A kind of humic acid-type fruit bag-free film agent and its application method

A technology of humic acid and potassium humate, which is applied in the field of agricultural applications, can solve problems such as being easily washed by rain, serious fruit shading, and fruit quality decline, and achieve excellent air permeability, good antibacterial effect, and improved shading performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

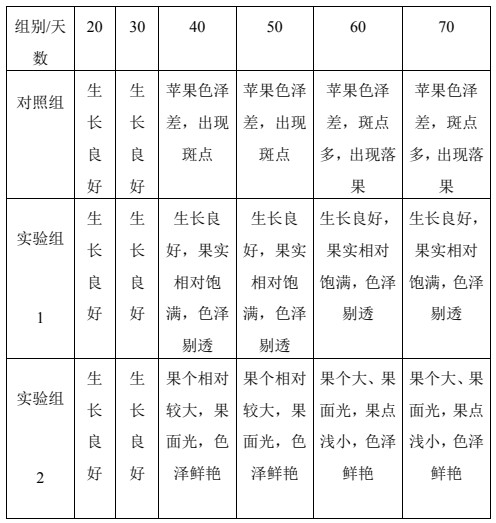

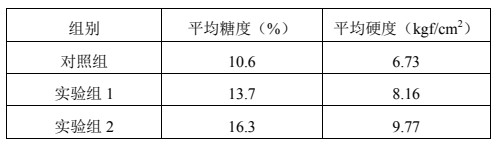

Examples

preparation example Construction

[0025] Specifically, a method of type humic acid-free fruit bagging film, the method comprising the steps of preparing:

[0026] 1) The sodium alginate was dissolved in water, adding Tween-20 and Span -20 After stirring uniformly, and mix them thoroughly mixed to form a sodium alginate solution. Wherein the alginate: water: Tween-20: Span -20 mass ratio is (5-8) :( 60-65) :( 0.5 to 0.8) :( 0.5 to 0.8).

[0027] 2) The potassium humate completely dissolved in water, glycerin, and completely mixed solution of potassium humate is formed. Wherein KHm: water: glycerin mass ratio of (0.3 to 0.5) :( 35 ~ 40) :( 1 to 1.2).

[0028] 3) step 1) and sodium alginate solution obtained in step 2) is made of potassium humate solution is sufficiently stirred until it became a homogeneous system, agent A can be formed. Wherein the potassium humate solution and sodium alginate solution volume ratio of 1: 1.

[0029] 4) calcium chloride dissolved in water to obtain a B agent, the A agent is sprayed ...

Embodiment 1

[0032] 1) The sodium alginate was dissolved in 60kg 5kg of water, was added Span -20 0.5kg and 0.5kg of Tween-20, after fully dissolved, mixed to form a sodium alginate solution with stirring.

[0033] 2) dissolved in the potassium humate 40kg 0.3kg water, adding glycerin 1kg uniformly mixed to give a homogeneous stirred solution of potassium humate.

[0034] 3) step 1) and sodium alginate solution obtained in step 2) prepared solution of potassium humate volume ratio 1: 1 was stirred sufficiently until it became homogeneous system, agent A can be formed.

[0035] 4) The calcium chloride was dissolved in 100kg water 1.5kg, was thoroughly dissolved to obtain B agent.

Embodiment 2

[0037] 1) The sodium alginate was dissolved in 65kg 8kg of water, was added Span -20 0.8kg and 0.8kg of Tween-20, after fully dissolved, mixed to form a sodium alginate solution with stirring.

[0038] 2) dissolved in the potassium humate 35kg 0.5kg water, glycerol was added 1.2kg uniformly mixed to give a homogeneous stirred solution of potassium humate.

[0039] 3) step 1) and sodium alginate solution obtained in step 2) prepared solution of potassium humate volume ratio 1: 1 was stirred sufficiently until it became homogeneous system, agent A can be formed.

[0040] 4) 2kg of calcium chloride was dissolved in 100kg of water, was thoroughly dissolved to obtain B agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com