Self-operated side valve with power failure protection function and its application method

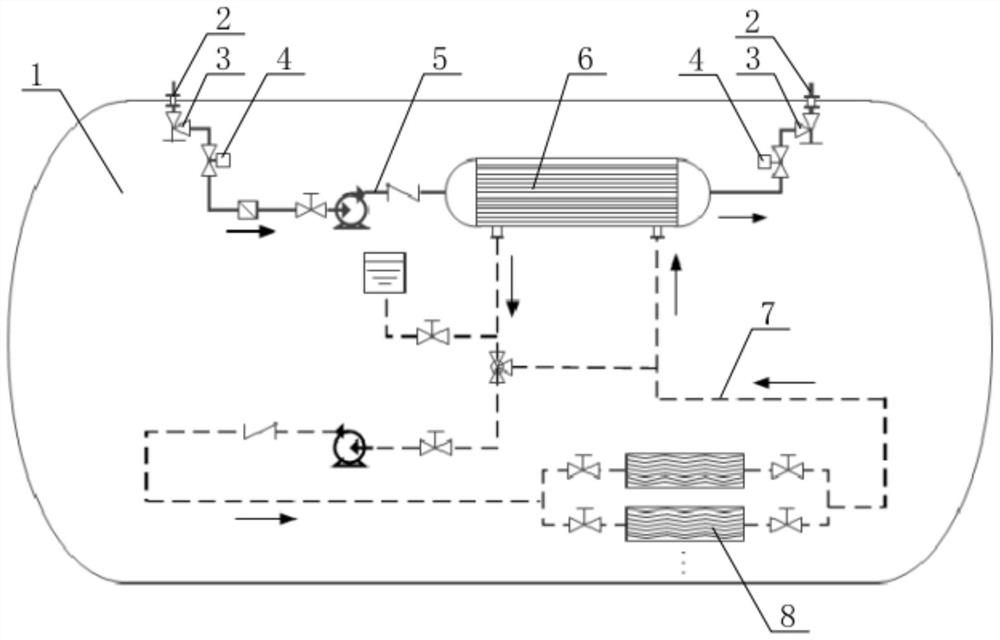

A power-off protection and self-operated technology, which is applied in the field of self-operated side valves, can solve the problems of hydraulic or electric actuators with large volume, difficult operation, and occupying space in the cabin, achieving good stability and operability, The overall structure is simple and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

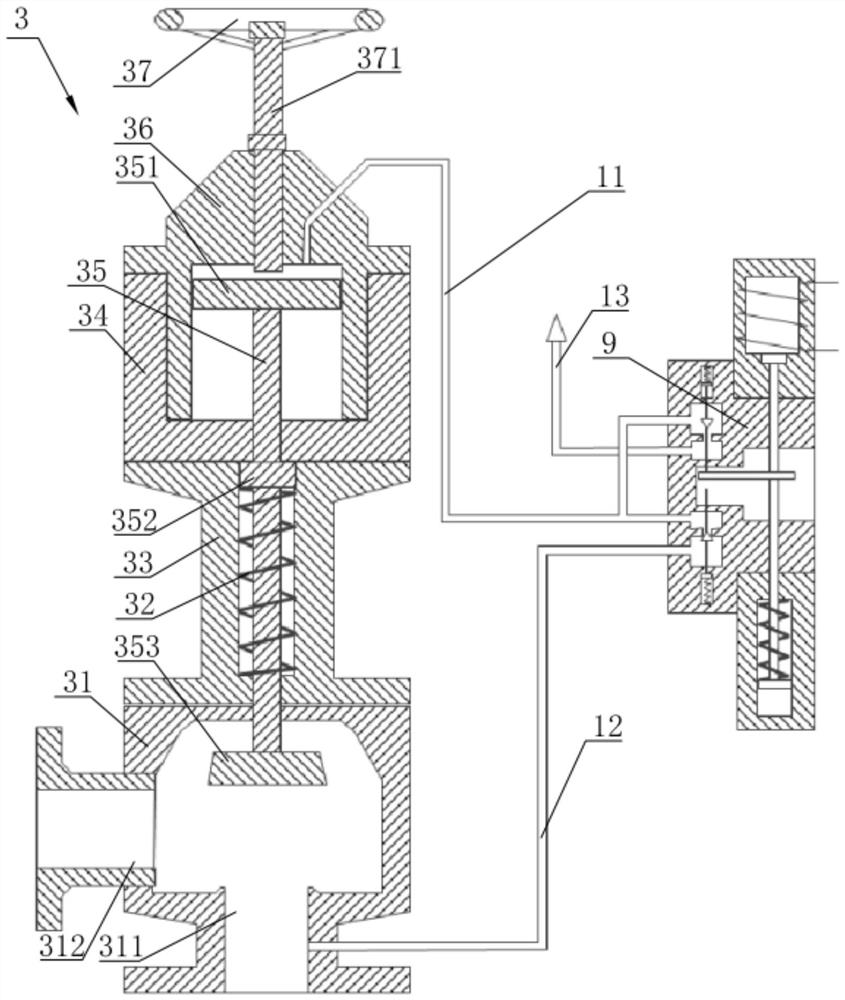

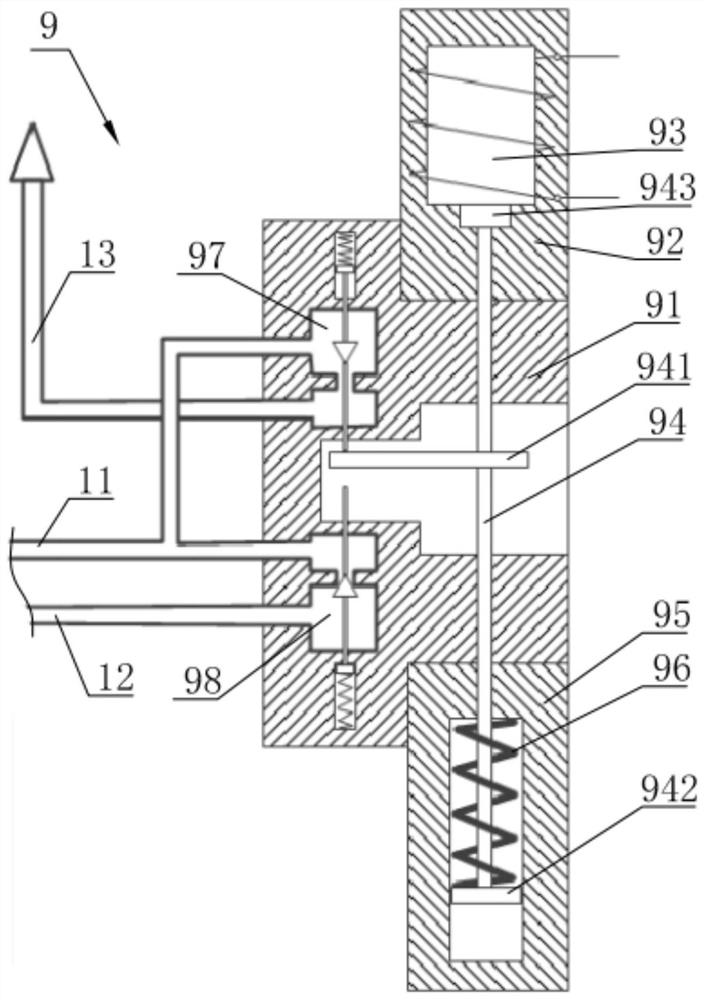

[0035] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0036] Such as figure 2 As shown, the self-operated side valve with power-off protection function in this embodiment includes a lower valve seat 31, which is provided with a flow port 1 311 and a flow port 2 312, and a top valve seat 31 is installed above the lower valve seat 31. The upper valve seat 34 of the opening, passes down from the upper valve seat 34 to the lower valve seat 31 and the main valve stem 35 is installed. The main valve stem 35 is located directly above the flow port one 311. Bonnet 36; also includes pilot valve 9, such as image 3 As shown, the pilot valve 9 includes an on-off valve 1 97 and an on-off valve 2 98 arranged at intervals opposite to each other. The opening and closing states of the on-off valve 1 97 and the on-off valve 2 98 are opposite. A push rod 941 is installed between the two off-valve valves 98,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com