Highway bridge construction supervision reinforcing steel bar spacing detection device

A technology for the spacing of steel bars and highway bridges. It is used in mechanical gap measurement and other directions. It can solve the problems of difficult tape measure end fixing, prone to errors, and small space between steel bars, so as to facilitate reading and recording, improve accuracy, and facilitate measurement. effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The application will be described in further detail below in conjunction with all the accompanying drawings.

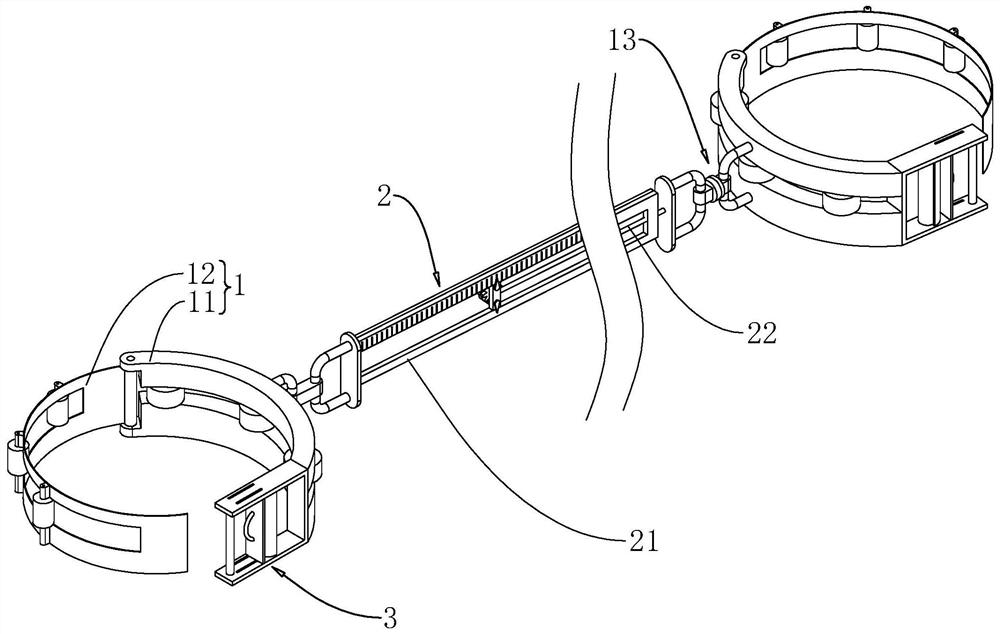

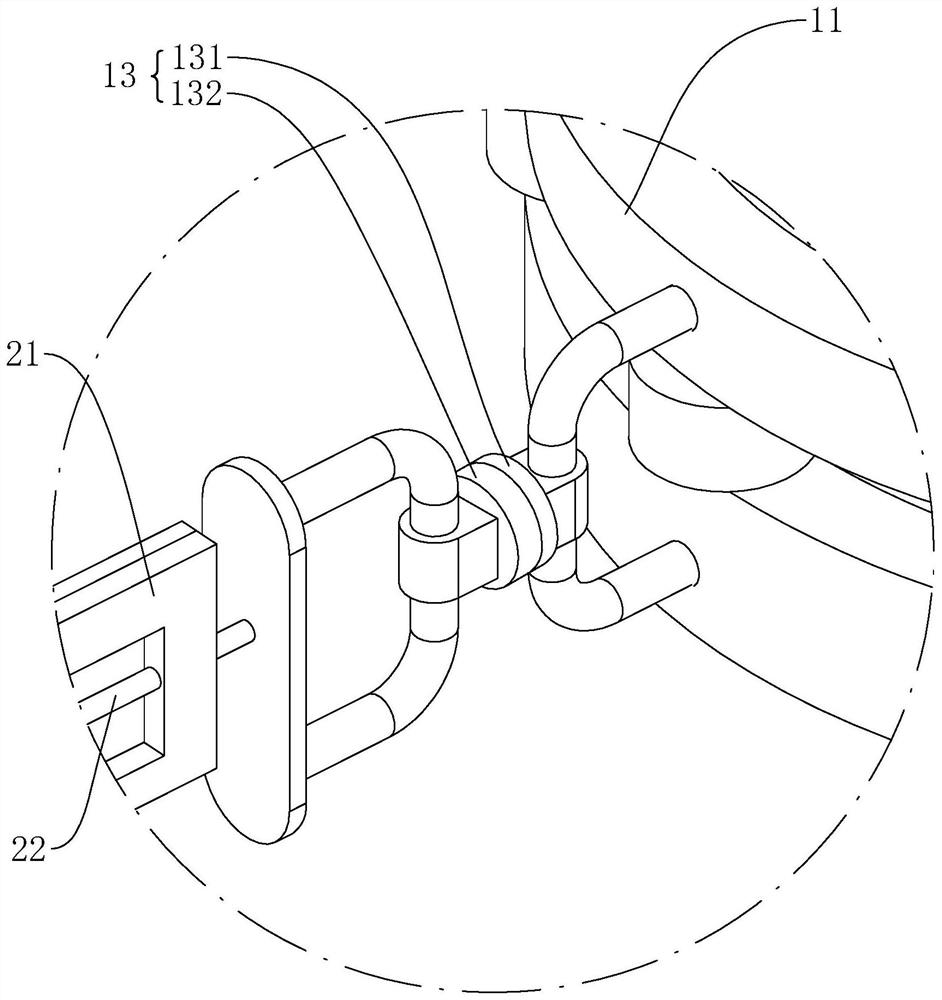

[0039] The embodiment of the application discloses a steel bar spacing detection device for highway bridge construction supervision. refer to figure 1, including two collars 1, the collars 1 are detachably connected to the reinforcement. A measuring mechanism 2 is arranged between the two collars 1 , and the measuring mechanism 2 is used for measuring the distance between the two collars 1 . By installing the collar 1 on the two steel bars, the user can measure the distance between the two steel bars through the measuring mechanism 2 .

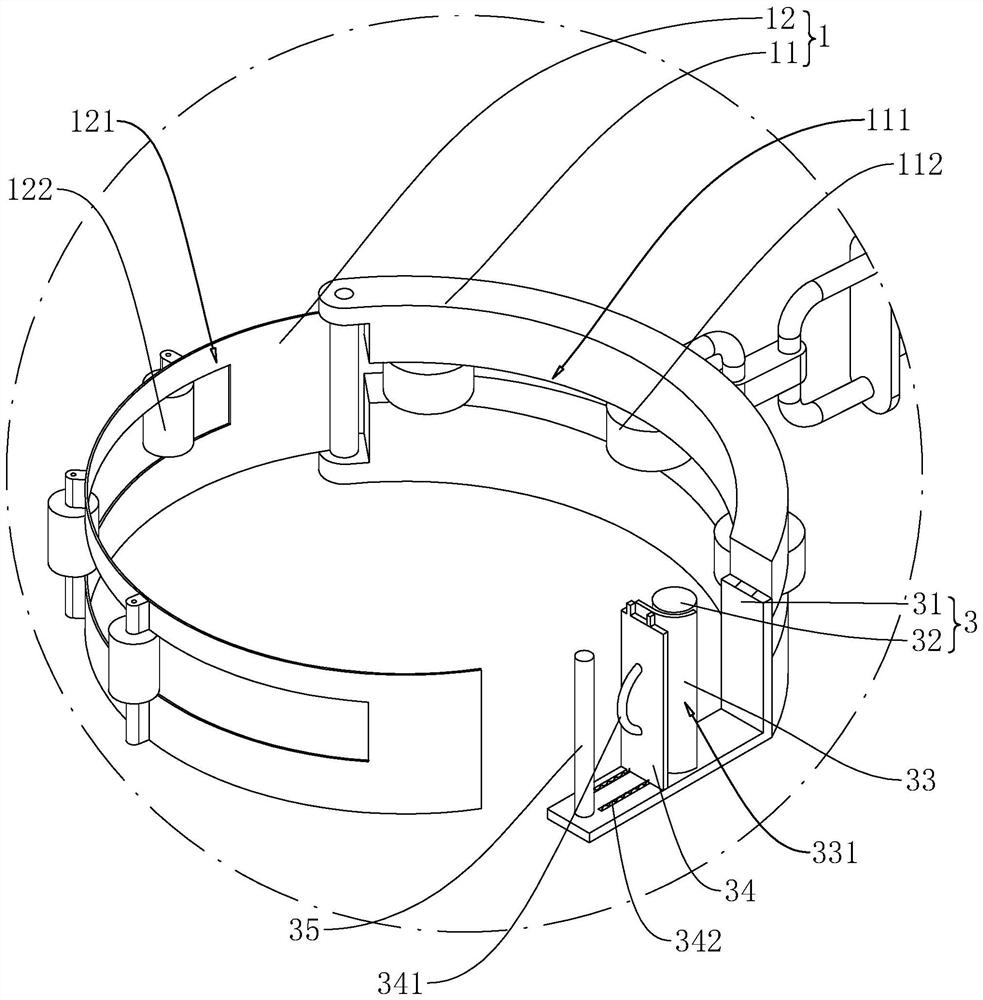

[0040] refer to figure 1 and figure 2 , The collar 1 includes an arc-shaped sleeve 11 and a belt body 12, the cross-section of the arc-shaped sleeve 11 is a sub-arc, and the end of the arc-shaped sleeve 11 away from the center of the arc is connected to the end of the measuring mechanism 2. The belt body 12 has flexibilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com