Floating type pipe clamp mounting device and pipe clamp mounting method

An installation device, floating technology, applied in the direction of pipes/pipe joints/fittings, pipe supports, pipe laying and maintenance, etc., can solve the problems of difficult installation of pipes and pipe clamps, and the inability of maintenance ships to enter the site, etc., to achieve low cost and cost , The effect of short construction preparation time and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

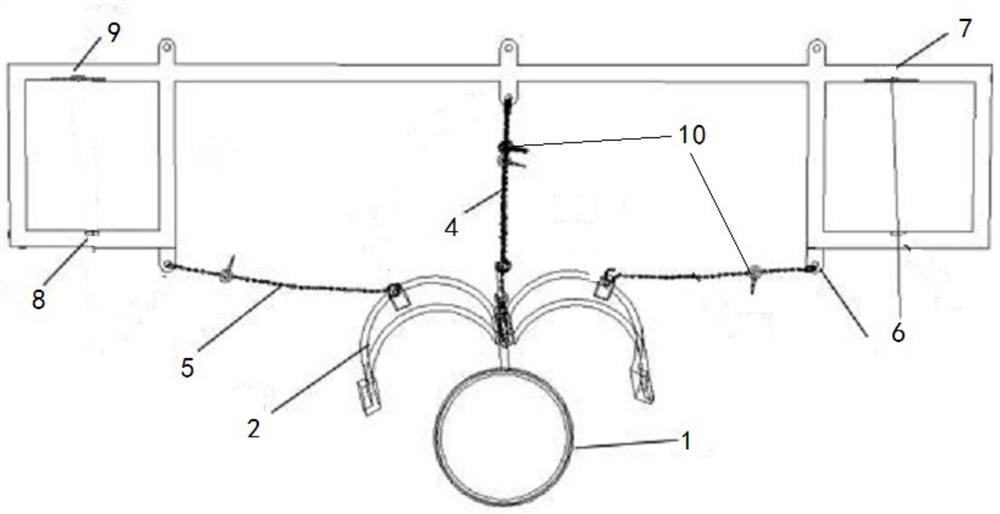

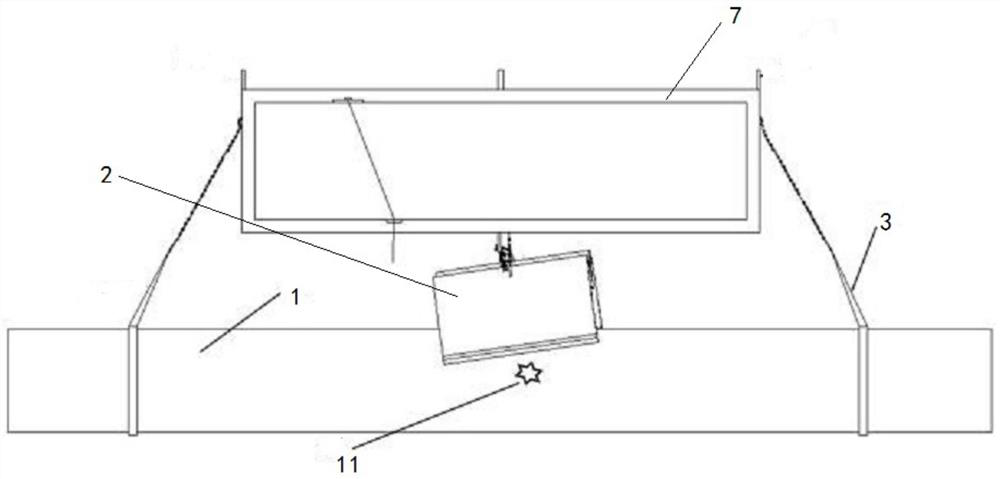

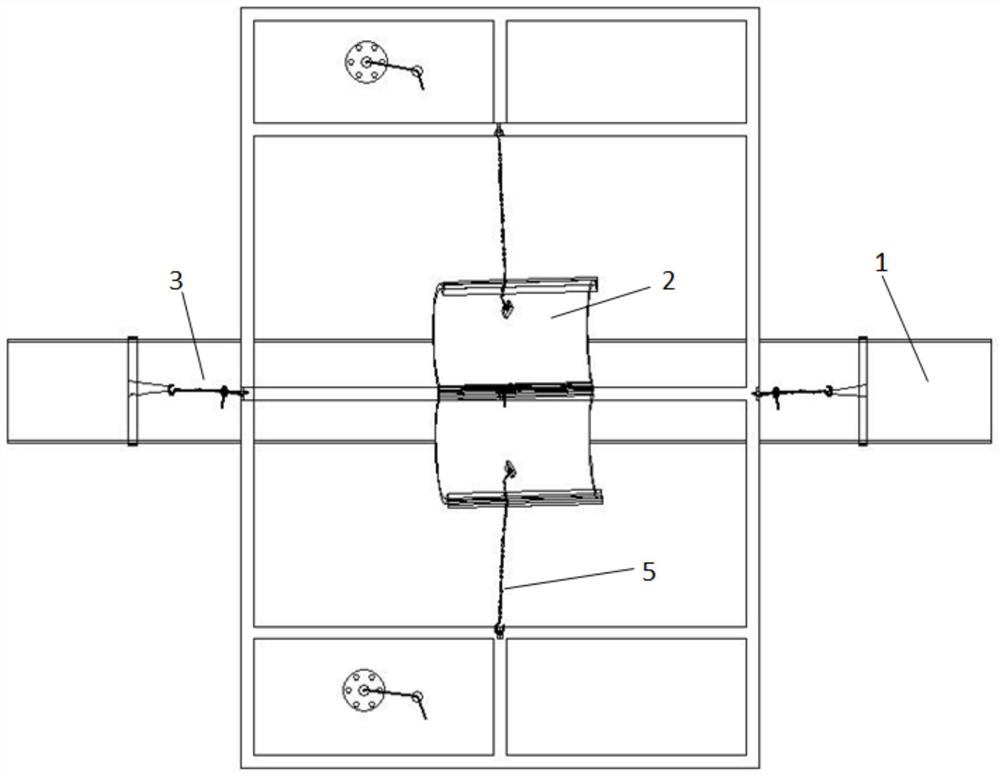

[0022] Example 1, such as Figure 1 to 4 As shown, the present invention discloses a specific implementation of each step of a floating tube mounting device as follows: The floating tube mounting device includes a stent 7, and both ends of the bracket 7 are provided with a floating box 6, and the two floating boxes 6 are tubes. Card mounting work area, bracket 7 on the pipe card installation work area, with pipe fixing rope 3, tube card adjustment rope 5, and tube card hoisting rope 4, and each rope is installed with hand plate hoist to adjust the elongation of the rope length.

[0023] Specifically, the stent 7 is a steel frame structure, which is welded from two main beams and several support beams, and the bracket 7 is provided, and the floating box 6 is mounted in the sub-frame. When the mounting point water depth is greater than 1.5 meters, the floating box 6 and the sub-frame are disposed below the bracket 7; when the mounting point water depth is less than 1.5 meters, the fl...

Example Embodiment

[0029] Embodiment 2, the present invention also discloses a method of mounting a tube card method on a damage to the conduit, and (1) selects a floating box 6, produces a floating box 6, and produces a stent 7; (2) according to mounting points. Water depth and tube card mounting area size, determine the size of the pipe fixing rope 3 and the handle of hoist 10; (3) Creating a suitable lifting point according to the weight of the tube card and the predictive traction angle; (4) according to the mounting point The water depth determines the position of the floating box 6; (5) Select the appropriate pipe card lifting rope 4 according to the tube card size and weight, the tube card adjustment rope 5 and the size of the handlers 10; (6) Lifting the tube card hoisting 4, tube 4 Card adjustment rope 5 and pipe fixing rope 3 separate and hand plate hoist assembly, and installed on a lifting point; (7) Install the tube card on the tube card lifting rope 4, and then damage the pipe 1 drag t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap