A kind of lithium ion energy storage device, its pre-lithiation, and preparation method

A lithium-ion, pre-lithiation technology, applied in the direction of structural parts, electrical components, final product manufacturing, etc., can solve the problems of increasing manufacturing costs, difficulty in coating tutorials, increasing manufacturing costs, etc., to avoid changes in battery thickness and manufacturing process. Simple and controllable, reducing the effect of pre-lithiation internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] According to another aspect of the present invention, a preparation method for preparing a lithium ion energy storage device is also proposed, comprising the following steps:

[0045] Step 1) coating or rolling the negative electrode slurry on the current collector to prepare a negative electrode sheet;

[0046] Step 2) coating or rolling the positive electrode slurry on the current collector to prepare a positive electrode sheet;

[0047] Step 3) preparing the prepared positive electrode sheet, negative electrode sheet and electrolyte or separator into a battery cell;

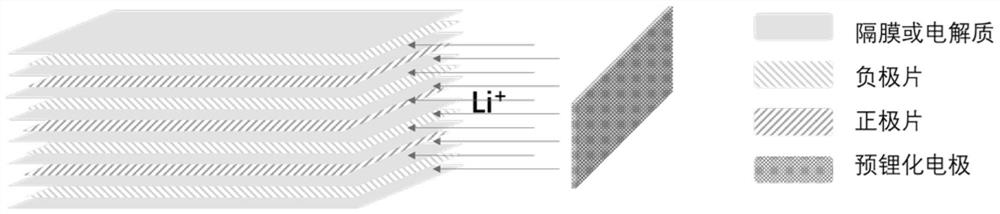

[0048] Step 4) pre-lithiation electrodes are arranged at a predetermined distance outside the cell and in the vertical direction of the positive and negative electrode sheets;

[0049] Step 5) injecting liquid into the energy storage device;

[0050] Step 6) Charge or discharge the pre-lithiation electrode, the positive electrode and the negative electrode, and perform pre-lithiation, so that the lith...

Embodiment 1

[0055] According to Embodiment 1 of the present invention, a method for preparing the above-mentioned lithium ion energy storage device is provided, and further pre-lithiation is performed, which specifically includes: mixing graphite, hard carbon, and carbon black in a mass ratio of 80:10:5 and an appropriate amount of sodium carboxymethyl cellulose solution, styrene-butadiene rubber emulsion and an appropriate amount of deionized water to prepare a negative electrode slurry for lithium ion batteries, and the slurry was extruded and coated on a copper foil with a thickness of 6um without through holes. , dried at 120°C and rolled to a suitable areal density, and then cut into a lithium-ion battery negative electrode sheet with a size of 70*105mm. Lithium-ion battery cathode slurry was prepared with the mass ratio of 12 μm and an appropriate amount of nitrogen-methylpyrrolidone. The slurry was extruded and coated on a 12um-thick aluminum foil without through-holes, dried at 120...

Embodiment 2

[0057] According to Embodiment 2 of the present invention, another method for preparing the above-mentioned lithium ion energy storage device is provided, and further pre-lithiation is performed, specifically comprising: mixing hard carbon and carbon black in a mass ratio of 90:5 and an appropriate amount of Sodium carboxymethyl cellulose solution, styrene-butadiene rubber emulsion and an appropriate amount of deionized water were used to prepare lithium-ion battery negative electrode slurry. After drying at ℃ and rolling to a suitable surface density, it is cut into a lithium-ion battery negative electrode sheet with a size of 70*105mm, and the activated carbon material, carbon black, and polyvinylidene fluoride are mixed in a mass ratio of 80:10:10 and an appropriate amount of nitrogen. - Methyl pyrrolidone is prepared as a positive electrode slurry for lithium ion batteries. The slurry is extruded and coated on an aluminum foil with a thickness of 12um without through-holes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com