Method of surface finish for glass substrate for magnetic disk and glass substrate for magnetic disk

一种玻璃基板、表面加工的技术,应用在磁盘用玻璃基板的表面加工和磁盘用玻璃基板领域,能够解决圆度偏差、加工尺寸精度下降、无法得到足够机械强度等问题,达到减少时间及成本、保证尺寸精度和圆度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

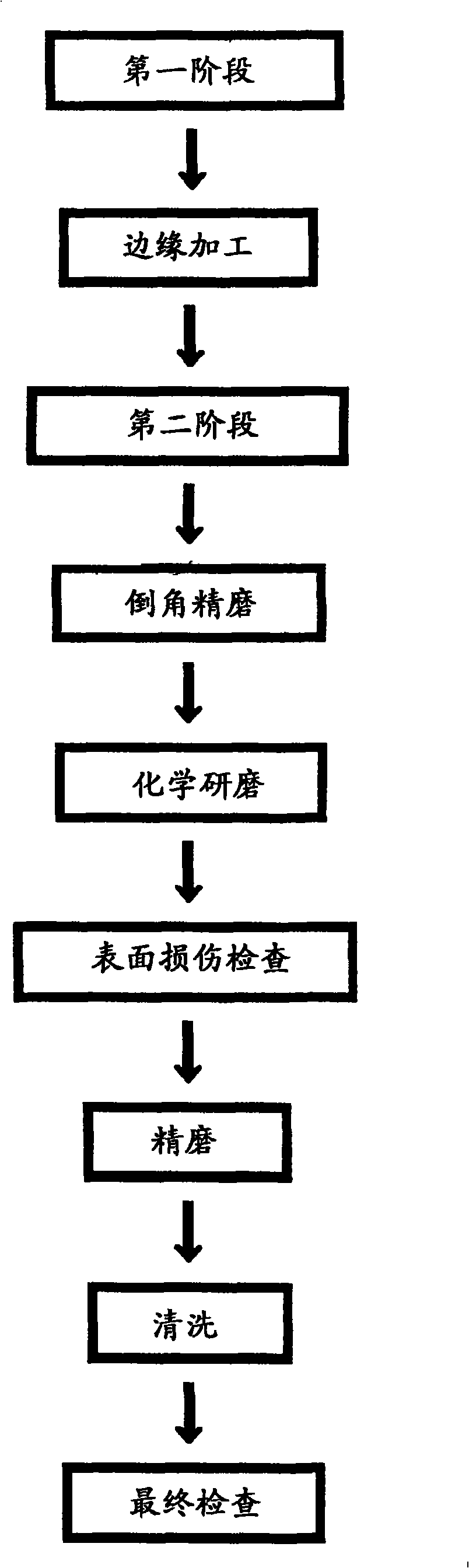

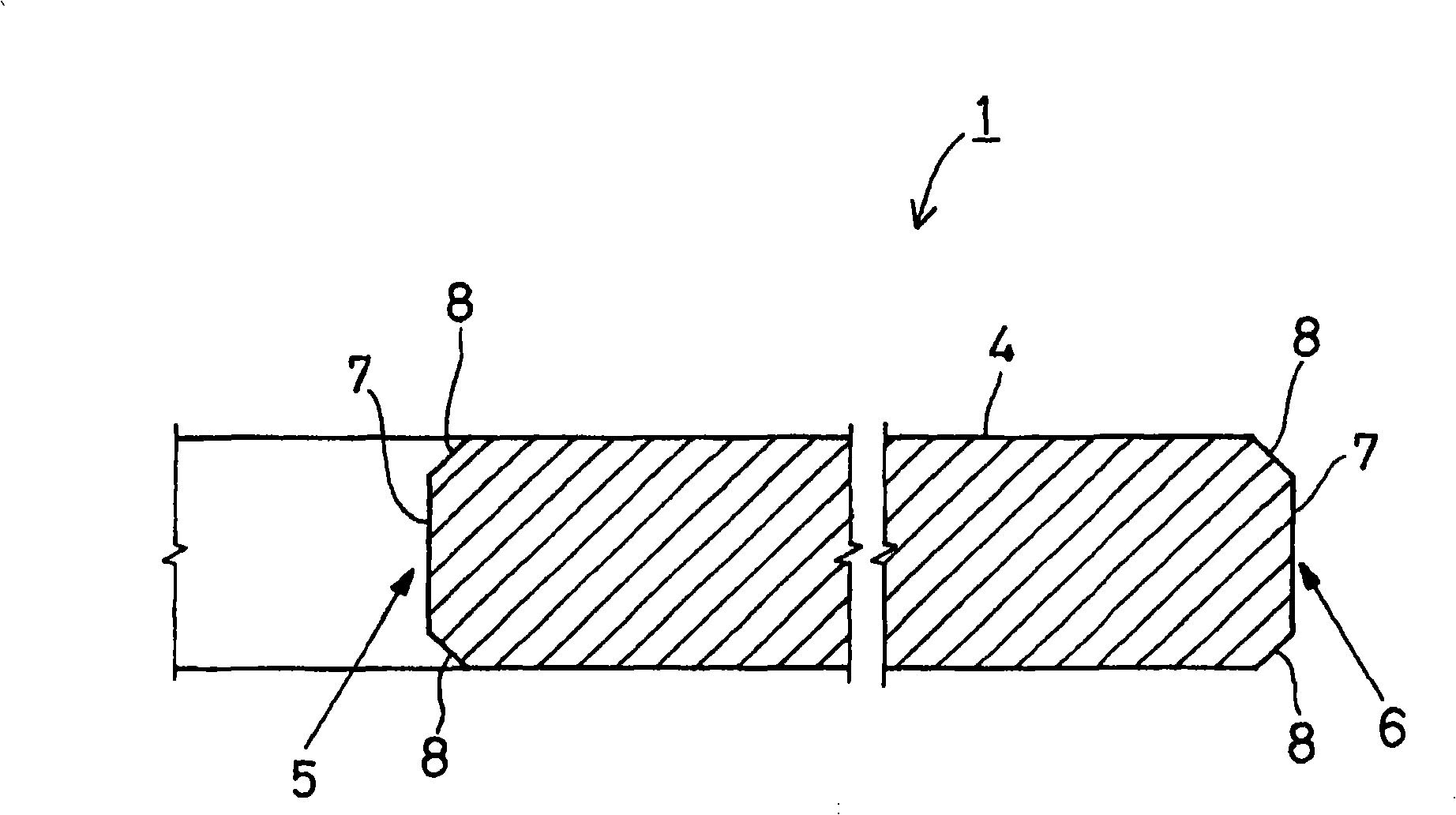

[0052] Carry out the first round of treatment to the soda-lime glass, edge processing, and make it into a ring-shaped green disk with an outer diameter of about 65φmm, an inner diameter of 20φmm, and a thickness of about 0.9mm.

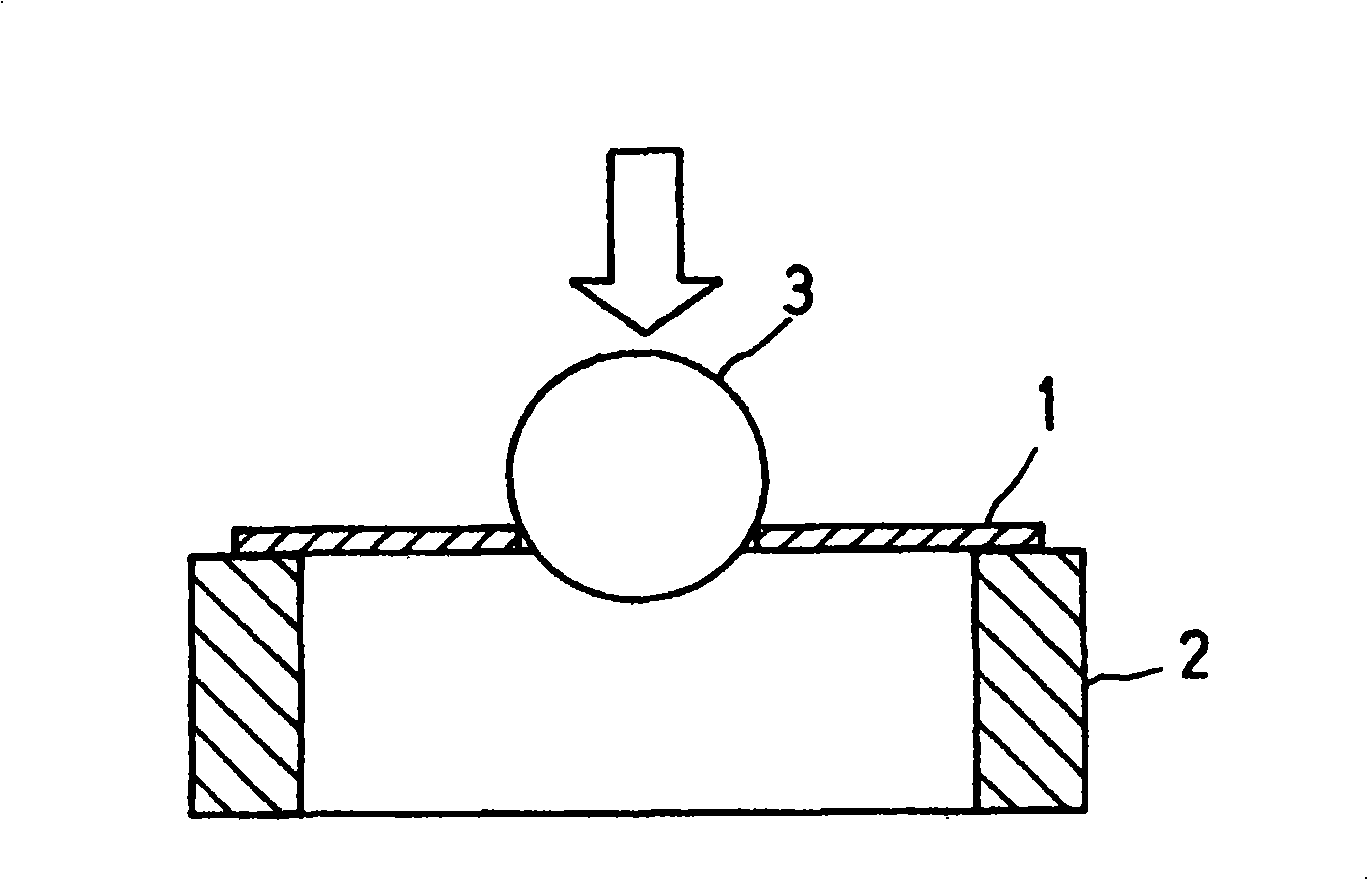

[0053] Subsequently, in the second stage (mechanical grinding of the main surface), the main surface is ground to a surface roughness expressed in Ra of 1 μm or less.

[0054] Subsequently, in the chamfering fine grinding, using a liquid such as an aqueous solution in which free abrasive grains such as cerium oxide with a particle size of several μm or less are dispersed, the abrasive material made of a soft non-woven fabric for grinding is ground. The pad makes rotational contact and sliding contact, and mechanically polishes the end surface of the inner peripheral part. Produce 6 kinds of samples, and the surface roughness of their inner peripheral end faces after mechanical grinding is respectively 2.7 (nm), 5.1 (nm), 9.0 (nm), 15 (nm), 1500 (nm), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com