Lens carrier for optical module coupling,optical module coupling device and use method of optical module coupling device

A coupling device and optical module technology, applied in the field of optical communication, can solve problems affecting coupling quality and coupling efficiency, lens cracking, lens skewing, etc., achieve the effect of reducing production cost and technical difficulty, and improving coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

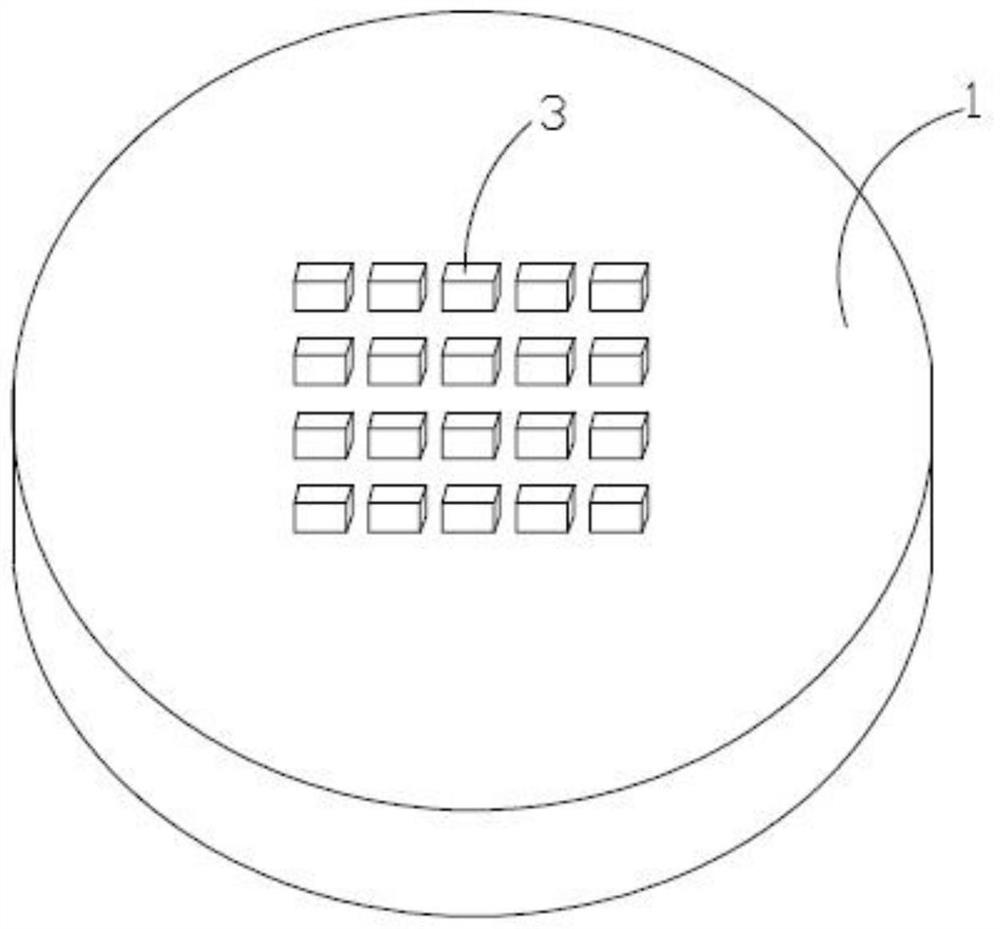

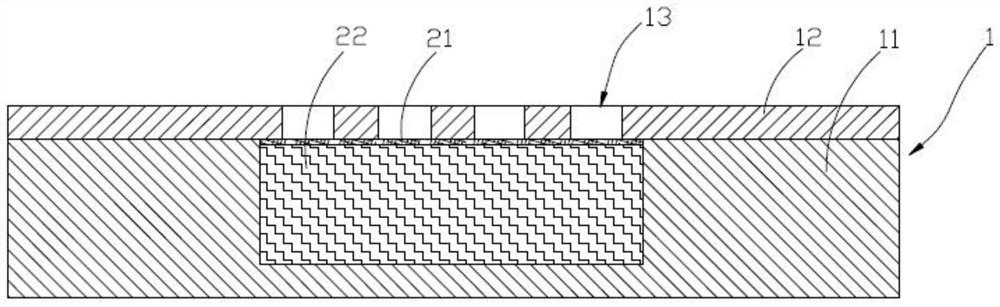

[0021] Such as figure 1 and figure 2 , the embodiment of the present invention provides a lens carrier for optical module coupling, including a base 1, at least one lens carrier for placing a lens 3 is formed on the top of the base 1, and each lens carrier is equipped with a A buffer mechanism that can be compressed when the lens 3 is under pressure.

[0022] Generally, the above-mentioned lens carrier can carry a plurality of lenses 3 , that is, it has a plurality of lens positions, and each lens position is preferably arranged in an array.

[0023] In one of the embodiments, an independent buffer mechanism can be configured for each lens loading position, for example, a plurality of loading slots can be provided on the base 1, and a buffer mechanism is provided at the bottom of each loading slot; wherein, the buffer mechanism can Use the following method:

[0024] (1) The buffer mechanism adopts elastic materials such as buffer sponge and buffer rubber, and the lens 3 ca...

Embodiment 2

[0034] An embodiment of the present invention provides an optical module coupling device, including a coupling machine, on which a lens carrier and a suction nozzle for picking up the lens 3 are arranged, and the lens carrier adopts the method provided in the first embodiment above. Lens carrier for optical module coupling.

[0035] The coupling machine and the suction nozzle are conventional equipment in the field, and the arrangement of the suction nozzle and the lens carrier on the coupling machine is a conventional structure in the field, and will not be described here.

[0036] The embodiment of the present invention also relates to the method of using the optical module coupling device as described above, including:

[0037] placing the lens 3 on the lens carrier;

[0038] Move the suction nozzle directly above the target lens 3, lower the suction nozzle and press the target lens 3;

[0039] After the suction nozzle picks up the target lens 3, the target lens 3 is move...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap