Shed tunnel structure capable of effectively resisting impact of falling stone

A technology of shed holes and rockfalls, applied in protective equipment, springs/shock absorbers, vibration suppression adjustment, etc., can solve the problem of shock absorbers being too late to deform and consume energy, and achieve the effect of simple and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

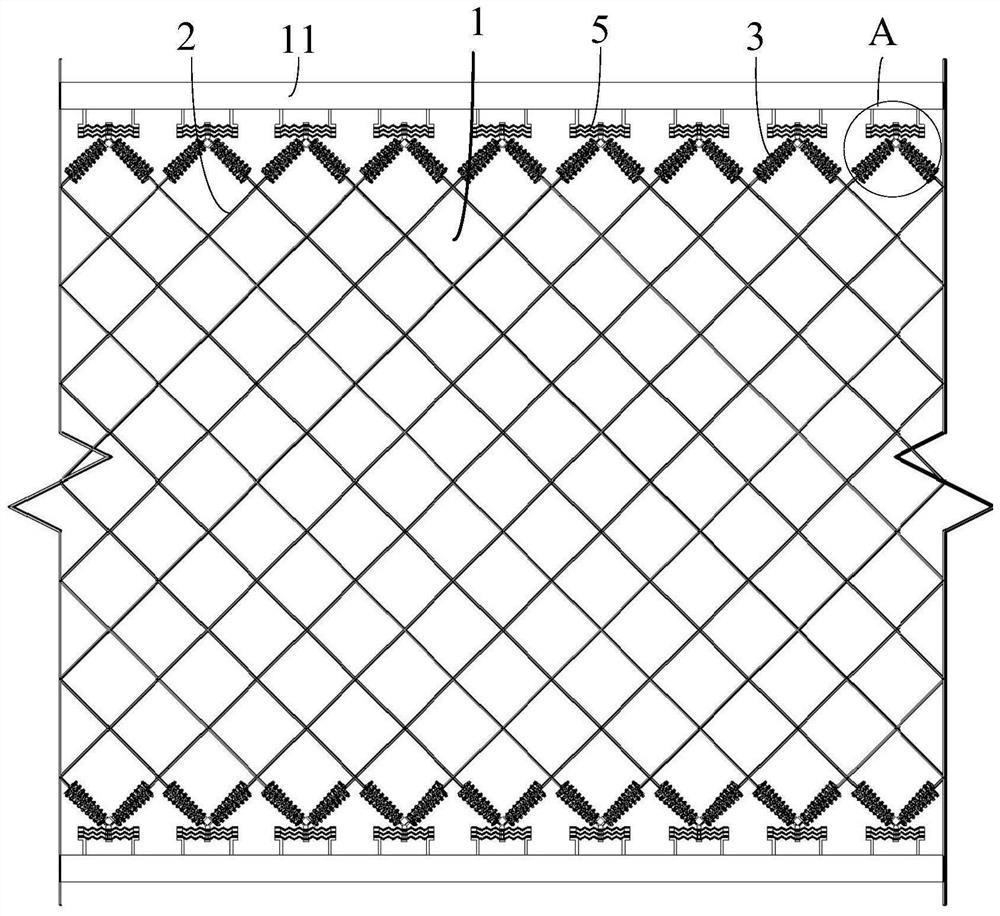

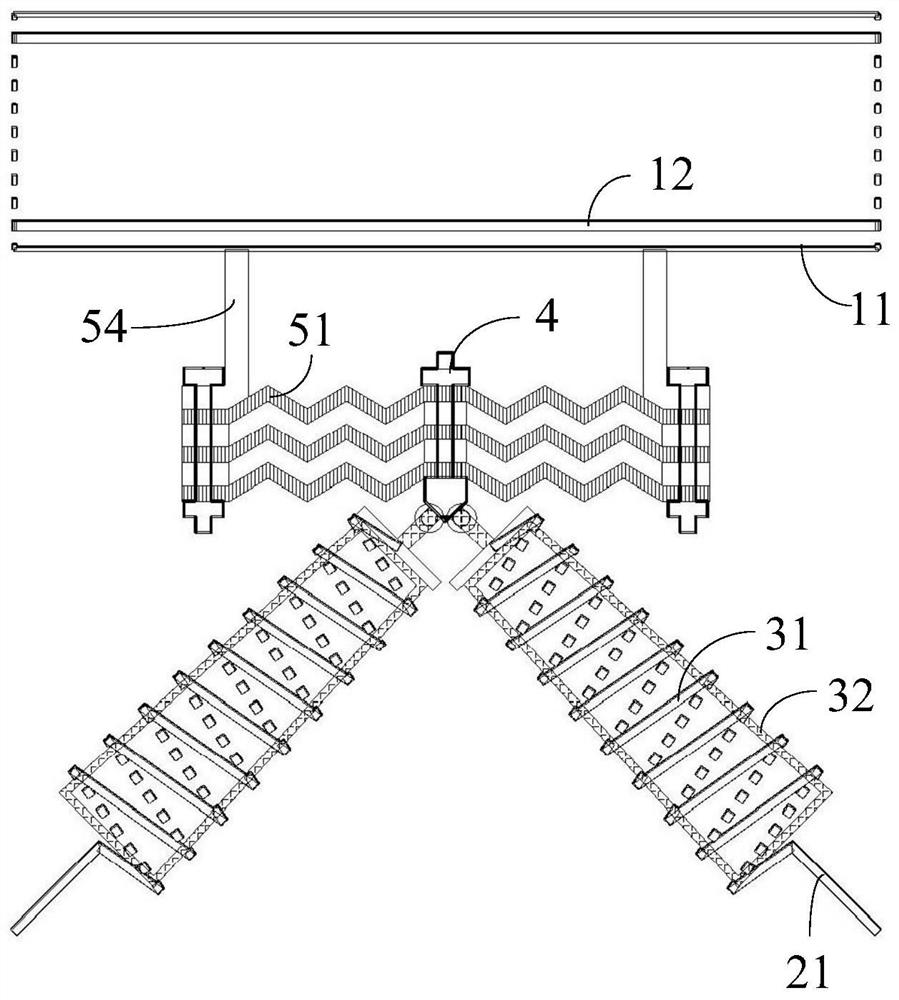

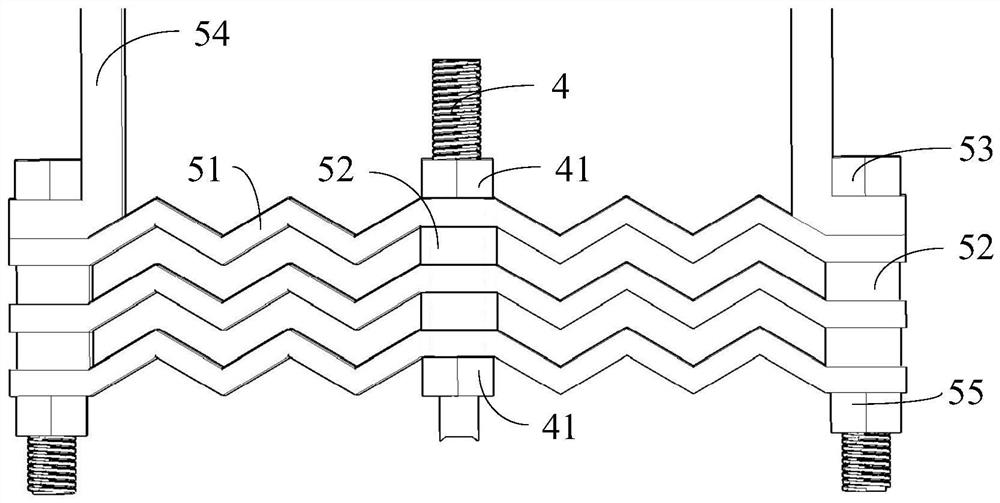

[0040] Such as figure 1 As shown, the shed cave structure effectively resisting the impact of falling rocks in the embodiment of the present invention includes a shed cave roof 1, a protective net 2, a plurality of elastic energy dissipation components 3 and a plurality of ductile energy dissipation components 5, wherein the shed cave roof 1 is Concrete slabs. Wherein the protective net 2 is arranged above the roof 1 of the shed cave at a certain interval, and the protective net 2 is formed by intersecting a plurality of hinge ropes 21; 31 provides a friction sleeve 32 that frictionally dissipates energy with the inner wall of the spring 31; the ductile energy-dissipating member 5 is detachably connected between the shed cave roof 1 and the elastic energy-dissipating component 3, and the ultimate tensile force of the ductile energy-dissipating member 5 is less than that of the elastic The ultimate tensile force of the energy dissipation component 3.

[0041] In this example,...

Embodiment 2

[0048] Compared with Example 1 Figure 1-8 and the second example Figure 1-4 , 6, 9-10, the difference between the second embodiment and the first embodiment lies in the connection assembly 6, combined with Figure 9-11 As shown, the connection assembly 6 includes a U-shaped plate 621 fixed at the end of the screw rod 4 and a connecting rod 622 hinged in the U-shaped plate 621 through a rotating shaft or a bolt and nut. One end of the connecting rod 622 passes through the through hole 34 and the friction sleeve 32 fixed connections, such as Figure 10 As shown, the opposite two side plates of the U-shaped plate 621 are respectively provided with perforations (non-threaded holes), and the connecting rod 622 of the friction sleeve 32 is also provided with perforations, and the bolts pass through the U-shaped plate 621 and the connecting rod 622. perforated and locked by nuts, wherein only one bolt is connected to each U-shaped plate 621 and connecting rod 622, so that the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com