Valve special for pneumatic conveying

A pneumatic conveying and valve technology, which is used in conveyors, conveying bulk materials, transportation and packaging, etc. It can solve the problems of operator hand burns, gas operator hand contact, and low safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

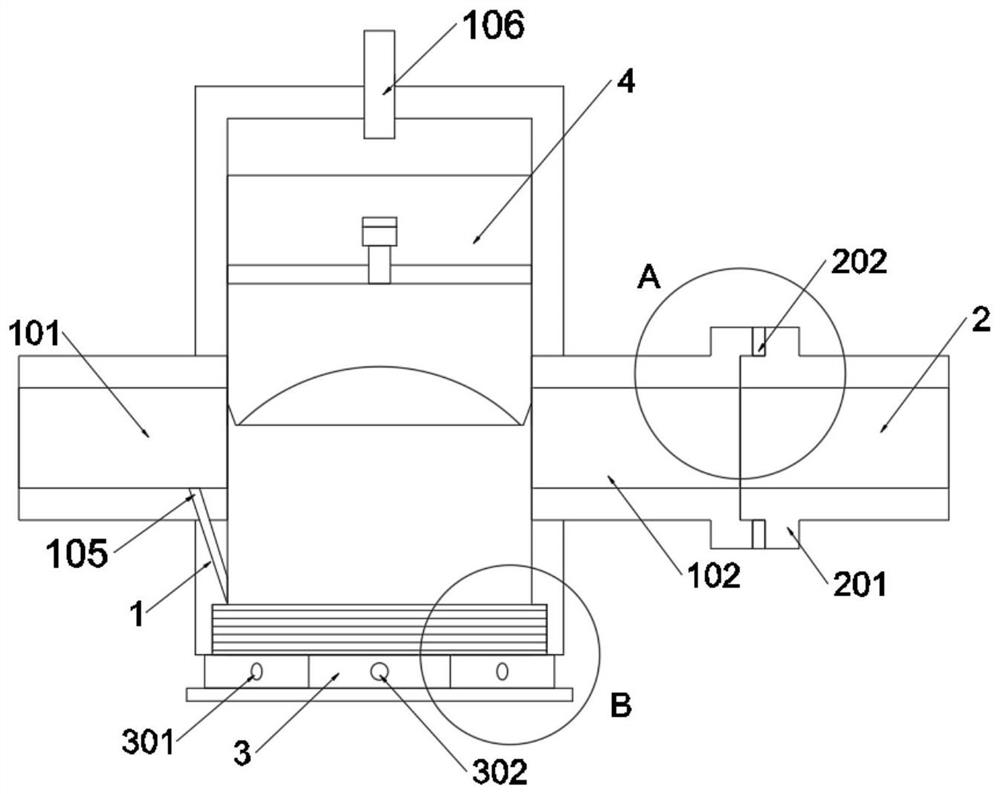

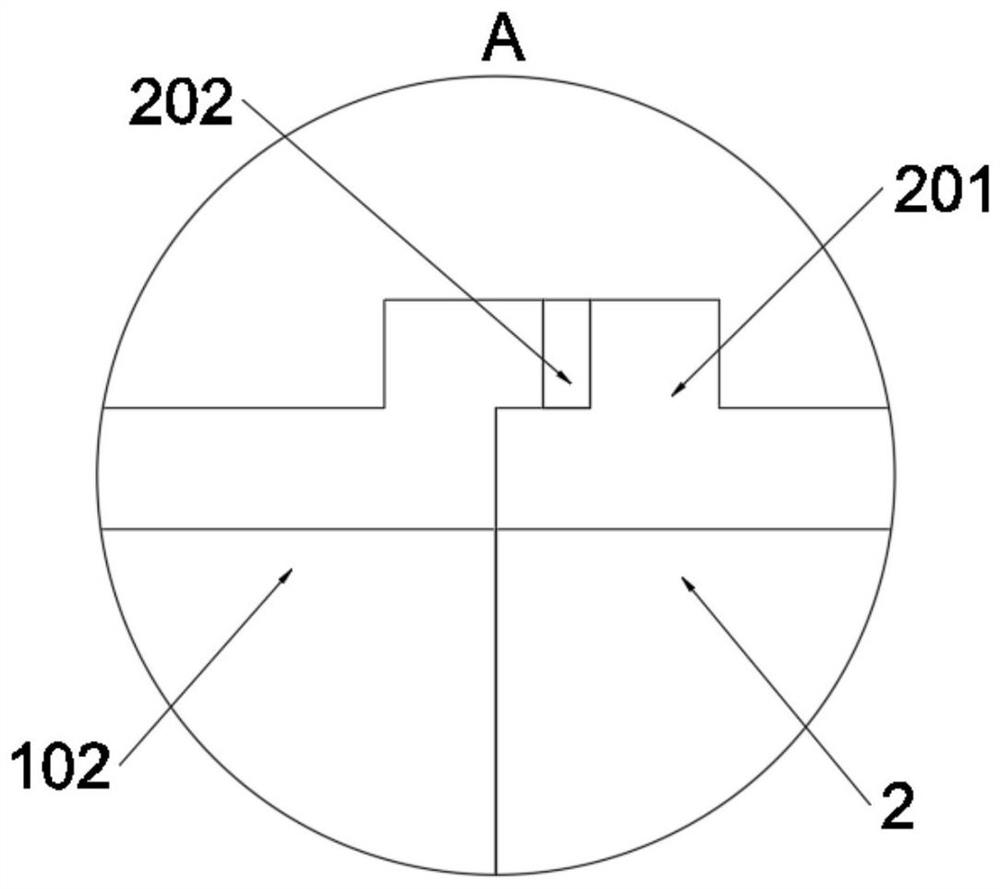

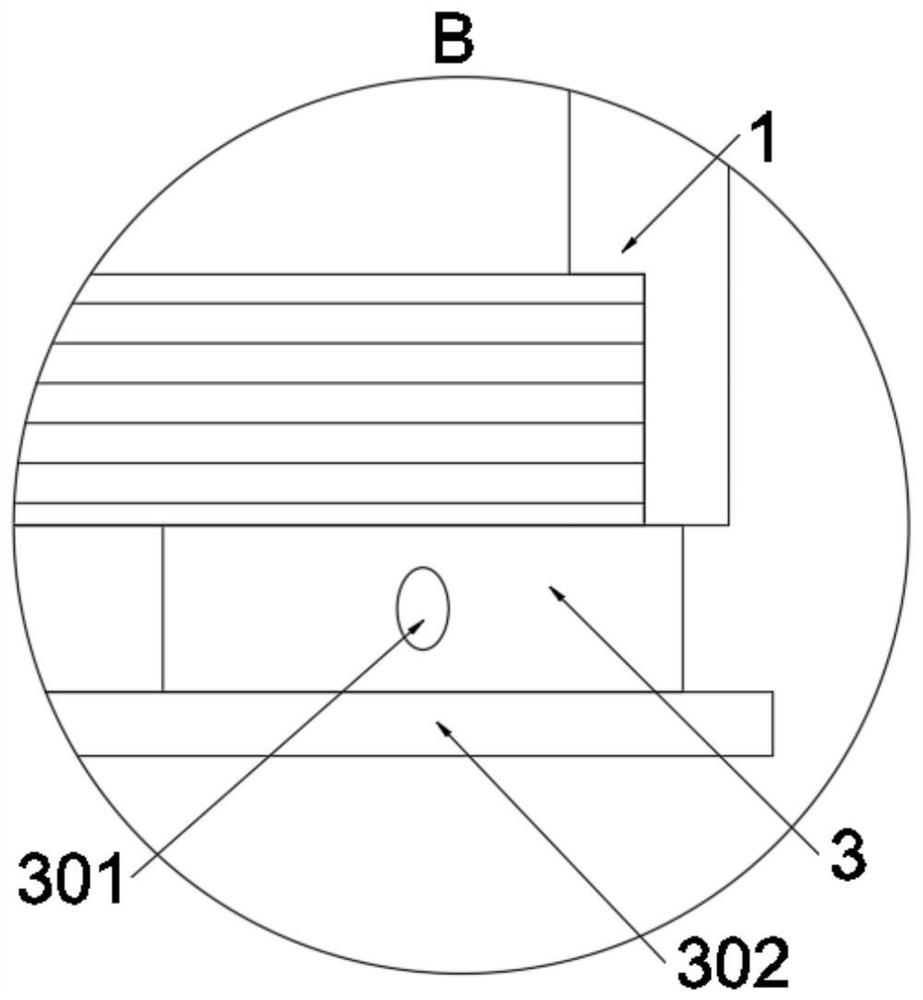

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036]The invention provides a special valve for pneumatic conveying, which includes a valve body 1; a connecting pipe 2 is threaded on the valve body 1, and a base 3 is threaded on the valve body 1; a switch structure 4 is installed on the valve body 1, and the valve An adjustment structure 5 is welded on the main body 1; refer to Figure 4 and Figure 8 The switch structure 4 includes a sliding groove 402, a piston head 403, a sliding rod 404 and an elastic member B405. The sliding groove 402 is set at the bottom of the piston 401, and the sliding groove 402 is a stepped groove structure; the top surface of the piston head 403 is welded with a sliding rod 404, and the sliding rod 404 is a stepped shaft-shaped structure, and the sliding rod 404 is slidably connected in the sliding groove 402; the elastic part B405 is sleeved on the sliding rod 404, and the elastic part B405 is a ring structure; the outer diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com