1-9 As shown, a kind of antifreeze type wind power device comprises a stabilizing device 1, a rotating frame 2, a rotating mechanism 3, a shrinking mechanism 4, a linkage mechanism 5 and a blade plate 6, and the rotating frame 2 is rotatably connected to the stabilizer 1 At the upper end, the rotating mechanism 3 is rotatably connected to the rotating frame 2, and the shrinking mechanism 4 is fixedly connected in the rotating mechanism 3. The right end of the shrinking mechanism 4 is evenly connected with four linkage mechanisms 5 in the circumferential direction, and each linkage mechanism 5 is connected with a fan. Blade 6.

[0031] The present invention can prevent the wind power device from working normally due to the low-temperature wind power device in cold areas in the field. When the temperature is low, the contraction mechanism 4 drives the fan blades on the four linkage mechanisms 5 to shrink, so that the fan blades 6 for wind power generation ...

specific Embodiment approach 2

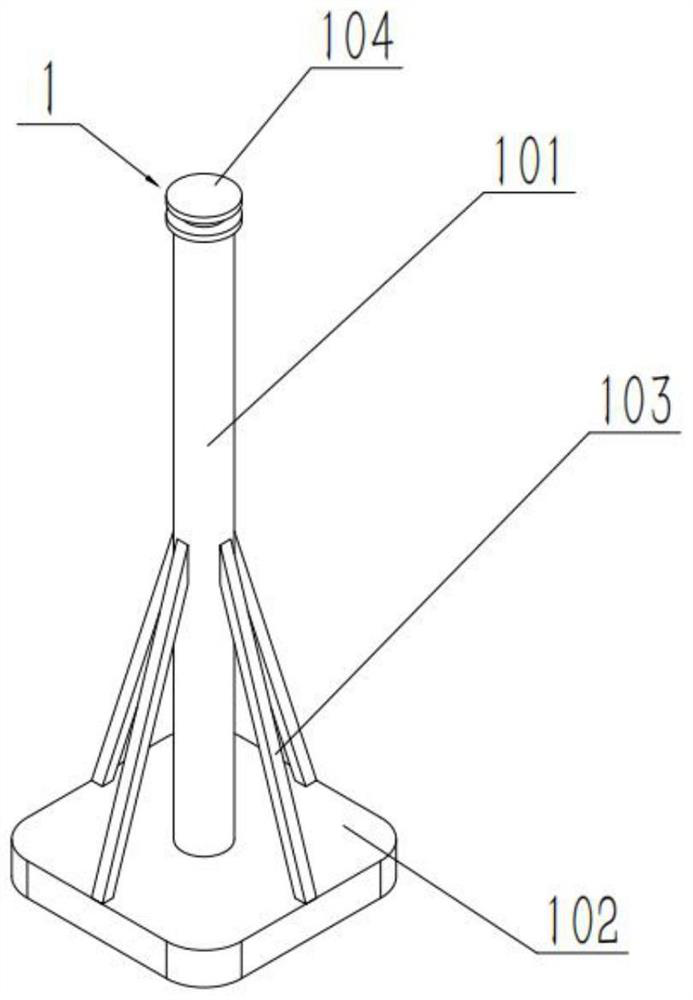

[0032] Such as Figure 1-9 As shown, an antifreeze wind power device, the stabilizing device 1 includes a column 101 , a base 102 and a rotating base 104 , the rotating base 104 is set on the upper end of the column 101 , and the base 102 is fixedly connected to the bottom end of the column 101 . When in use, the column 101, the base 102 and the rotating seat 104 can be placed in any position, and it is convenient for storage and transportation. The base 102 is square, which is more stable during use. The rotating seat 104 is polished to facilitate installation on the rotating seat. Turn on 104.

specific Embodiment approach 3

[0033] Such as Figure 1-9 As shown, an antifreeze type wind power device, the rotating frame 2 includes a square frame 201, a bottom horizontal plate 202, a limit ring 203 and a bottom ring 204, and the bottom horizontal plate 202 is arranged at the lower end of the middle part of the right side of the square frame 201, The limit ring 203 is affixed to the right end of the square frame 201 , the bottom ring 204 is arranged at the middle part of the bottom horizontal plate 202 , and the bottom ring 204 is rotatably connected to the rotating seat 104 . In order to cater to changes in wind direction, thereby enhancing the wind-receiving area and freely rotating to adapt to changes, the bottom ring 204 in the middle of the bottom horizontal plate 202 can rotate freely on the rotating seat 104, which is convenient for adapting to changes in wind direction and enhancing the subsequent wind power generation capacity. The structure is simple and convenient disassembled for storage. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com