Device and method for improving box-in structure for noise reduction of converter transformers in operation

A technology of BOX-IN and converter transformers, which is applied in transformer/inductor components, transformer/inductor noise damping, transformer/inductor shells, etc., which can solve the problem of converter transformer electrical safety, fire protection, operation and maintenance. Satisfies and affects the "BOX-IN" noise reduction effect, the low height of the neutral point bushing, etc., and achieves the effect of facilitating the safe charging distance of the equipment and maintenance operations, improving the heat dissipation effect, and optimizing the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is a further description of the present invention, rather than a limitation of the present invention.

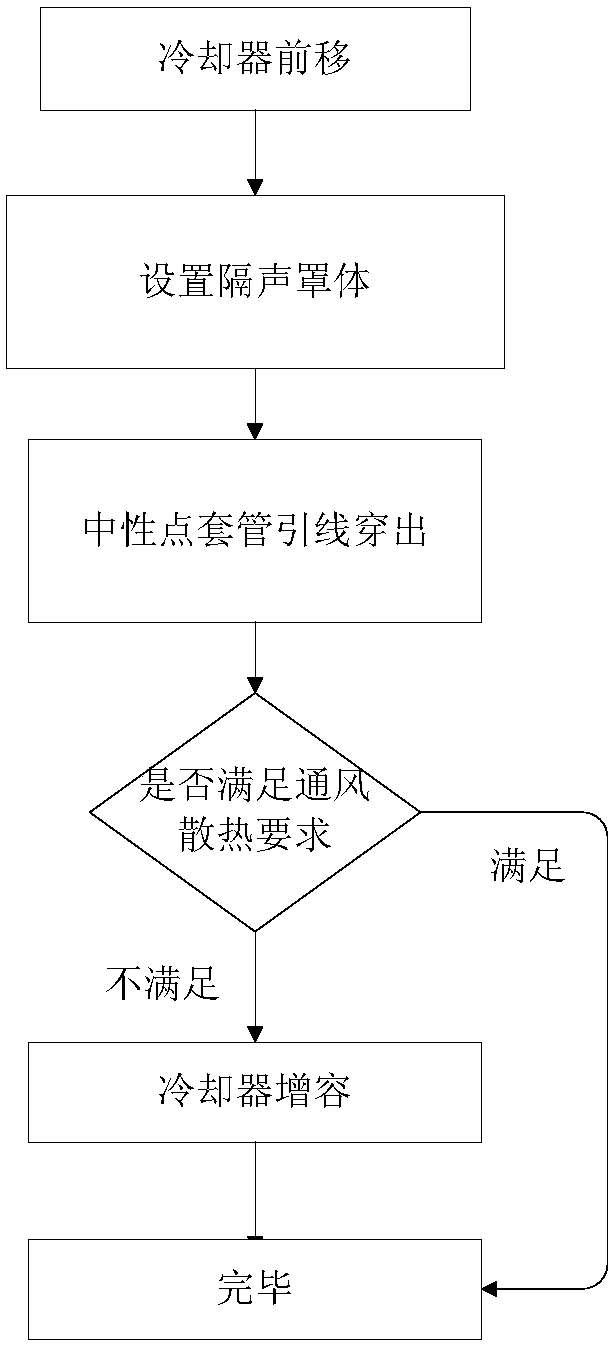

[0039] like figure 1 The shown method for improving the BOX-IN structure for noise reduction of the put into operation converter transformer includes the following steps:

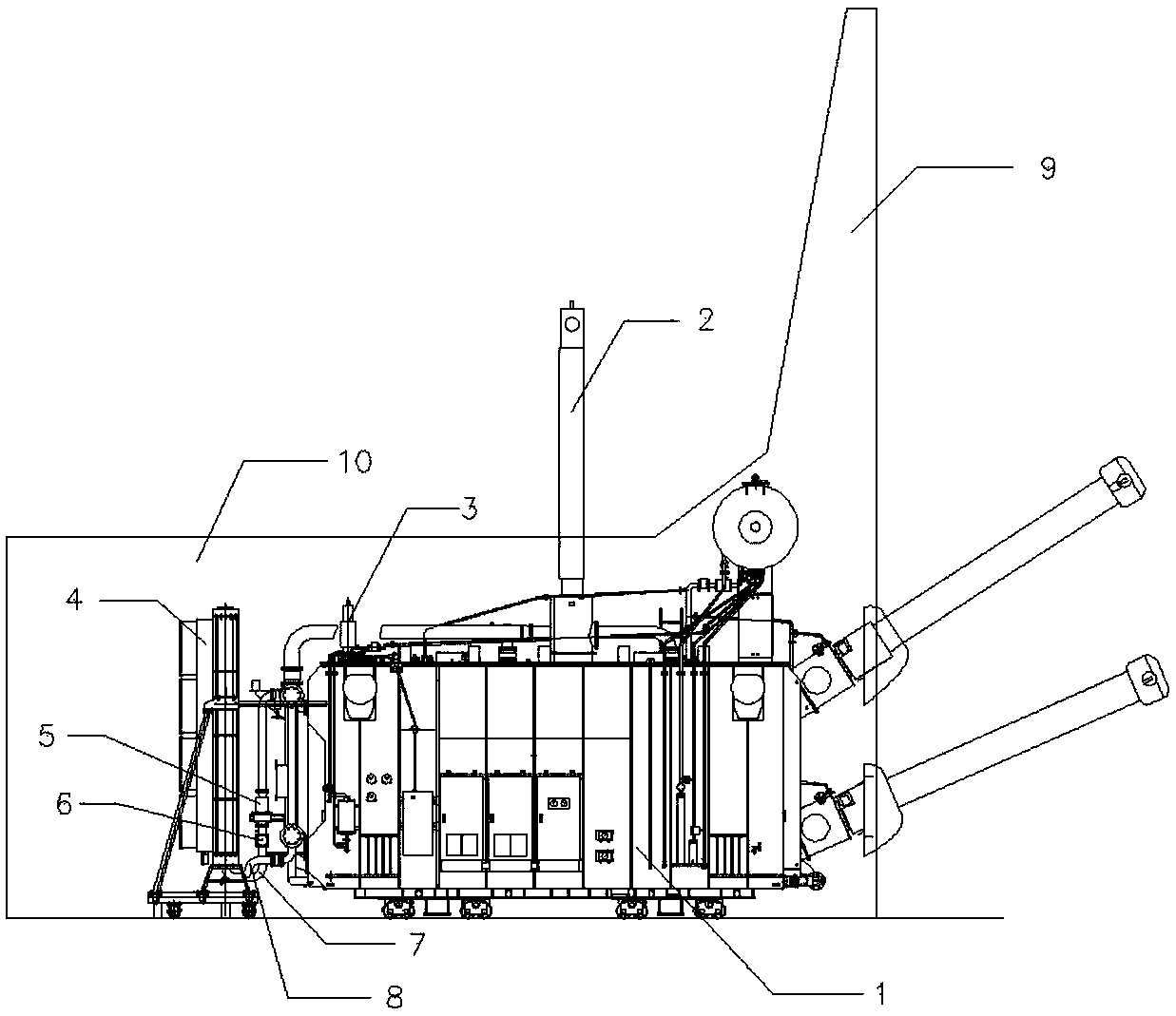

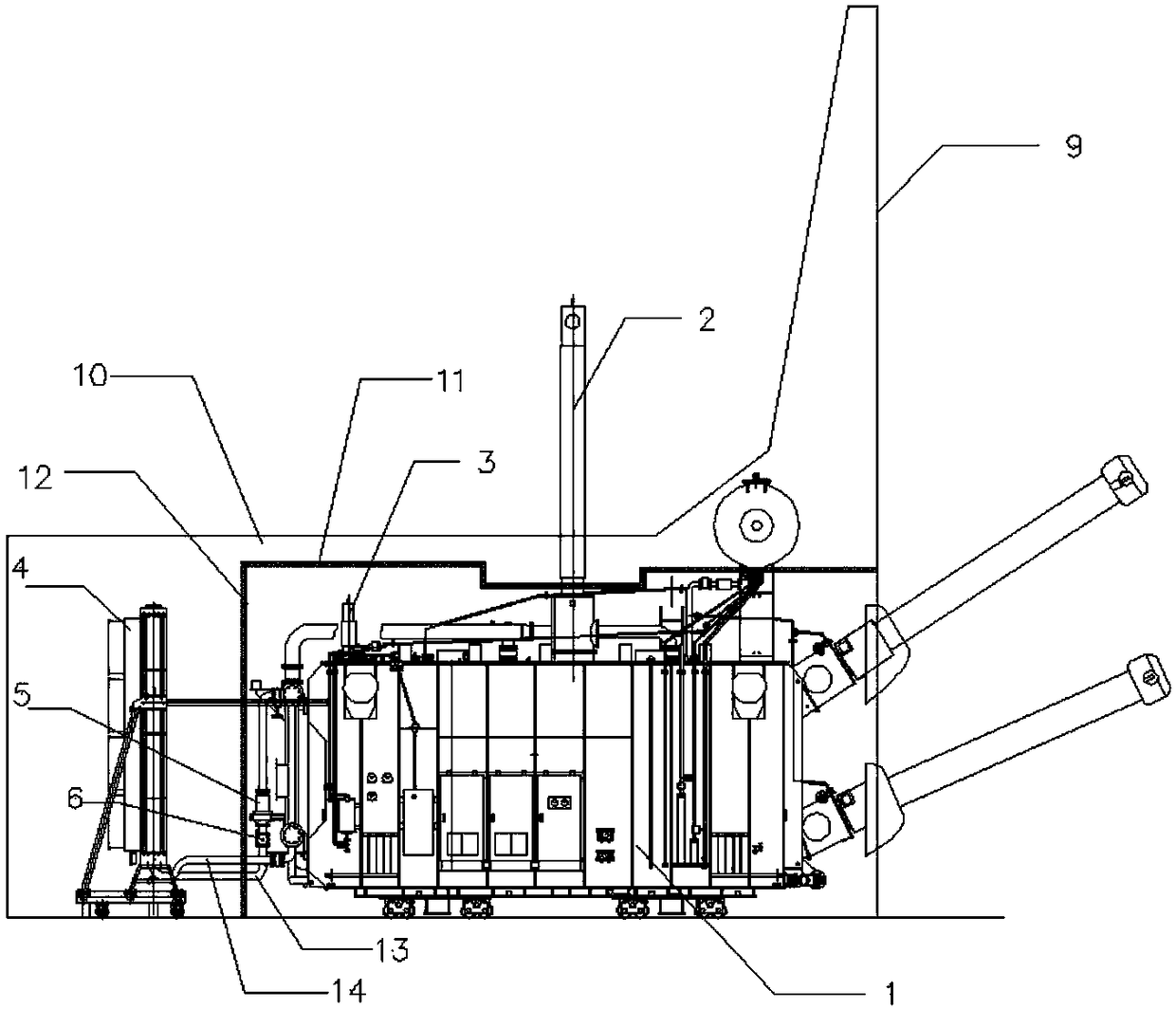

[0040] 1) The cooler is moved forward, such as Figure 2-3 As shown, by replacing the original converter transformer oil inlet pipe 7 under the oil pump 5 and the oil flow relay 6, the oil inlet pipe 13 of the converter transformer is extended, and the oil outlet pipe 8 of the original converter transformer is replaced to extend the output of the converter transformer. The oil connecting pipe 14 increases the distance between the converter transformer body 1 and the cooler 4 . Preferably, the forward distance of the cooler is greater than the distance between the original cooler and the main body of the converter transformer. Replace the inlet and outlet oil connecting pipes of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com