Combined capacitor

A capacitor and combined technology, which is applied in the field of capacitance, can solve the problems of deviation feeding, accidental collision of capacitor core, and low accuracy of tin feeding position of the bracket, so as to achieve the effect of strengthening the connection relationship and ensuring the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

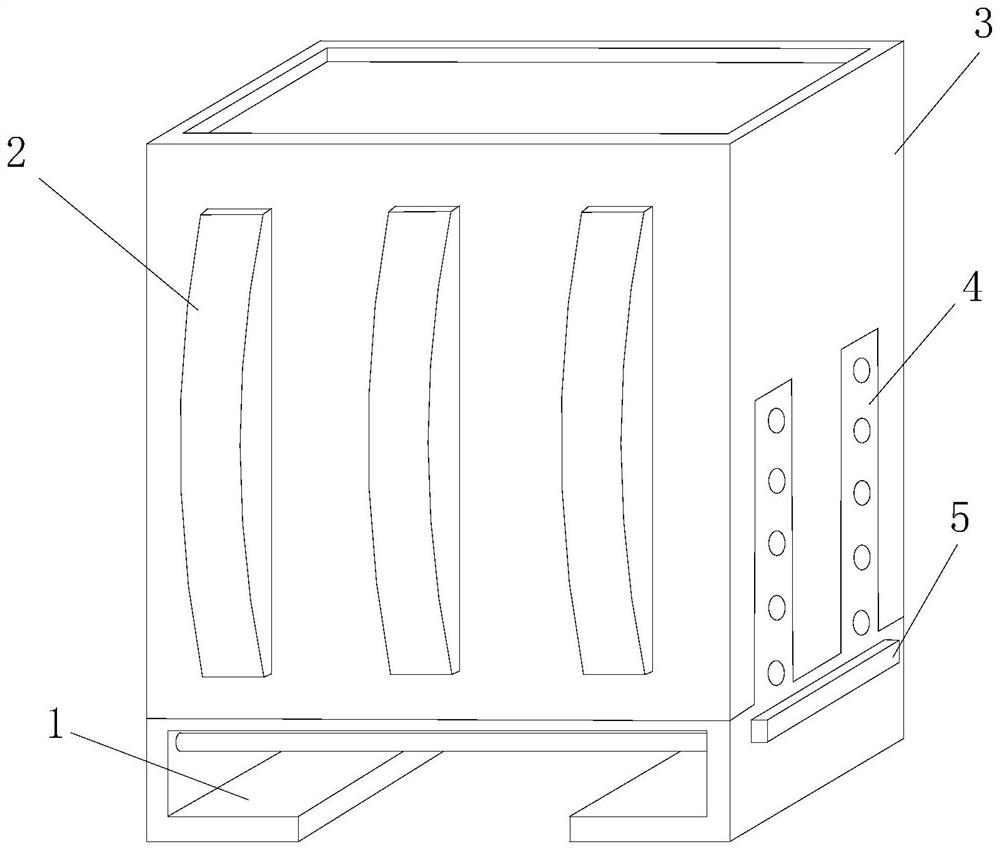

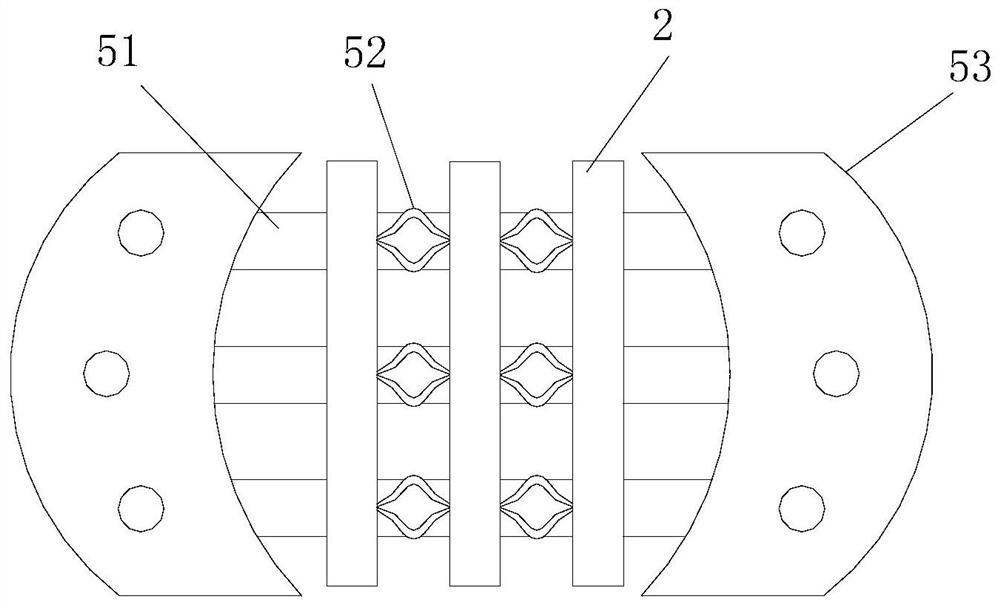

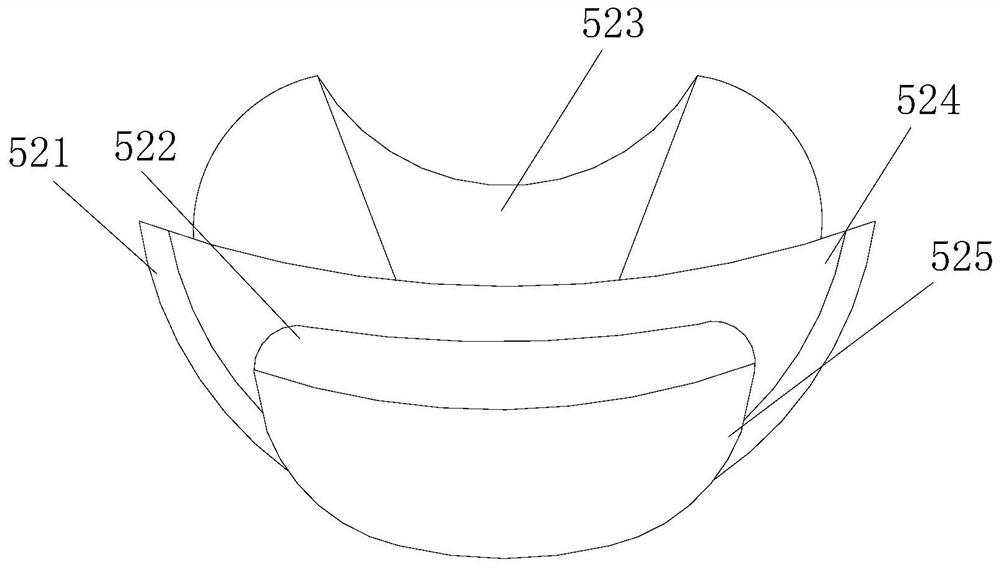

[0029] Such as Figure 1-Figure 4 As shown, the present invention provides a combined capacitor, the structure of which includes a base 1, a capacitor core 2, a main body 3, an exhaust net 4, and a receiving seat 5. The base 1 is fixedly connected to the bottom of the main body 3, and the main body 3 One side is embedded and connected with an exhaust net 4, and the inside of the main body 3 is equipped with a capacitor core 2 and a receiving seat 5. The receiving seat 5 includes a circuit board 51, a bracket 52, and a frame buckle 53, and the frame buckles 53 are fixed. A circuit board 51 is connected, and a bracket 52 is installed between the circuit board 51 and the capacitor core 2, and the bracket 52 includes a touch frame 521, a collar plate 522, a booster assembly 523, a basin 524, and a touch package 525 , the touch frame 521 is embedded and connected to the circuit board 51 through the touch package 525, the touch package 525 is fixedly connected with the collar plate ...

Embodiment 2

[0031] Such as Figure 5-Figure 8 As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components. The straightening piece 234 includes a sliding block 341, an outer limit layer 342, a top file 343, an end sleeve clamp 344, and a pressing buckle 345 The sliding block 341 is in oblique sliding contact with the inner side of the partition 524, and both sides are fixedly connected with a pair of pressing buttons 345, and the bottom of the pair of pressing buttons 345 is sleeved and connected with a top file 343, and the top file 343 is movable. Closed inside the protective clip 233, and its bottom is embedded with an outer limit layer 342, the outer limit layer 342 is hingedly connected to the bottom of the basin 524, and the square part 234 includes a check and balance structure 351, a limit antenna 352, and a side wing 353 , a pendulum ball 354, a balance structure 351 is installed vertically in the middle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com