Computer self-dedusting radiator

A self-dusting and computer technology, applied in the field of computer heat dissipation, can solve the problems such as the difficulty of dust removal of heat dissipation fins, and achieve the effect of small friction coefficient, stable rotation and smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

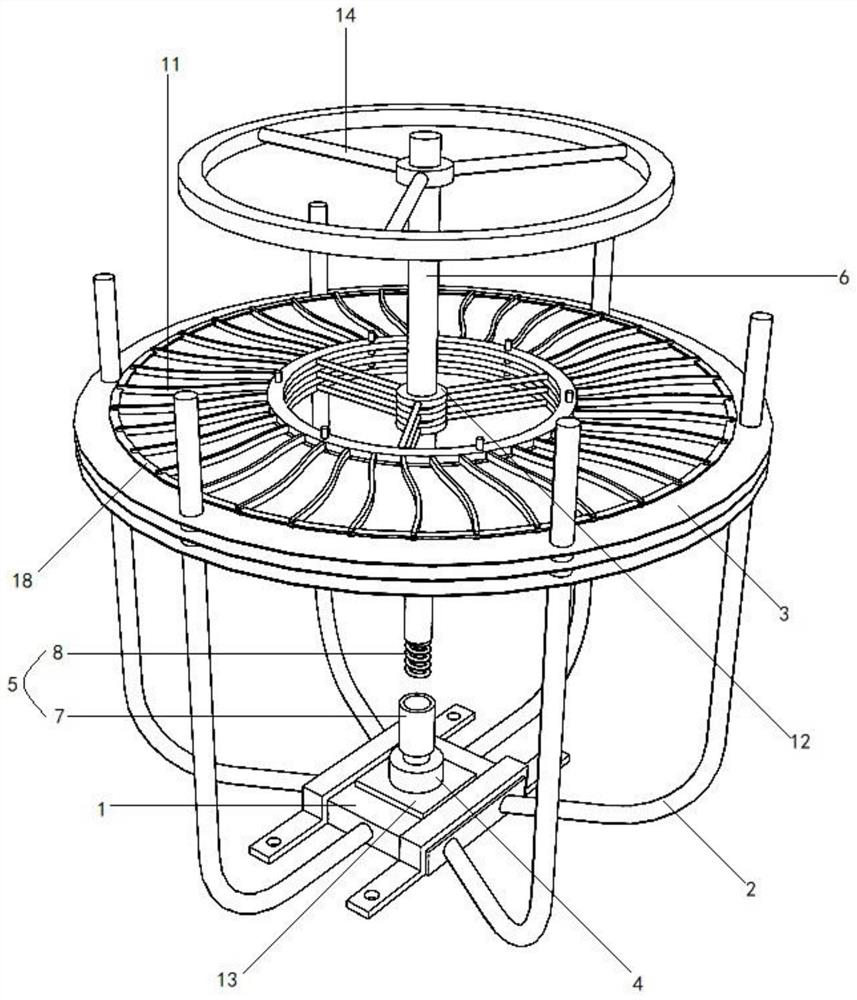

[0022] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

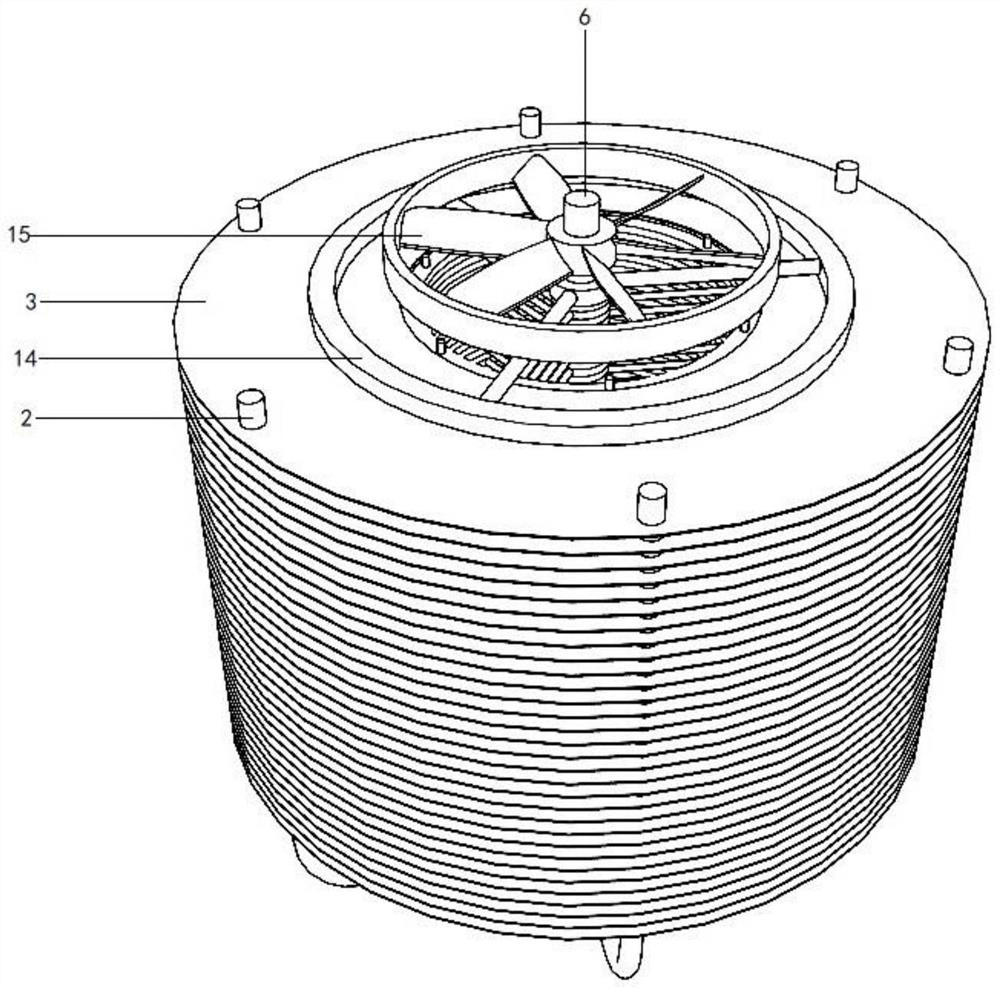

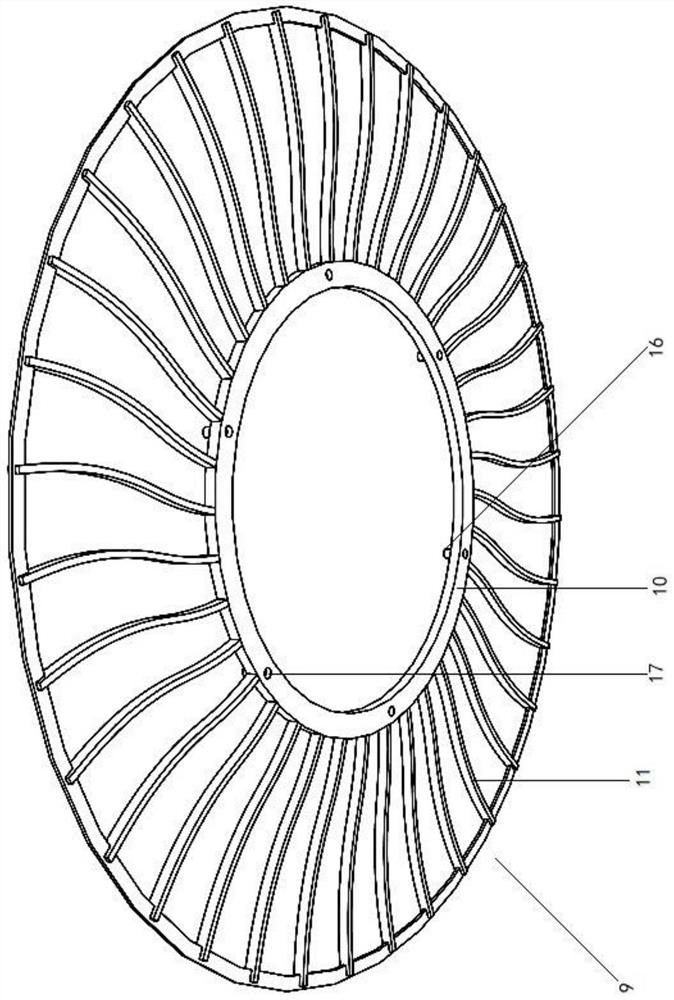

[0023] Such as Figure 1-3 As shown, the computer is self-removing a heat sink, including a thermally conductive base 1, and a heat pipe is uniformly distributed in the circumferential direction, and the heat-conducting base 1 is uniformly distributed well with a cooling fin 3, and the heat dissipation fin 3 is a circle. The ring shape; the upper portion of the heat pipe 2 is sequentially fixed in the outer side of the heat dissipation fin 3; the heat dissipating fin 3 is fixed; the heat-conducting base 1 is mounted on the upper end of the heat conductive base 1, and the driving motor 4 is mounted vertically upward and by the elastic support seat 5 coaxial connection. There is a central axis 6; the elastic support seat 5 includes a sleeve 7 that is attached to the driving motor 4 output; a spring 8 is provided in the sleeve 7; the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com