Laying equipment for heat distribution pipeline

A thermal pipeline and equipment technology, applied in the field of laying equipment for thermal pipeline installation, can solve problems such as increasing workload, affecting equipment reuse, soil falling, etc., and achieves the effects of quick cleaning, easy maintenance, and avoiding rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

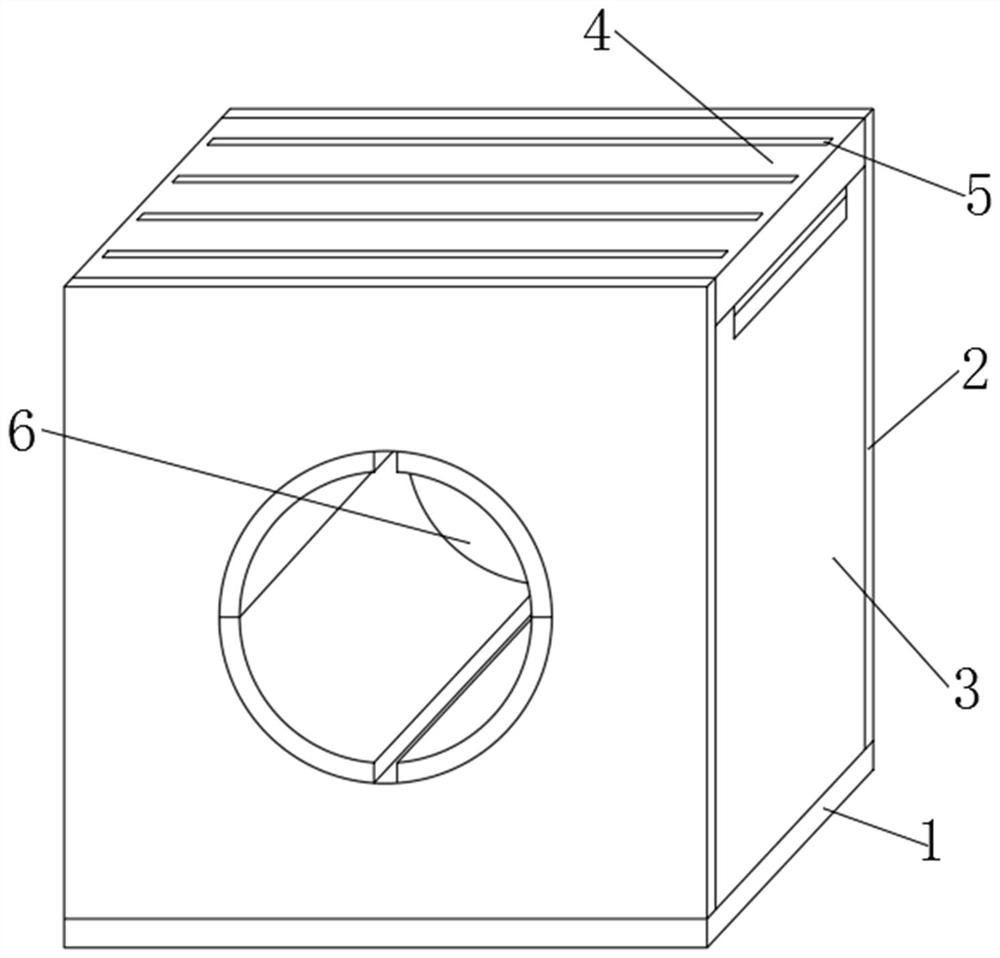

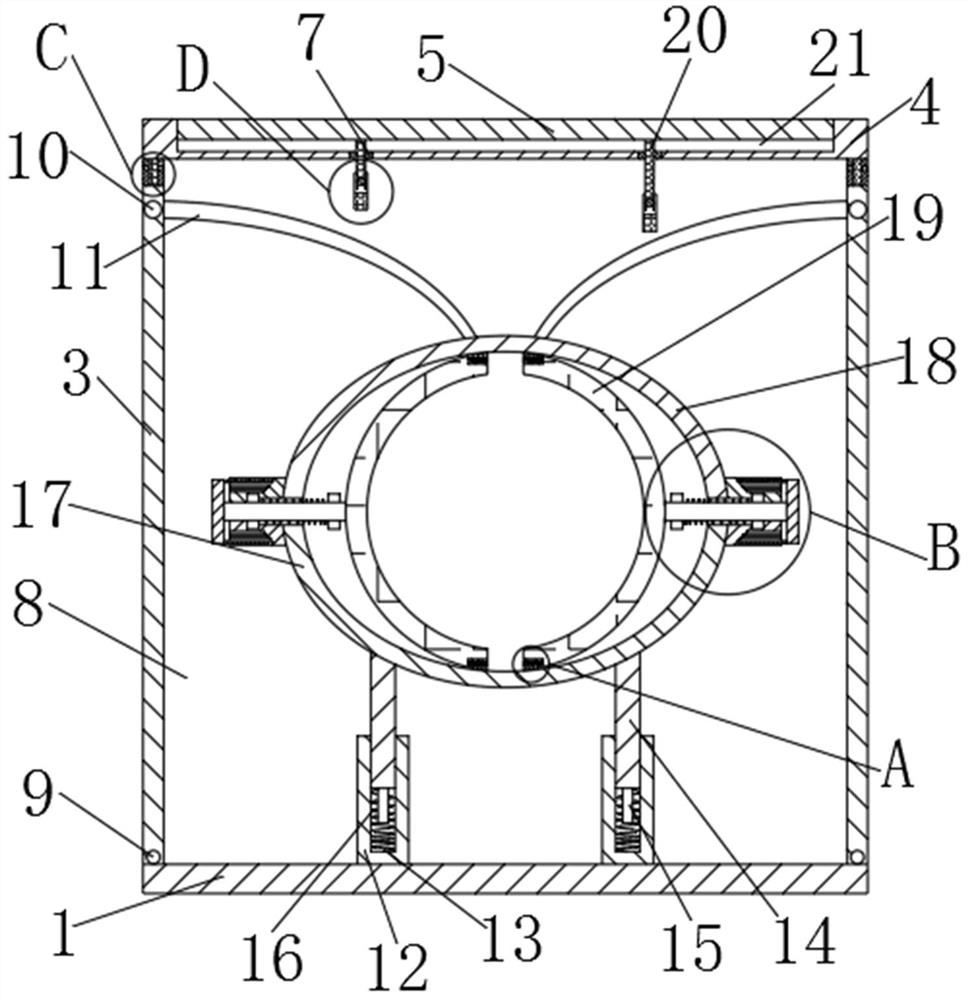

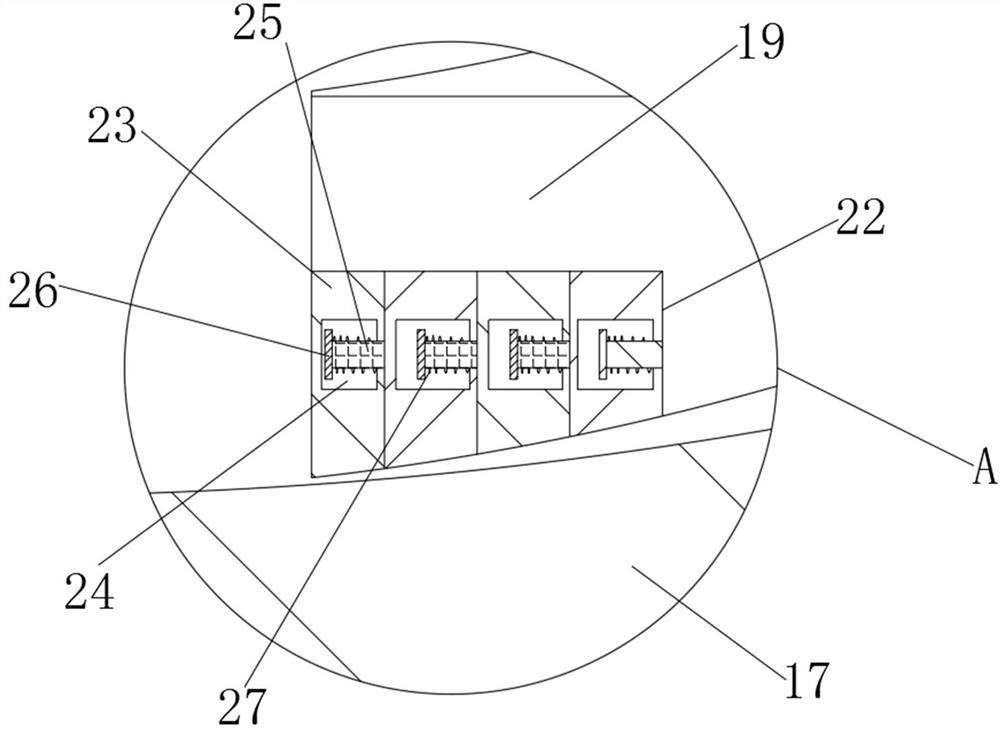

[0033] Such as Figure 1-6 As shown, a laying equipment for thermal pipelines includes a base 1, a vertical plate 2 is fixed on both sides of the upper surface of the base 1, and a mounting hole 6 is opened on the vertical plate 2, and the upper surface of the base 1 is The other two sides of the rotating plate 3 are provided with a rotating shaft 9 below the side of the rotating plate 3, and the two ends of the rotating shaft 9 are inserted into the vertical plates 2 on both sides, and the upper side of the vertical plate 2 is A limiting groove 11 is opened, and a limiting rod 10 is fixed above the two sides of the rotating plate 3, and the limiting rod 10 is inserted into the limiting groove 11. Turning plates 37 are arranged on both sides of the upper surface of the rotating plate 3, The turning plate 37 and the rotating plate 3 are rotationally connected by a fixed shaft 36, the upper end of the turning plate 37 is fixed with a compression member 38, and a cover plate 4 is...

Embodiment 2

[0037] A laying equipment for thermal pipelines, comprising a base 1, a vertical plate 2 is fixed on both sides of the upper surface of the base 1, and an installation hole 6 is opened on the vertical plate 2, and the other two on the upper surface of the base 1 The side is provided with a rotating plate 3, the bottom of the rotating plate 3 side is provided with a rotating shaft 9, the two ends of the rotating shaft 9 are inserted into the vertical plates 2 on both sides, the base 1, the vertical plate 2 and the rotating plate 3 to form a cavity 8, the upper surface of the base 1 is fixed with two groups of bottom plates 12, the upper surface of the bottom plate 12 is provided with a vertical groove 13, and a movable plate 14 is inserted in the vertical groove 13, and the movable plate 14 is inserted into the vertical groove 13. Several sets of sleeve rods 15 are fixed on the lower surface of the plate 14 , and first springs 16 are sleeved on the sleeve rods 15 .

[0038] The...

Embodiment 3

[0046] A method for using laying equipment for thermal pipelines, the specific steps are as follows:

[0047] Step 1: Place the device at the maintenance place, and move the clip 19 to both sides by pulling the first fixing plate 29. When the pipe passes through the installation hole 6, loosen the first fixing plate 29 so that the clip 19 is at the Under the action of the three springs 30, it is closely attached to the surface of the pipeline, and with the action of the third spring 30, the clamping plate 35 is inserted into the corresponding fixing groove 34, and the inserting plates 39 on both sides of the lower surface of the cover plate 4 are inserted and turned over. between plates 37;

[0048] Step 2: When it is necessary to maintain the pipeline, clean up the soil around the device. When only cleaning the soil around the device, because the device is not within the scope of cleaning, the cleaning is relatively fast. When cleaning the soil above the device, the The lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com