Multi-scouring-angle high-temperature and high-flow-rate corrosion test device and test method thereof

A technology of corrosion test and test method, which is applied in the field of high temperature and high flow rate corrosion test equipment, can solve the problems of single erosion test angle, etc., and achieve the effects of convenient carrying, installation and operation, avoiding excessive erosion, and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

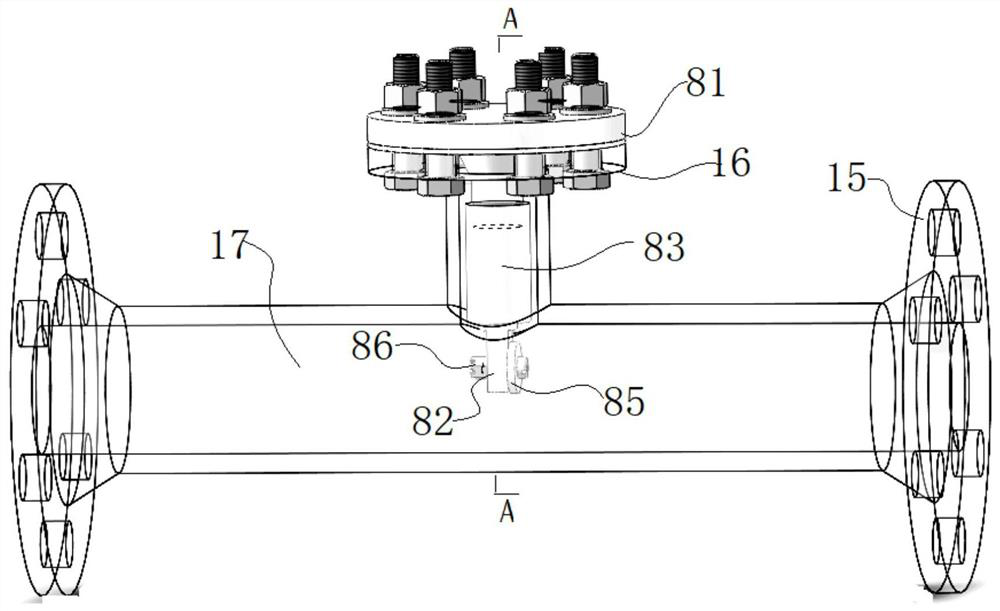

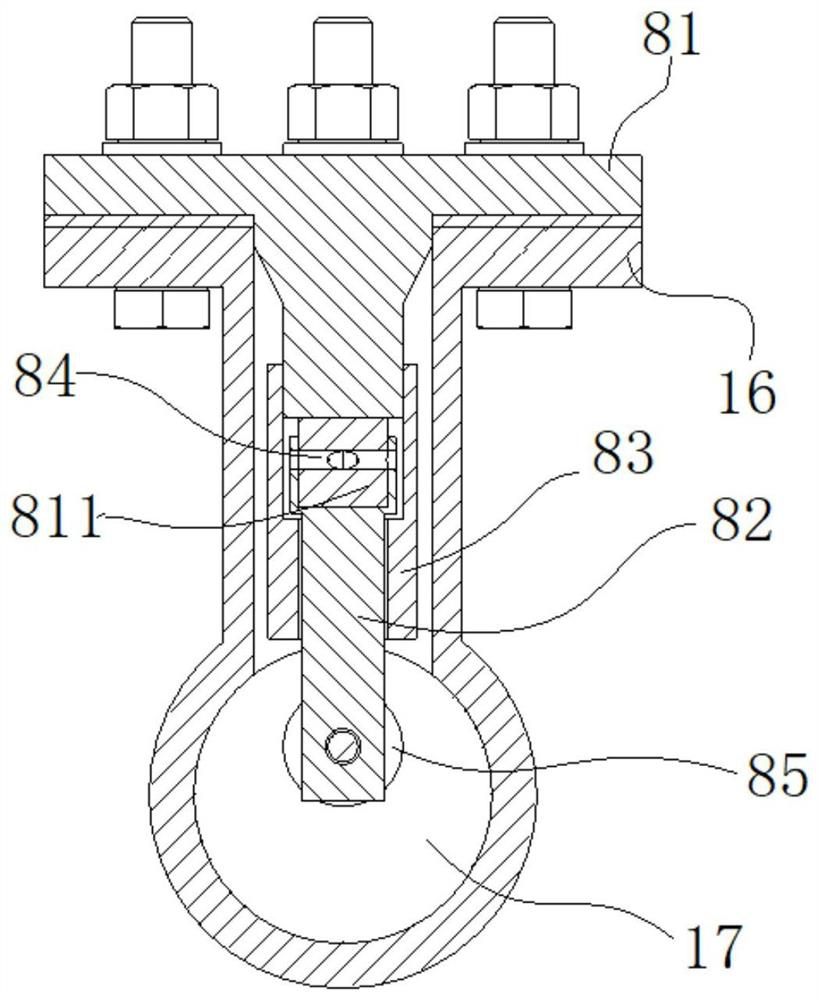

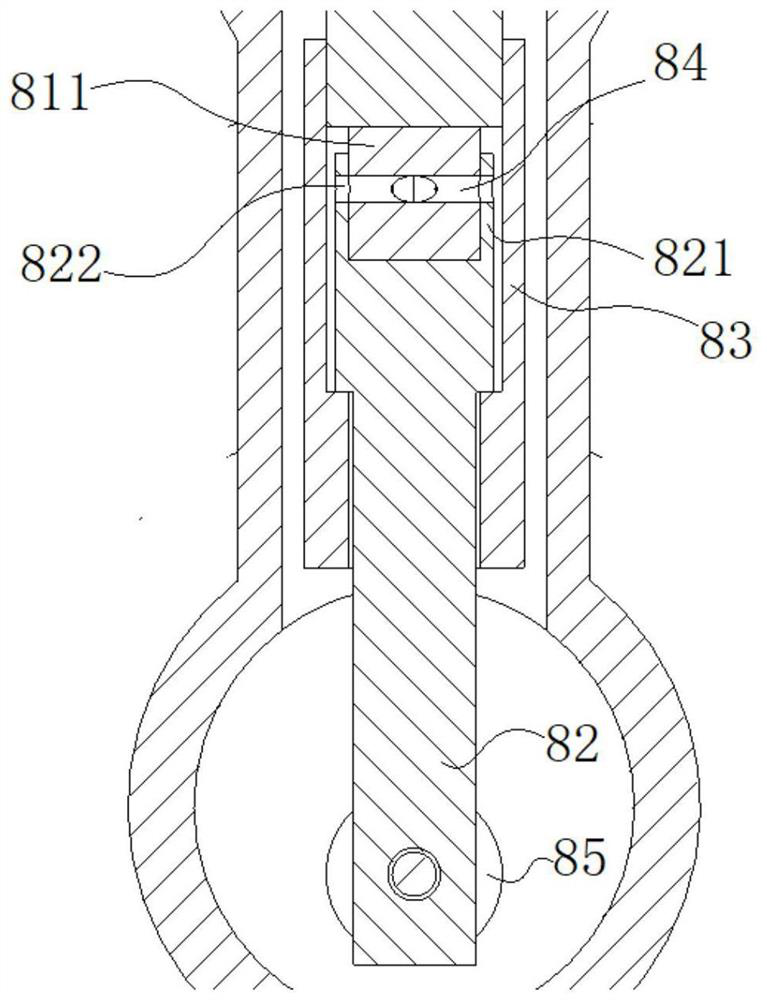

[0040] A kind of high-temperature high-flow rate corrosion test device with multiple scour angles of the present embodiment, such as figure 1 , 2 , 3, 4, 5, and 6, including the pipe flow test device 8 fixed on the oil pipeline 17 through the flange 15, the pipe flow test device 8 includes a "T" shaped upper flange 81, the upper flange The bottom of 81 is connected with a sample rod 82 through a multi-angle connector, and the bottom of the sample rod 82 is detachably connected with a sample piece 85, and the sample rod is connected with a multi-angle connector to realize multi-angle washing of the sample piece. And then reach the technical effect of multi-angle test high temperature and high flow velocity oil body corrosion, multi-angle connector includes boss 811 at the bottom of upper flange 81, groove 821 and pin 84 at the top of sample rod 82, said boss 811 It is fitted with the groove 821, and both of them are perforated horizontally to form a pin hole 822. The pin hole ...

Embodiment 2

[0046] A kind of high-temperature high-flow rate corrosion test device with multiple scour angles of this embodiment has the same basic structure as that of Embodiment 1, the differences and improvements are as follows: figure 2 , 3 As shown, the outer sleeve of the multi-angle connector is connected with a sleeve 83, and the sleeve 83 is detachably connected with the upper flange 81 to protect the pin 84 and the pin hole 822, and prevent the pin 84 from being easily damaged after excessive washing. Dismounting, also can avoid that pin 84 comes off. The upper flange 81 is fixed on the oil pipeline 17 through the flange fitting 16 at the bottom, the sample rod 82 is vertically inserted into the oil pipeline 17, and the sample piece 85 is set facing the oil flow direction of the oil pipeline 17, which is convenient for disassembly during the test , so as to adjust the angle in time.

Embodiment 3

[0048] A kind of high-temperature high-flow-rate corrosion test device with multiple scour angles of this embodiment has the same basic structure as that of Embodiment 2, the differences and improvements are as follows: Figure 7 As shown, it also includes a cut-off valve 15, a speed regulating valve 6, a differential pressure reducing valve 7, a thermometer and a pressure gauge arranged on the oil pipeline 17; the number of pin holes 822 on the boss 811 and the groove 821 There are 6, which can be tested by adjusting the flow rate of the oil body. Moreover, it may also include a shut-off valve II9, a heating unit 10 and a casing heat exchanger 11 arranged on the oil pipeline 17, which is advantageous for testing by adjusting the temperature of the oil body.

[0049] The test method of the high temperature and high flow rate corrosion test device with multiple scour angles of the present embodiment comprises the following steps:

[0050] Preliminary preparation: if Figure 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com