Small deviation rapid correction method for carrying capacity of solid binding carrier rocket

A technology of carrying capacity and launch vehicle, which is applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve the problems of high computational complexity and large amount of calculation of carrying capacity, achieve considerable technical application prospects, and fully exploit , the effect of full carrying capacity potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

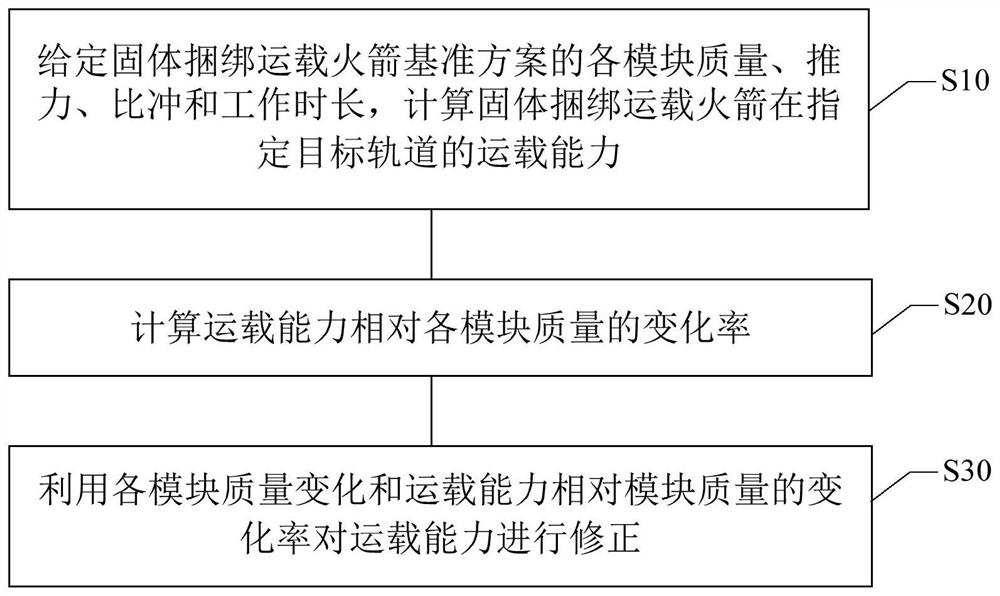

Method used

Image

Examples

Embodiment 1

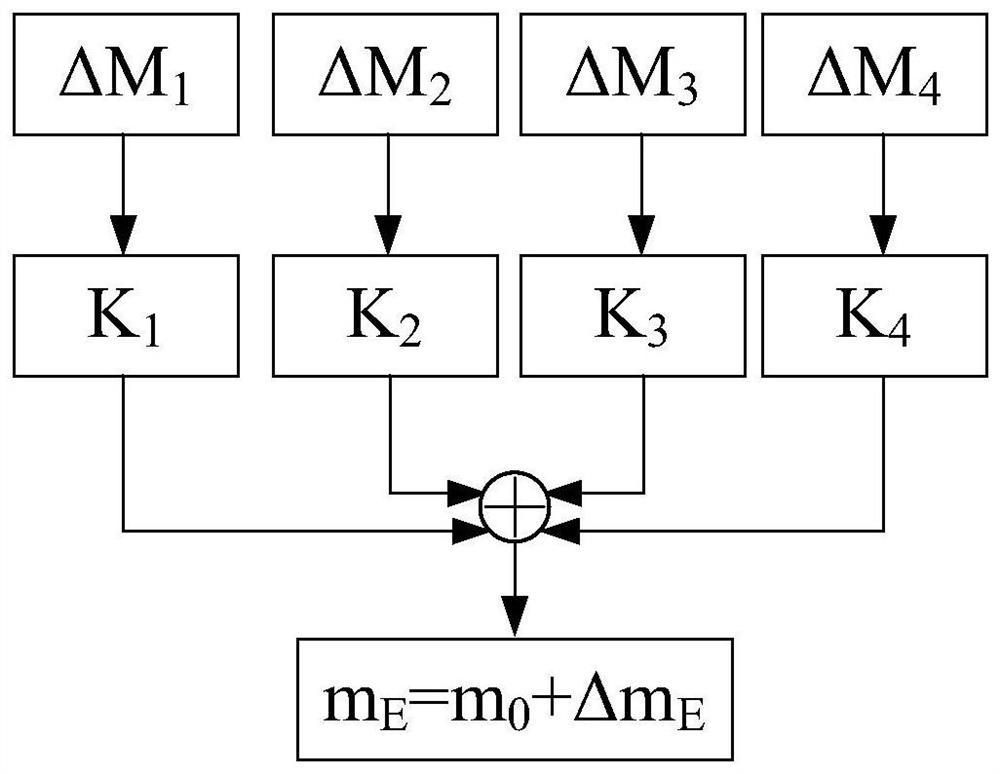

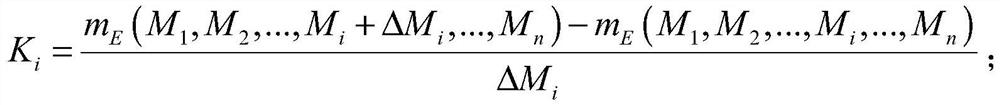

[0044] The H-2B carrier rocket has a two-and-a-half-stage configuration. The core stage is propelled by liquid hydrogen and liquid oxygen. The first stage is equipped with two LE-7 engines, the second stage is equipped with an LE-5B engine, and four solid boosters are bundled. ; launch a 350km, 51° inclination LEO circular orbit at the Tanegashima launch site, and the correction constant K of the mass of the solid booster to the carrying capacity 1 is -0.1, the correction constant K of the primary mass of the core to the carrying capacity 2 is -0.3, the correction constant K of the mass of the upper stage to the carrying capacity 3 is -1, therefore, the change value of carrying capacity ΔM E The expression is:

[0045] Δm E =-0.1ΔM 1 -0.3ΔM 2 -ΔM 3 ;

[0046] According to the above expression, it can be seen that for every 1t increase in the mass of the solid booster, the carrying capacity will decrease by 100kg; for every 1t decrease in the mass of the solid booster, t...

Embodiment 2

[0048] The Ariane 5ECA carrier rocket has a two-and-a-half-stage configuration. The core stage is propelled by liquid hydrogen and liquid oxygen. The first stage is equipped with a Vulcan engine, the second stage is equipped with a Vinci engine, and two solid boosters are bundled. Launching a 250km, 5° inclination LEO circular orbit at the Guyana launch site, the correction constant K of the mass of the solid booster to the carrying capacity 1 is -0.13, the correction constant K of the primary mass of the core to the carrying capacity 2 is -0.113, the correction constant K of the mass of the upper stage to the carrying capacity 3 is -1, therefore, the change value of carrying capacity ΔM E The expression is:

[0049] Δm E =-0.13ΔM 1 -0.113ΔM 2 -ΔM 3 ;

[0050] According to the above expression, it can be seen that for every 1t increase in the mass of the solid booster, the carrying capacity will decrease by 130kg; for every 1t decrease in the mass of the solid booster, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com