Blow-moulded container used with oil film formed on inner surface

A blow molding, inner surface technology, applied in the field of blow molding containers, can solve problems such as uneven formation of liquid film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

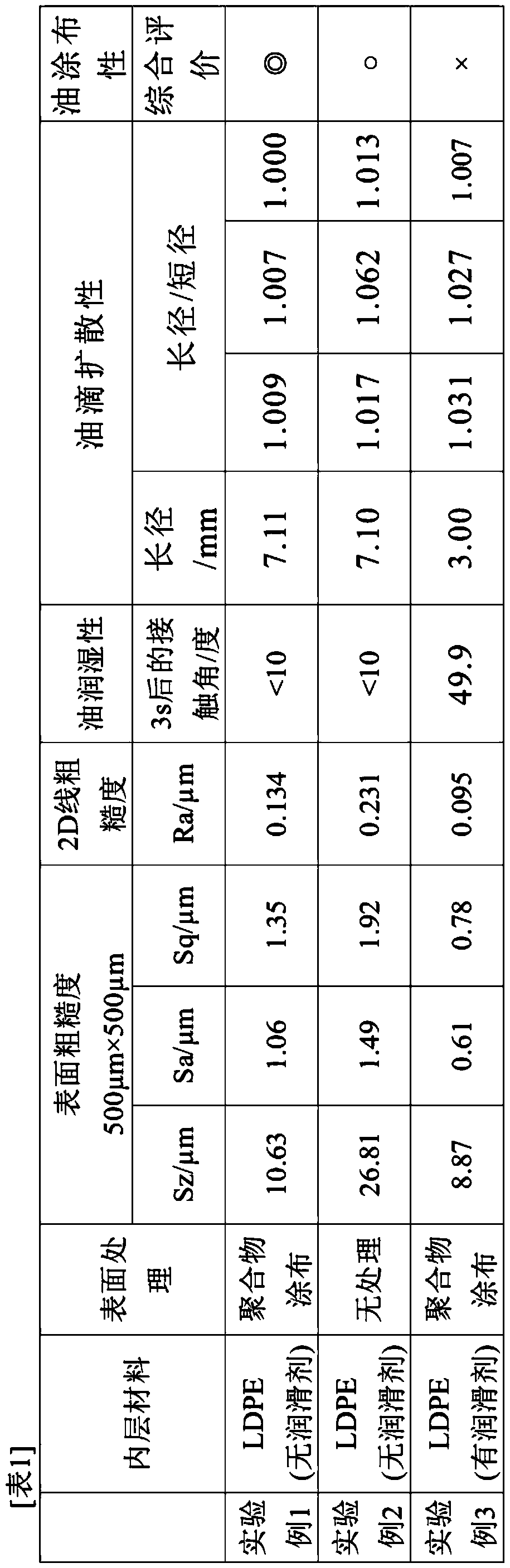

[0085] The effects of the present invention will be described below with reference to experimental examples.

[0086] Methods for measuring various characteristics, physical properties, etc., and resins used for molding blow-molded containers, etc., in Experimental Examples are described below.

[0087] 1. Measurement of the surface roughness of the inner surface of the bottle

[0088] A 10 mm×10 mm test piece was cut out from the body portion of the bottle formed by the method described later for 3D shape measurement of the inner surface of the bottle body portion by using a microscope (VK-100 manufactured by KEYENCE CORPORATION). From the data thus obtained, the surface roughness of a 500 μm×500 μm area was calculated (ISO25178-2:2012).

[0089] 2. Measurement of the 2D line roughness of the inner surface of the bottle

[0090] A test piece of 20 mm x 20 mm was cut out from the main body of the bottle formed by the method described later to measure the surface roughness by...

experiment example 1

[0116] Low-density polyethylene (LDPE-A) as a resin for forming an outer layer was supplied to the 40 mm extruder-A. A blend material (resin for barrier layer formation) of ethylene-vinyl alcohol copolymer (EVOH) and polyolefin was supplied to 40 mm extruder-B. The 50mm extruder is supplied with low-density polyethylene (LDPE-A) as the resin for forming the middle layer, and the 40mm extruder-C is supplied with low-density polyethylene (LDPE-A) as the resin for forming the inner layer. B). A polymer-coated core was mounted to the discharge side of the extruder from which the molten parison was to be discharged, extruding the molten parison from a multilayer die at 210°C. The parisons were then subjected to direct blow molding at a forming temperature of 24° C. to produce a 20 g bottle comprising five five layers with a capacity of 400 g. The layer structure of the bottle is as follows.

[0117] Outer Layer / Adhesive Barrier / Middle Layer / Adhesive Barrier / Inner Layer

[0118]...

experiment example 2

[0121] A bottle was prepared in the same manner as in Experimental Example 1 except that a core without surface treatment was attached to the discharge side for discharging the molten parison, and the bottle was subjected to various evaluations. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com