A kind of reaction furnace for graphene preparation

A technology of graphene and reaction furnace, which is applied in the field of reaction furnace for graphene preparation, can solve the problems of low efficiency of graphene, and achieve the effects of high production efficiency, convenient operation and increased work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

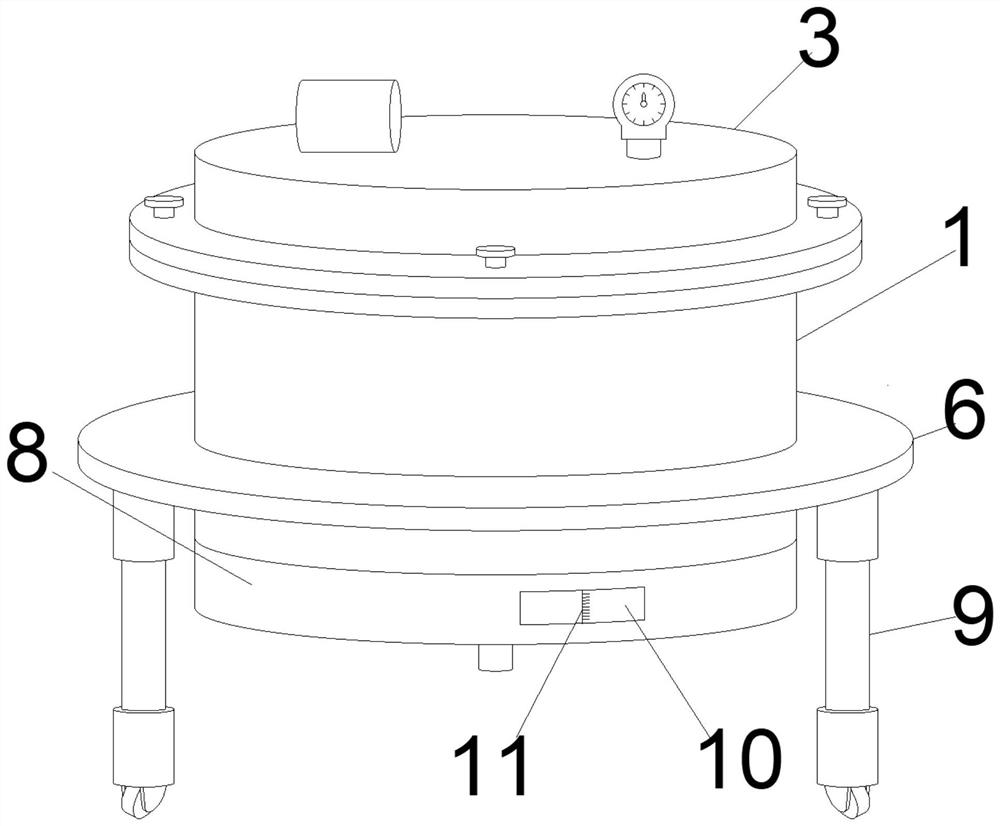

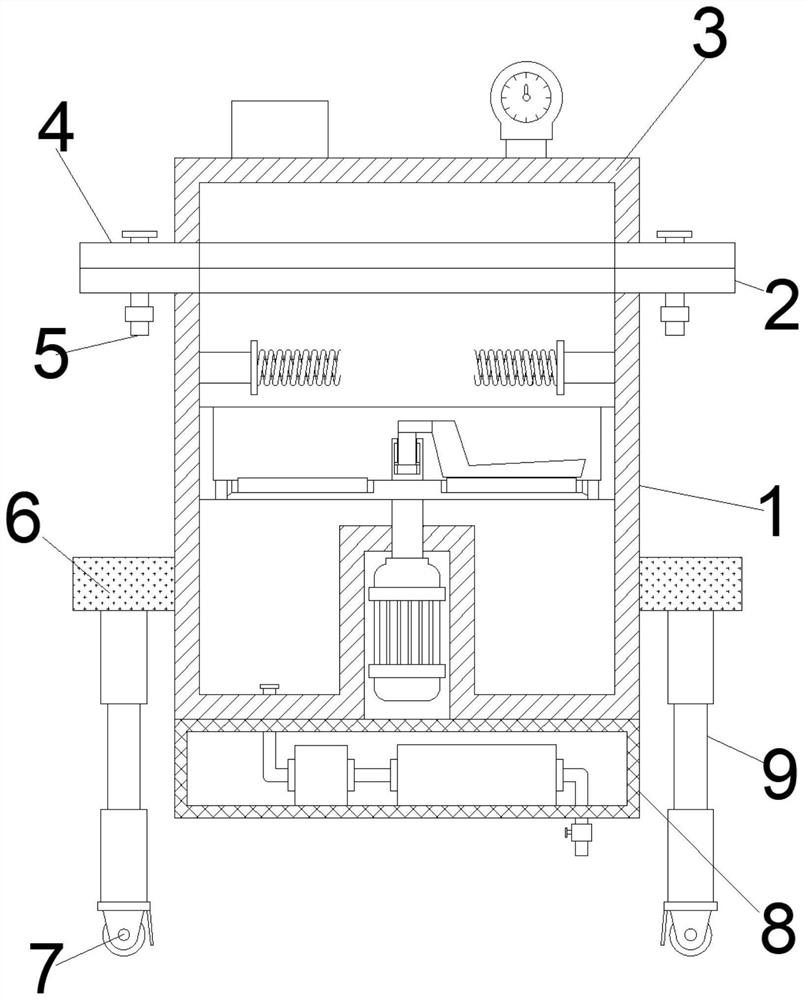

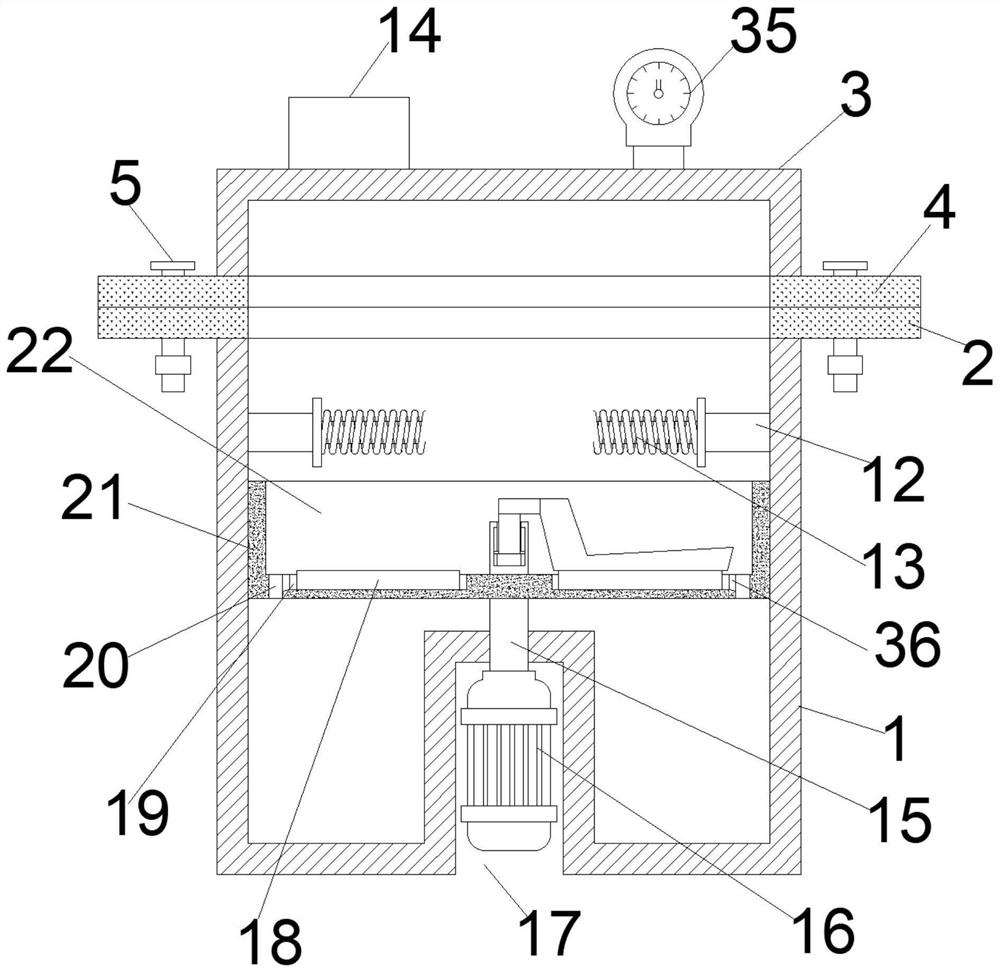

[0030] Such as Figure 1-5 As shown, the embodiment of the present invention provides a reaction furnace for preparing graphene, comprising a lower furnace body 1 and an upper furnace body 3, the center of the lower end surface of the lower furnace body 1 is provided with a motor groove 17, and the inside of the motor groove 17 is fixedly provided with a motor 16. The output end of the motor 16 is fixedly connected with a rotating rod 15, and a preparation plate 21 is fixedly arranged in the middle of the lower furnace body 1, and a preparation tank 22 is opened at the center of the upper end surface of the preparation plate 21, and a ring is opened on the bottom surface of the preparation tank 22. Groove 19, the bottom surface of preparation tank 22 is located on both sides of ring groove 19 and is provided with downflow hole 20, and between ring groove 19 and two downflow holes 20, there is a through groove 36, and downflow hole 20 is used for draining graphene to fall on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com