Patents

Literature

30results about How to "Prevent thickness variation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

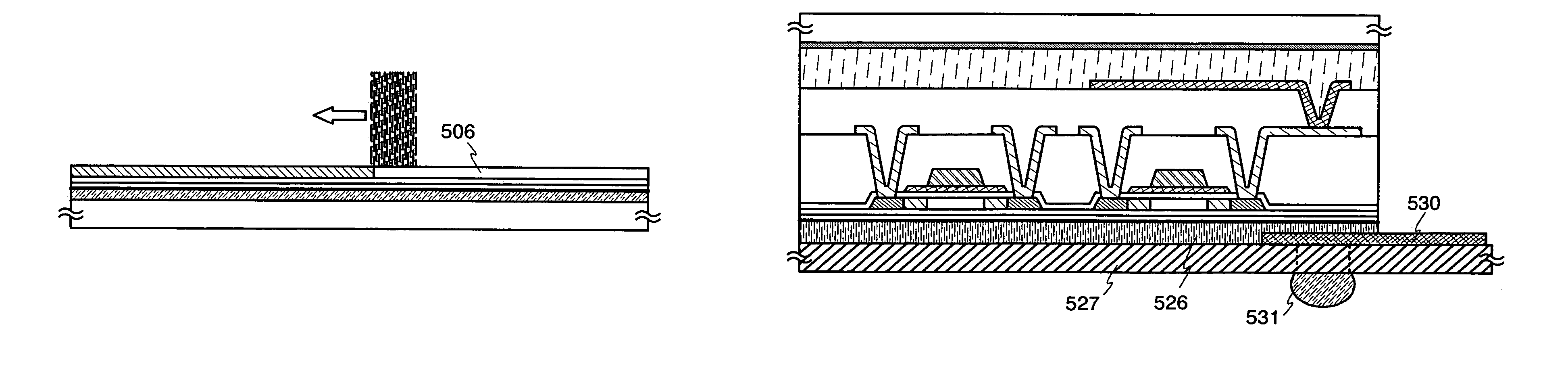

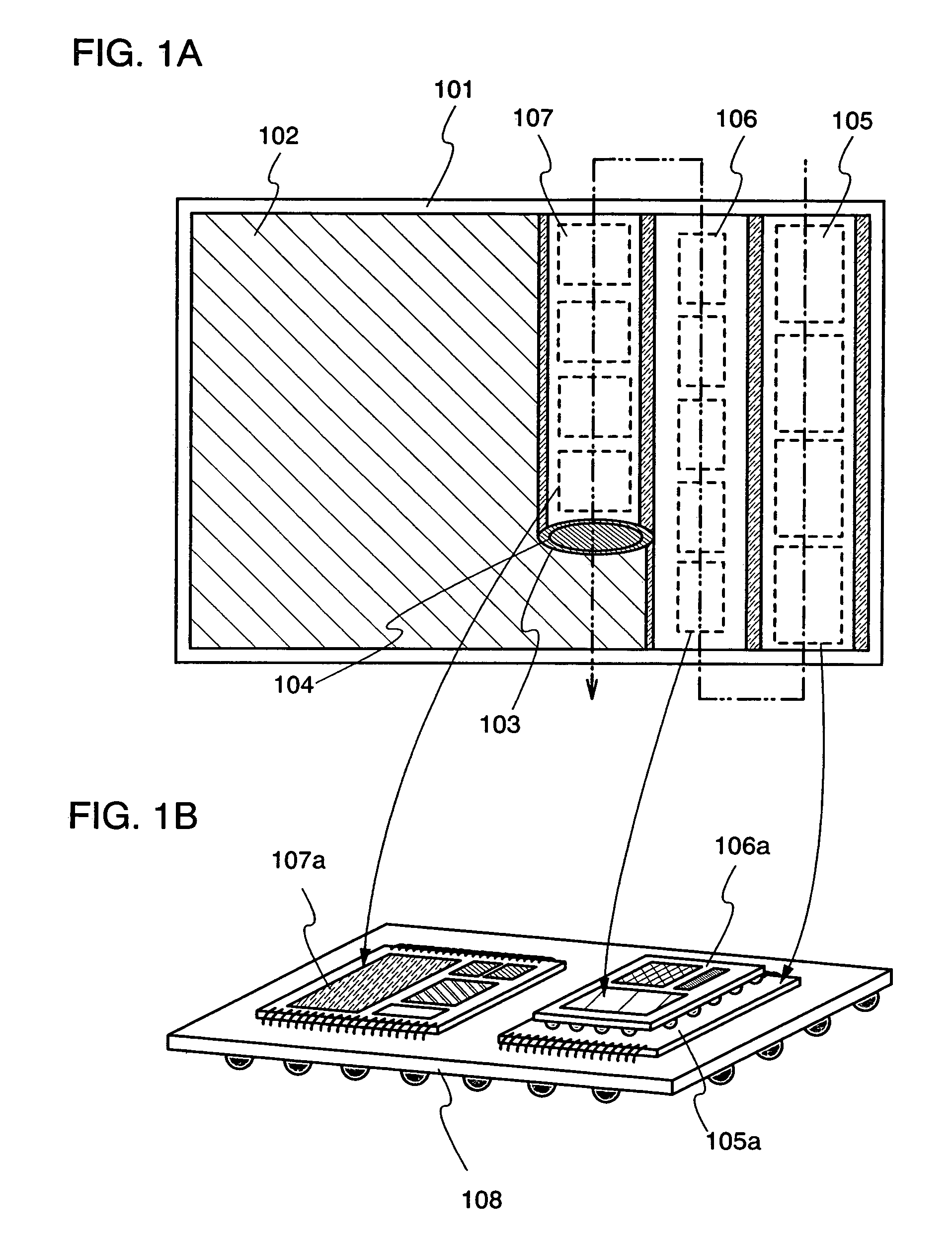

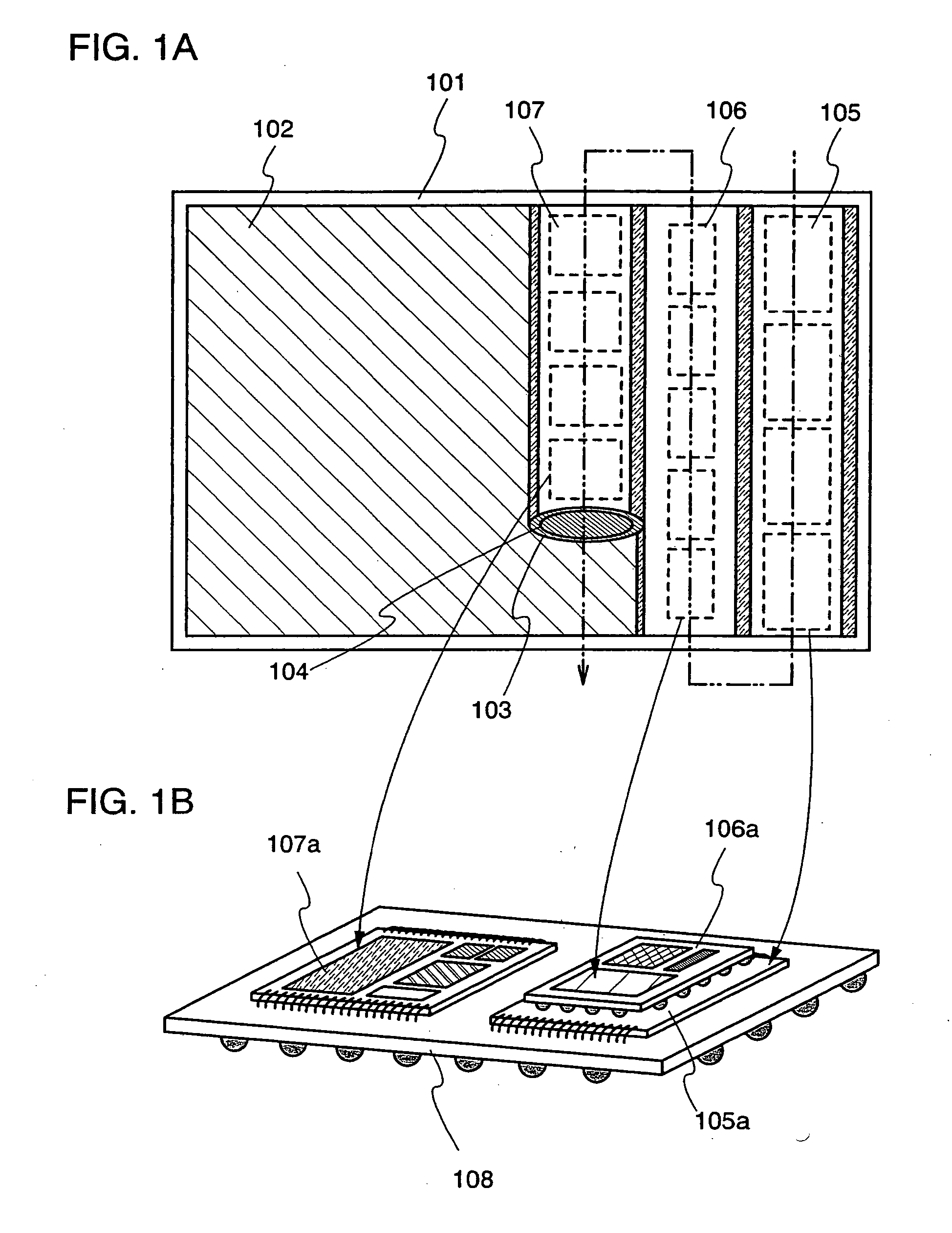

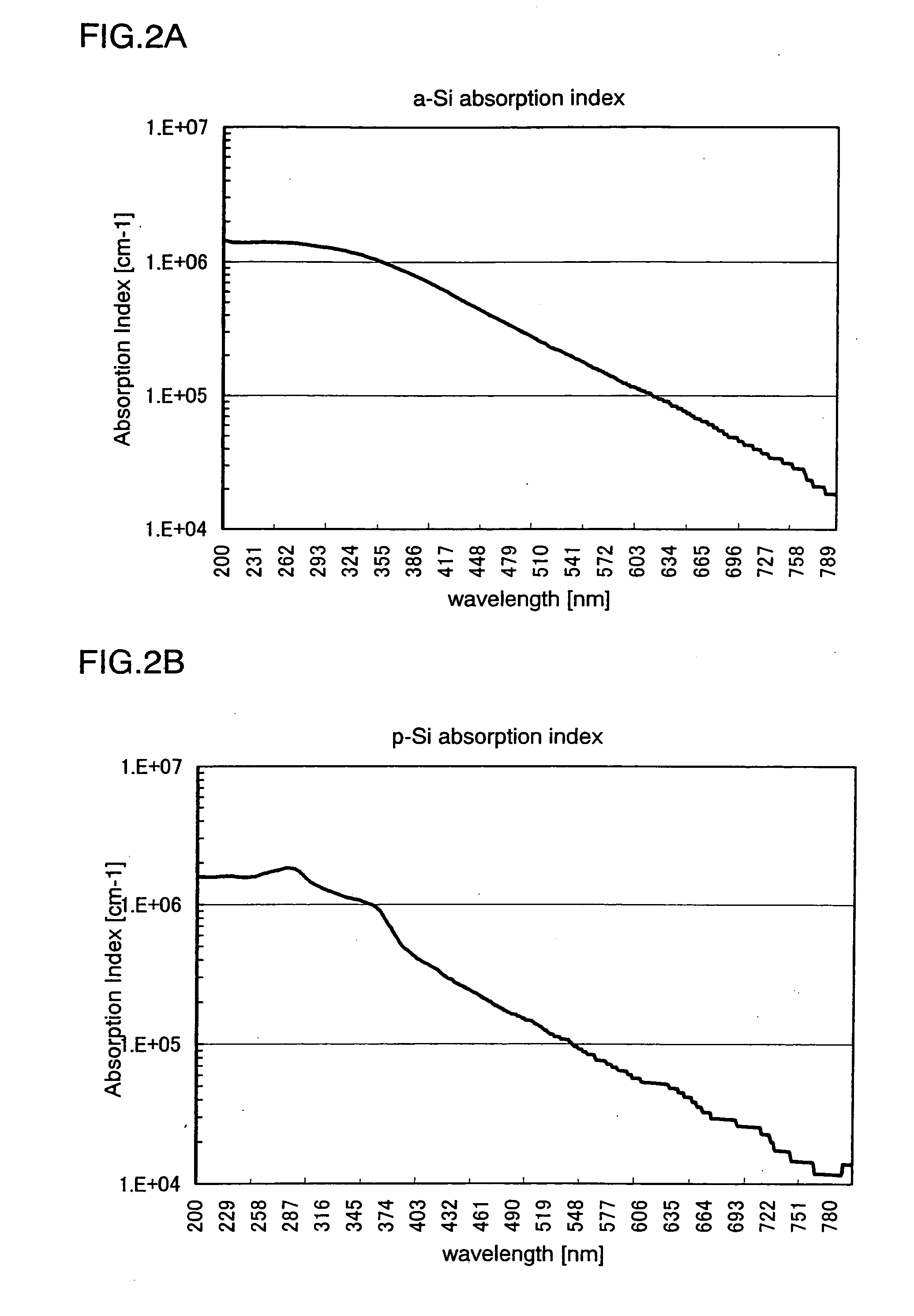

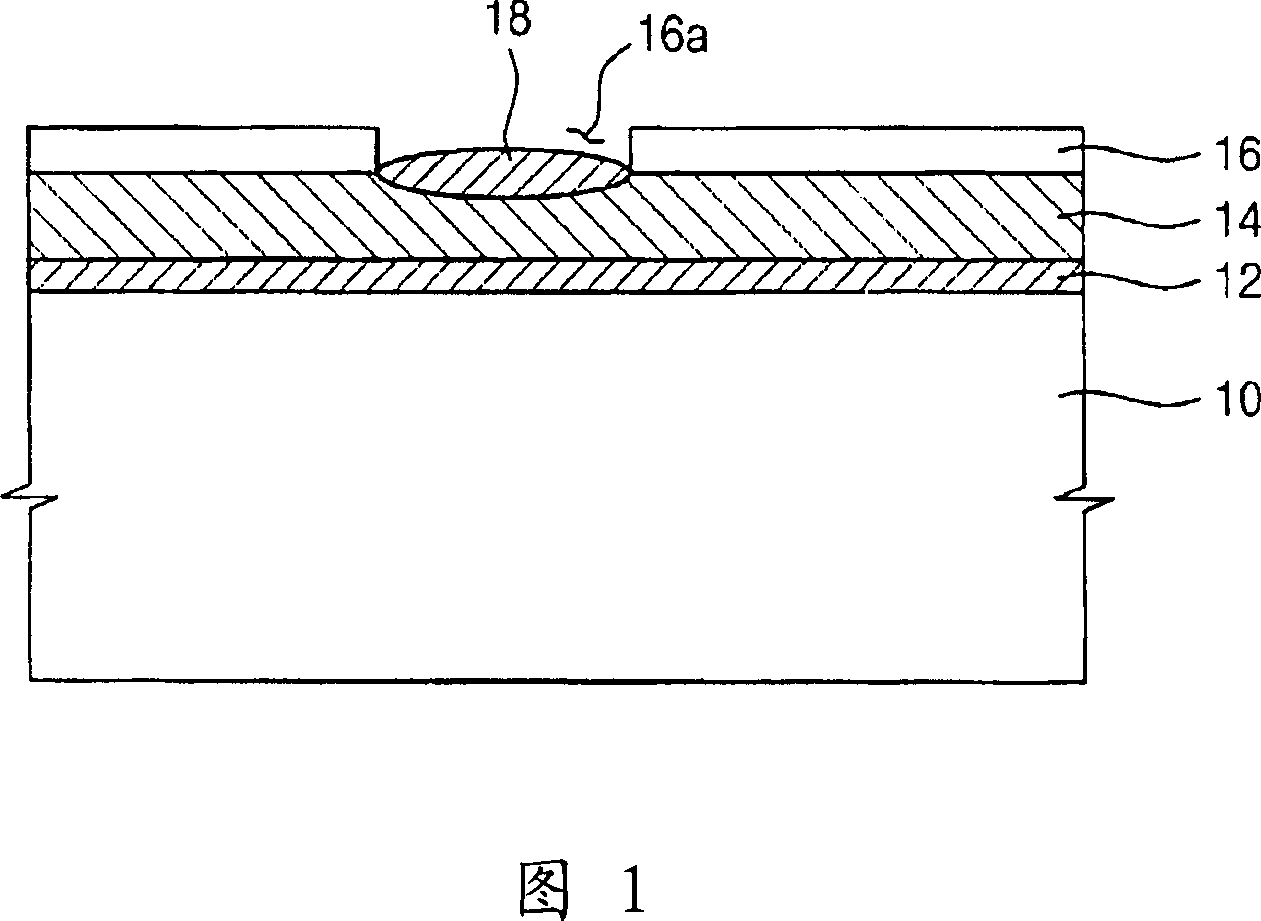

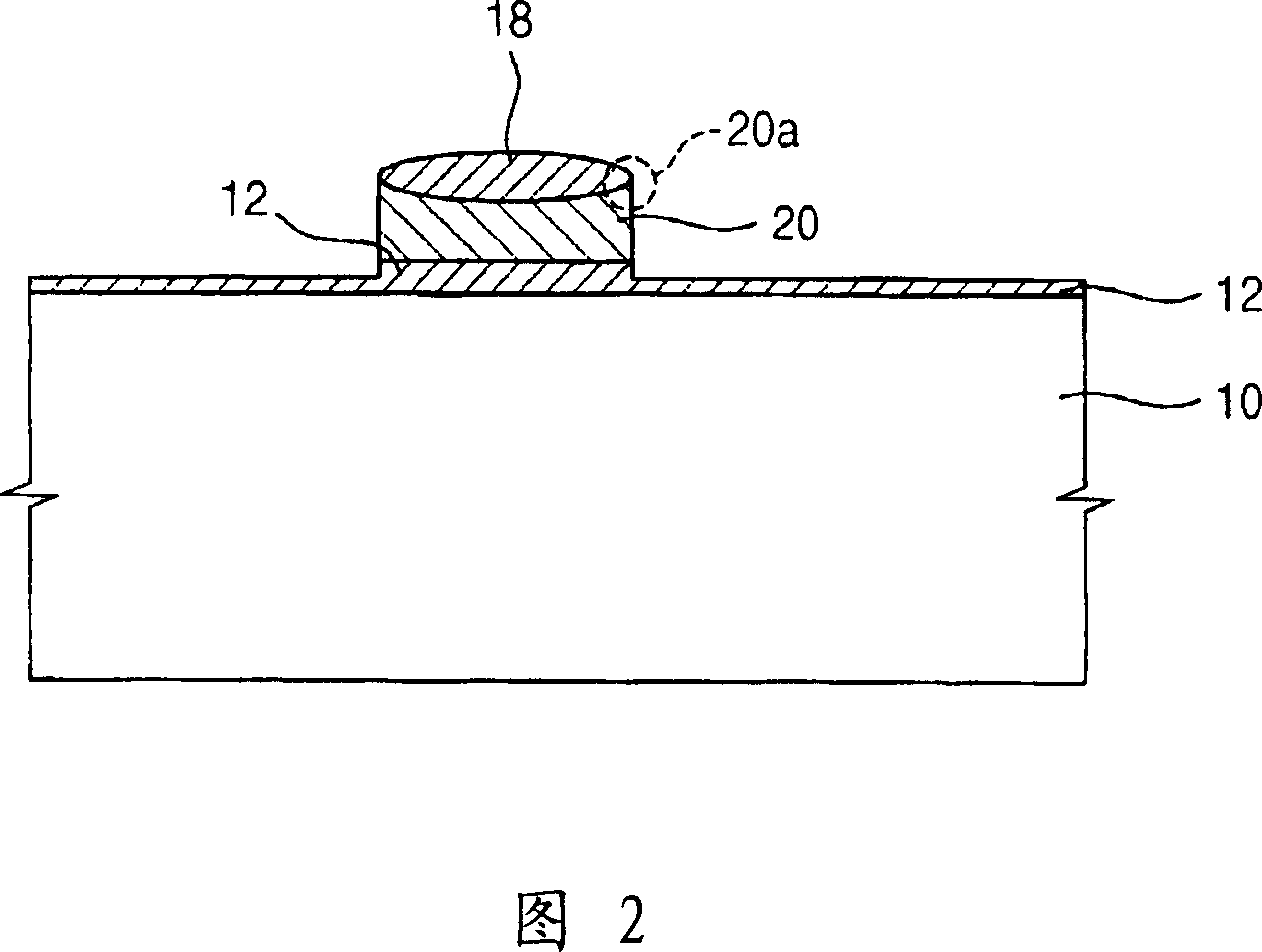

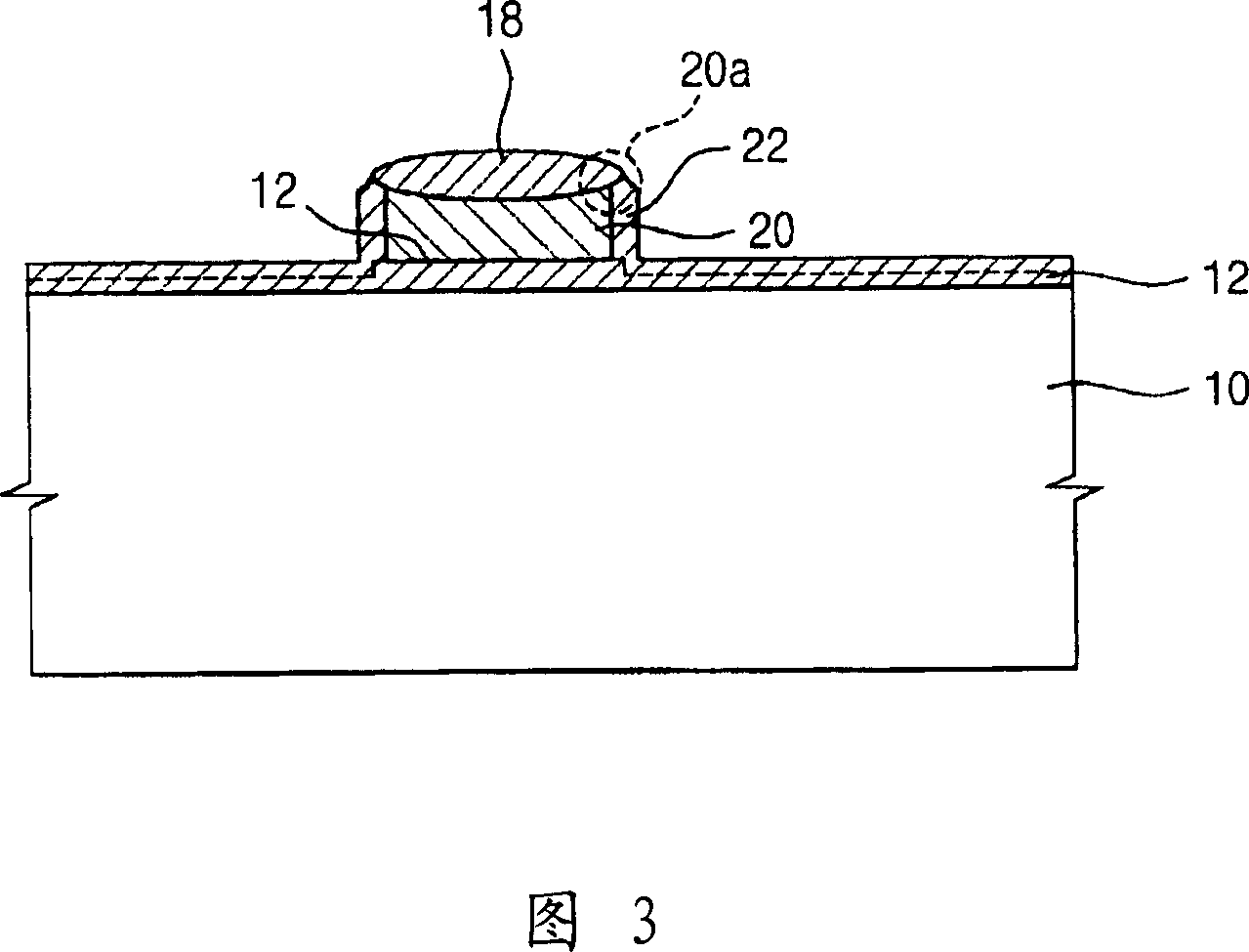

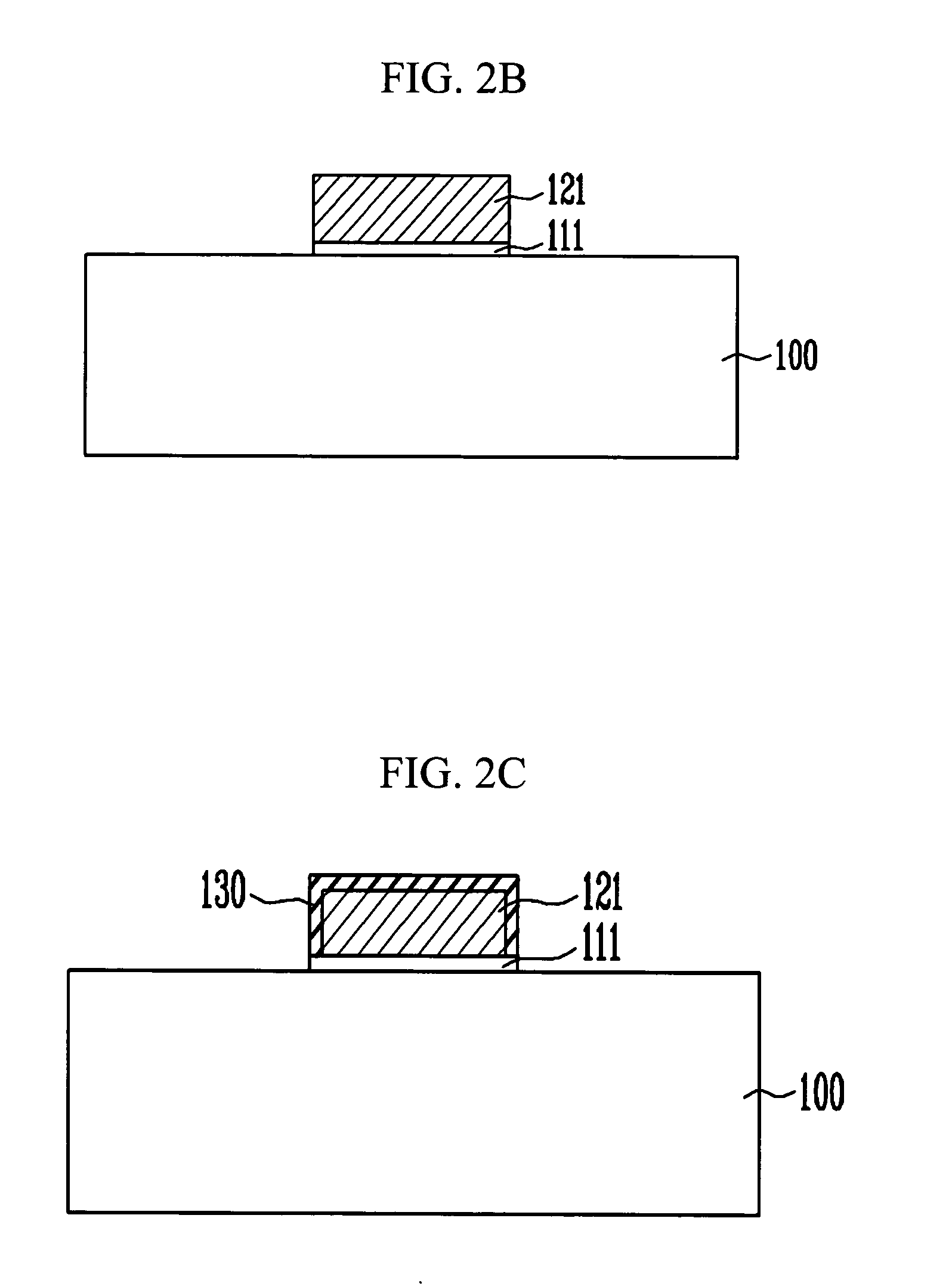

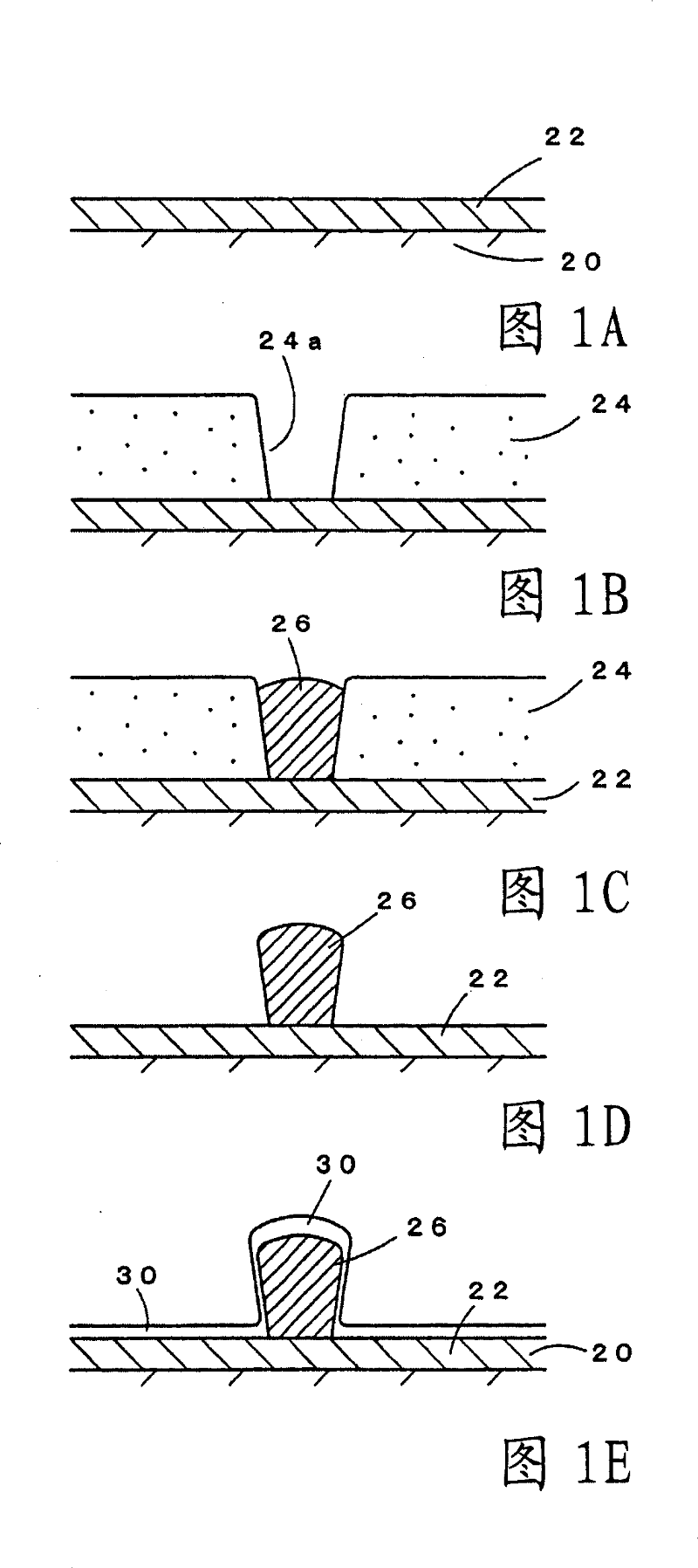

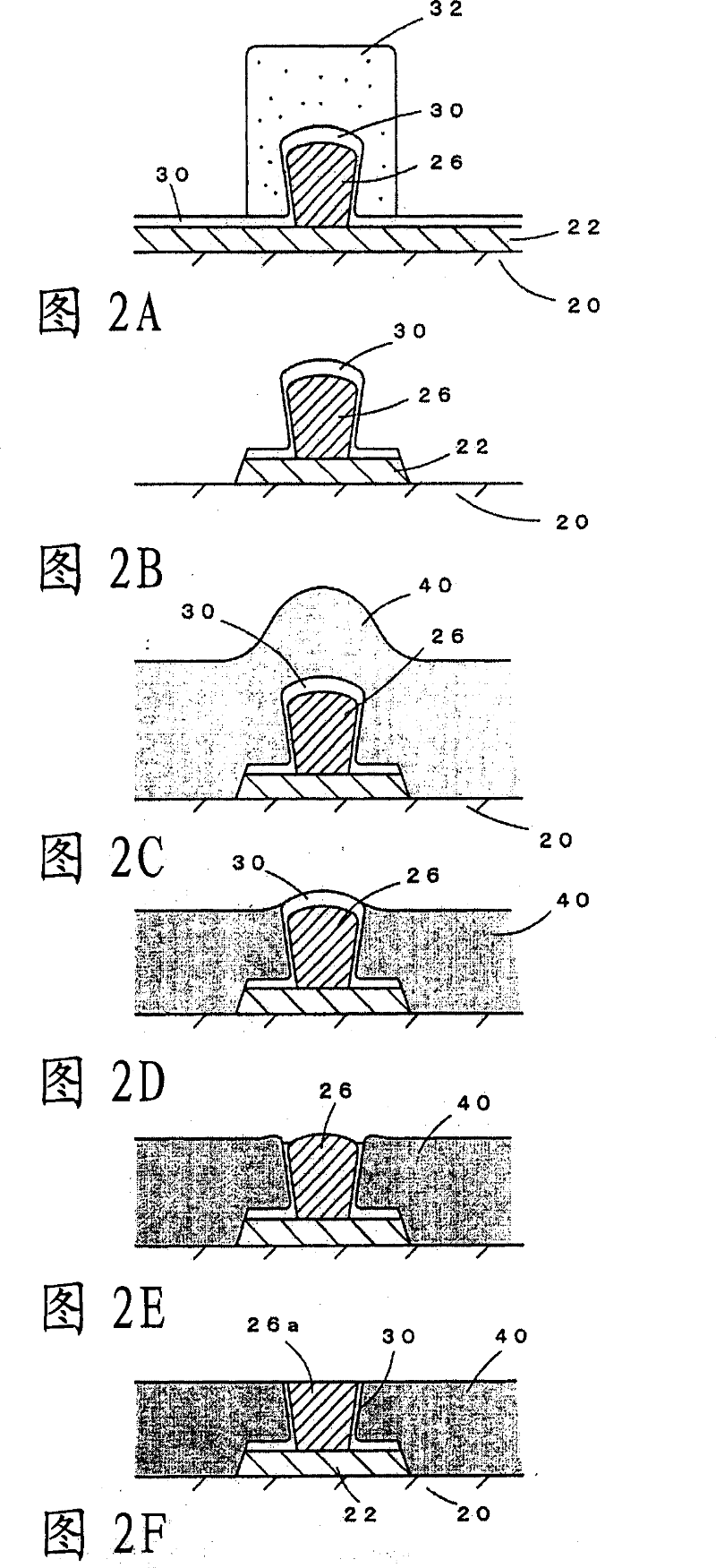

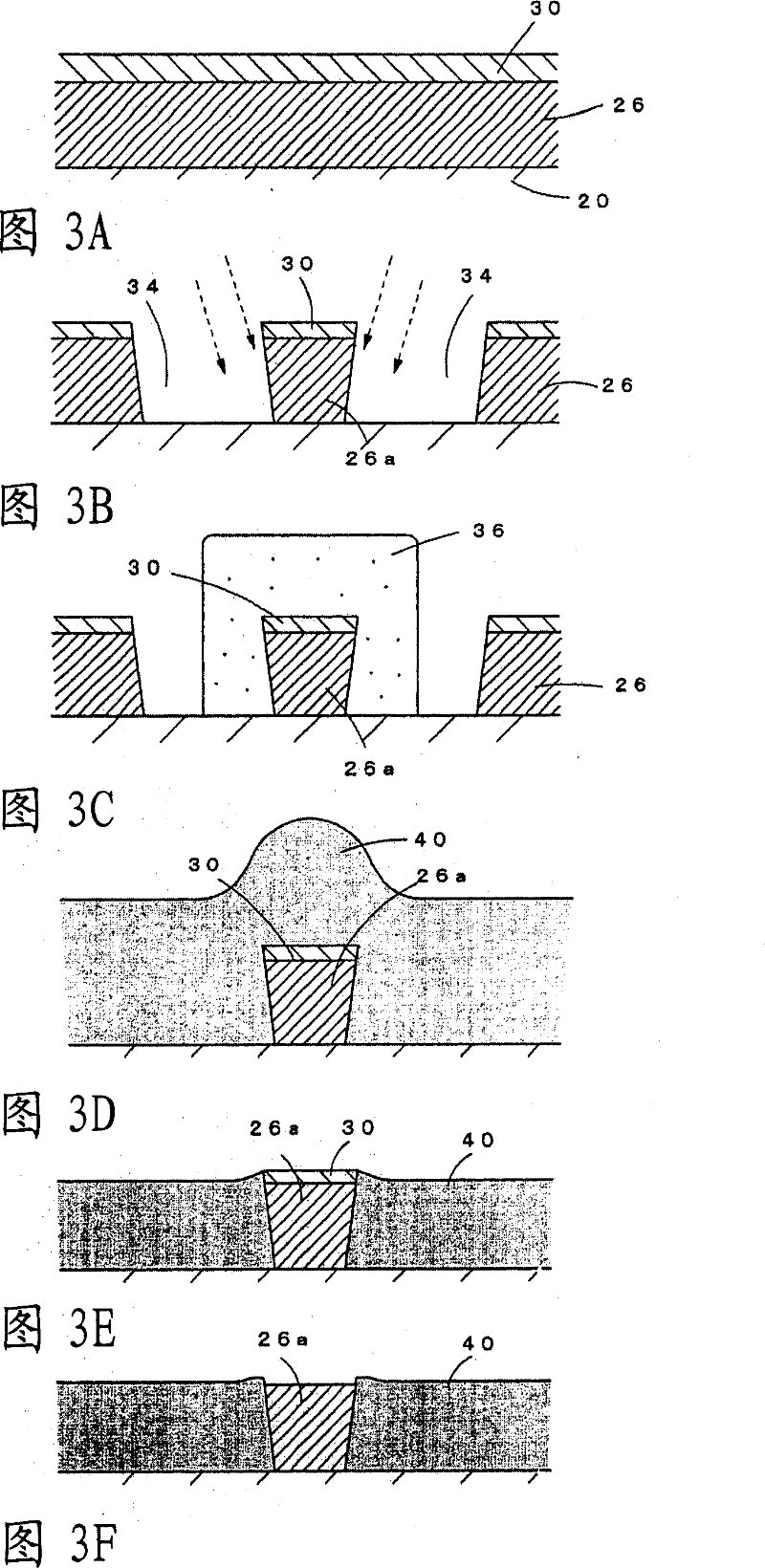

Method for manufacturing semiconductor apparatus, and semiconductor apparatus and electric appliance

ActiveUS7056810B2Low costImprove throughputPolycrystalline material growthSemiconductor/solid-state device detailsEngineeringCw laser

According to the package and the method for manufacturing the package of the present invention, a chip can be formed extremely to be thin, and manufactured at lower cost and higher throughput, and the variations of a chip thickness can be reduced without back grind that causes cracks or polishing marks. In the present invention, a semiconductor film with a thickness of at most 500 μm deposited over a substrate serving as a support medium is crystallized with a CW laser light, and a chip having a semiconductor device is formed to have a total thickness of 5 μm, preferably at most 2 μm by using the crystallized semiconductor film. Consequently, the chip is mounted on an interposer after separating a substrate.

Owner:SEMICON ENERGY LAB CO LTD

Method for manufacturing semiconductor apparatus, and semiconductor apparatus and electric appliance

ActiveUS20060220211A1Thickness drasticallyLow costPolycrystalline material growthSemiconductor/solid-state device detailsCrazingDevice material

According to the package and the method for manufacturing the package of the present invention, a chip can be formed extremely to be thin, and manufactured at lower cost and higher throughput, and the variations of a chip thickness can be reduced without back grind that causes cracks or polishing marks. In the present invention, a semiconductor film with a thickness of at most 500 μm deposited over a substrate serving as a support medium is crystallized with a CW laser light, and a chip having a semiconductor device is formed to have a total thickness of 5 μm, preferably at most 2 μm by using the crystallized semiconductor film. Consequently, the chip is mounted on an interposer after separating a substrate.

Owner:SEMICON ENERGY LAB CO LTD

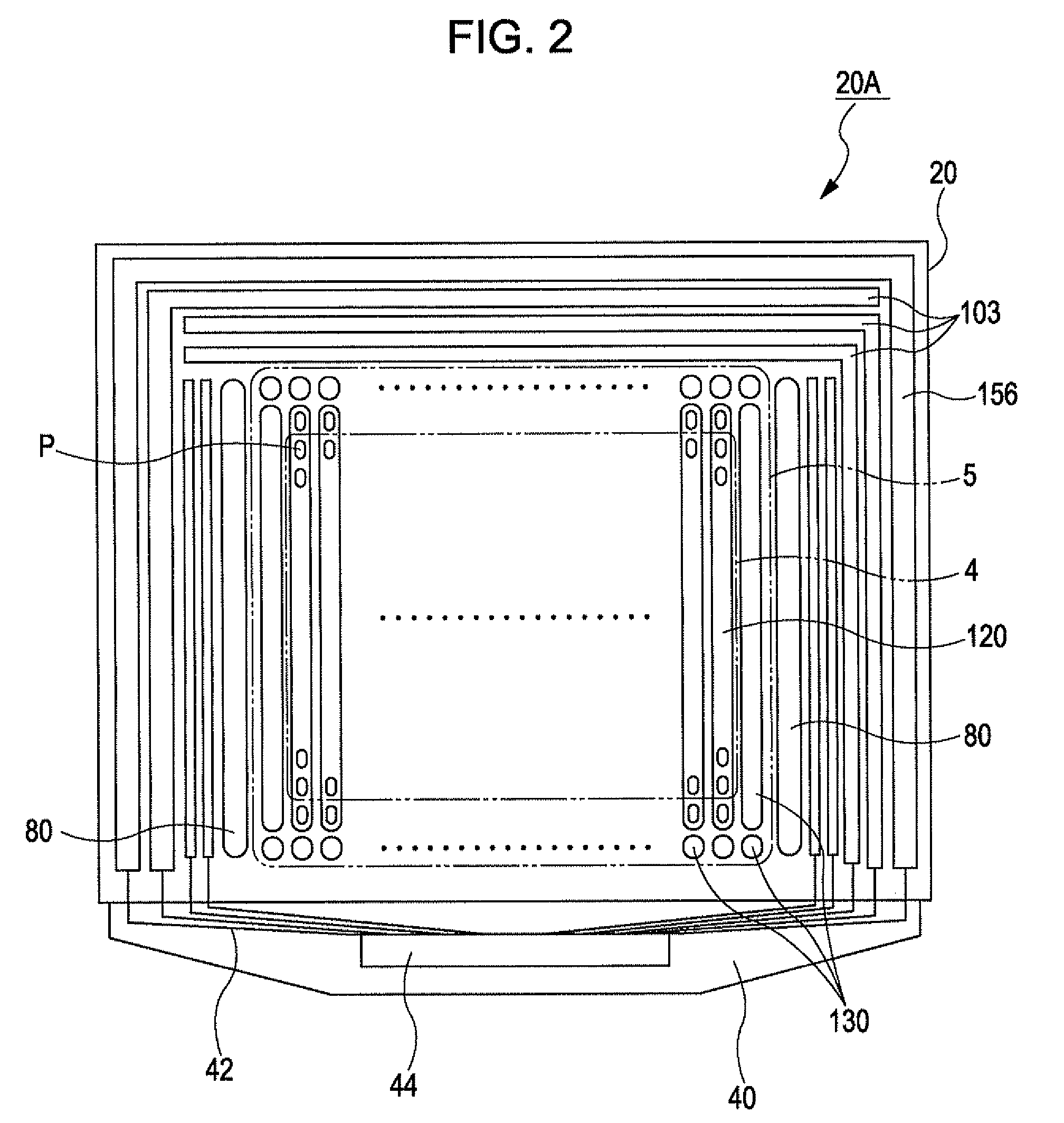

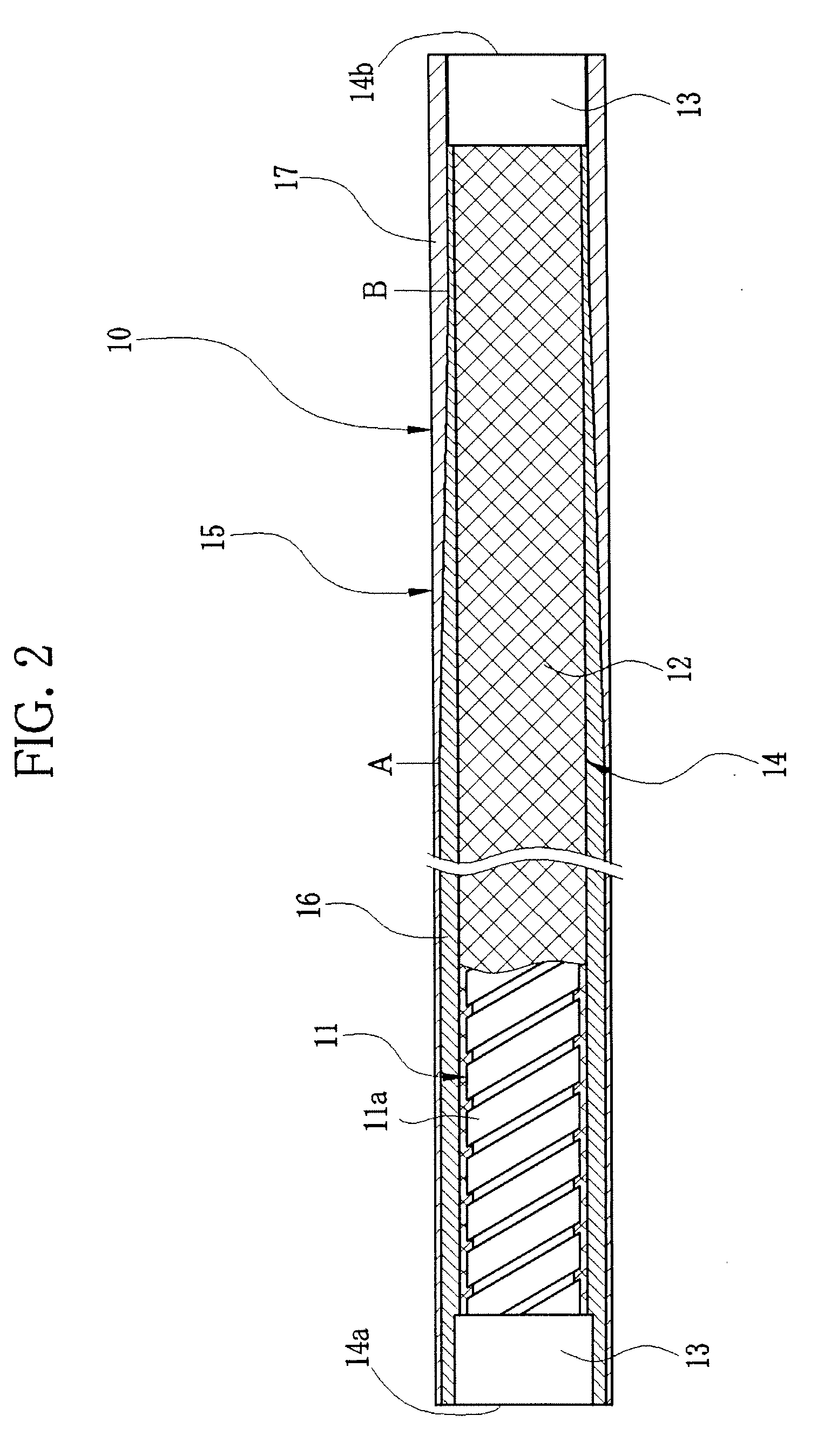

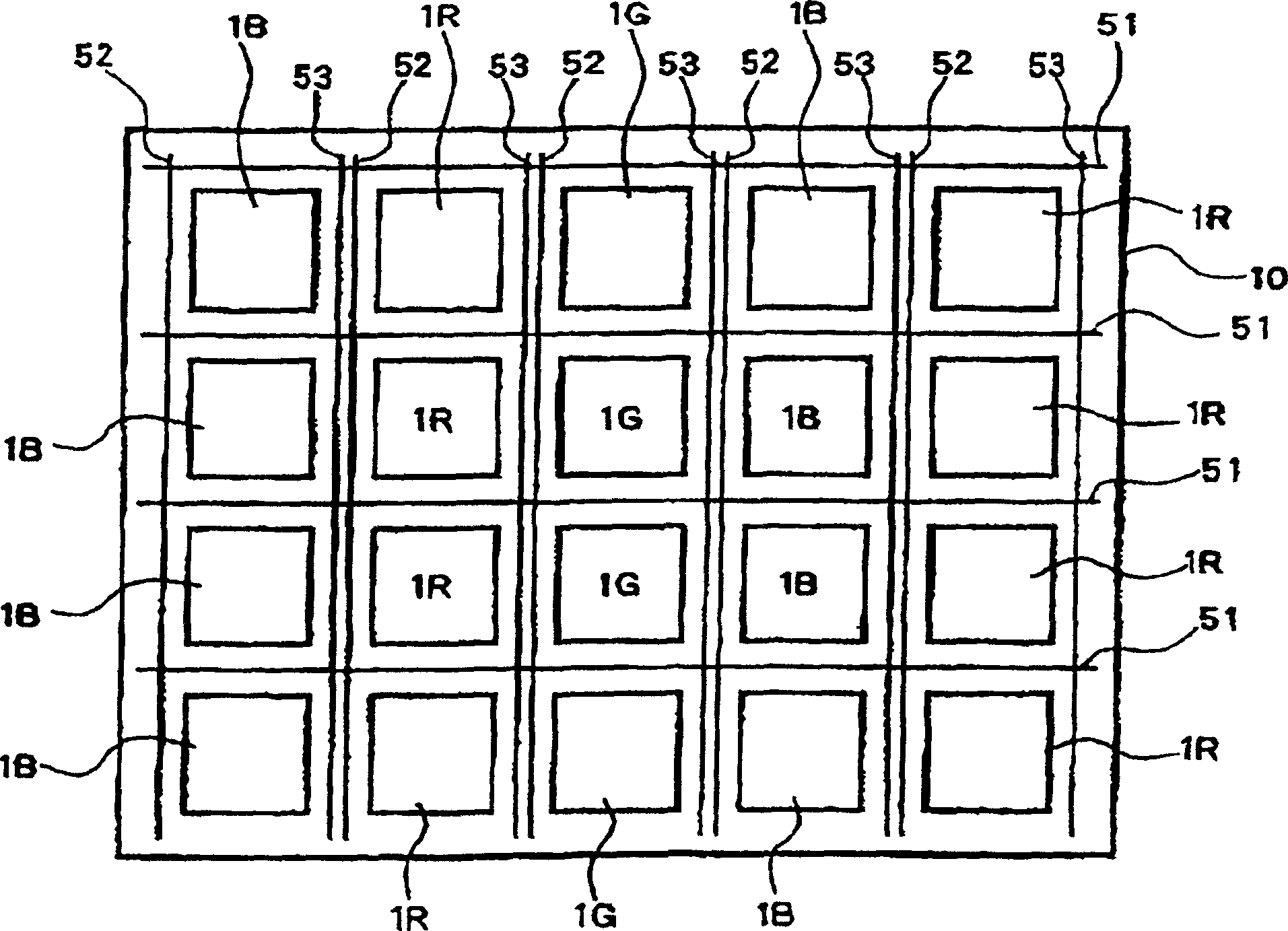

Method for manufacturing organic electroluminescent device and organic electroluminescent device

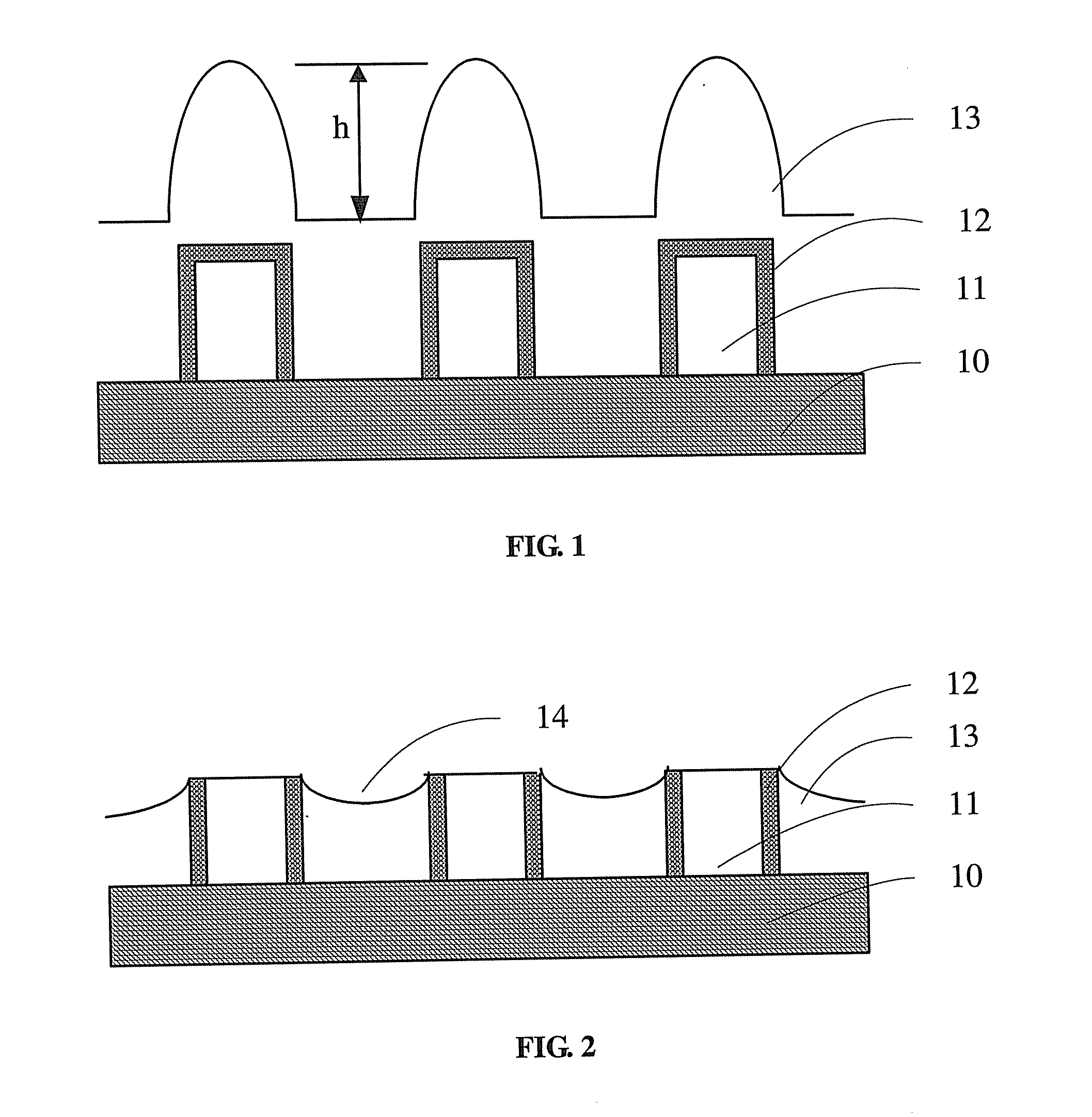

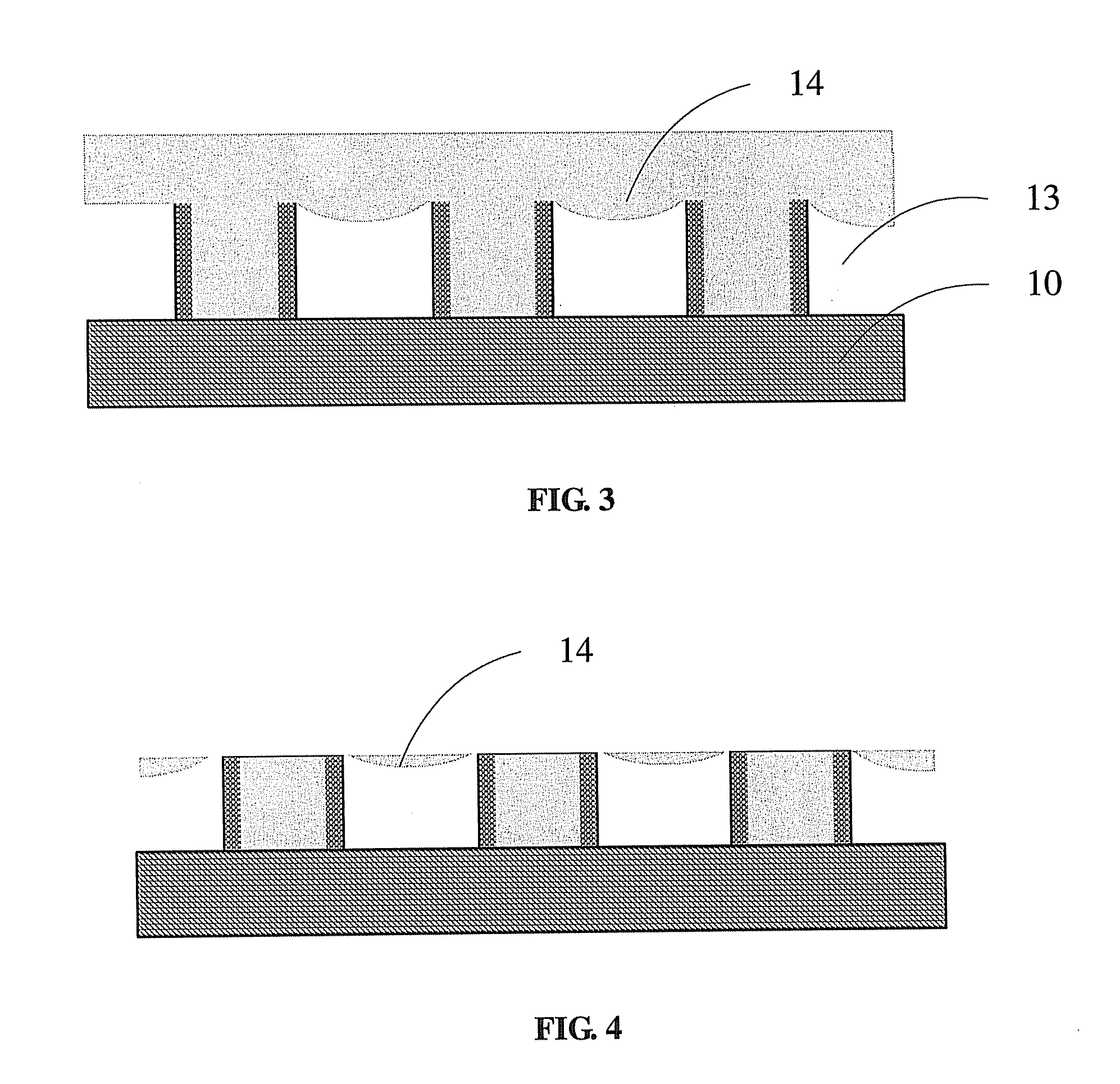

InactiveUS20090128020A1Prevent thickness variationHigh quality imagingDischarge tube luminescnet screensLamp detailsOrganic layerOrganic electroluminescence

An organic electroluminescent device includes partition walls dividing a region into a first region, a second region and a third region, a first organic layer disposed in the first region, a second organic layer disposed in the second region, and a third organic layer disposed in the third region. The first region includes a plurality of effective pixels involved in light emission, continuously disposed along a first aligning axis. Each effective pixel includes an effective pixel electrode, a common electrode, and the first organic layer between the effective pixel electrode and the common electrode. The second region and the third region oppose each other with the first region therebetween, and the first region, the second region and the third region are aligned along the first aligning axis.

Owner:SEIKO EPSON CORP

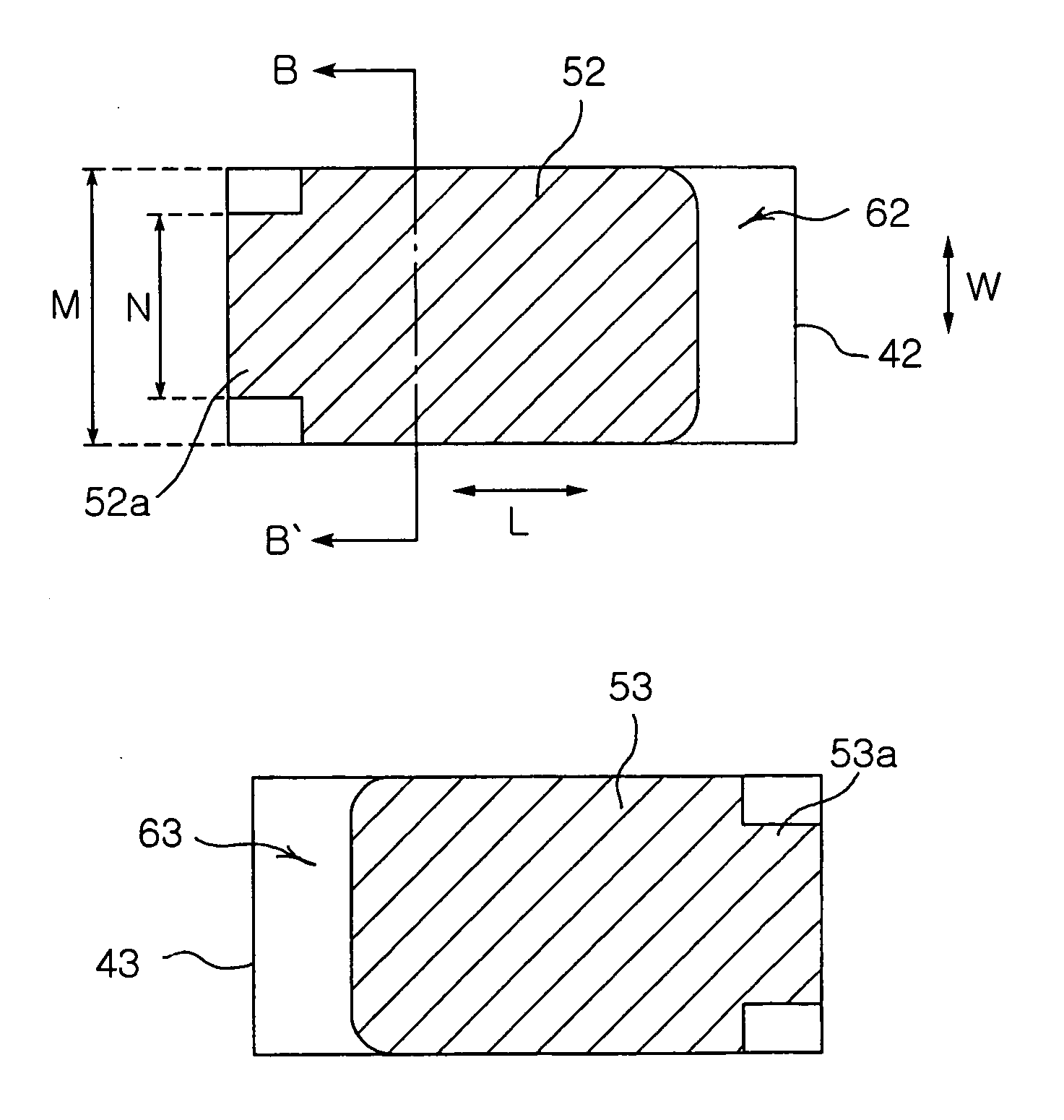

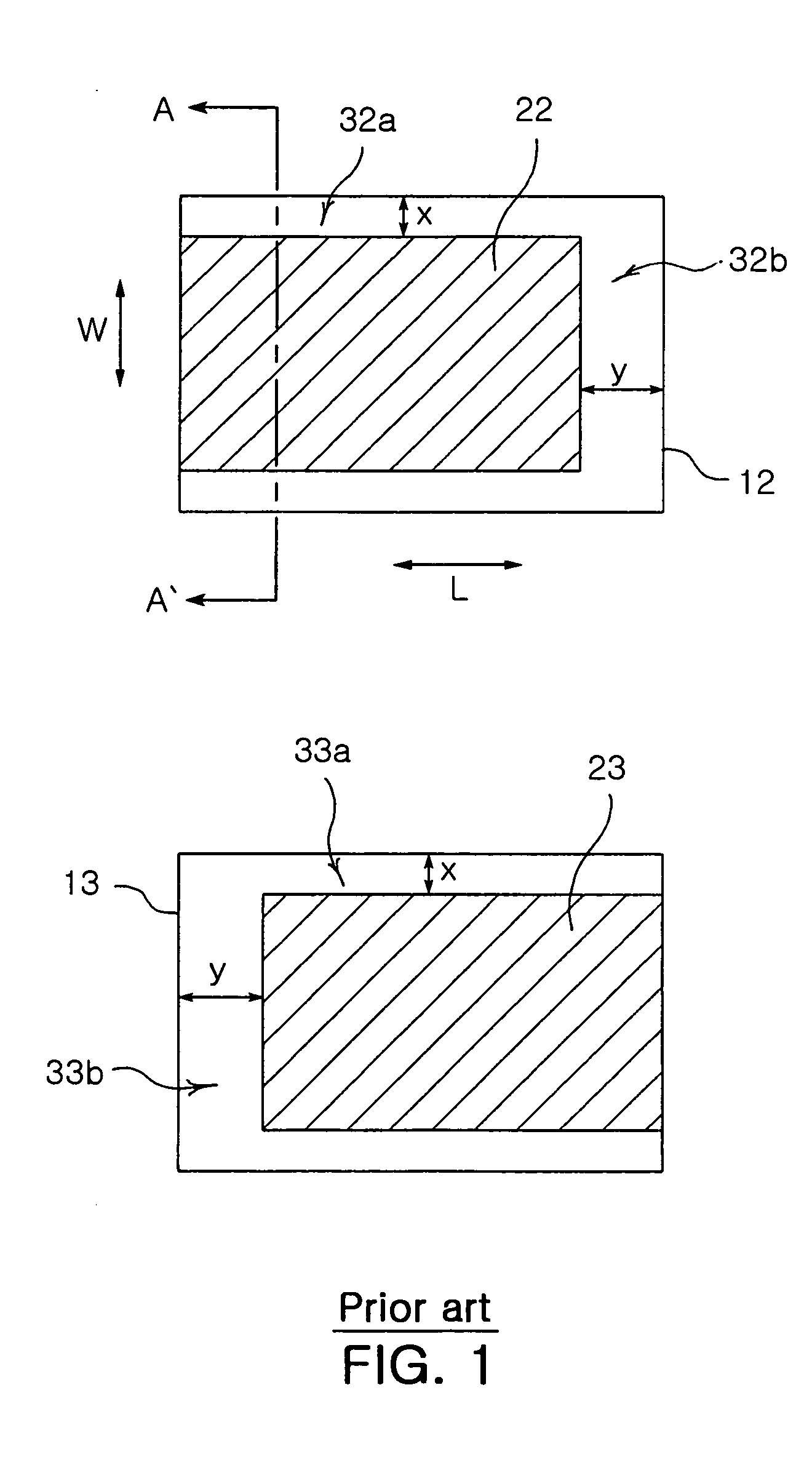

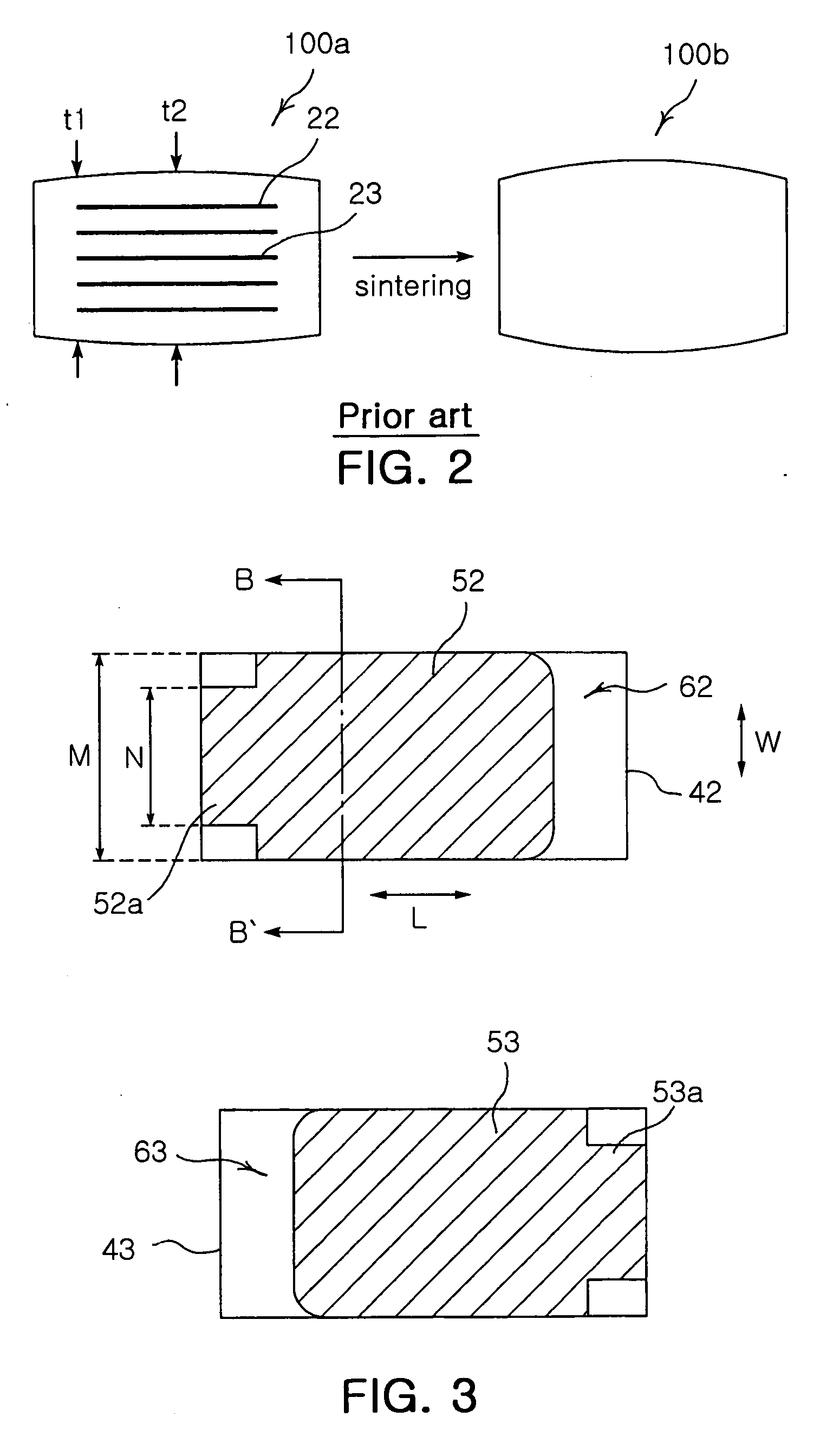

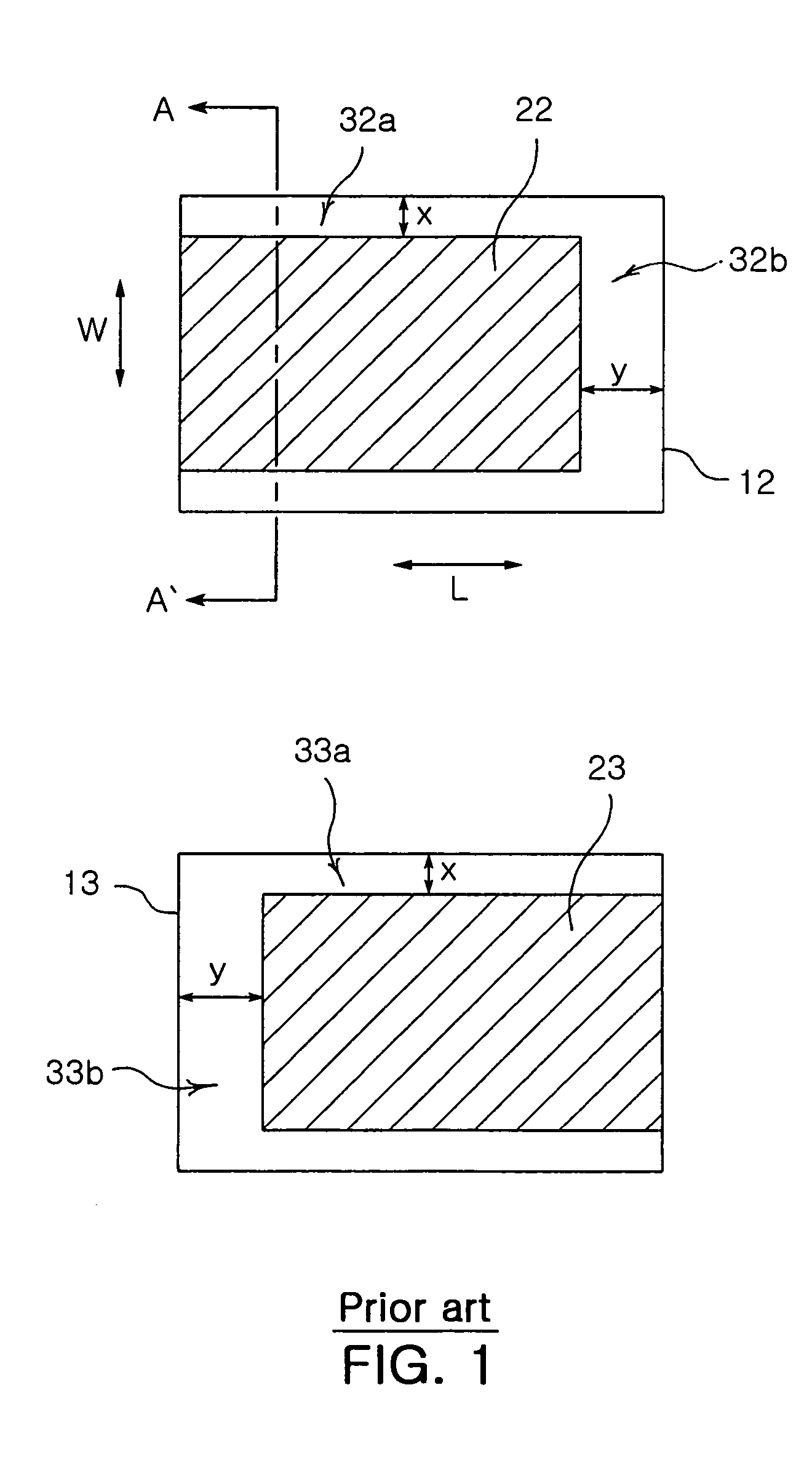

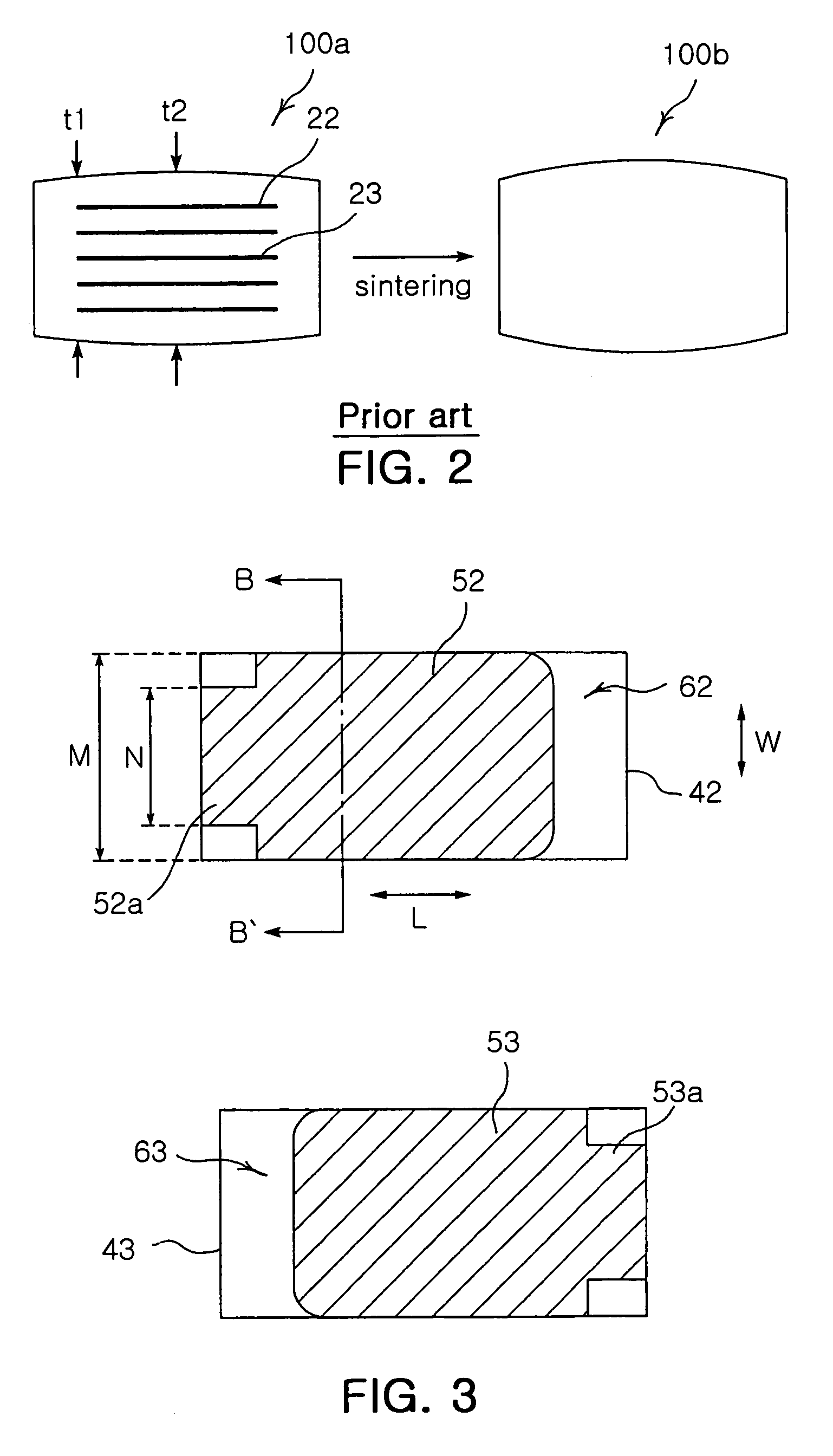

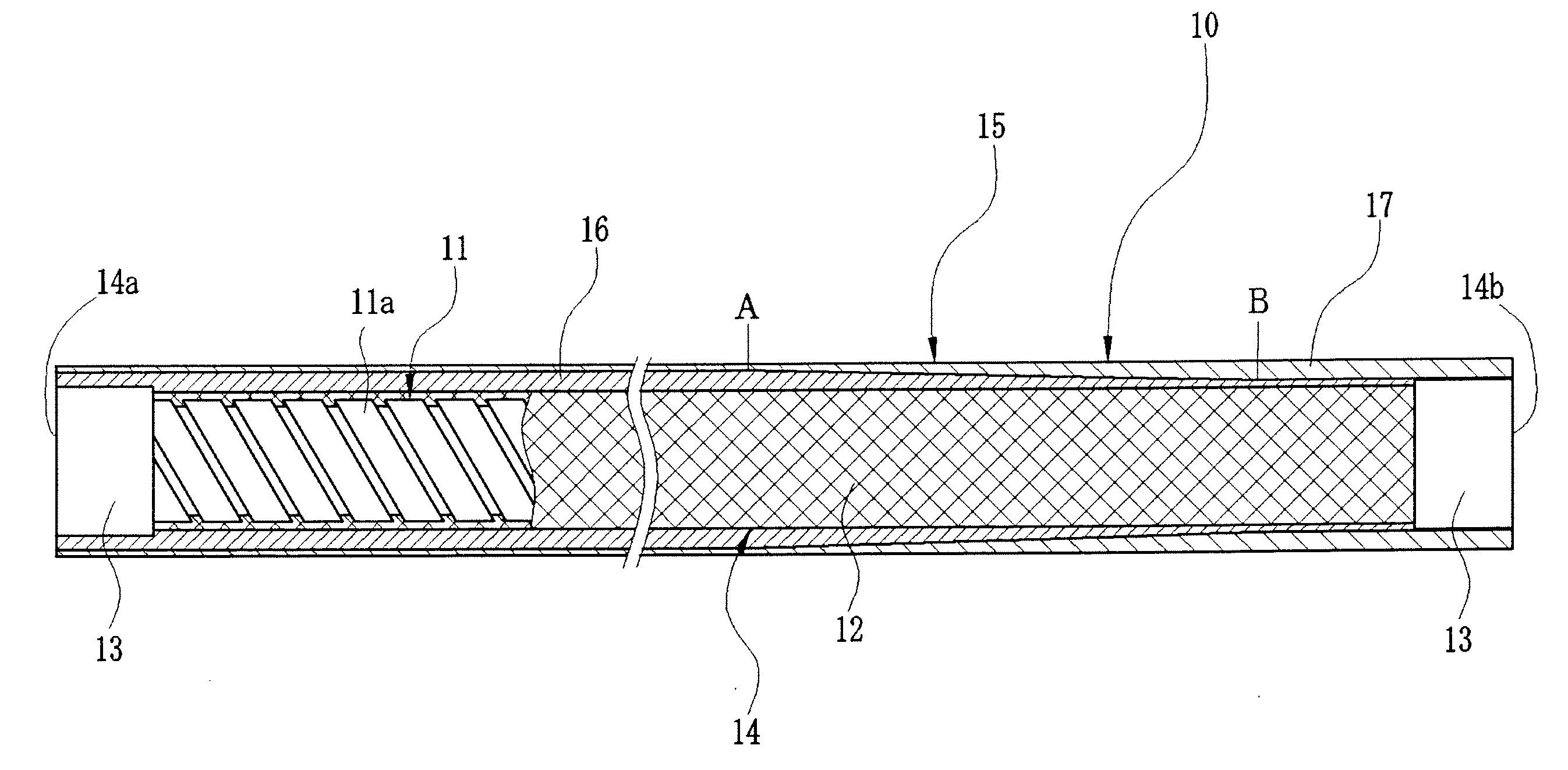

Multilayer chip capacitor and method for manufacturing the same

InactiveUS20060139848A1Undesired shortNarrow widthFixed capacitor electrodesFixed capacitor dielectricDielectric layerCapacitor

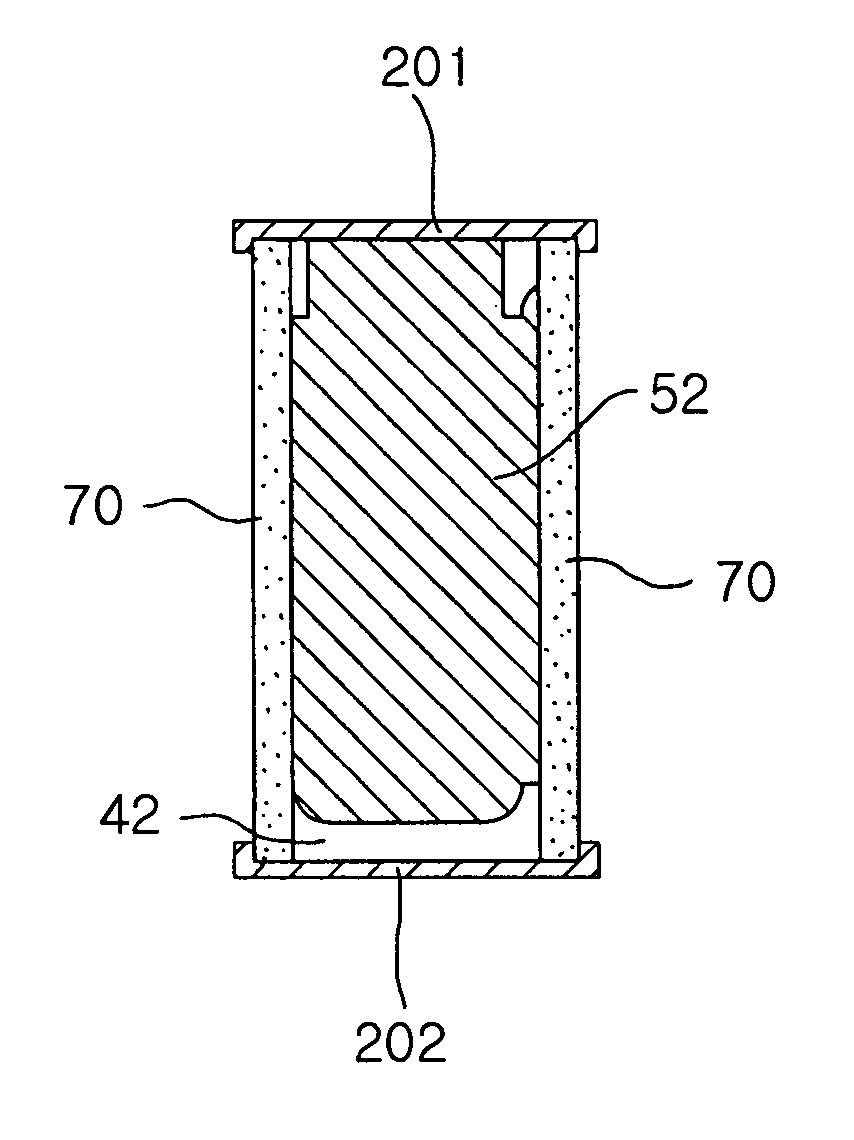

A multilayer chip capacitor, and a method for manufacturing the same are Provided. The capacitor comprises a capacitor body having a plurality of dielectric layers stacked therein, a plurality of first and second internal electrodes formed on the dielectric layers, each of the internal electrodes including a main electrode portion and a lead portion, chip-protecting side members formed on both sides of the capacitor body to contact both sides of the first and second internal electrodes, and a pair of external electrodes formed on the outer surface of the capacitor body. The width of the main electrode portion is the same as that of the dielectric layers, and the width of the lead portion is smaller than that of the dielectric layers.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

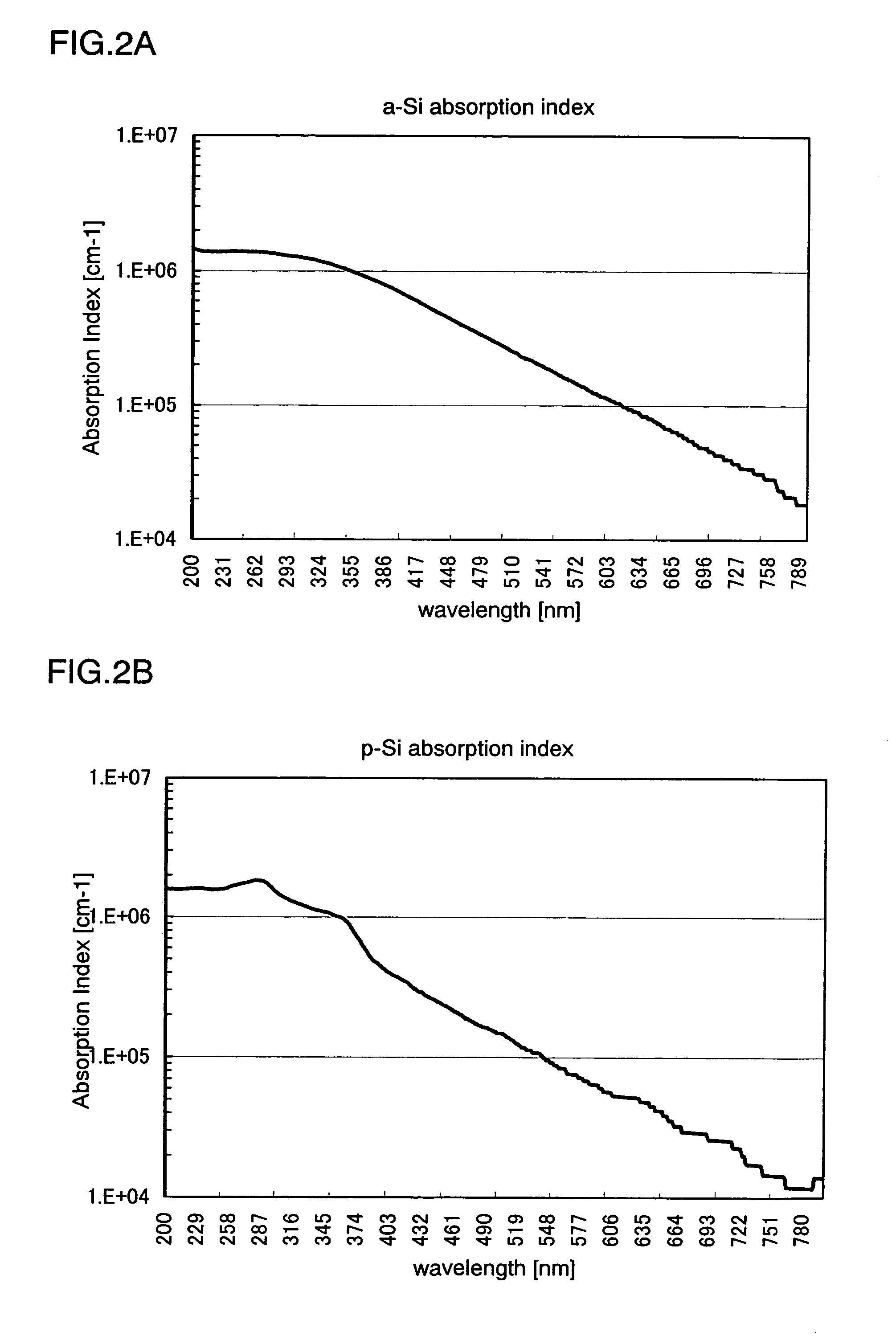

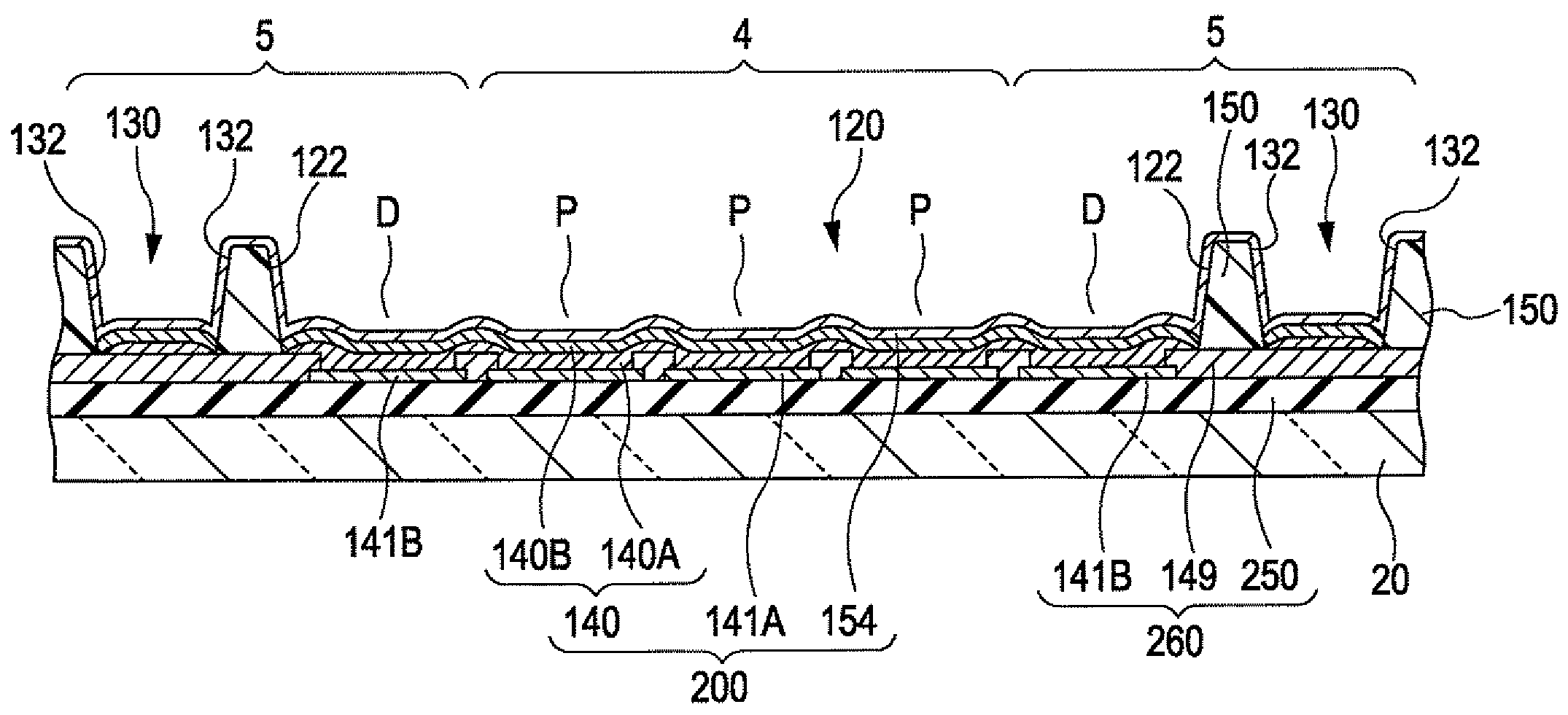

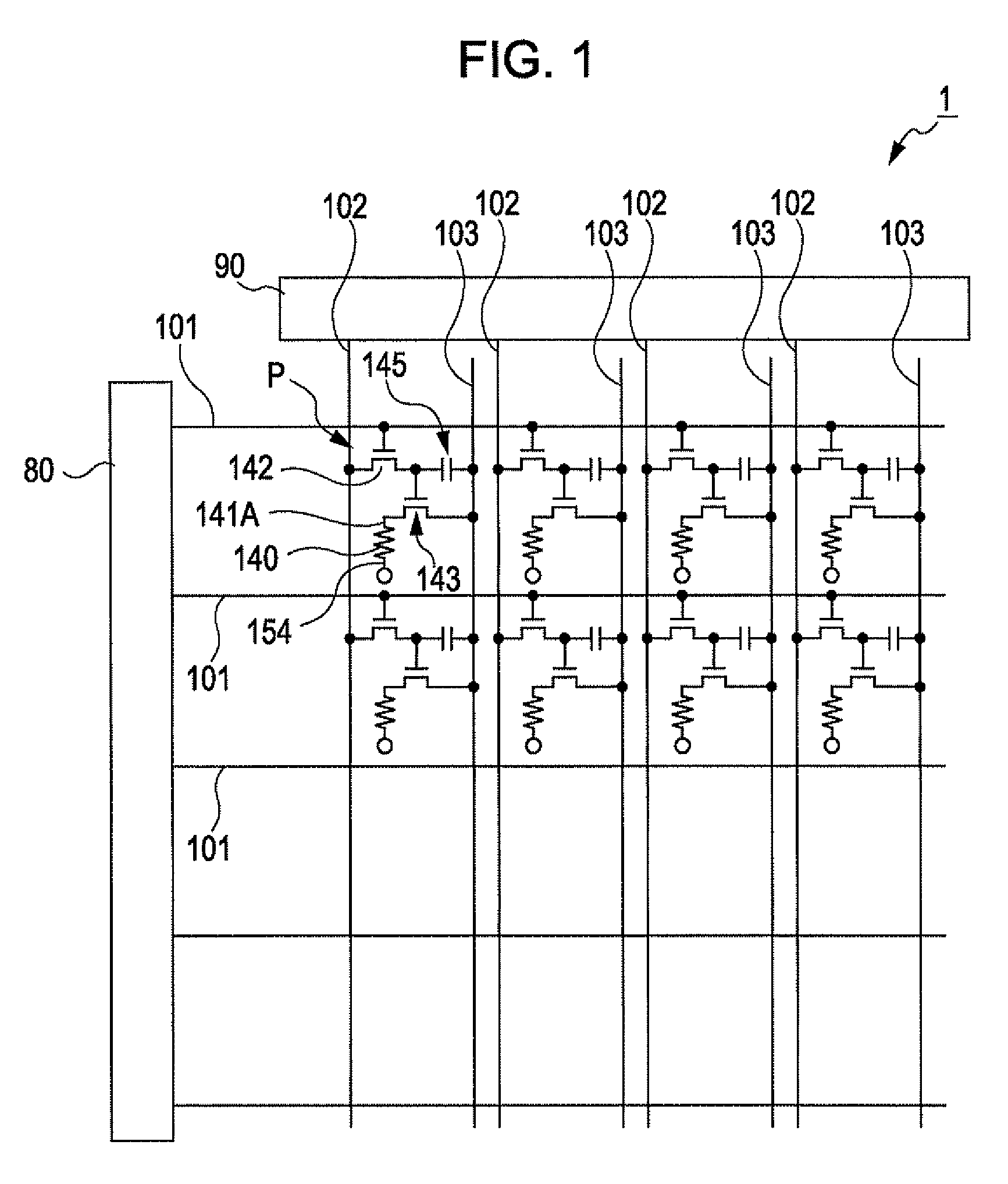

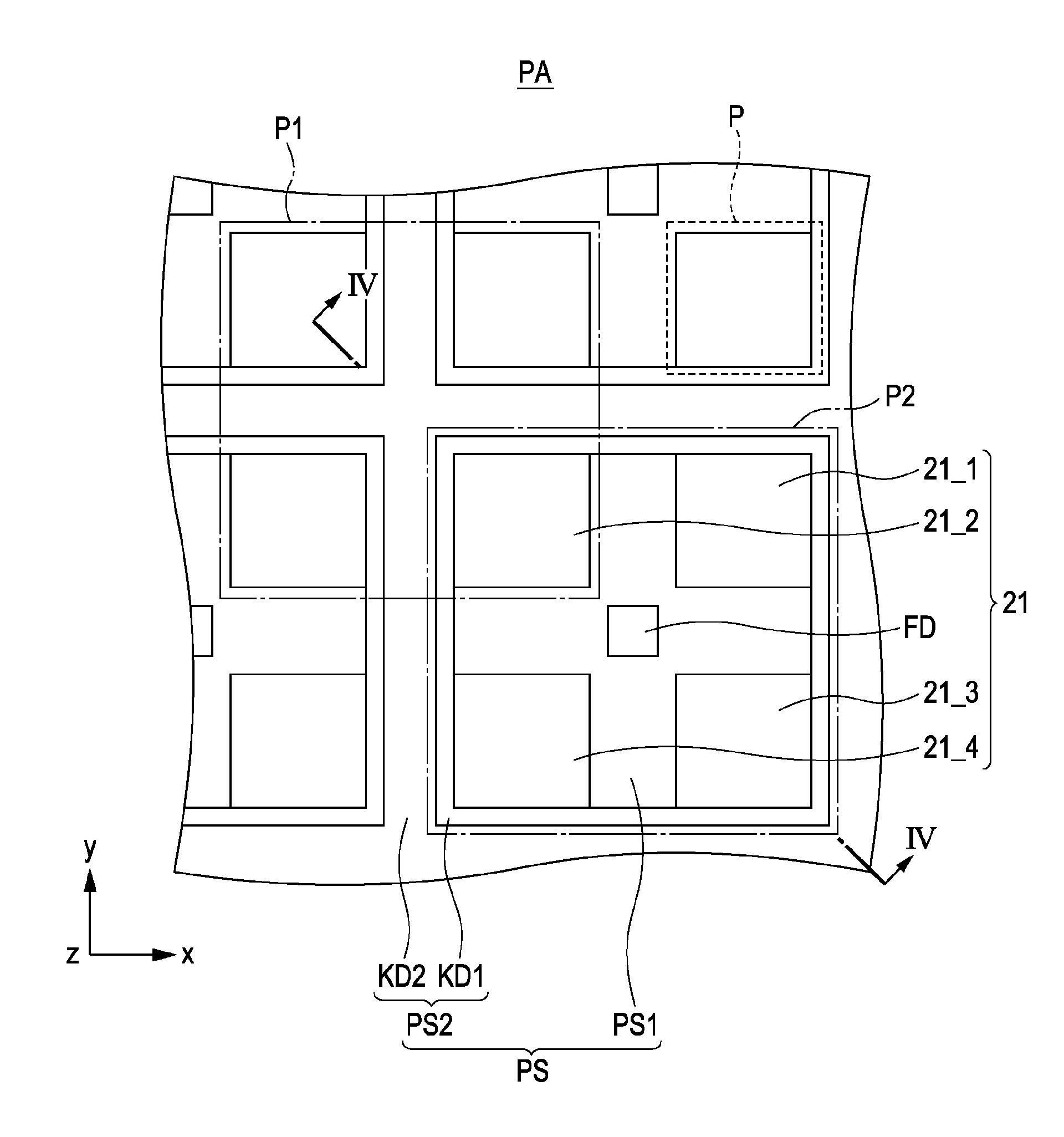

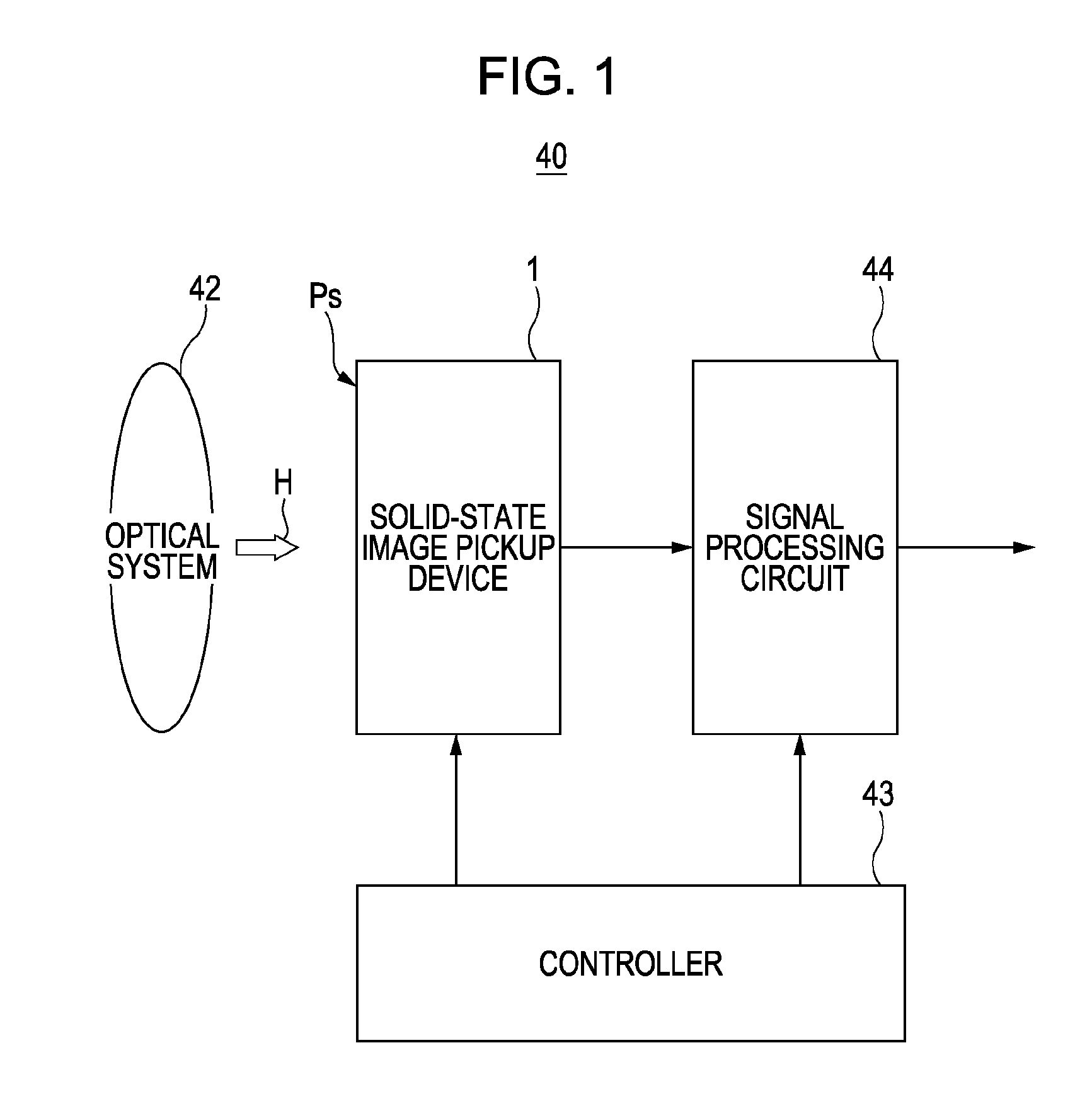

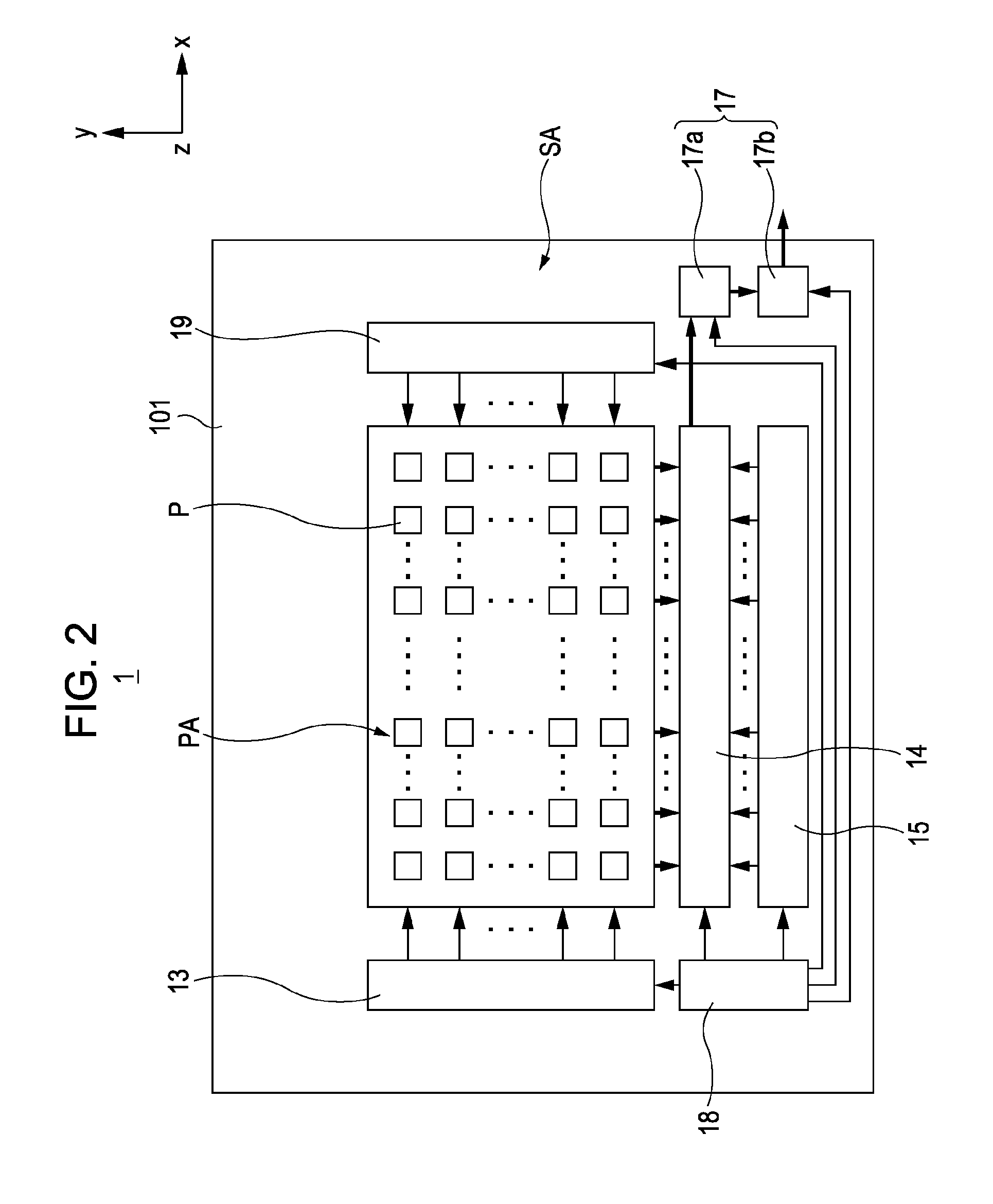

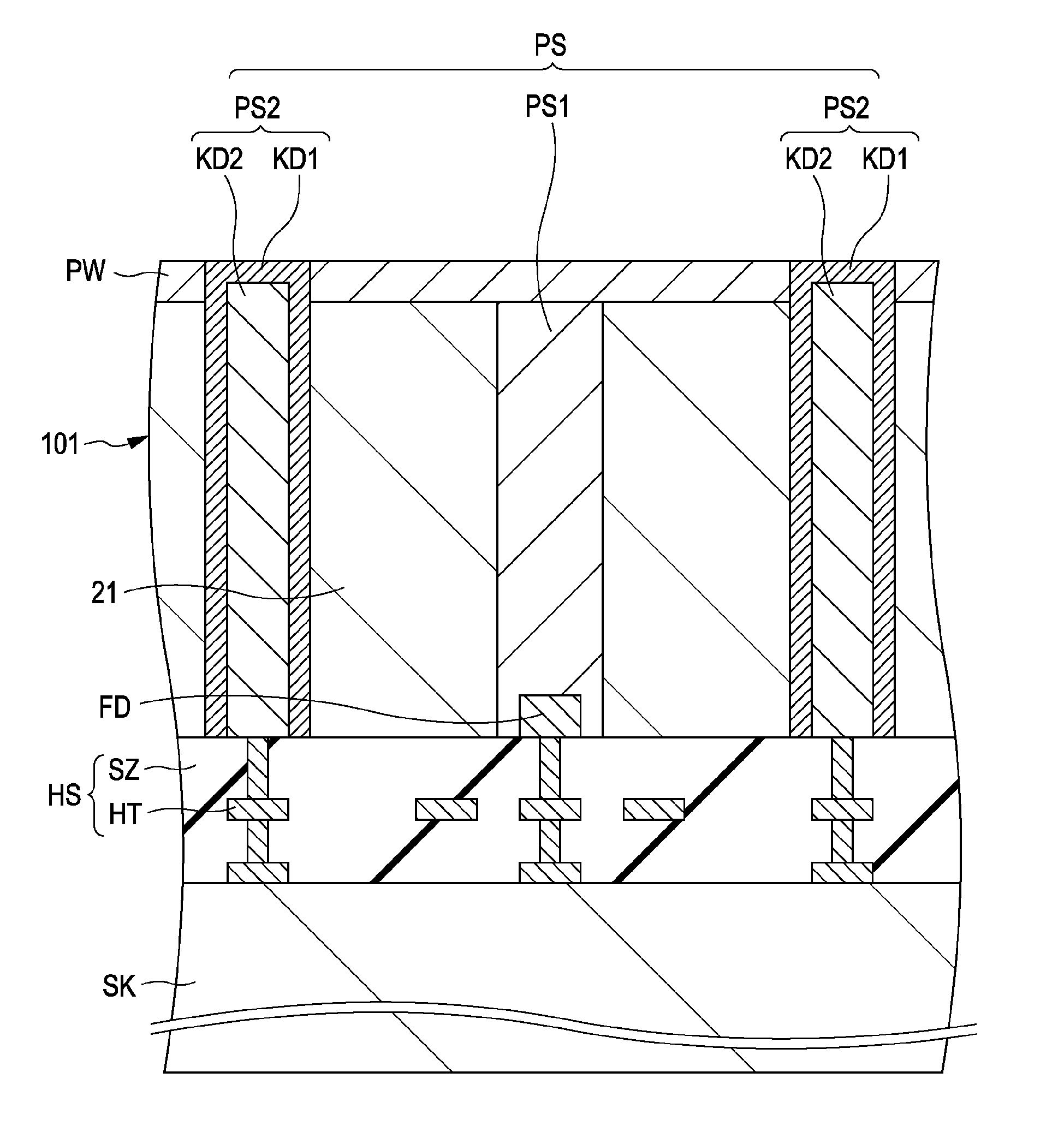

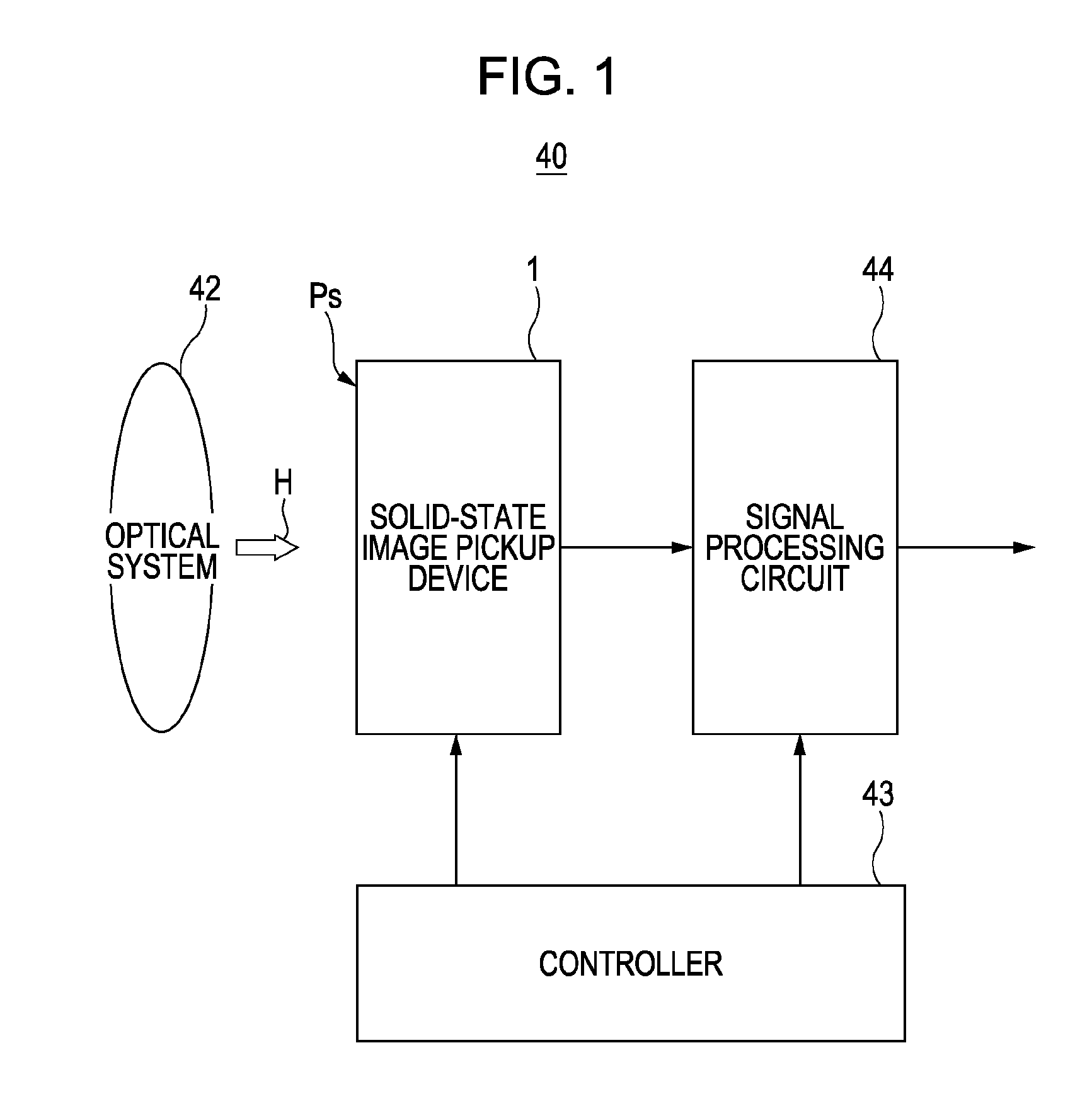

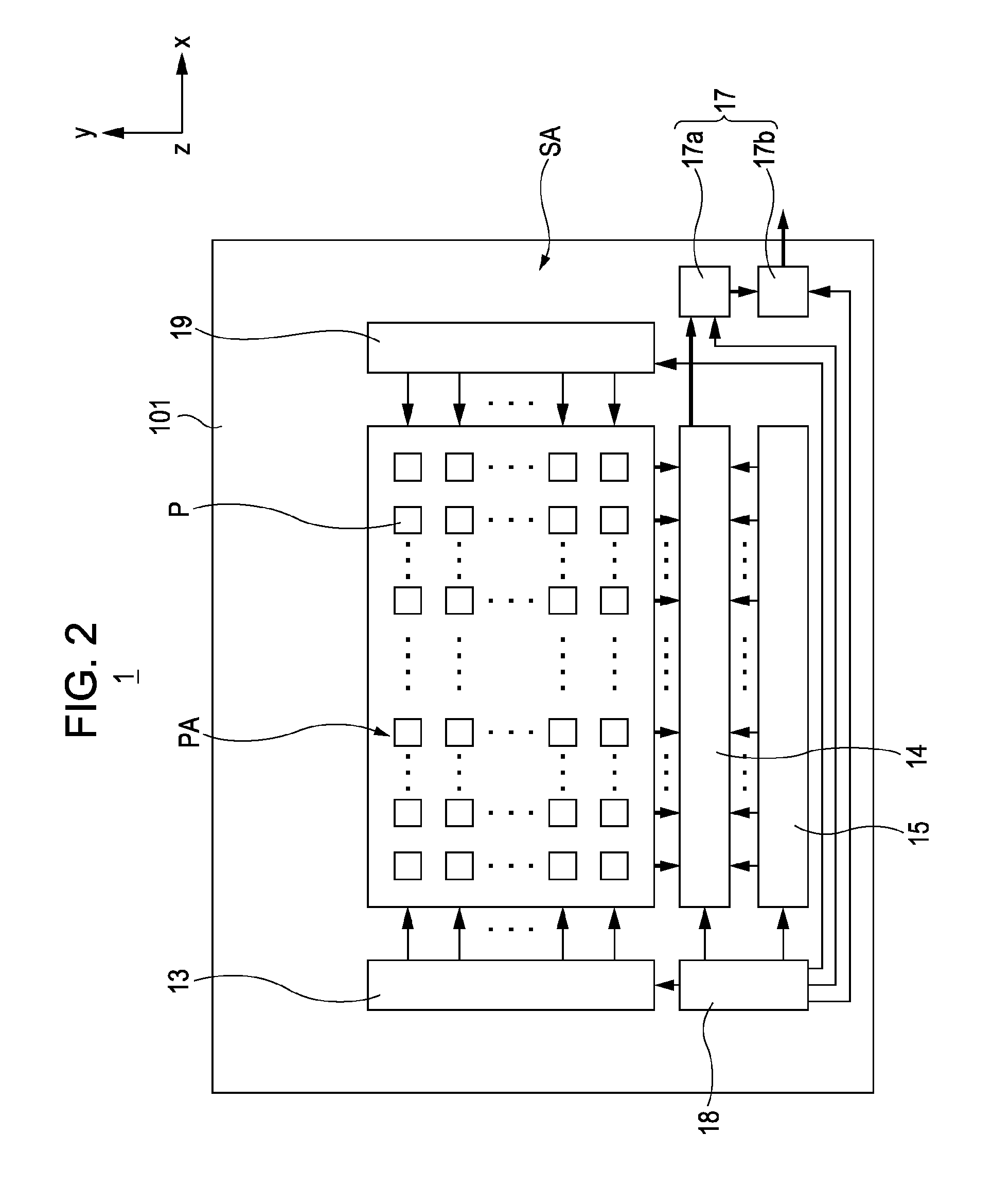

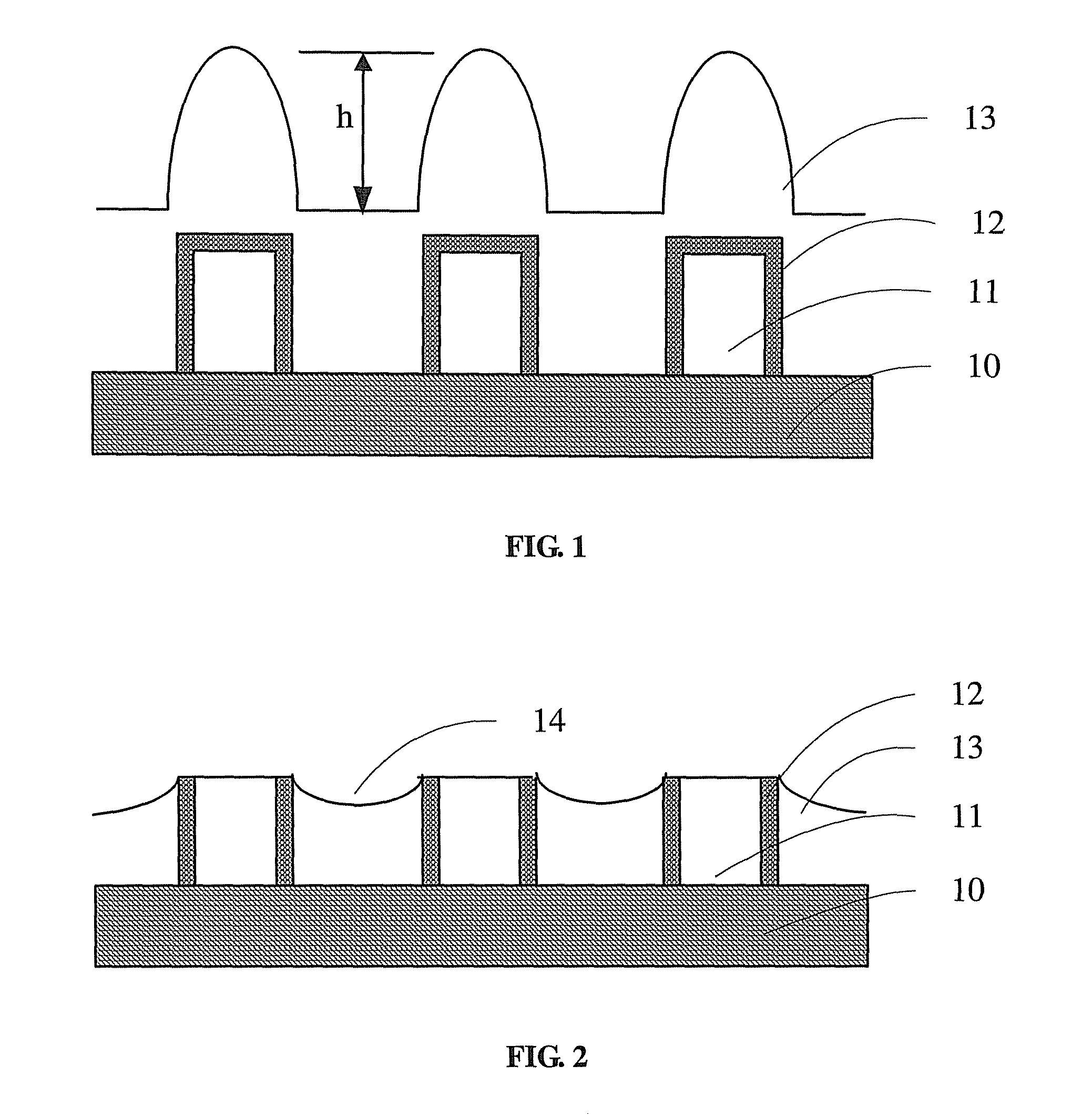

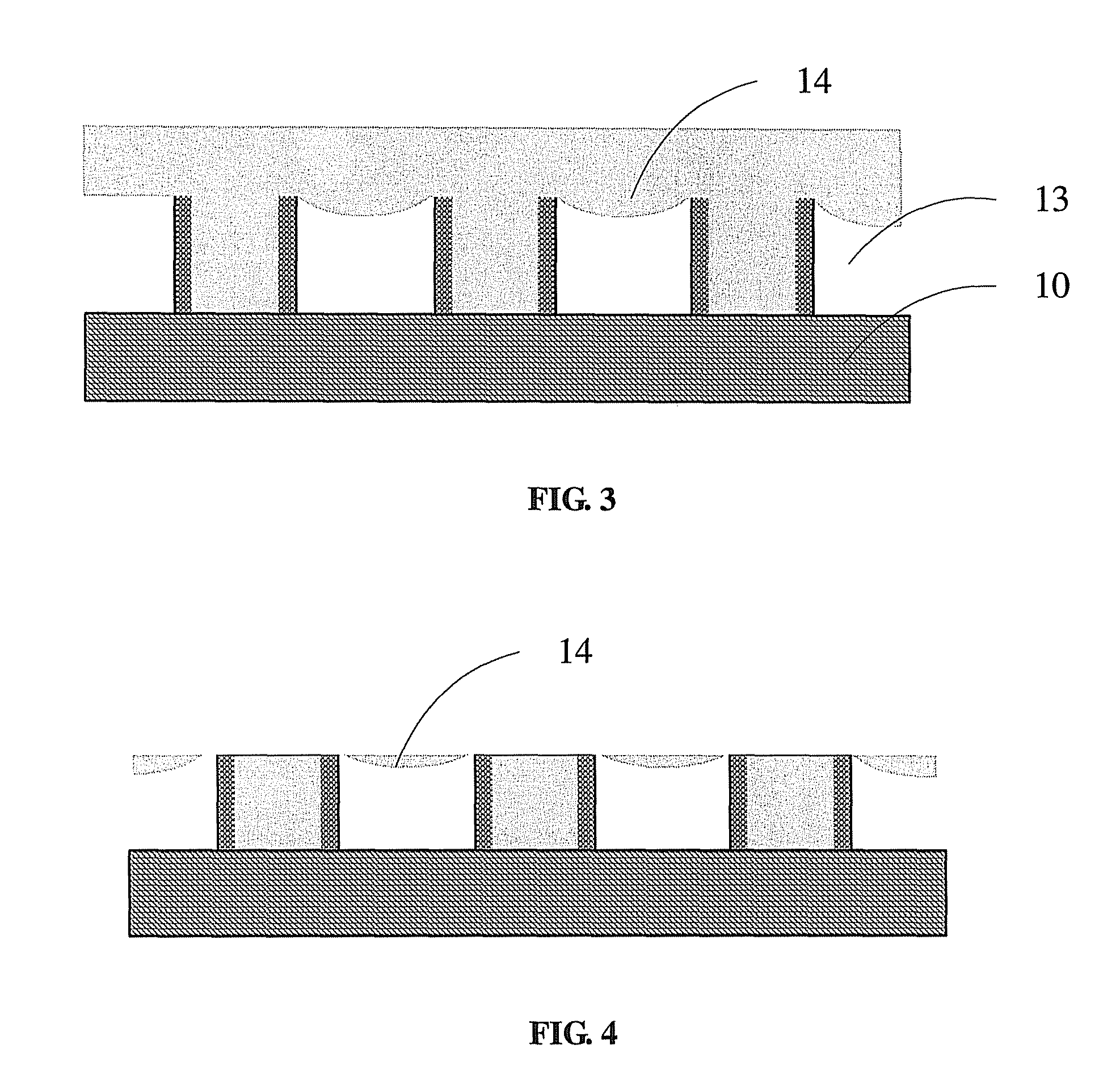

Solid-state image pickup device, method for manufacturing the same, and electronic apparatus

ActiveUS20110079866A1Efficient preparationHigh quality imagingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringImpurity ions

A method for manufacturing a solid-state image pickup device is provided. In this method, a pixel isolation member is formed in a semiconductor substrate including pixels, and the thickness of the substrate is reduced by CMP. For forming the pixel isolation member, a first pixel isolation member is formed by implanting impurity ions in a region of the substrate so that the pixels are disposed between portions of the region when viewed from a surface of the substrate. A second isolation member is also formed by forming a trench in a region of the substrate different from the first pixel isolation member so that the pixels are disposed between portions of the region, and then filling the trench with an electroconductive material harder to polish by CMP than the substrate. The CMP is performed on the rear side of the substrate using the second pixel isolation member as a stopper.

Owner:SONY CORP

Solid-state image pickup device, method for manufacturing the same, and electronic apparatus

ActiveUS8426238B2Prevent thickness variationReduce thicknessSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringImpurity ions

A method for manufacturing a solid-state image pickup device is provided. A first pixel isolation member is formed in a semiconductor substrate including pixels by implanting impurity ions in a first region of the substrate to separate pixels in the first region from each other when viewed from a surface of the substrate. A second pixel isolation member is also formed in the substrate by forming a trench in a second region of the substrate different from the first region to separate pixels in the second region from each other, and filling the trench with an electroconductive material harder to polish by CMP than the substrate. The thickness of the substrate is reduced by CMP on a rear surface of the substrate using the second pixel isolation member as a stopper.

Owner:SONY CORP

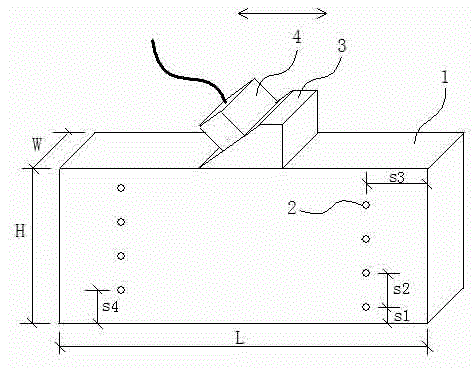

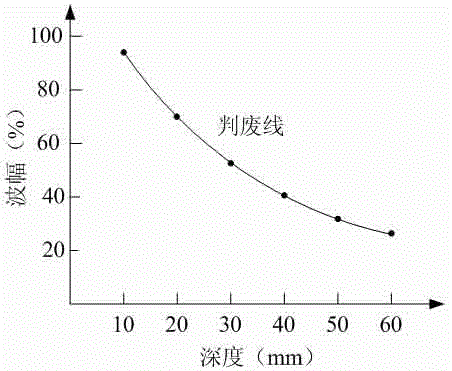

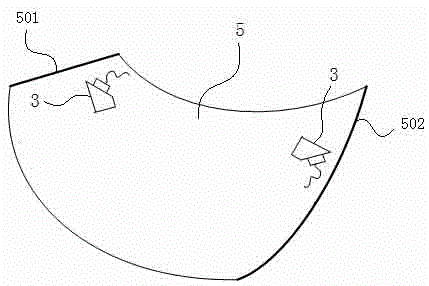

Method for detecting weld defect of stainless steel runner blade of water turbine

InactiveCN102944610APrevent thickness variationOvercoming difficulties such as thickness changesAnalysing solids using sonic/ultrasonic/infrasonic wavesReflection Wave AmplitudeWater turbine

The invention discloses a method for detecting a weld defect of a stainless steel runner blade of a water turbine, comprising the following steps of: 1, selecting an instrument; 2, calibrating the instrument; 3, drawing a rejection judging line for detection: (1) making a reference block; and (2) testing the detected surface of the reference block through a wedge block by using a probe of the instrument, recording the current gain of the instrument and the height values of reflection wave amplitudes of through holes at different heights in the reference block, drawing points according to the height values of the reflection wave amplitudes on a two-dimensional coordinate system, and connecting the points into a smooth curve to draw the rejection judging line; 4, detecting the weld of the blade; and 5, recording the defect: displaying the height of an echo signal according to the instrument and comparing the height of the echo signal with the rejection judging line by taking the rejection judging line as a reference, making corresponding marks on the surface of the blade, and finally detecting whether the blade has a defect according to the marks on the surface of the blade. By using the method, the weld defect of the stainless steel runner blade can be reliably, conveniently and rapidly detected.

Owner:湖南省湘电锅炉压力容器检验中心有限公司 +2

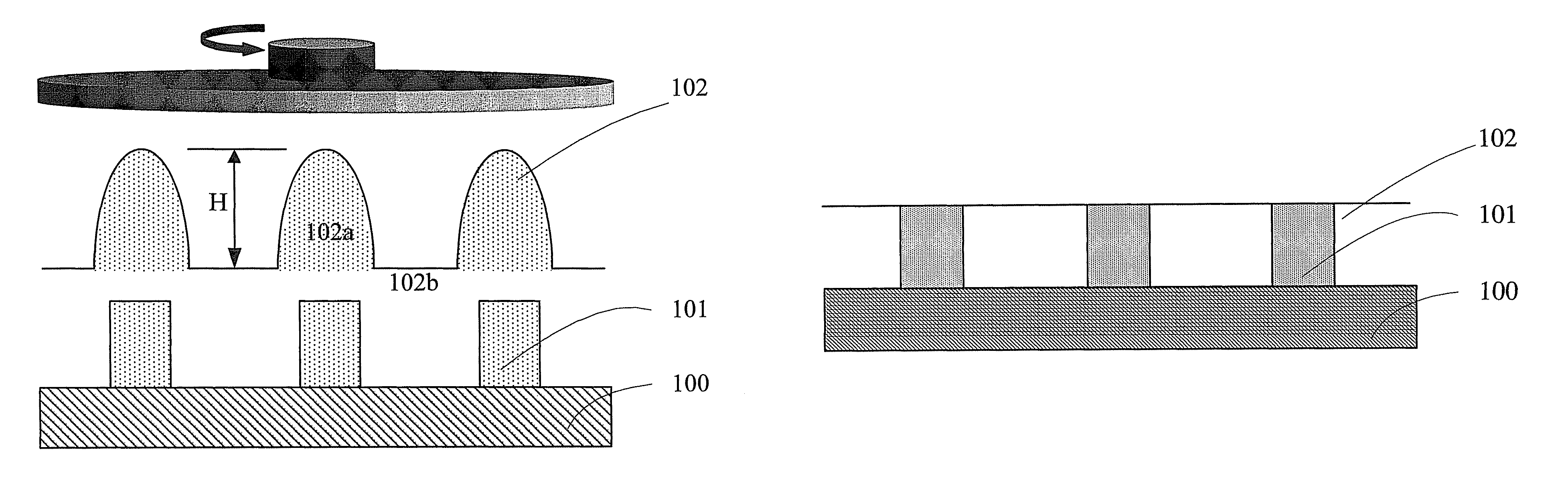

Chemical-mechanical planarization method and method for fabricating metal gate in gate-last process

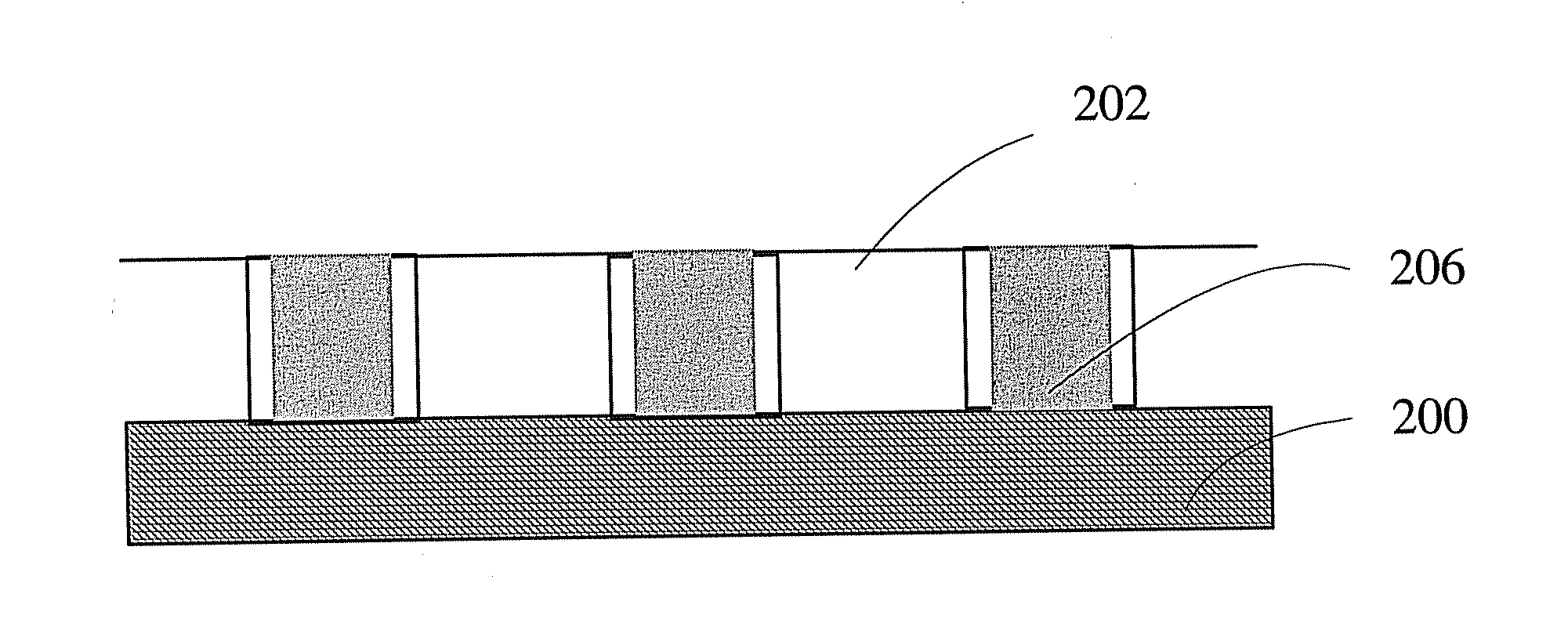

ActiveUS8252689B2Prevent short-circuitingImprove uniformitySemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSlurry

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Chemical-mechanical planarization method and method for fabricating metal gate in gate-last process

ActiveUS20120135589A1Improved within-die uniformityPrevent short-circuitingSemiconductor/solid-state device manufacturingSemiconductor devicesSlurryEngineering

The present invention provides a chemical-mechanical planarization method and a method for fabricating a metal gate in gate last process. The chemical-mechanical planarization method includes: providing a substrate including a gate and source / drain regions on the sides of the gate, the gate and the source / drain regions being overlay by an insulating layer, and the insulating layer including a protruding part above the gate and a recessed part above a surface of the substrate between gates; selectively doping the insulating layer such that only the protruding part is doped; and performing CMP on the substrate after doping, to remove the protruding part and planarize the surface of the substrate. By selectively doping the insulating layer, the method makes only the protruding part of the insulating layer doped, enhancing the corrosive attacks on the material of the protruding part by the slurry in the CMP, and increasing the removal rate of the material of the protruding part by the CMP, thereby improving the within-die uniformity of the process, consequently, there will not be excess metal in the insulating layer between gates, thereby preventing device short circuit risk induced by POP CMP process.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Multilayer chip capacitor and method for manufacturing the same

InactiveUS7251119B2Improve equipment reliabilityReduce frequencyFixed capacitor electrodesFixed capacitor dielectricEngineeringDielectric layer

A multilayer chip capacitor, and a method for manufacturing the same are provided. The capacitor includes a capacitor body having a plurality of dielectric layers stacked therein, a plurality of first and second internal electrodes formed on the dielectric layers, each of the internal electrodes including a main electrode portion and a lead portion, chip-protecting side members formed on both sides of the capacitor body to contact both sides of the first and second internal electrodes, and a pair of external electrodes formed on the outer surface of the capacitor body. The width of the main electrode portion is the same as that of the dielectric layers, and the width of the lead portion is smaller than that of the dielectric layers.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

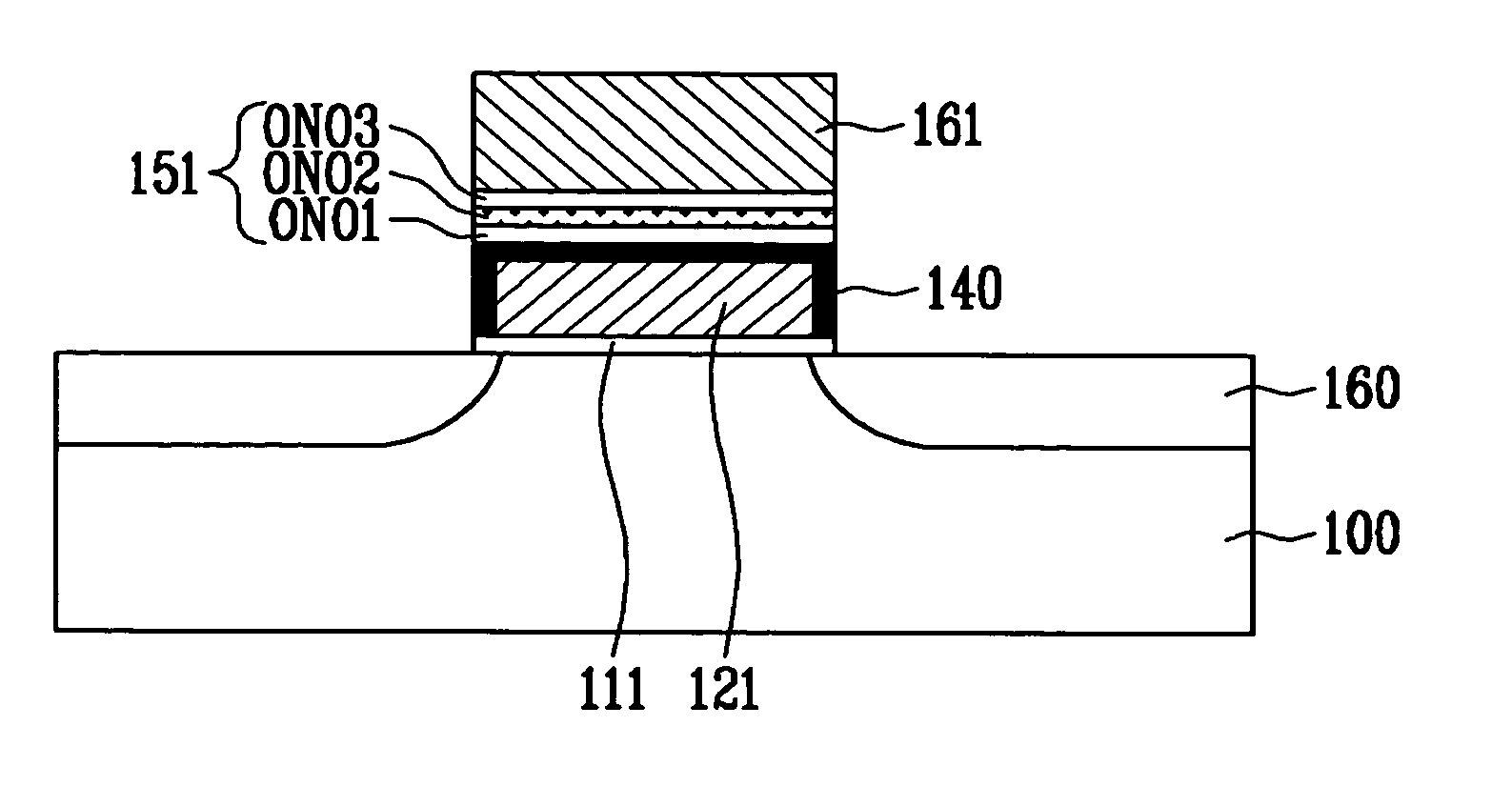

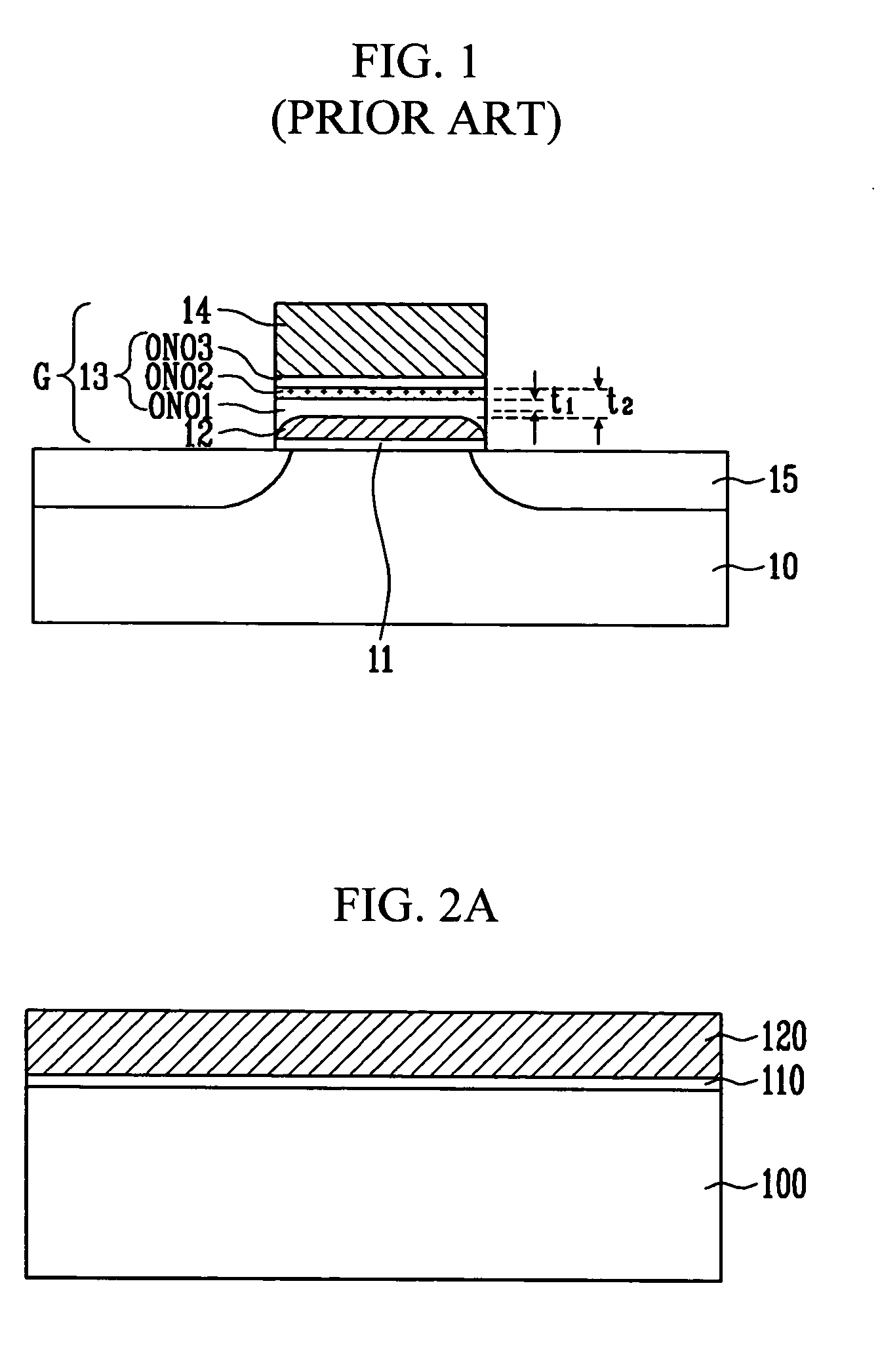

Method of manufacturing a non-volatile memory device

InactiveCN1945798AImproved data erasure featureImproved data programming featuresTransistorSolid-state devicesInsulation layerNon-volatile memory

In a method of manufacturing a non-volatile memory device, a first gate insulation layer and a conductive layer are formed on a substrate and then the conductive layer is partially oxidized to form an oxide layer pattern. The conductive layer is partially etched using the oxide layer pattern as an etching mask to form a floating gate electrode on the first gate insulation layer and then the silicon layer is formed on the substrate including the floating gate electrode. The silicon layer is oxidized to form a tunnel insulation layer and a second gate insulation layer on a sidewall of the floating gate electrode and on a surface portion of the substrate adjacent to the floating gate electrode and then a control gate electrode is formed on the tunnel insulation layer and the second gate insulation layer. The present invention can restrain the change of an end profile of a floating gate electrode on the floating gate electrode and the change of the thickness of a gate insulation layer in the heating oxidation technics to form a tunnel oxide layer. Thus, the character of the data erasure and the data programme of the non-volatile memory device can be improved.

Owner:SAMSUNG ELECTRONICS CO LTD

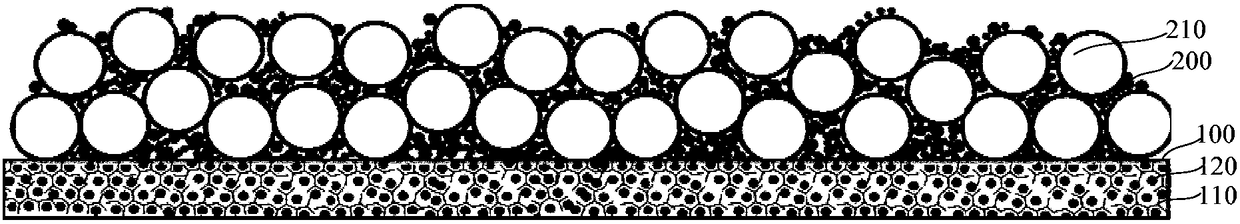

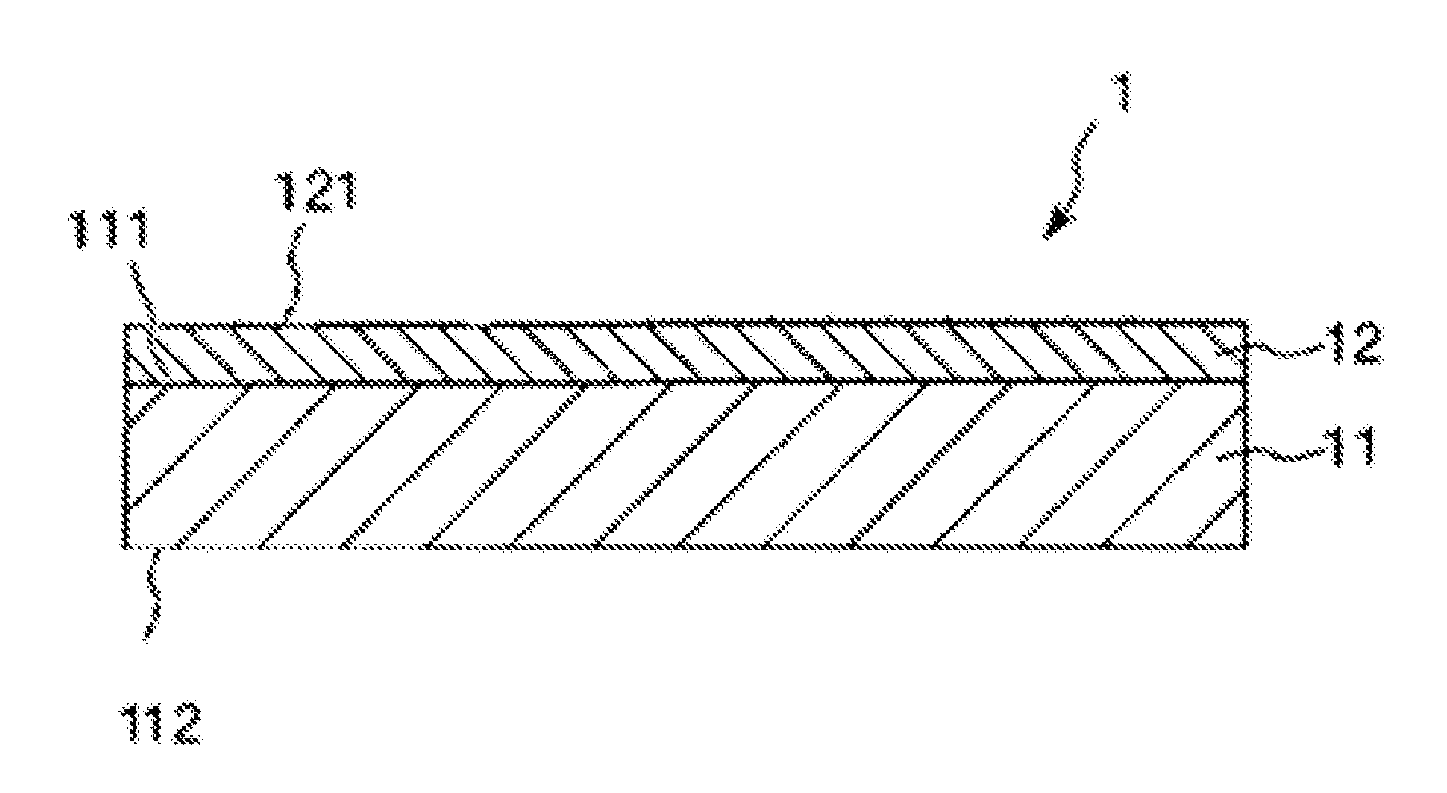

Anode current collector and preparation method thereof, negative electrode sheet, and lithium ion battery

PendingCN109244474AImprove distribution uniformityIncrease energy densityElectrode carriers/collectorsSecondary cellsLithium-ion batteryMaterials science

The invention discloses a negative electrode current collector comprising a porous metal substrate and a lithium-containing material incorporated in the porous metal substrate, the lithium-containingmaterial being uniformly loaded in pores of the porous metal substrate, and the lithium-containing material being capable of being removed from the pores during a lithium ion battery cycle. The invention also discloses a negative electrode sheet, comprising the negative electrode current collector and a negative electrode active material layer of the negative electrode current collector surface, wherein the negative electrode material layer comprises a negative electrode active material. The invention also discloses a preparation method of the negative electrode current collector and a lithiumion battery.

Owner:GREE ELECTRIC APPLIANCES INC

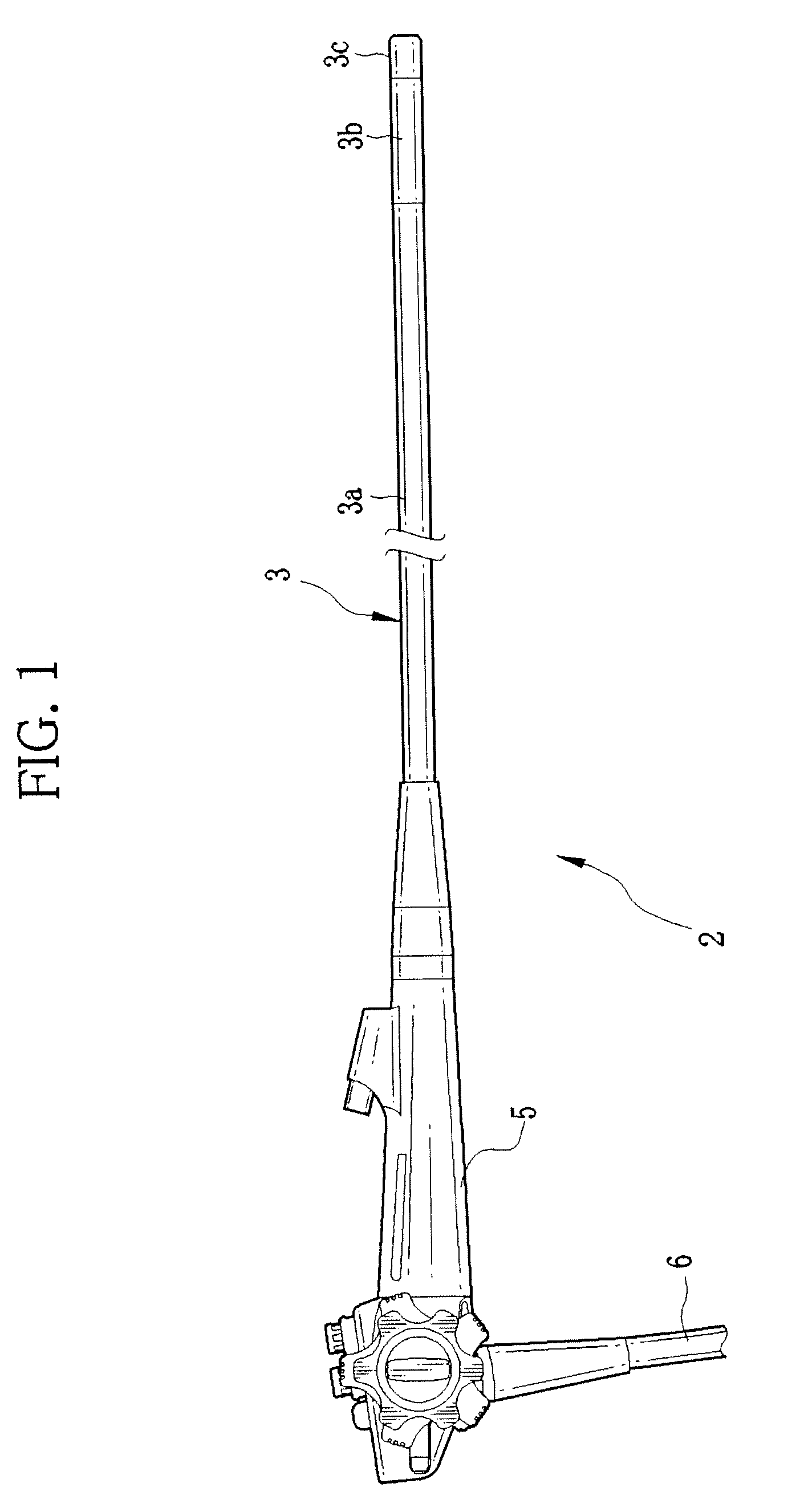

Method for production of flexible tube for endoscope

Upon starting continuous extrusion, the temperature of a hard resin and a soft resin is increased in extrusion sections. A screw of the extrusion section of the hard resin is set at high rpm at first. The hard resin reaches a maximum temperature α(° C.) by heating of friction with the screw, and comes to have high flowability. Upon starting conveyance of an assembly, a large amount of molten hard resin and a small amount of molten soft resin are extruded onto the periphery of a tubular structure. Upon passage of a point A of the tubular structure under annular discharge throats, the extrusion amount of the hard resin starts gradually decreasing, and the extrusion amount of the soft resin starts gradually increasing. Since the temperature of the hard resin starts dropping a short time after the decrease in the extrusion amount, the hard resin maintains the high flowability.

Owner:FUJIFILM CORP

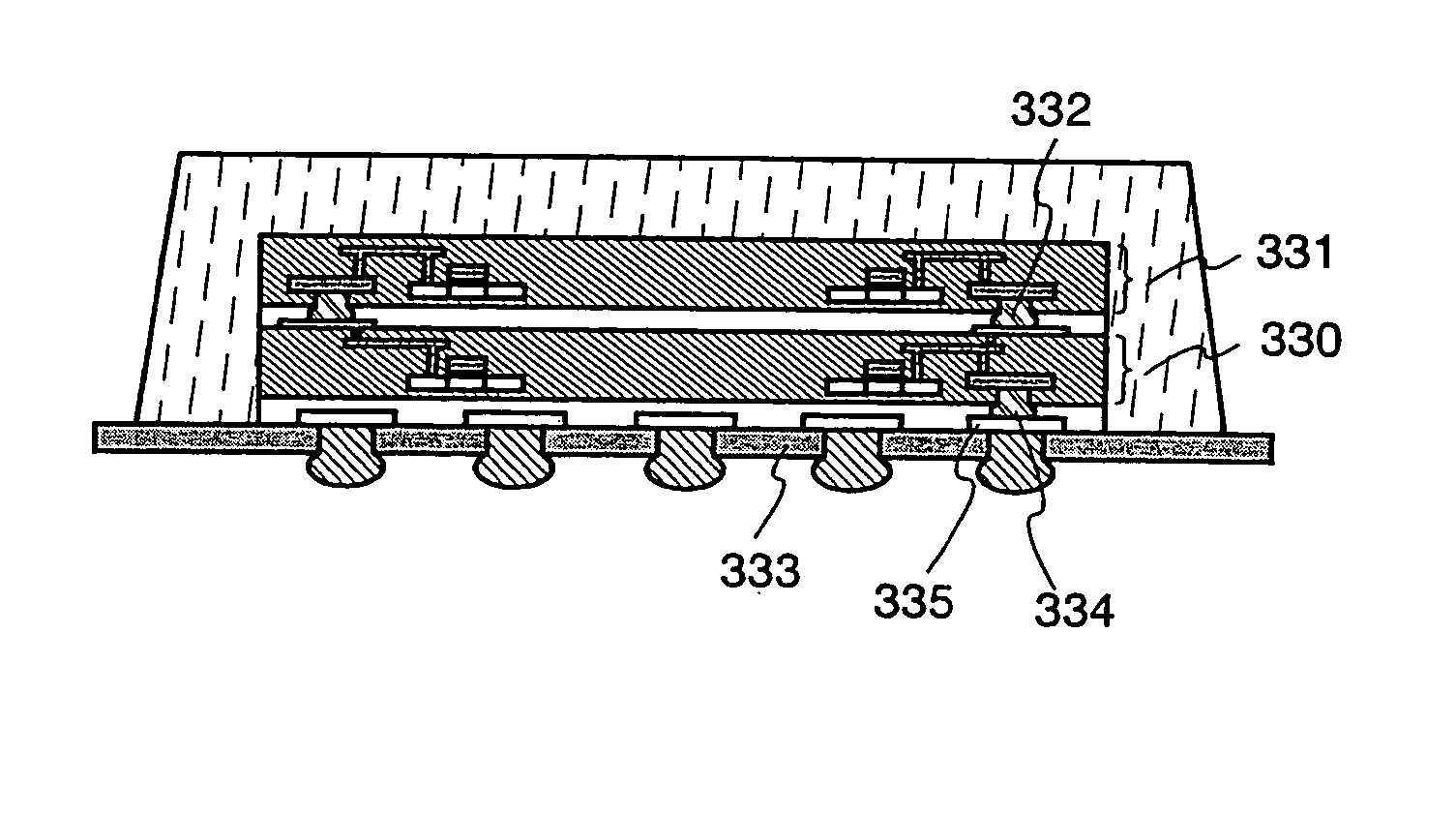

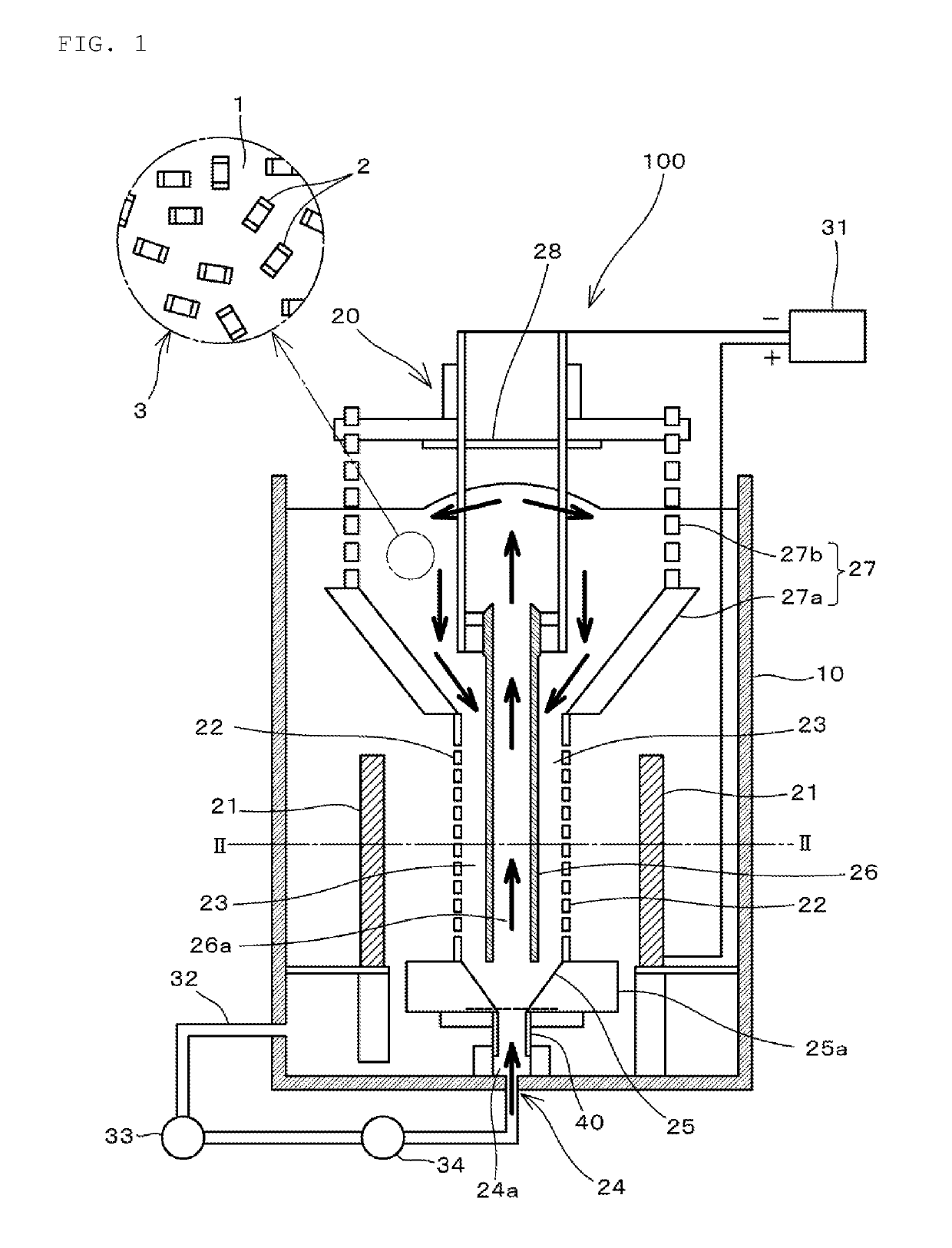

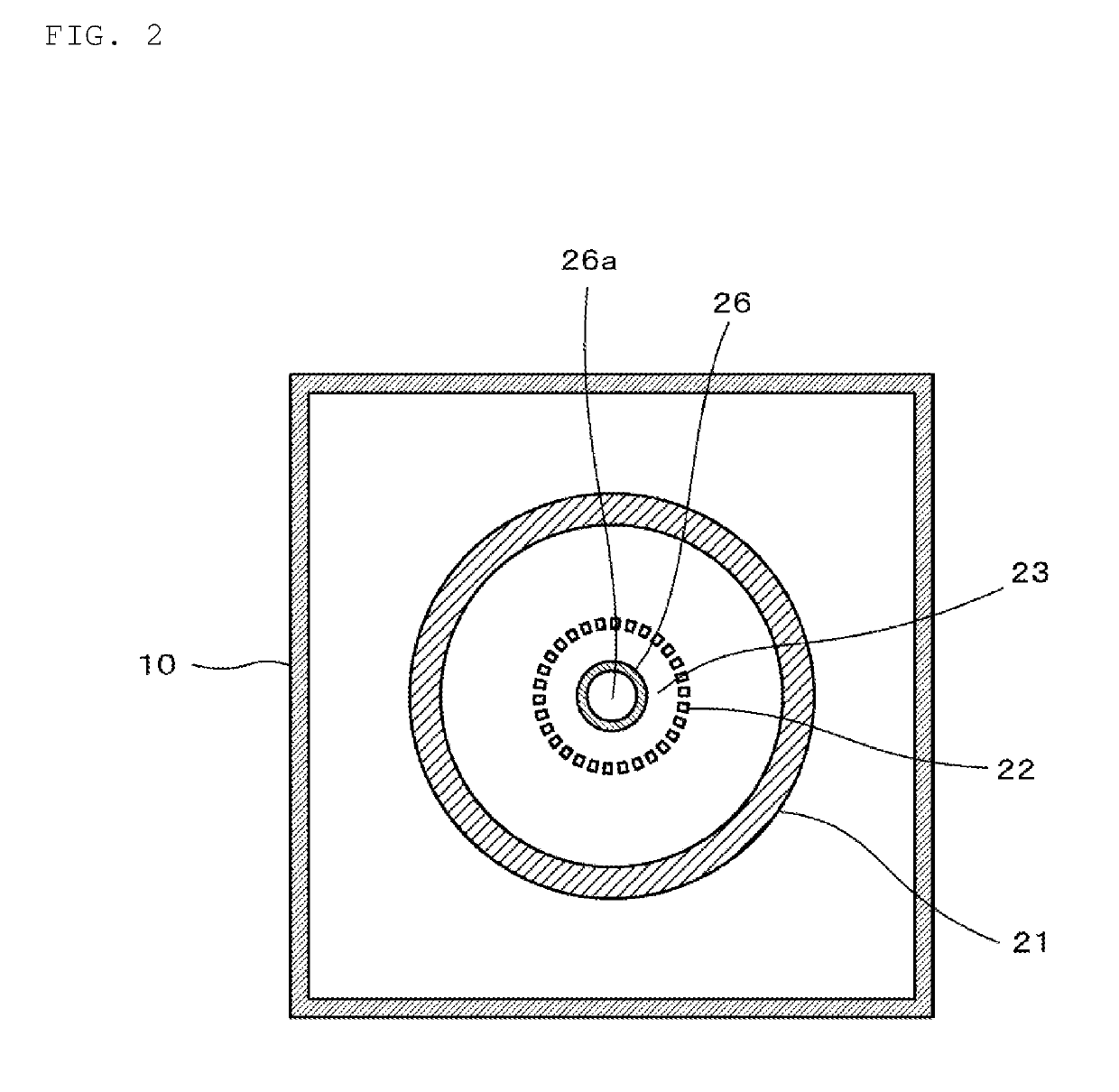

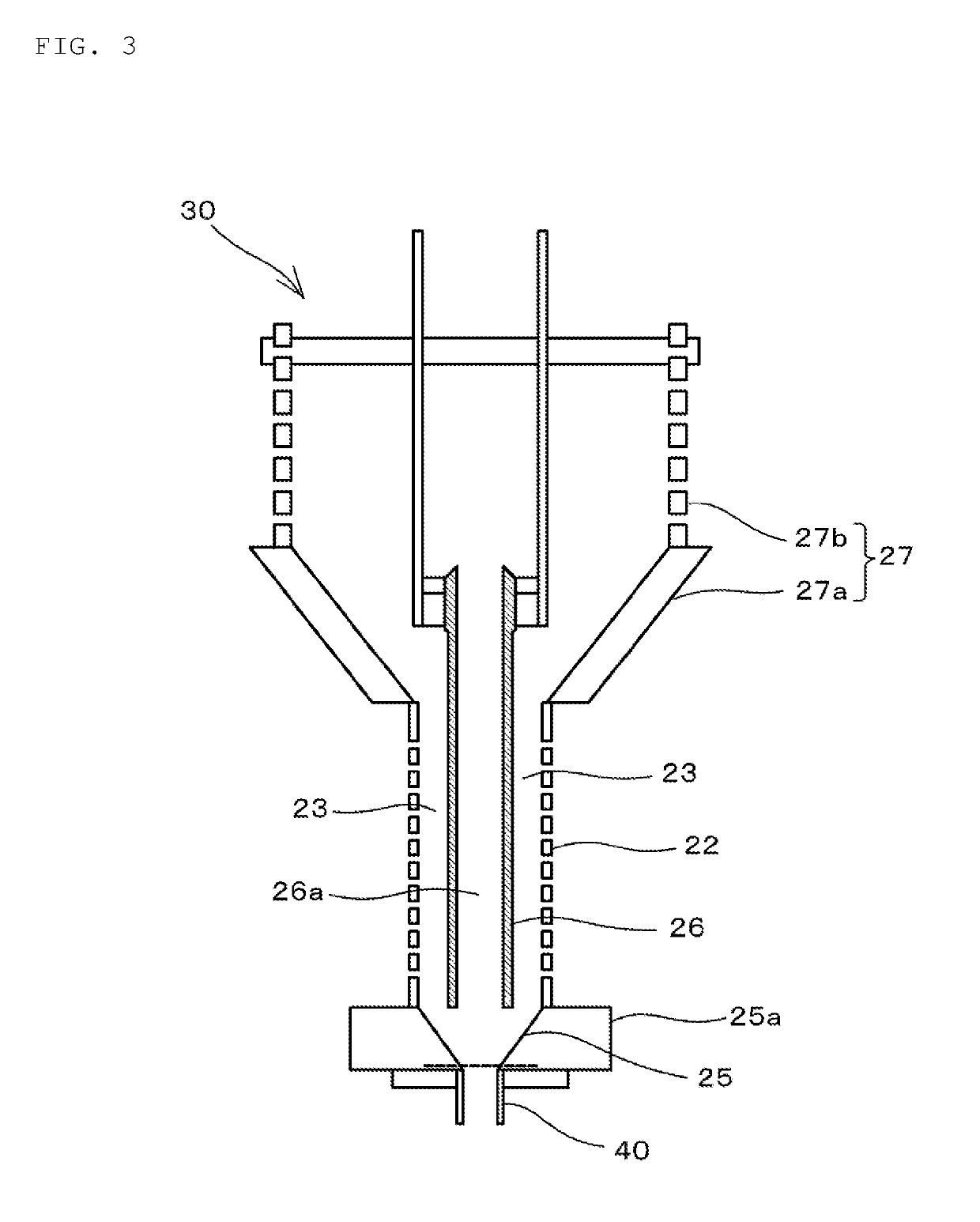

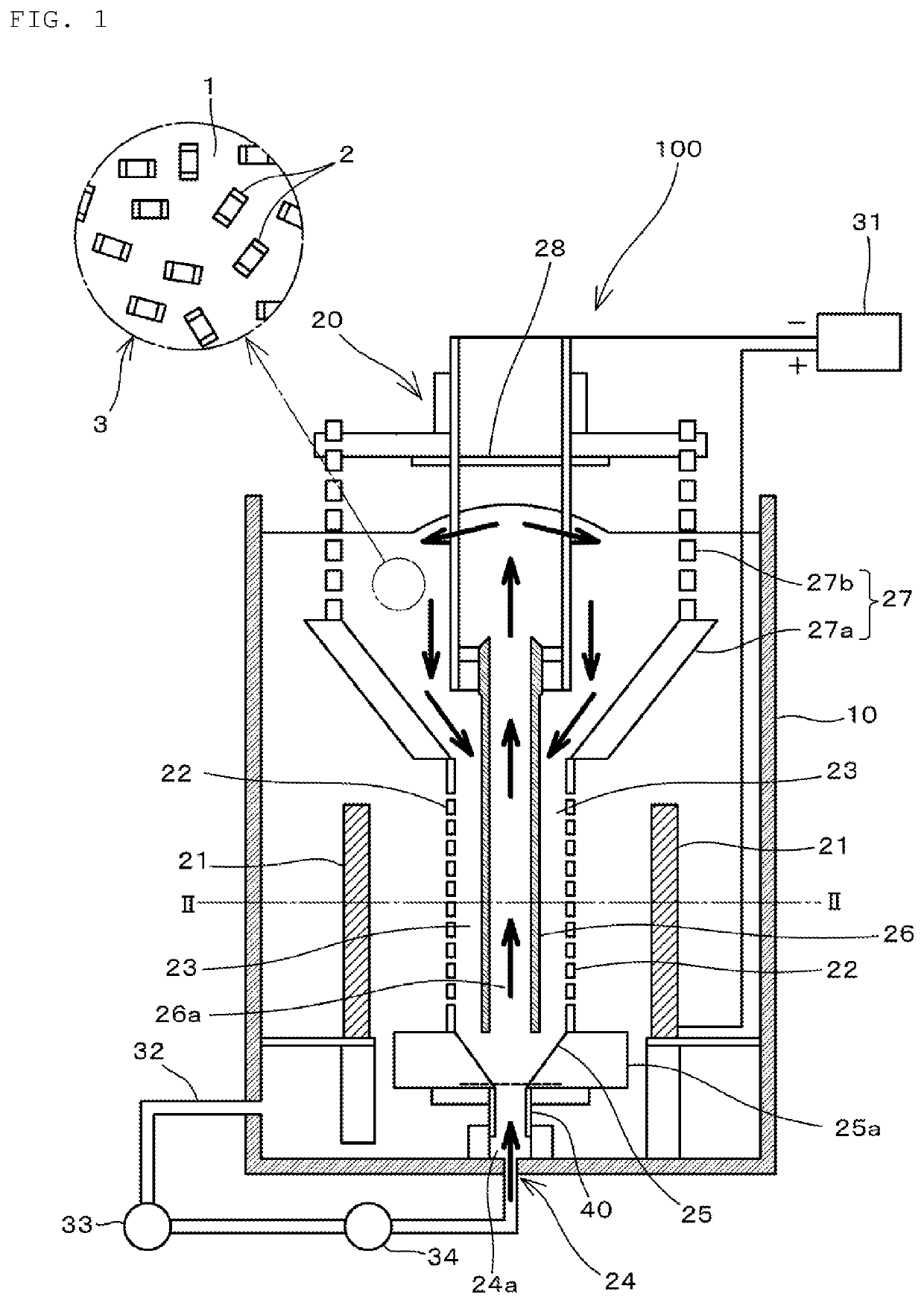

Plating apparatus and plating method

ActiveUS20190112728A1Satisfactory platingStable current densityCellsTanksMechanical engineeringElectroplating

Owner:MURATA MFG CO LTD

Method for forming dielectric layer between gates in flash memory device

ActiveUS6984562B2Prevent thickness variationTransistorSolid-state devicesNitrogen gasDielectric layer

Owner:STMICROELECTRONICS SRL +1

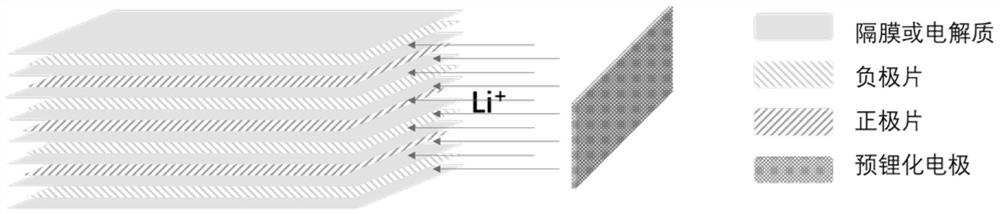

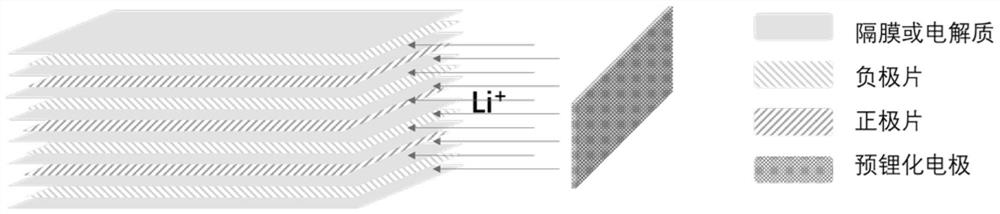

Lithium ion energy storage device and pre-lithiation and production method thereof

ActiveCN112993208AAvoid applyingShorten the timeFinal product manufactureSecondary cellsEngineeringBattery cell

The invention provides a lithium ion energy storage device and a pre-lithiation and production method thereof. One or more pre-lithiation electrodes are arranged at a preset distance outside a battery cell of the lithium ion energy storage device in a direction vertical to a pole piece, and then the pre-lithiation electrodes are charged or discharged with a positive electrode and a negative electrode so that lithium ions in the pre-lithiation electrodes enter the electrode through gaps among the positive electrode, the negative electrode and the diaphragm along the direction parallel to an electrode plate, and the pre-lithiation method avoids the design scheme that the lithium ions must penetrate through the electrode plate of the energy storage device along the vertical direction in the traditional pre-lithiation method. The method completely overcomes the defect that a positive electrode foil and a negative electrode foil must be hole foils and the negative influence on the production efficiency and the finished product quality caused by the hole foils so that the production process is simpler and more controllable, meanwhile, the technology can also be used for secondary lithium supplement operation of the finished product lithium ion energy storage device, and help is provided for regeneration of the lithium ion energy storage device.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Method for manufacturing organic electroluminescent device and organic electroluminescent device

InactiveUS8237357B2Prevent thickness variationHigh quality imagingDischarge tube luminescnet screensElectroluminescent light sourcesOrganic layerOrganic electroluminescence

An organic electroluminescent device includes partition walls dividing a region into a first region, a second region and a third region, a first organic layer disposed in the first region, a second organic layer disposed in the second region, and a third organic layer disposed in the third region. The first region includes a plurality of effective pixels involved in light emission, continuously disposed along a first aligning axis. Each effective pixel includes an effective pixel electrode, a common electrode, and the first organic layer between the effective pixel electrode and the common electrode. The second region and the third region oppose each other with the first region therebetween, and the first region, the second region and the third region are aligned along the first aligning axis.

Owner:SEIKO EPSON CORP

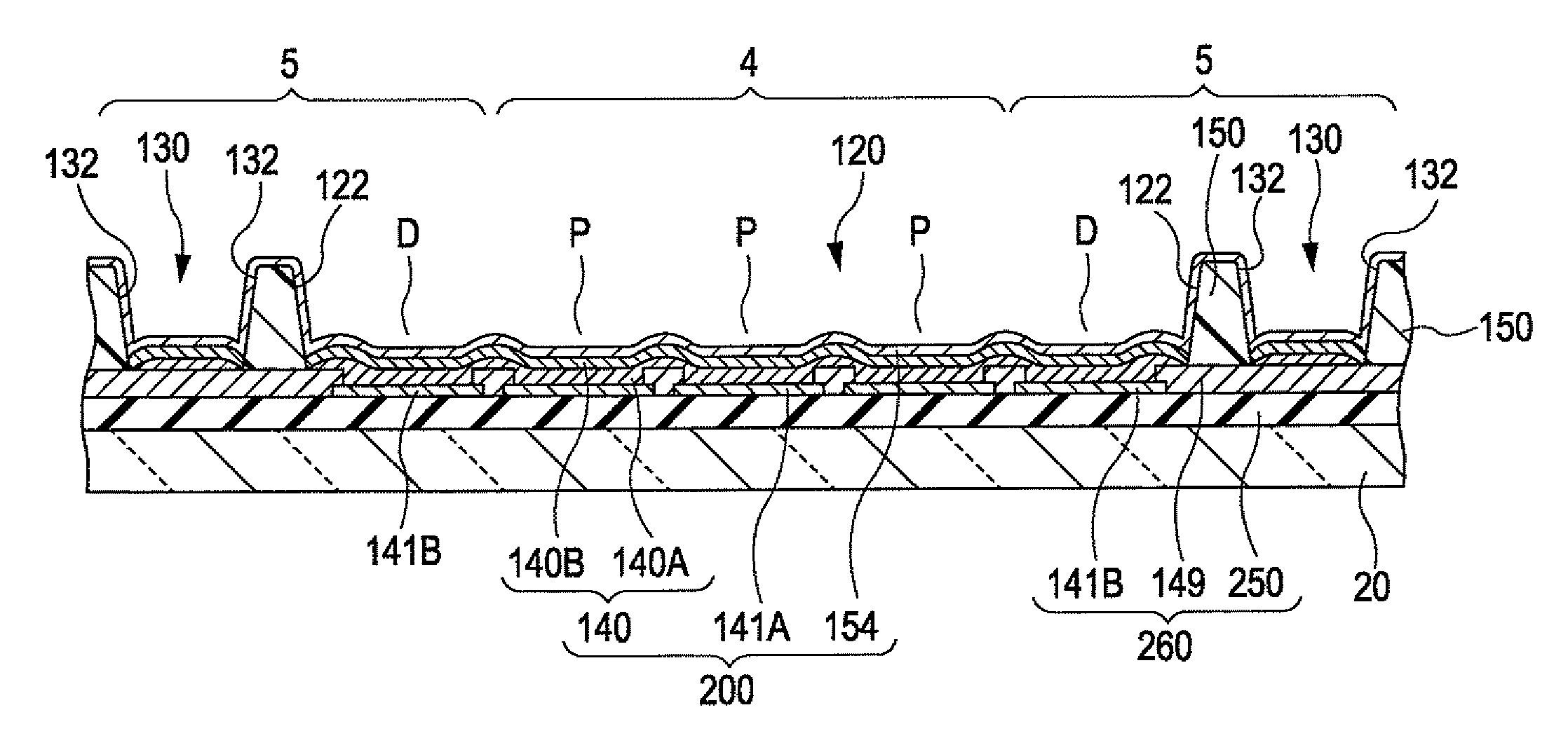

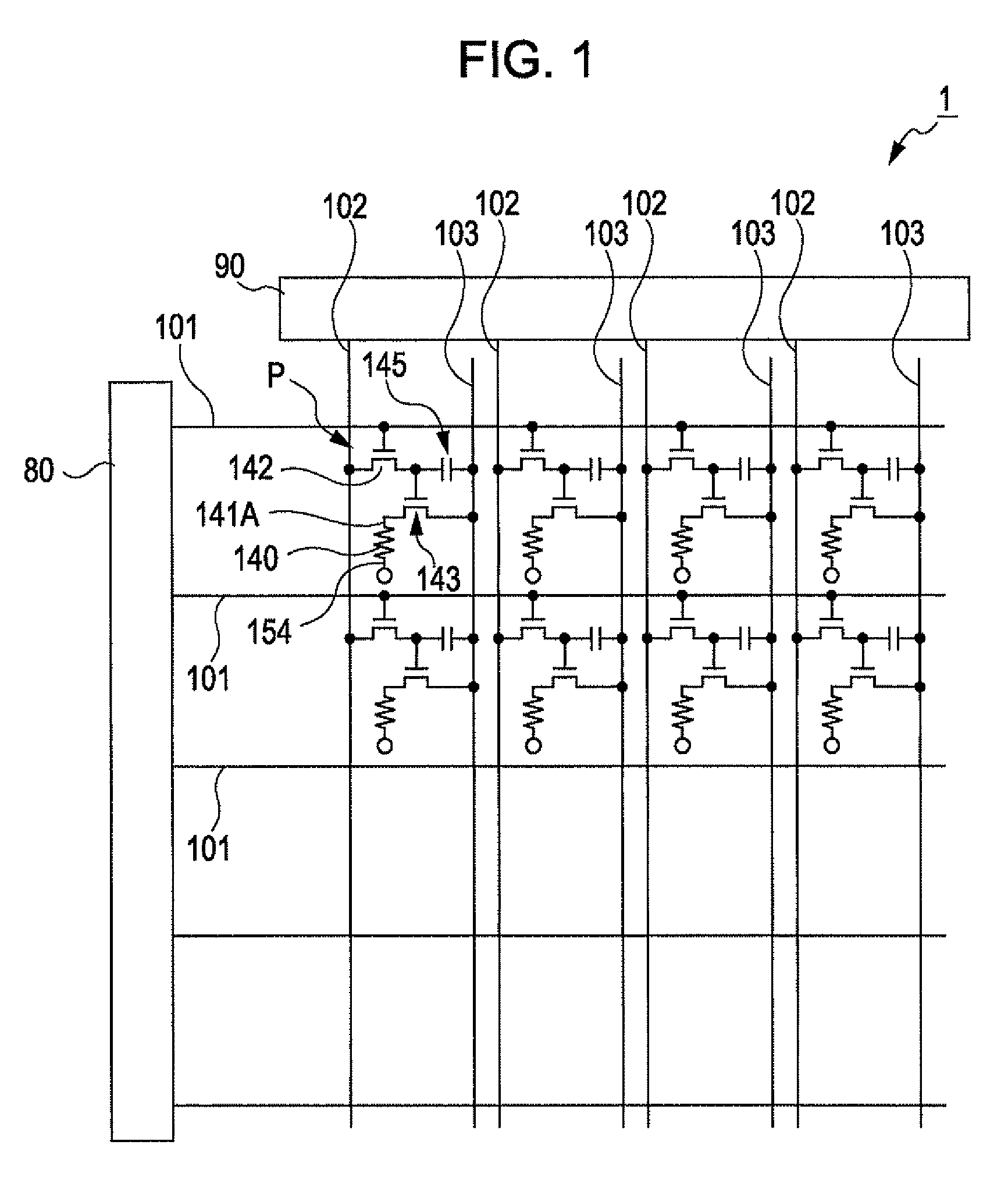

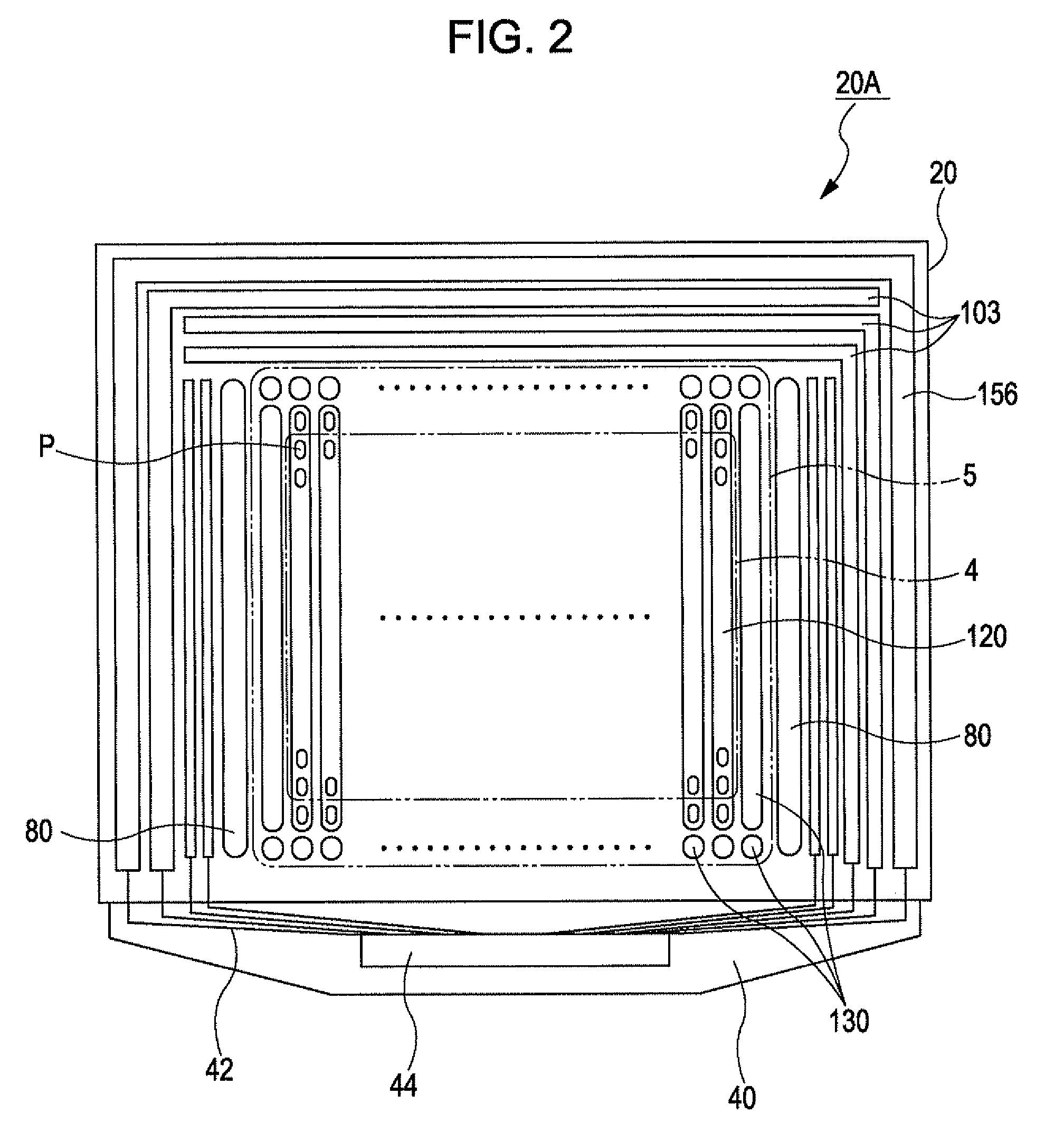

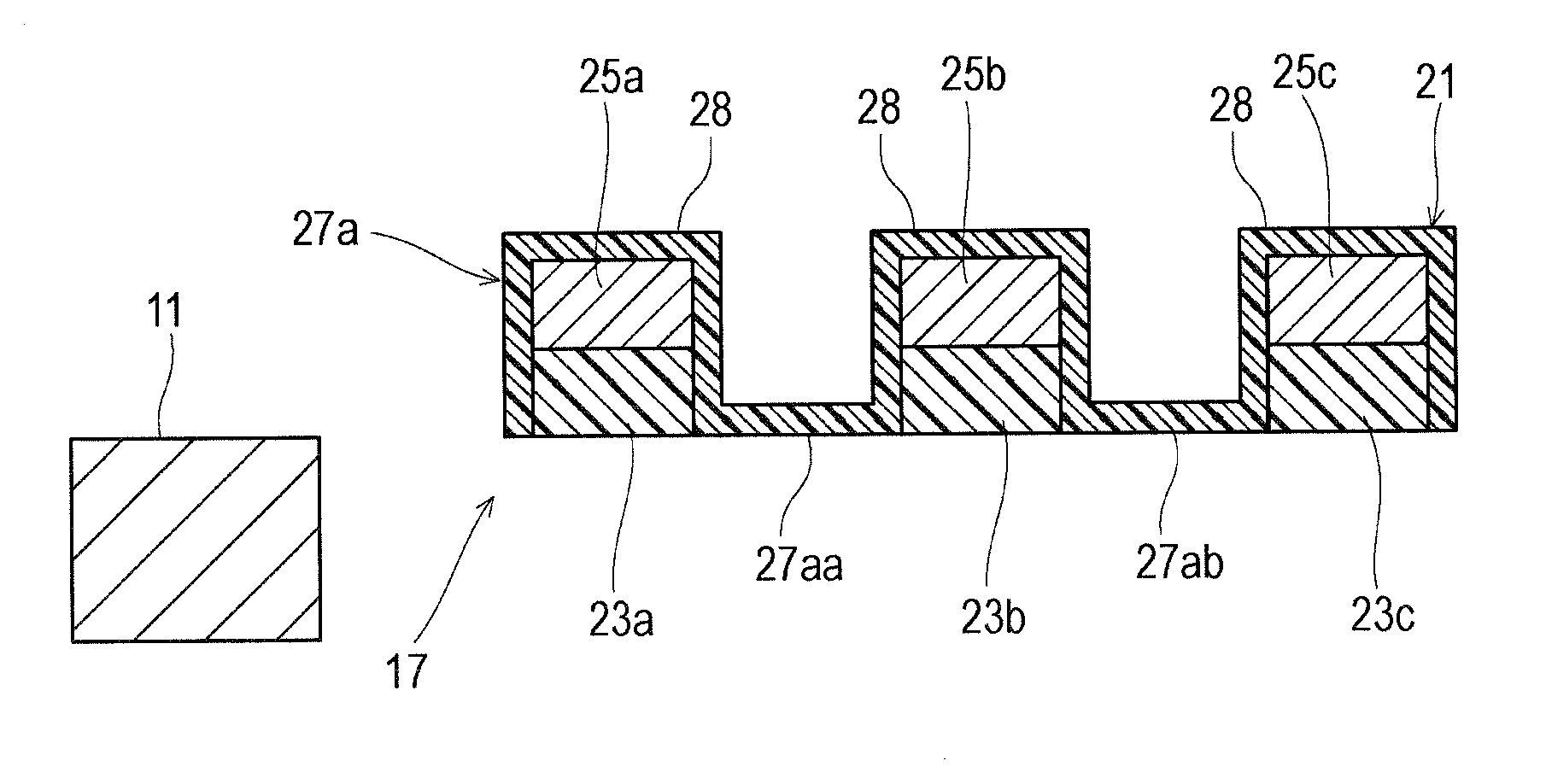

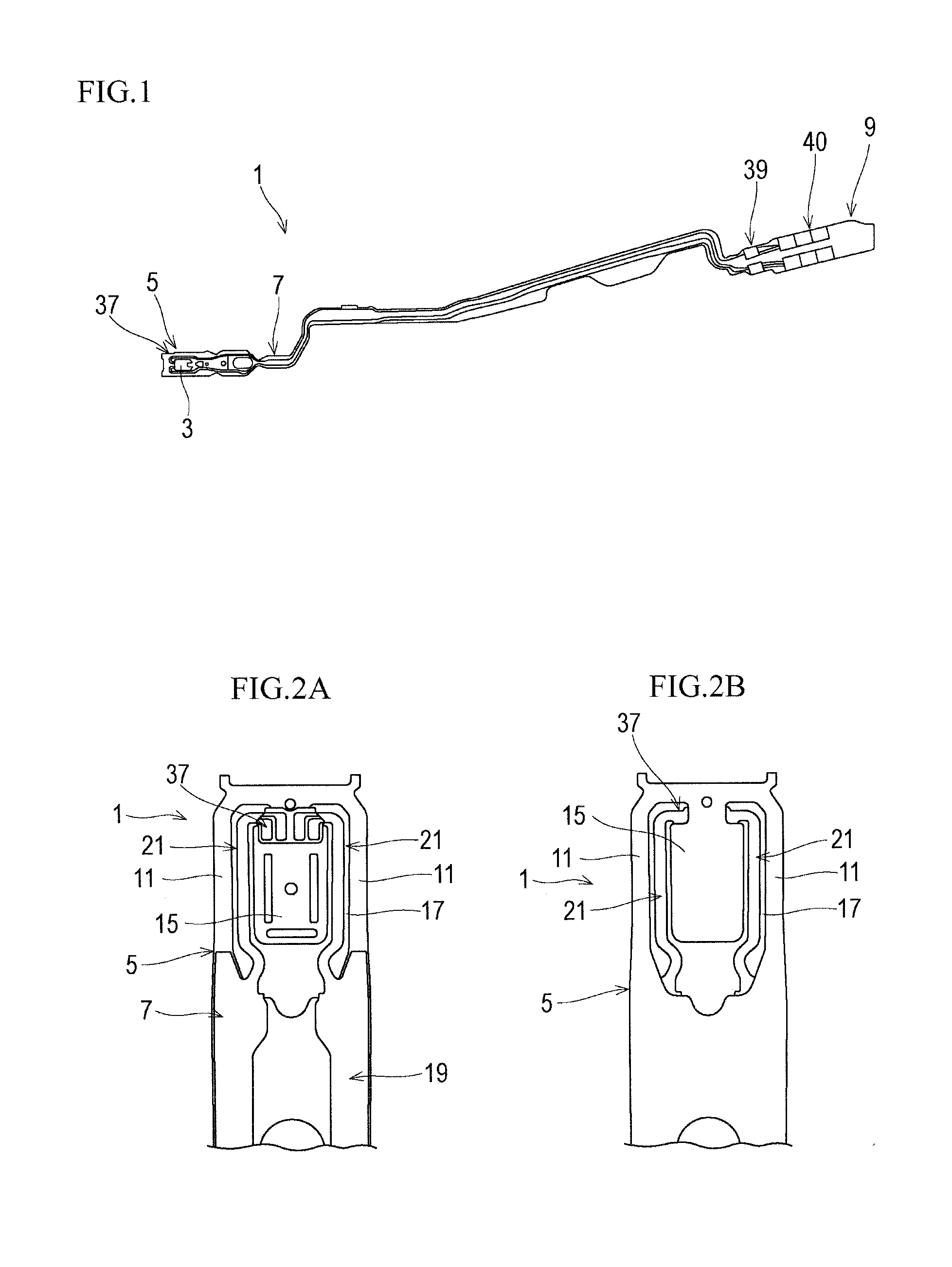

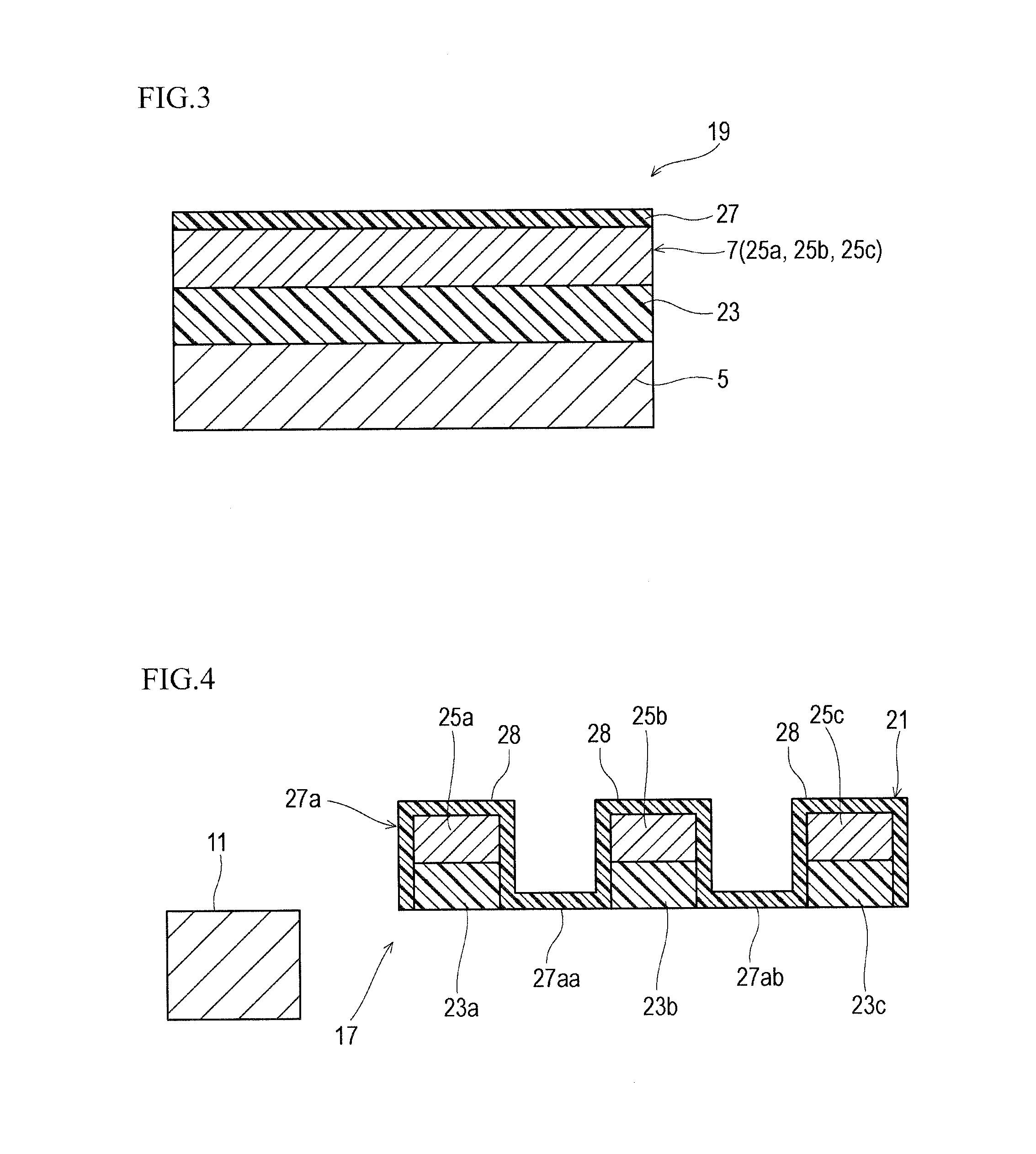

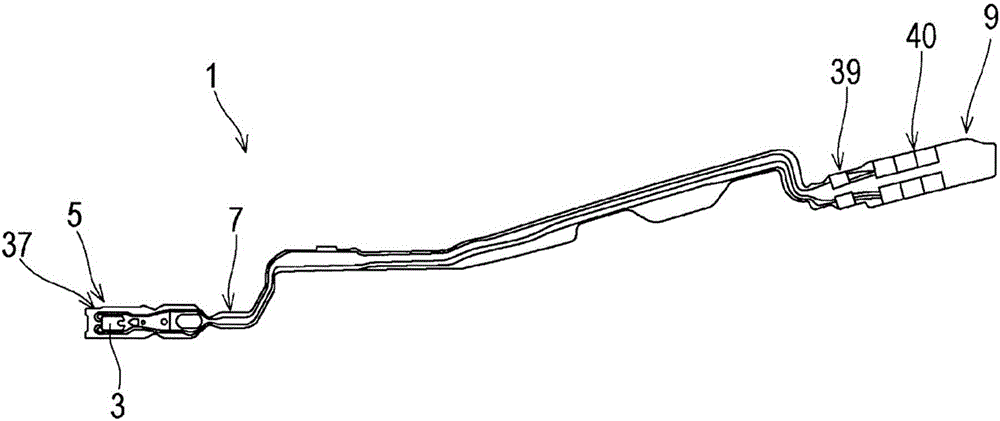

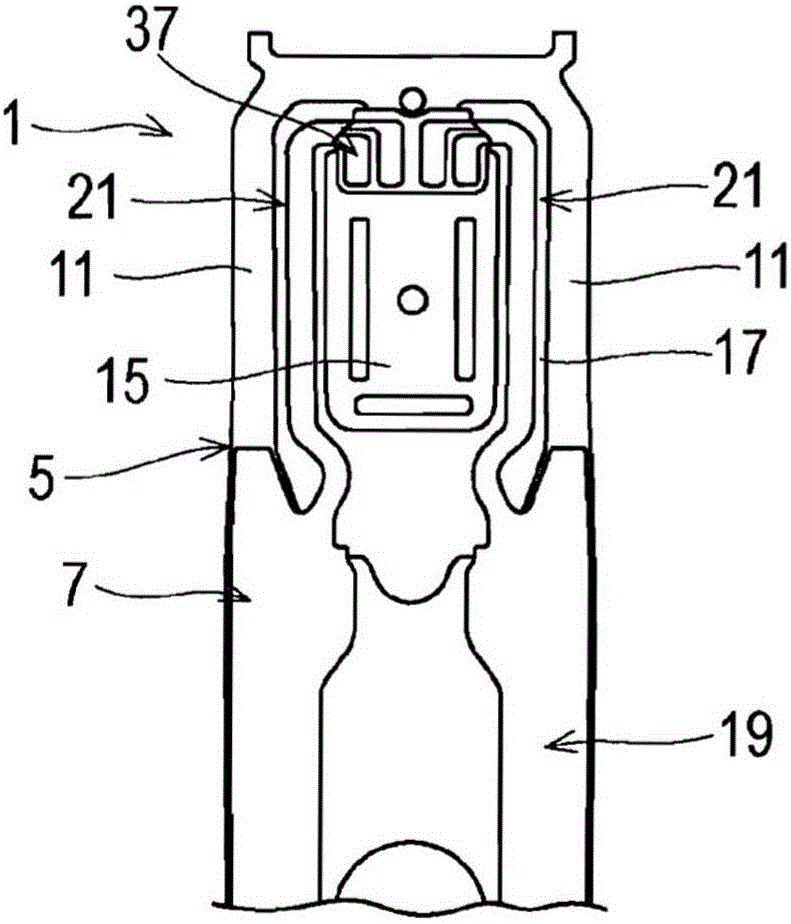

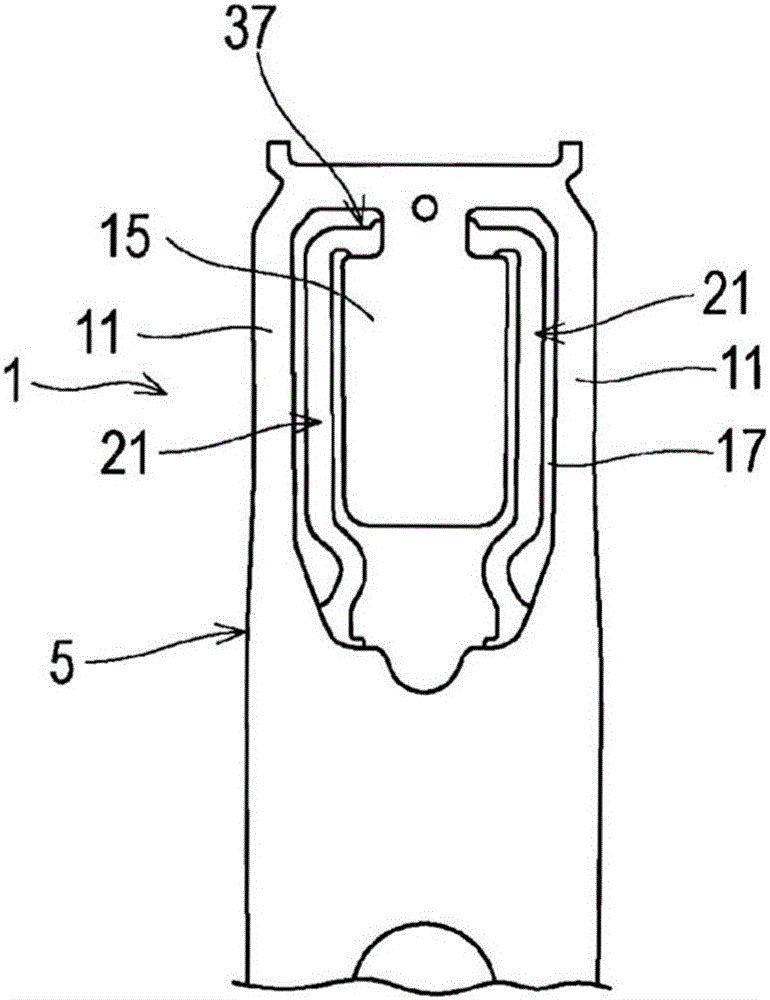

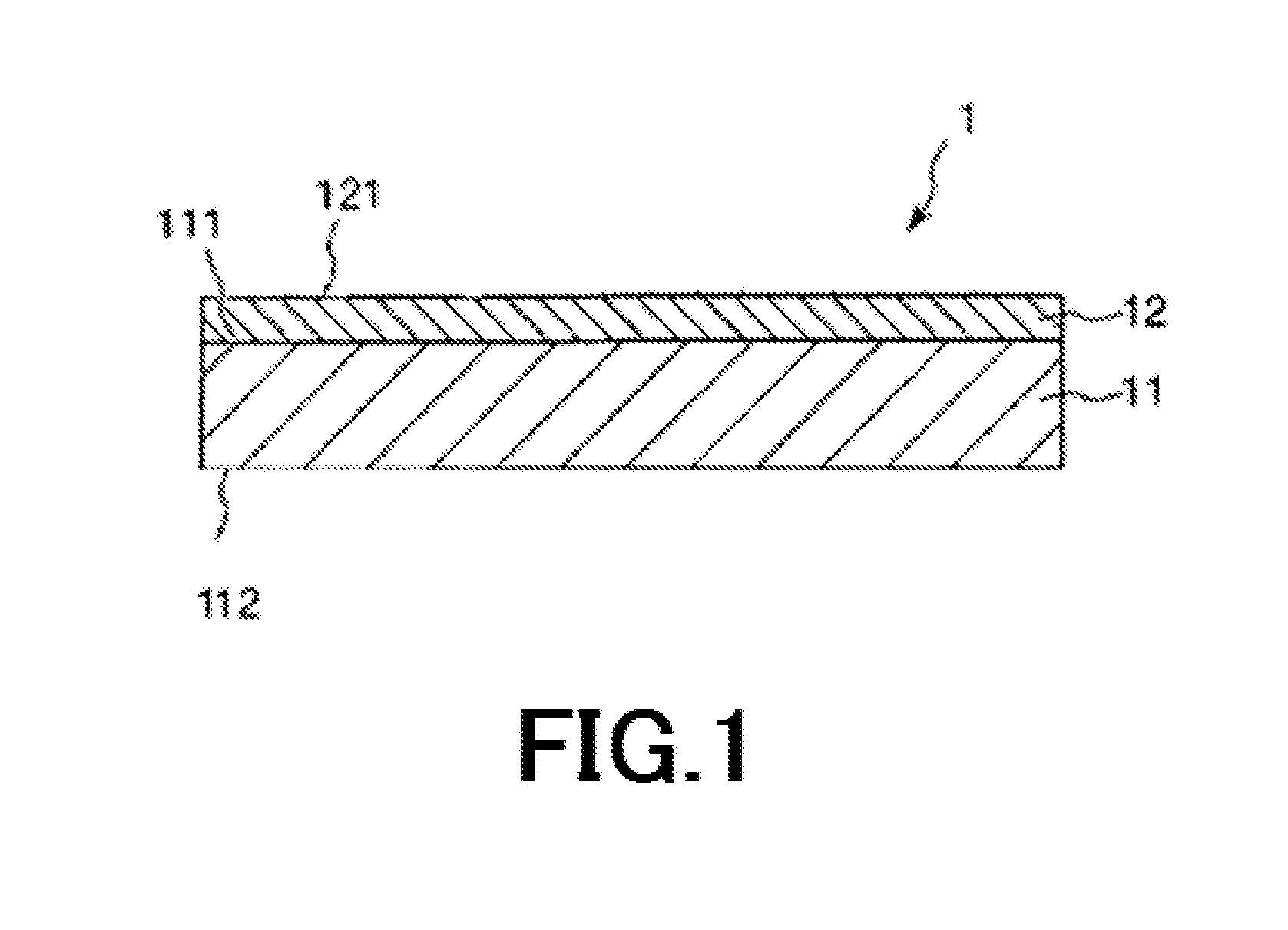

Wiring thin plate having aerial wiring portion and method of manufacturing the same

ActiveUS20160316555A1Reduce stiffnessPrevent thickness variationElectrical connection between head and armPrinted circuit aspectsEngineeringTextile

Provided is a wiring thin plate capable of suppressing deterioration of an electric characteristic and variation in thickness of an aerial wiring portion while advancing reduction of rigidity of the aerial wiring portion. The wiring thin plate includes an aerial wiring portion including wiring traces and passing over an airspace, aerial base layers provided at the respective wiring traces in the aerial wiring portion and being apart from each other, and an aerial cover layer provided in the aerial wiring portion and spanning from the wiring traces of the aerial wiring portion through the aerial base layers to interspaces between adjacent aerial base layers of said aerial base layers.

Owner:NHK SPRING CO LTD

A kind of lithium ion energy storage device, its pre-lithiation, and preparation method

ActiveCN112993208BAvoid applyingShorten the timeFinal product manufactureSecondary cellsEngineeringMaterials science

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Wiring thin plate having aerial wiring portion and method of manufacturing the same

ActiveCN106068057APrevent thickness variationElectrical connection between head and armPrinted circuit detailsEngineeringTextile

Provided is a wiring thin plate capable of suppressing deterioration of an electric characteristic and variation in thickness of an aerial wiring portion while advancing reduction of rigidity of the aerial wiring portion. The wiring thin plate includes an aerial wiring portion including wiring traces and passing over an airspace, aerial base layers provided at the respective wiring traces in the aerial wiring portion and being apart from each other, and an aerial cover layer provided in the aerial wiring portion and spanning from the wiring traces of the aerial wiring portion through the aerial base layers to interspaces between adjacent aerial base layers of said aerial base layers.

Owner:NHK SPRING CO LTD

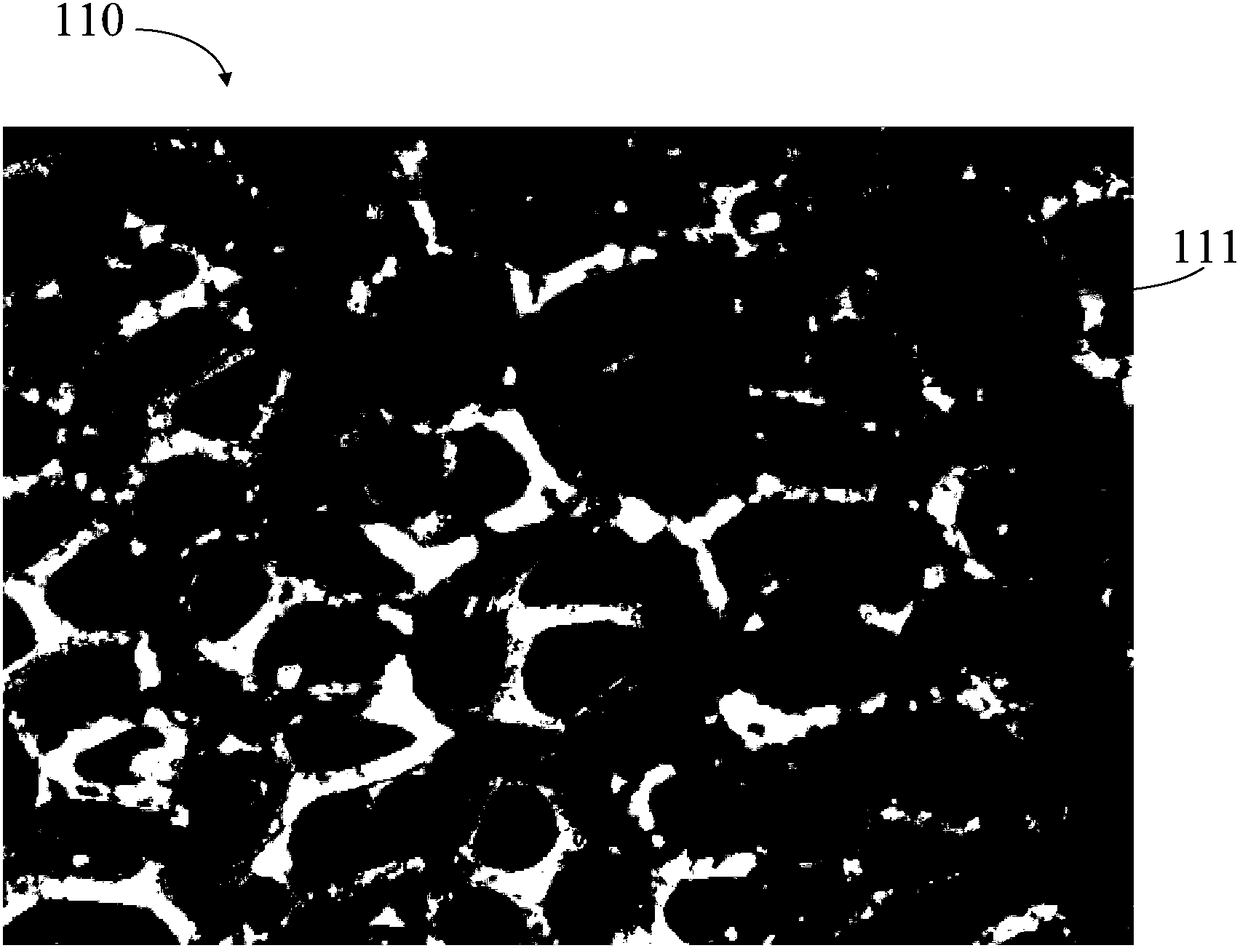

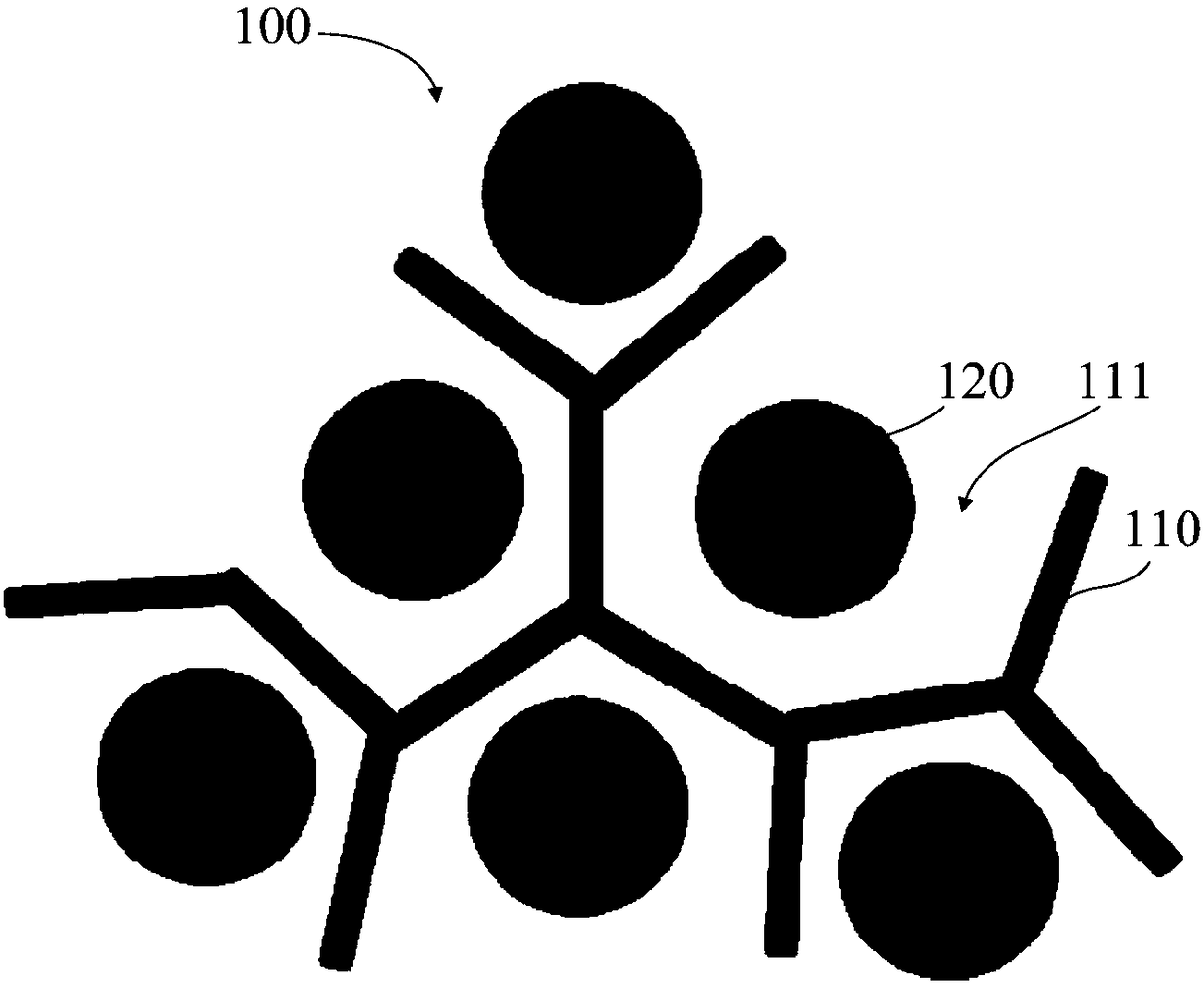

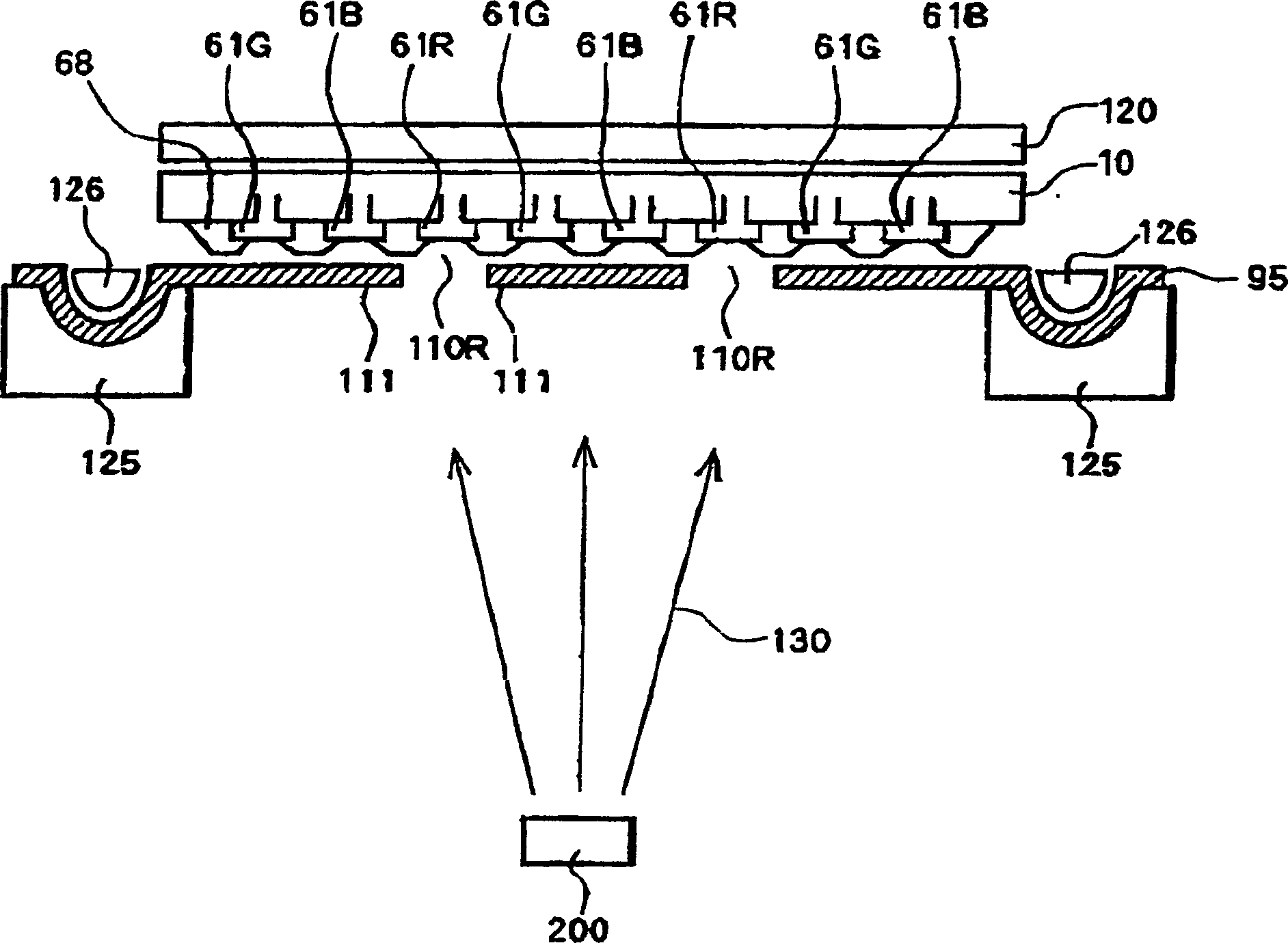

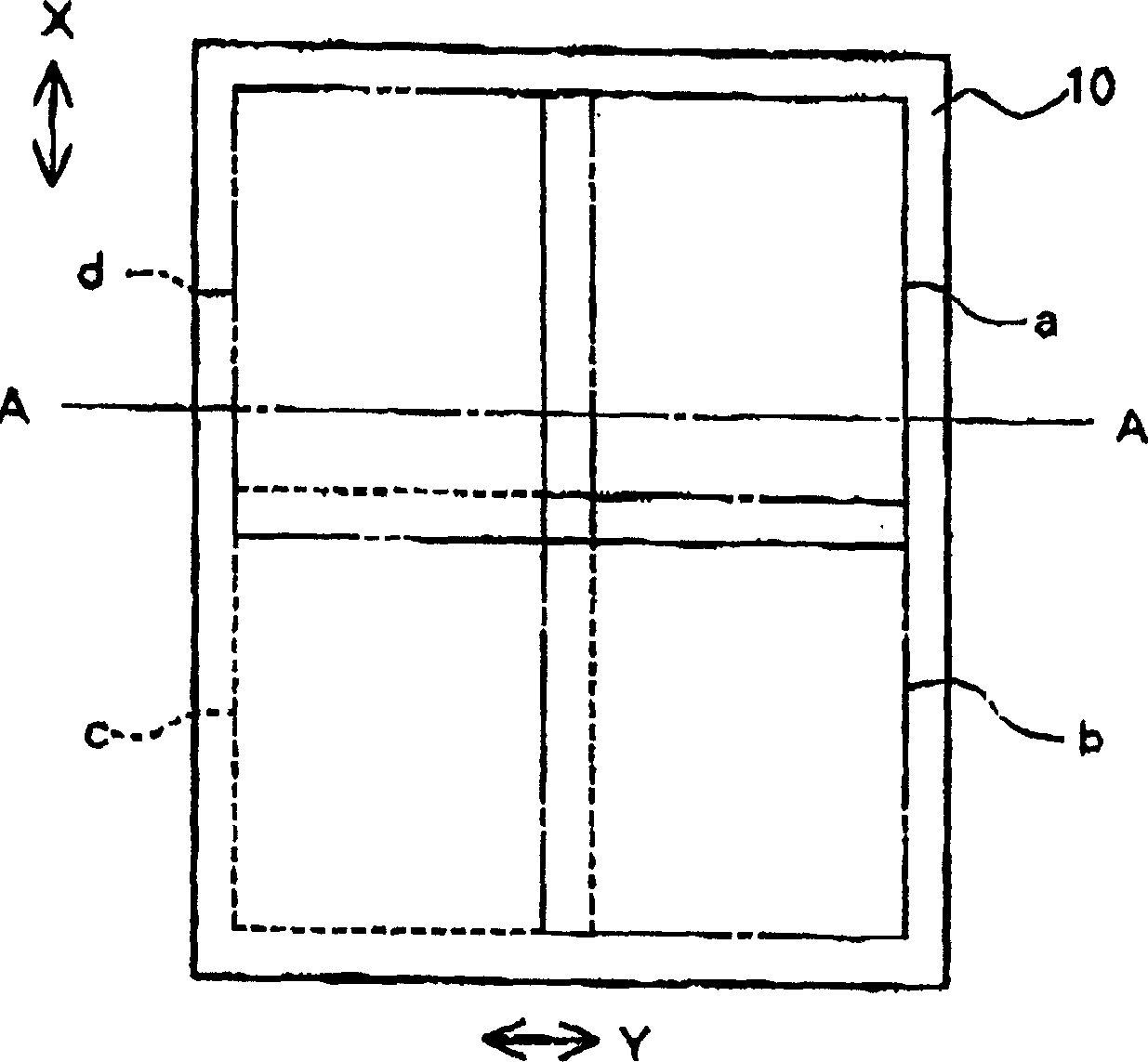

Laminated material and lamination method by using mask with preset pattern on substrate

InactiveCN1265680CPrevent thickness variationElectroluminescent light sourcesSolid-state devicesEngineeringMechanical engineering

Upon formation of a layer such as an emissive layer of an organic EL element by attaching an emissive material onto a substrate (10), an evaporation mask (100) including an opening (110) corresponding to the layer formed to have a plurality of individual patterns and having an area, for example, smaller than the substrate is disposed between the substrate (10) and a material source (200). A relative position between the mask (100) and the material source (200), and the substrate (10) is slid by a predetermined pitch corresponding to the size of a pixel of the substrate (10), thereby forming a material layer (such as the emissive layer 64) in a predetermined region of the substrate. As a result, the material layer can be formed on the substrate through, for example, evaporation with a high accuracy.

Owner:SANYO ELECTRIC CO LTD

Plating apparatus and plating method

A plating apparatus includes a plating tank and a plating unit that performs electrolytic plating on an object. The plating unit includes a workpiece passage region including a partition wall that allows passage of the plating solution but does not allow passage of the object, the workpiece passage region passing the object from above toward below, an injection unit that injects the plating solution from below toward above, a mixing unit that mixes the plating solution injected by the injection unit and the object to be plated passing through the workpiece passage region, an anode outside the workpiece passage region, a cathode inside the workpiece passage region including a hollow region through which a mixed fluid of the plating solution and the object to be plated passes from below toward above, and a guidance unit that guides the mixed fluid to the workpiece passage region.

Owner:MURATA MFG CO LTD

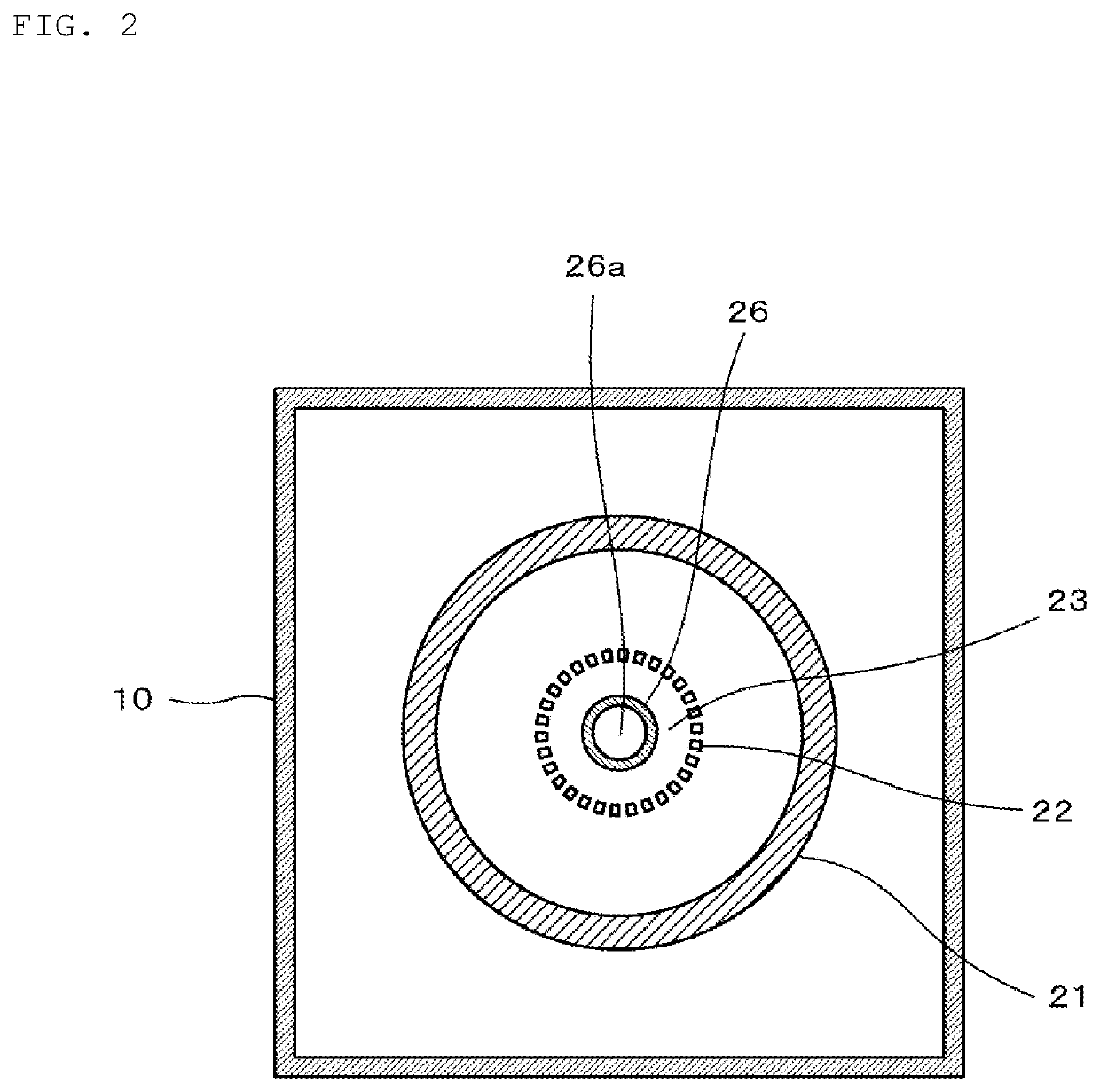

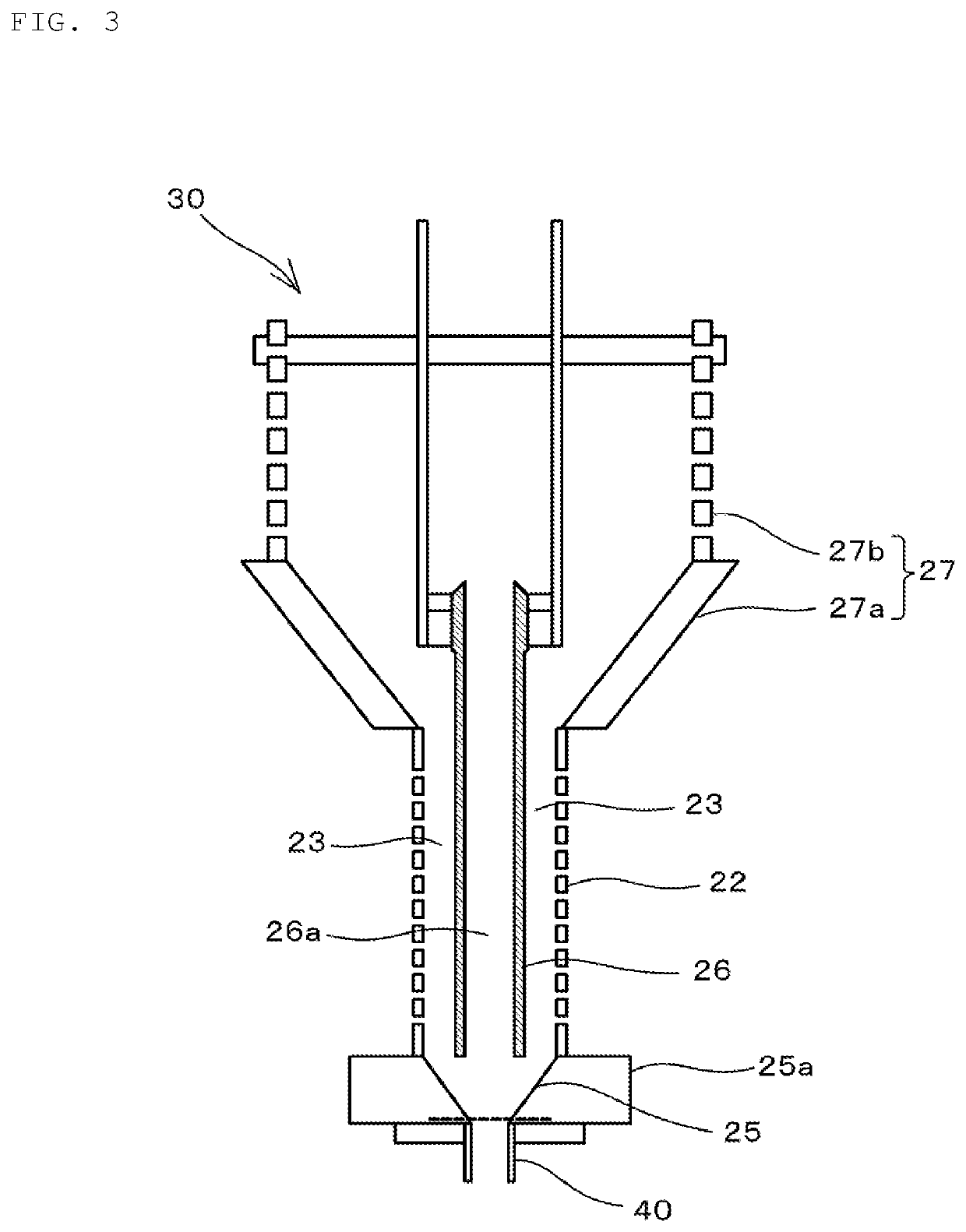

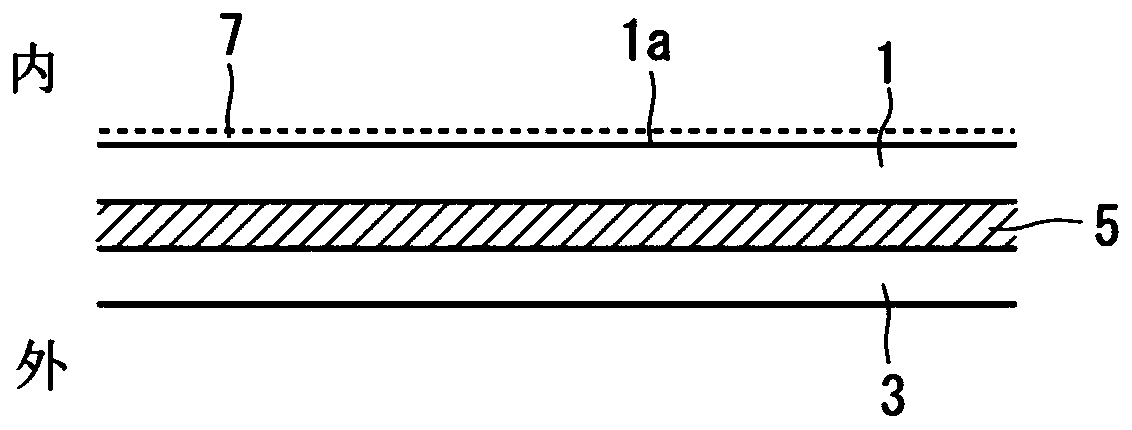

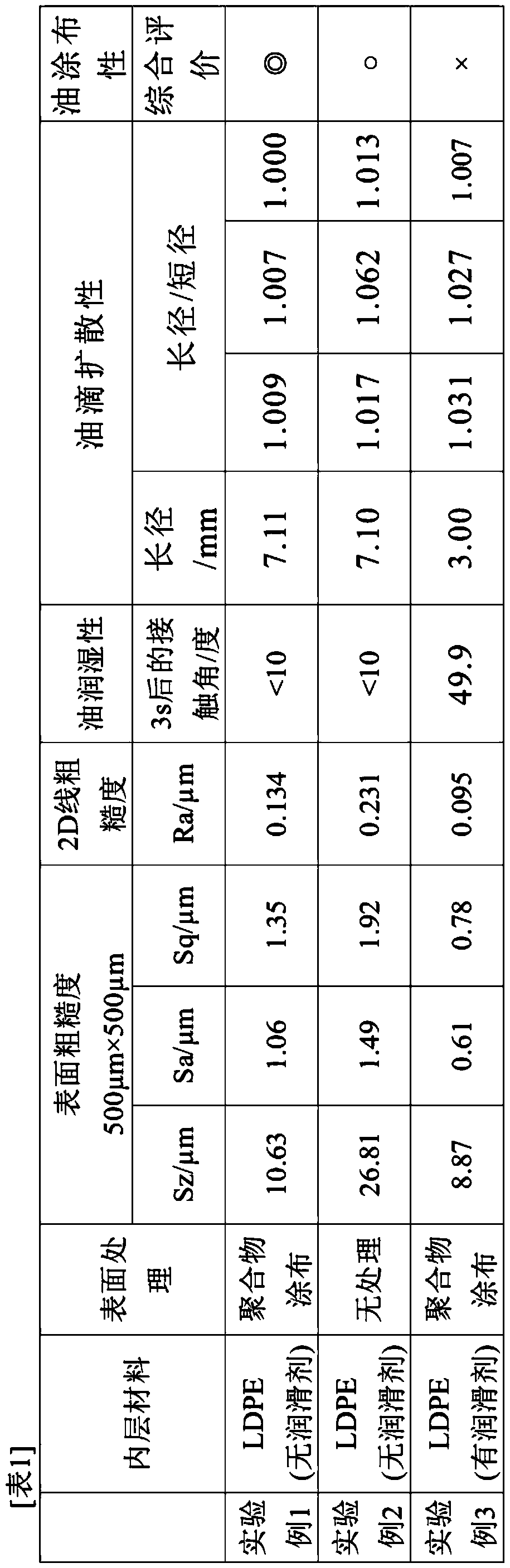

Blow-moulded container used with oil film formed on inner surface

InactiveCN110997504AEasy to slidePrevent thickness variationFlexible coversWrappersPolymer scienceTriglyceride

The purpose of the present invention is to provide a blow-moulded container onto which an oil film can be formed without unevenness across the entire inner surface of the container by coating the inner surface with an oil-based liquid. The blow-moulded container thereby exhibits stable lubricity with respect to a contained substance, and is capable of effectively inhibiting the contained substancefrom adhering to the inside of the container and remaining as residue. The blow-moulded container has an inner surface (1a) made of an olefin resin, and is characterised in that said inner surface (1a) uses a medium-chain fatty acid triglyceride as a standard oil, and when 0.8 [mu]l of said standard oil, maintained at 23 DEG C, is dropped, the oil droplet dispersion, defined by the length of themajor axis of a dropped oil droplet, is no less than 5.0mm.

Owner:TOYO SEIKAN KAISHA LTD

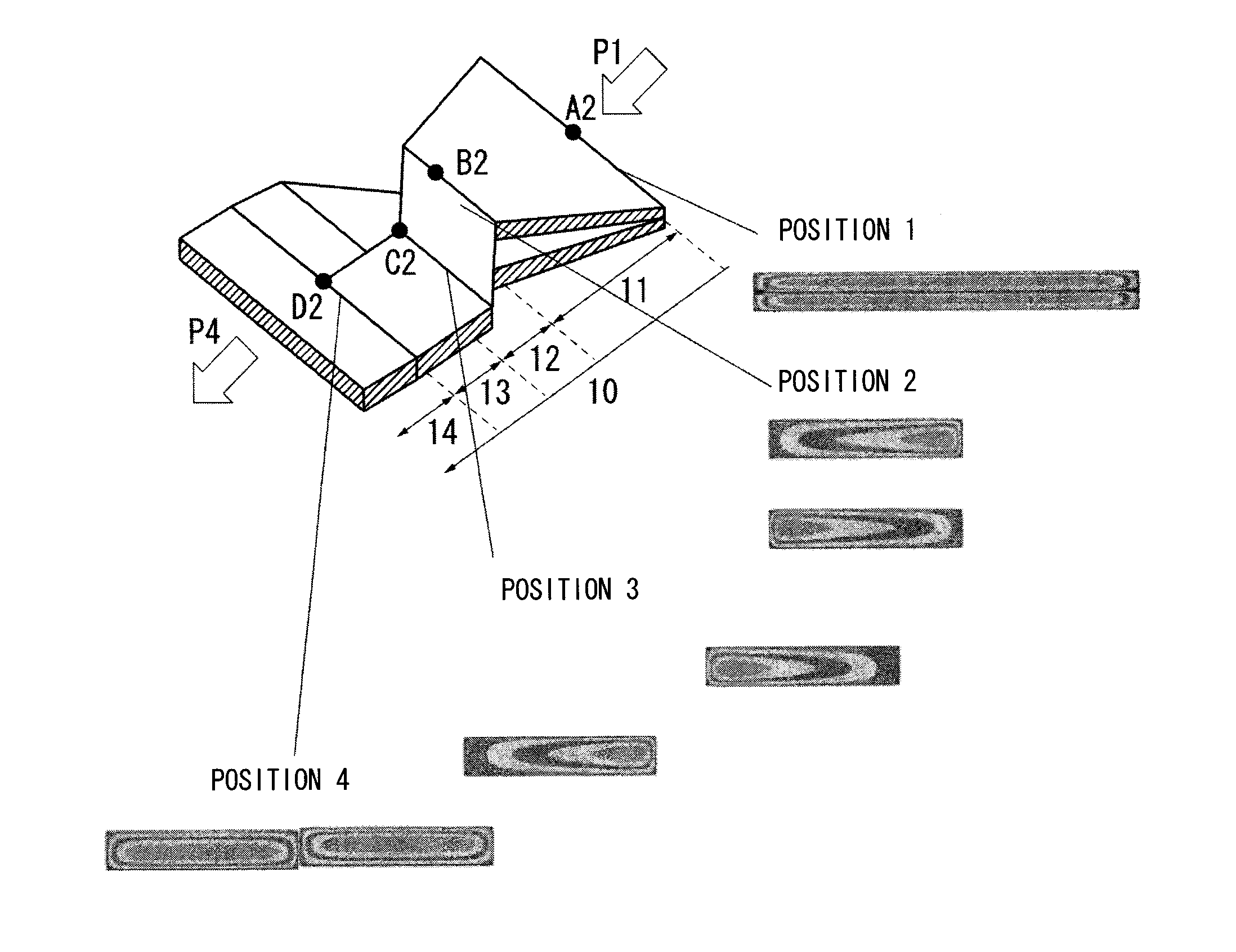

Method of producing magnetic head and magnetic head

InactiveCN101042872AAvoid wear and tearPrevent thickness variationHeads using thin filmsRecord information storageMagnetic polesEngineering

The method of the present invention is capable of highly precisely producing a magnetic head. The method comprises the steps of: forming a pole end part of a magnetic layer, which becomes a magnetic pole and which is formed on a surface of a work piece on which the magnetic head will be formed, into a prescribed shape; coating at least a top part of the magnetic layer with a stopper layer; coating a surface of the work piece, on which the stopper layer has been formed, with an insulating layer, whose polishing rate is higher than that of the stopper layer; polishing the surface of the work piece until the stopper layer, which coats the top part of the magnetic layer, is exposed from the insulating layer; and removing the stopper layer, which has been exposed in a surface of the magnetic layer.

Owner:FUJITSU LTD

Manufacturing method of electric moistening element

The invention discloses a manufacturing method of an electric moistening element. The manufacturing method includes the steps of firstly, providing liquid-state ink, freezing the ink into a crystal state, and grinding the crystal-state ink into powder; secondly, providing a first fluid, mixing the first fluid with the powdered ink obtained in the first step, and coating a substrate below with the mixture along the surface of the substrate, wherein the substrate comprises a pixel wall, and the pixel wall comprises a plurality of pixel cells; the first fluid comprises a solvent, and the solvent is optional one of C6-C16 alkanes, cycloalkanes, aromatic series, aliphatic series or silicone oil; thirdly, filling the pixel cells with the powdered ink obtained in the first step; fourthly, providing an electrolyte solution with the temperature being 80-120 DEG C, and soaking the substrate after the filling into the electrolyte solution for 1-2 hours so as to allow the substrate to absorb the electrolyte solution; fifthly, taking out the substrate, and drying.

Owner:重庆秉为科技有限公司

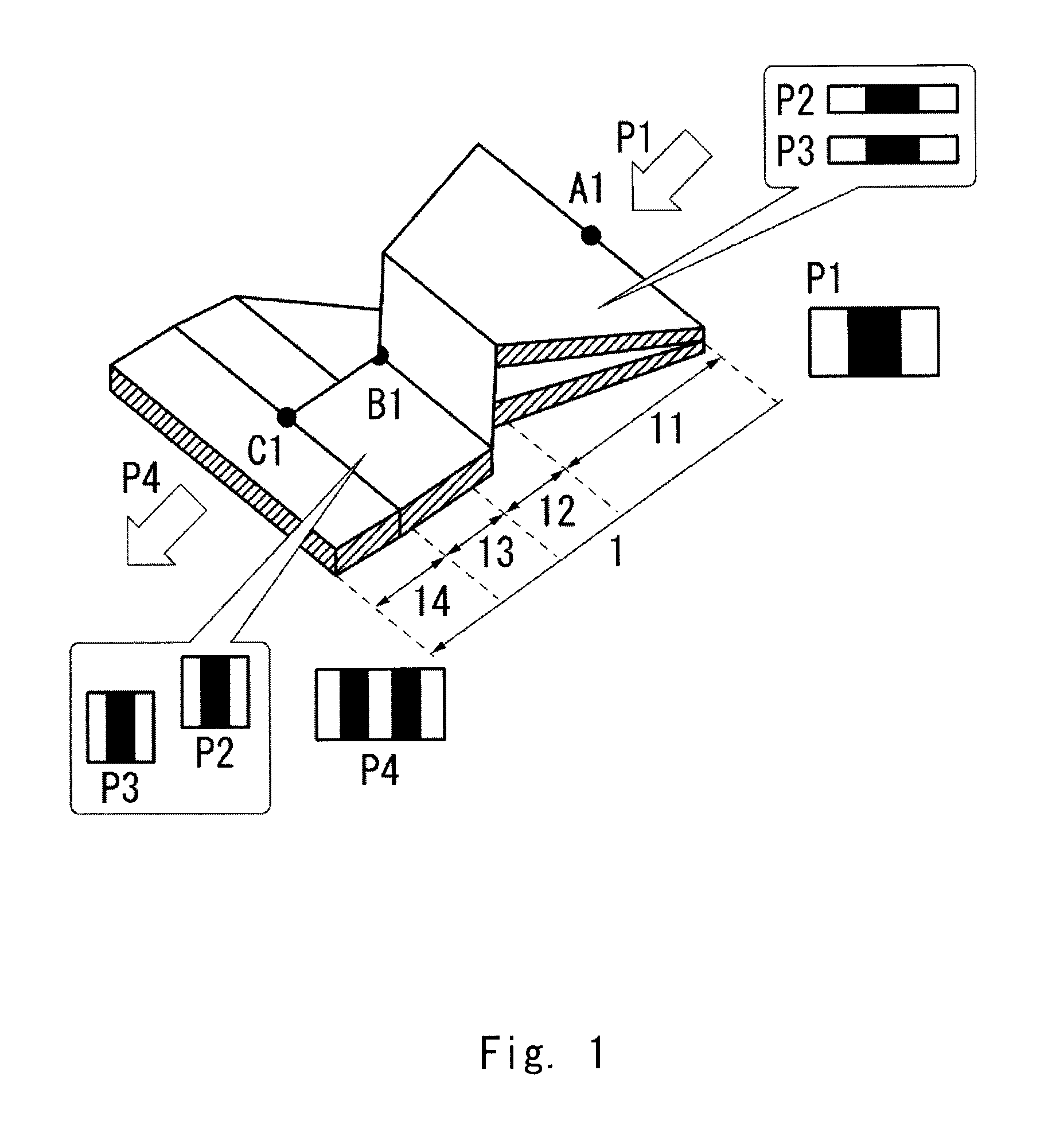

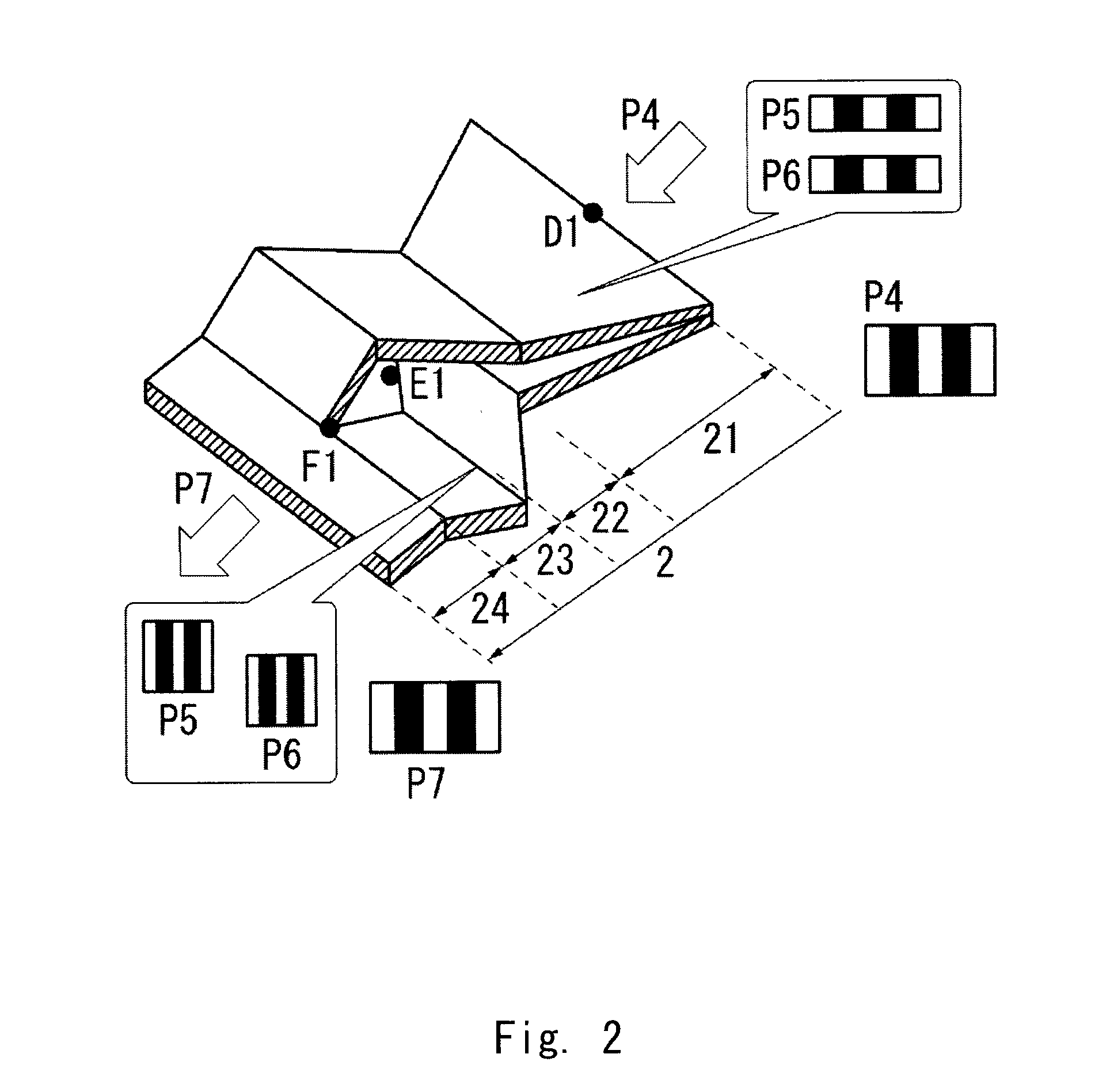

Manufacturing method for multi-layered body, manufacturing equipment for same, and multi-layered body

ActiveUS20130065015A1Improve the immunityAvoid missingConfectioneryOptical articlesMechanical engineeringIndustrial engineering

A manufacturing method of a multi-laminated body according to the present invention includes a step 1 (L-flow path) for vertically dividing a laminated flow obtained by arranging at least two molten resins adjacent to each other in a lengthwise direction into two sections, guiding the divided laminated flows to opposite directions relative to the flow direction, and then guiding both laminated flows toward the center of the flow direction, and rearranging the laminated flows adjacent to each other in the horizontal direction and thereby joining the laminated flows together, and a step 2 (R-flow path) for vertically dividing a laminated flow obtained by arranging at least two molten resins adjacent to each other in a lengthwise direction into two sections, guiding the divided laminated flows to directions opposite to the above-mentioned directions relative to the flow direction, and then guiding both laminated flows toward the center of the flow direction, and rearranging the laminated flows adjacent to each other in the horizontal direction and thereby joining the laminated flows together, in which the step 1 (L-flow path) and the step 1 (R-flow path) are alternately repeated in this listed order, and a number of the steps to be performed is at least three. According to this method, it is possible to prevent the layer disappearance at both ends, prevent the layer thickness variations or the disruption in the lengthwise arrangement, and thereby manufacture a multi-laminated body having a more excellent uniformity.

Owner:KURARAY CO LTD

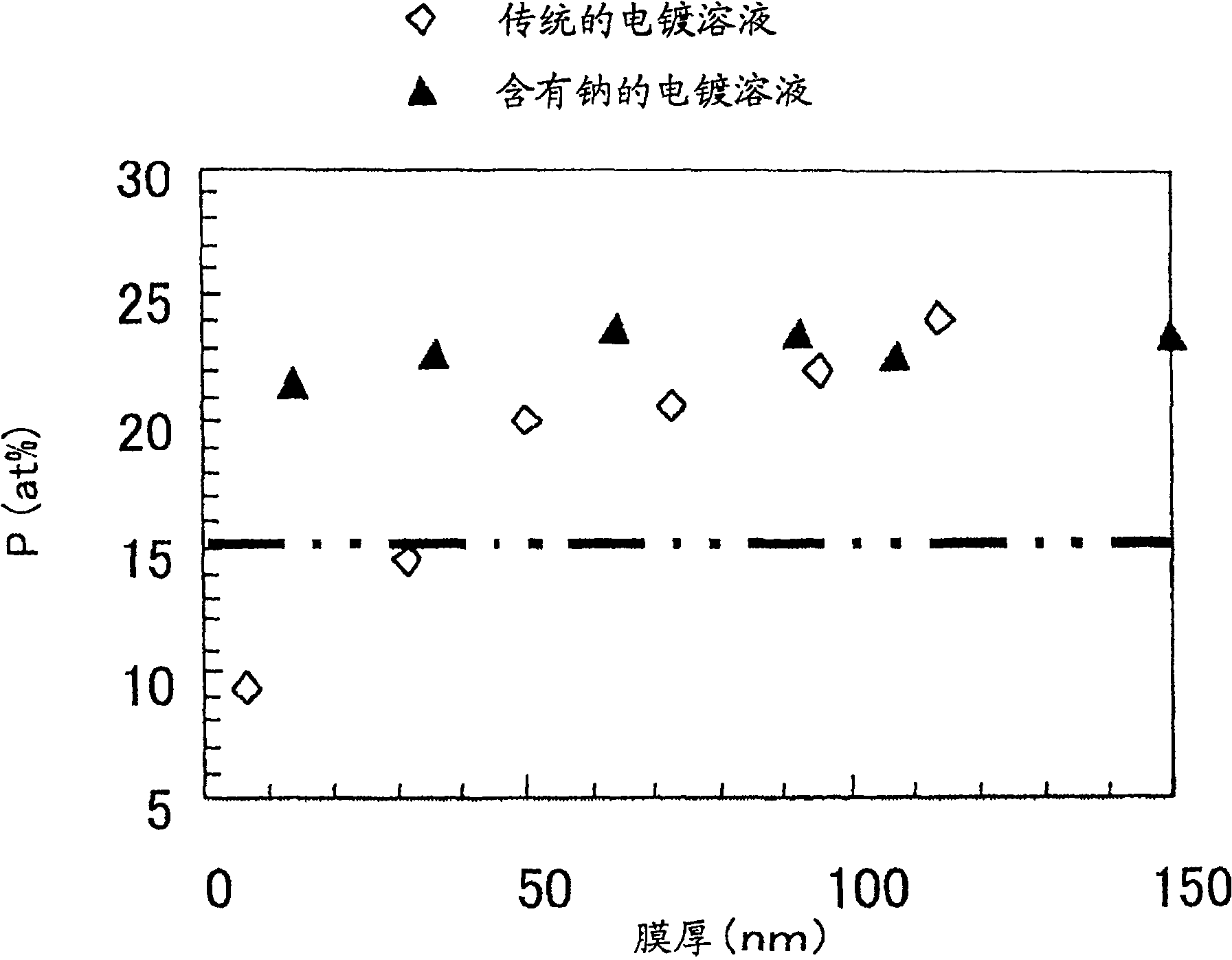

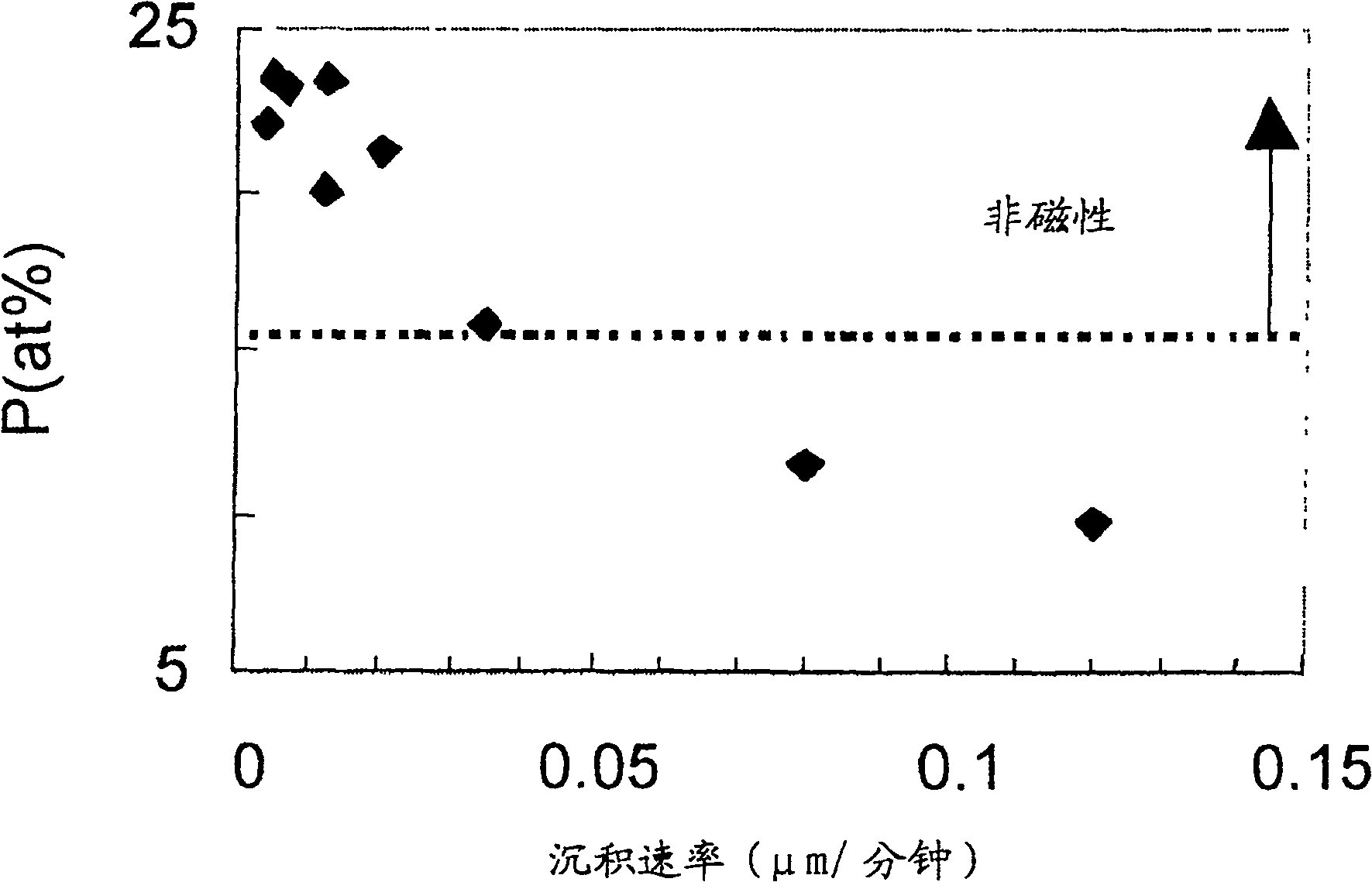

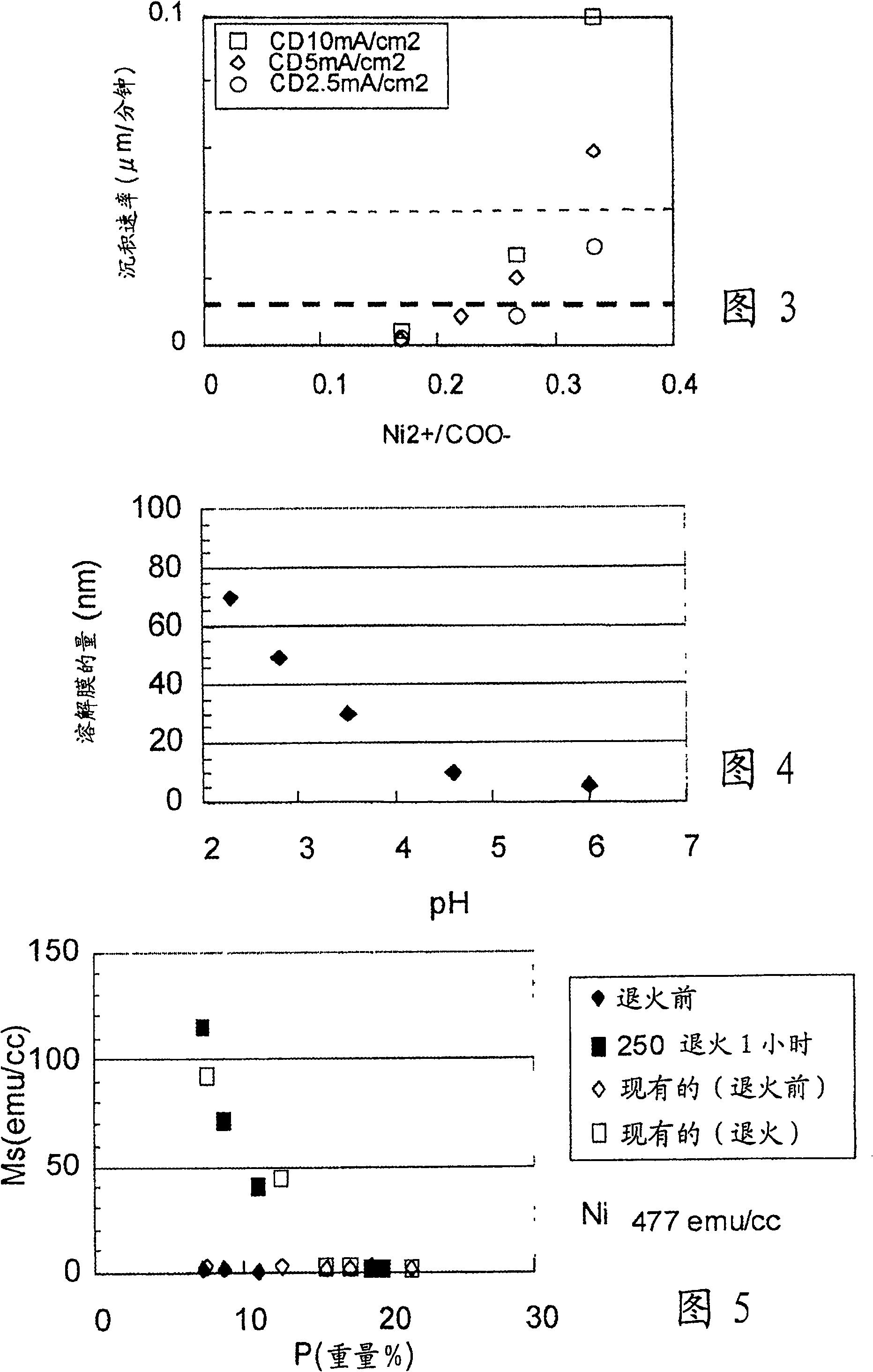

Method of forming NiP nonmagnetic film and method of manufacturing magnetic head using the film

InactiveCN100429698CEasy and safe to formSimple manufacturing processHeads using thin filmsRecord information storageElectrolysisChloride salt

The method is capable of easily and securely forming a NiP nonmagnetic film. In the method of forming the NiP nonmagnetic film by electrolytic plating, the electrolytic plating is performed in NiP plating solution consisting of: a reagent for supplying nickel ions; a reagent for supplying phosphorus ions; and a reagent including carboxyl groups. For example, sulfates and chloride salts of nickel, etc. may be use as the reagent for supplying nickel ions; phosphorus acid, sodium phosphite, etc. may be used as the reagent for supplying phosphorus ions.

Owner:FUJITSU LTD

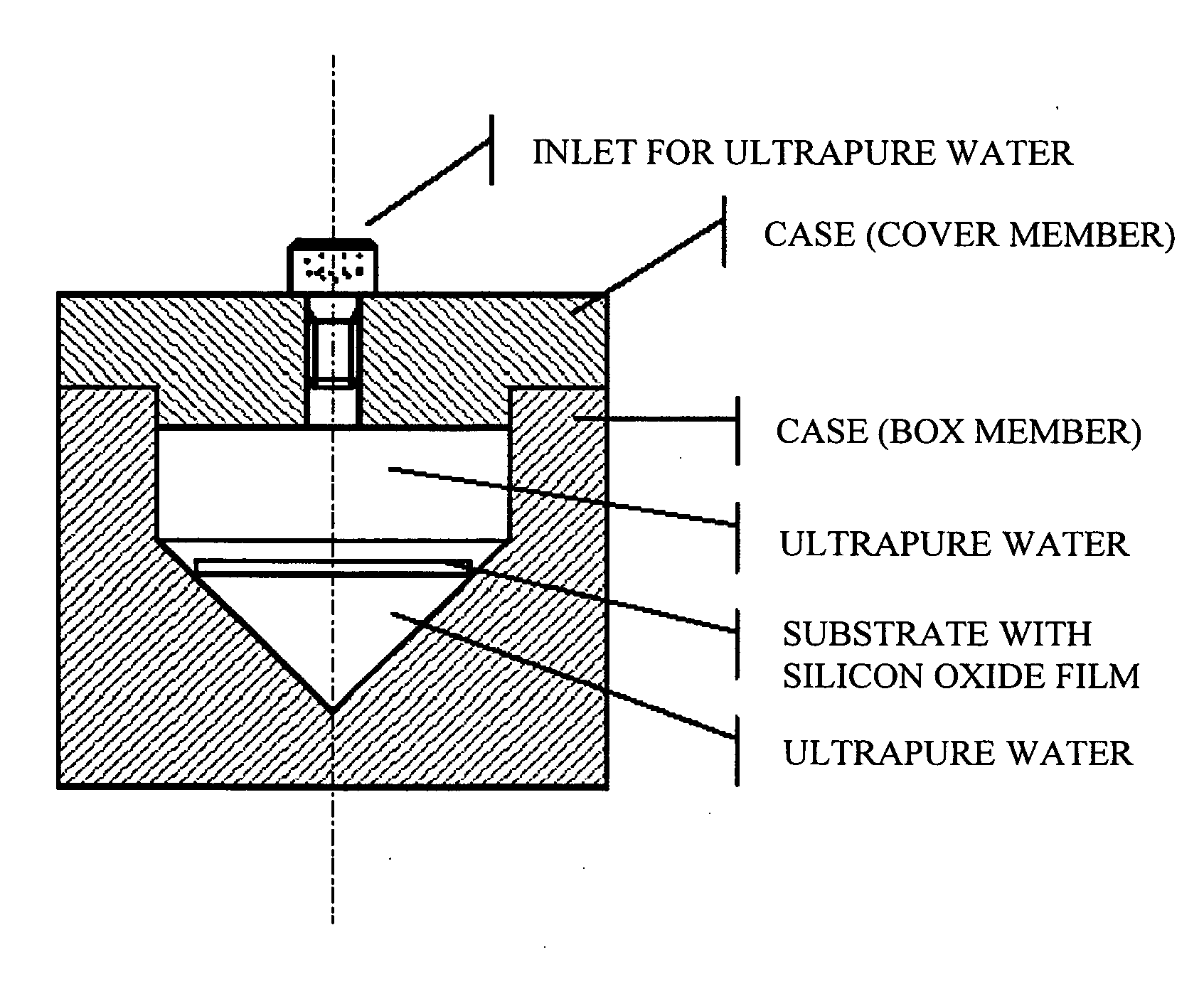

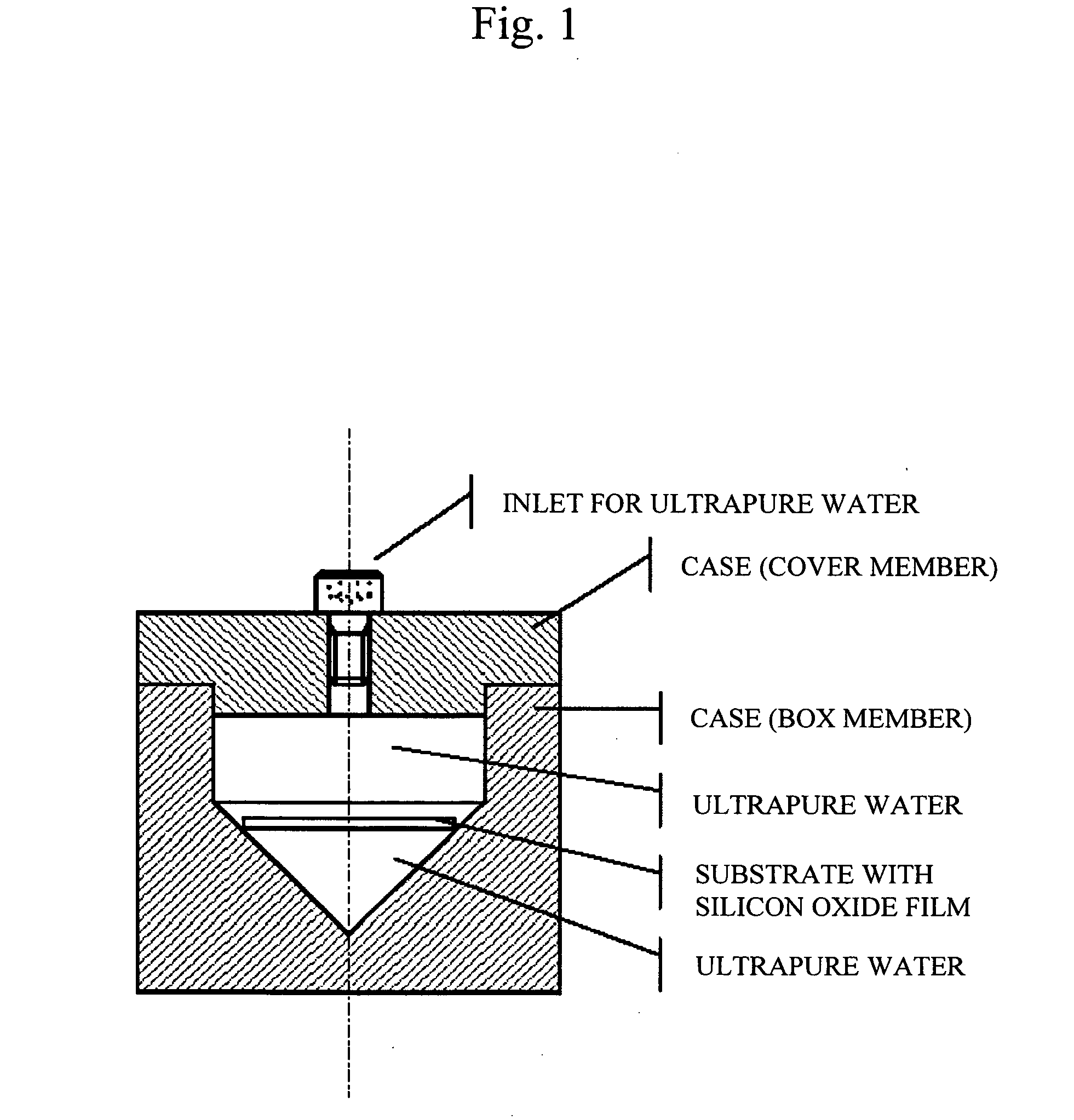

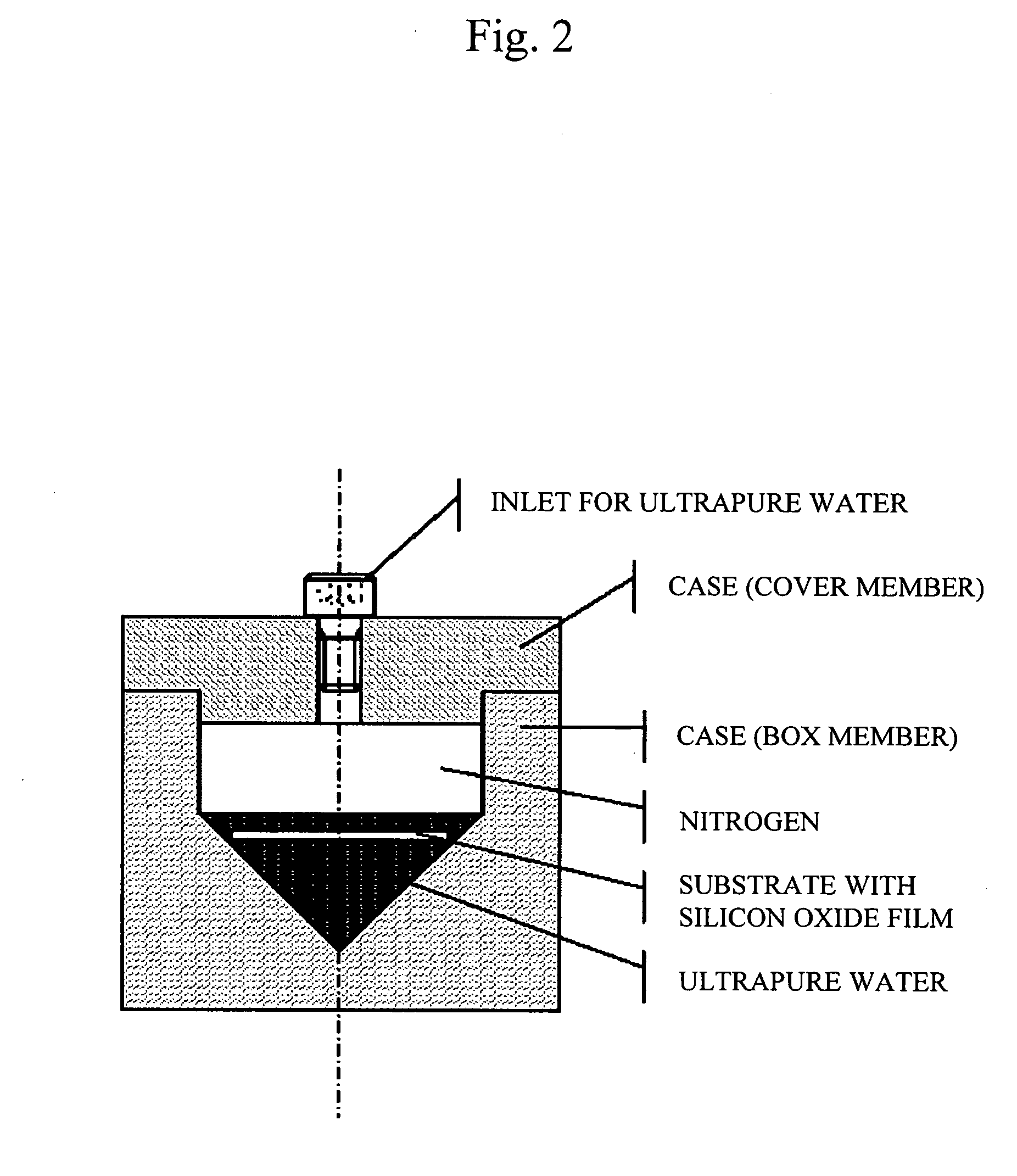

Method for storing silicon substrate having silicon oxide film formed thereon

InactiveUS20060207688A1Avoid changePrevent thickness variationSemiconductor/solid-state device manufacturingSemiconductor devicesSilicon oxideAqueous medium

In storing a silicon substrate having a silicon oxide film formed thereon, the present invention provides a means for preventing changes in the silicon oxide film thickness. The present invention relates to a method for storing a silicon substrate having a silicon oxide film formed thereon by immersing the substrate in an aqueous medium contained in a case.

Owner:NAT INST OF ADVANCED IND SCI & TECH

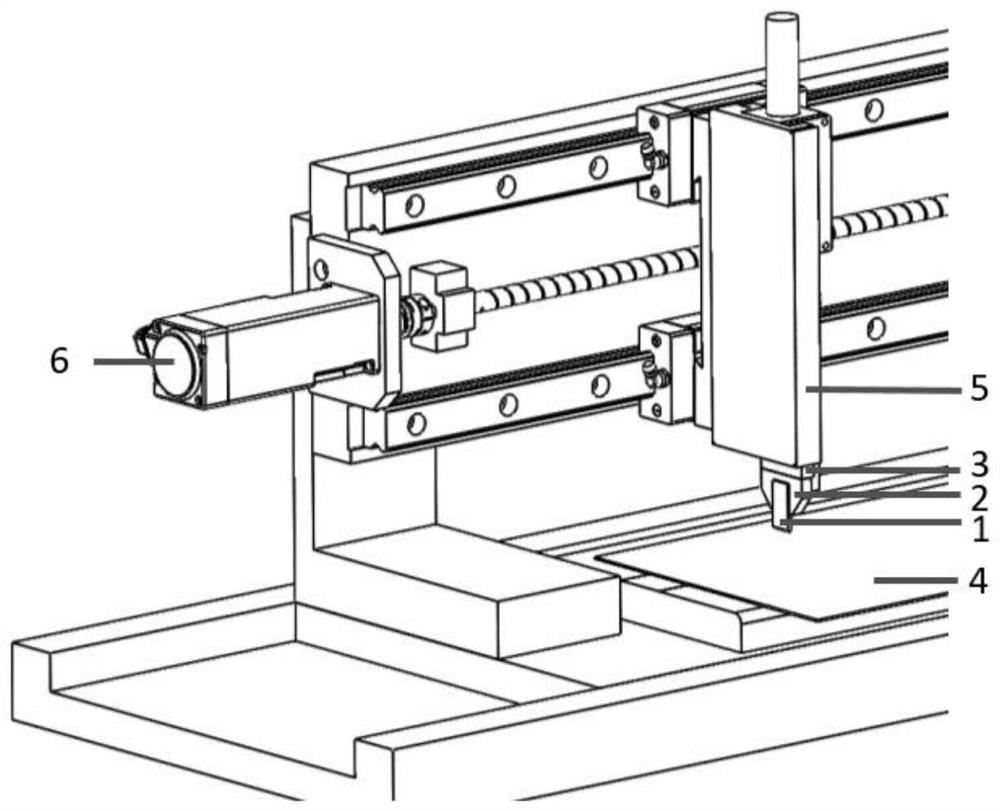

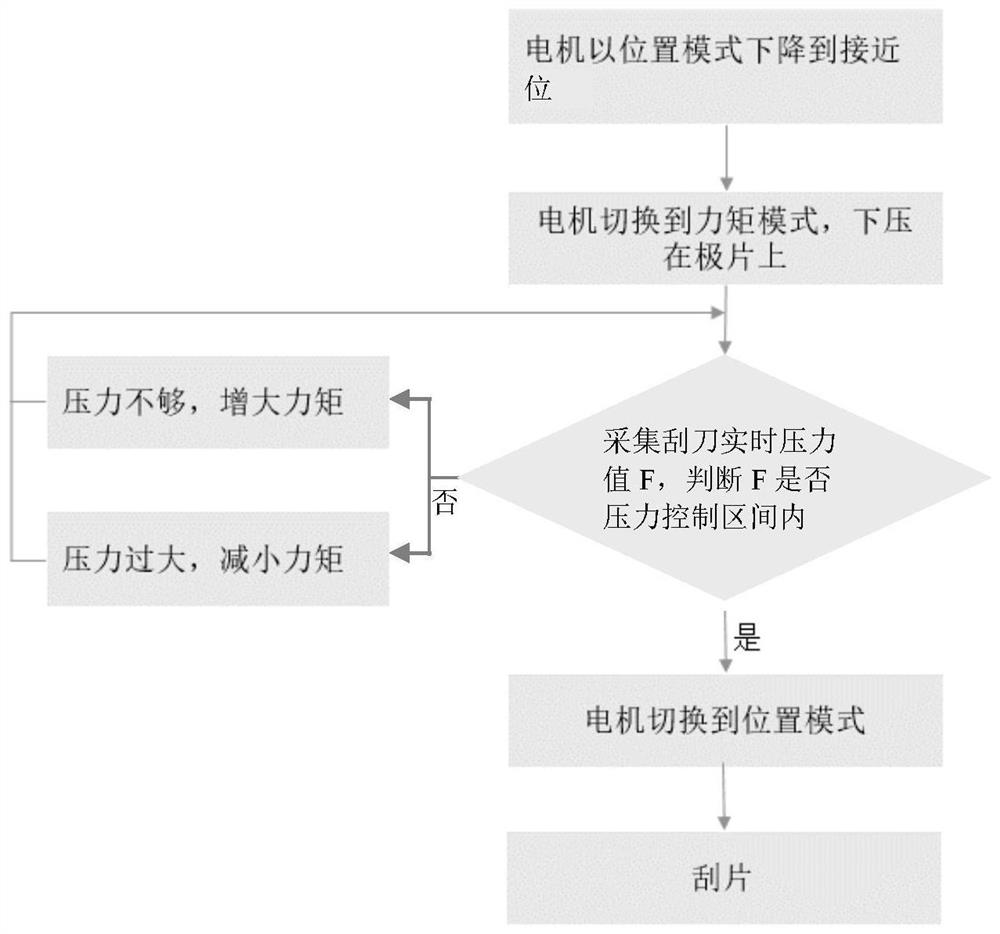

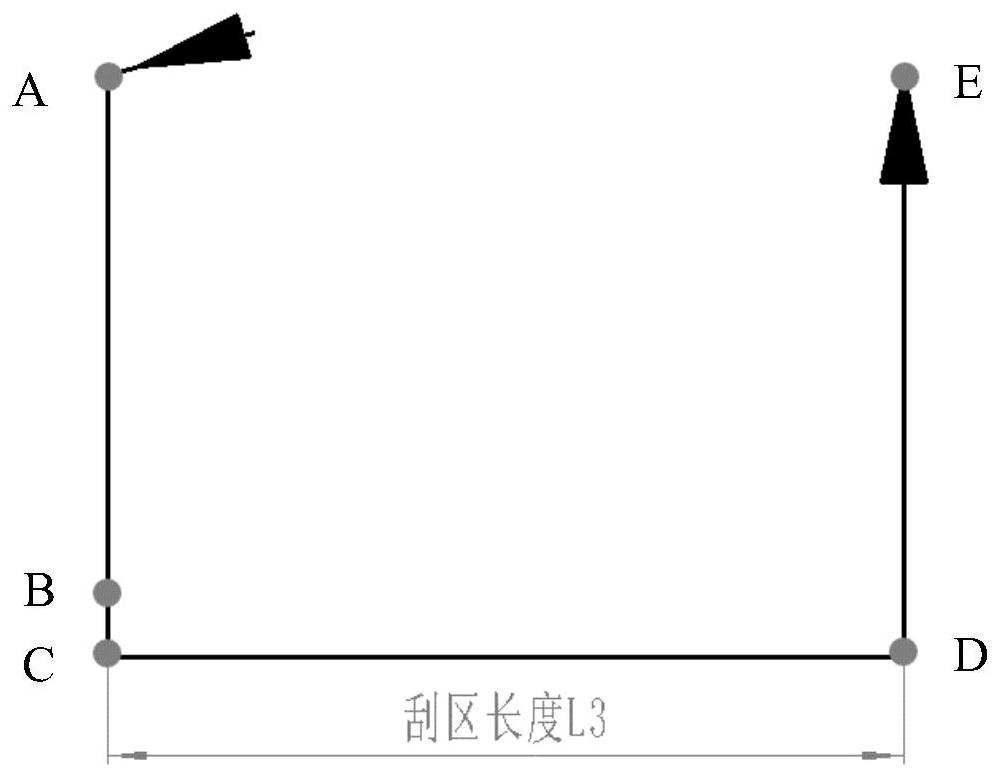

Scraping knife control method and pole piece coating scraping method

ActiveCN113351533AAvoid wear and tearPrevent looseningCleaning using toolsElectric machineryEngineering

The invention discloses a scraping knife control method and a pole piece coating scraping method. A first motor operates in a position mode to drive a scraping knife to move to an approaching position, and then operates in a torque mode to drive the scraping knife to move so that the scraping knife can be inserted into a coating to be scraped, the real-time pressure value of the scraping knife is collected and compared with a pressure control interval, pressure compensation is not needed to be carried out when the real-time pressure value is in the pressure control interval, the current position of the scraping knife serves as a scraping area starting point and is stored, and pressure compensation is carried out when the real-time pressure value is not in the pressure control interval; Updating is carried out on the torque set value according to the pressure compensation value, then the updated torque set value serves as a torque instruction signal, returning to and executing the previous step are carried out; after the scraping area starting point is stored, the first motor operates in a position mode to drive the scraping knife to move to the scraping area starting point; and a second motor drives the scraping knife to horizontally move from the scraping area starting point to a scraping area ending point, and the scraping knife resets. According to the method, the position of the scraping knife is accurately and efficiently controlled in a control mode of combining a position mode and a torque mode.

Owner:ZHUHAI COSMX BATTERY CO LTD

Release film for producing green sheet

InactiveUS20150064402A1Avoid partialPrevent thickness variationSynthetic resin layered productsRecord information storageMetallurgyMaterials science

A release film for producing a green sheet of the present invention includes a base material having a first surface and a second surface and a release agent layer formed at a side of the first surface of the base material. A maximum projection height Rp2 of the second surface of the base material is in the range of 60 to 500 nm. An area occupation ratio of projections having a height of 60 nm or higher in the second surface is 10% or less. According to the present invention, it is possible to prevent pinholes and variation in partially thickness from occurring to the green sheet.

Owner:LINTEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com