Method of forming NiP nonmagnetic film and method of manufacturing magnetic head using the film

A non-magnetic film and magnetic film technology, applied in the application of magnetic film to substrate, magnetic head using thin film, magnetic recording head, etc., can solve the problem of reduced reliability of magnetic head, and achieve high accuracy and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

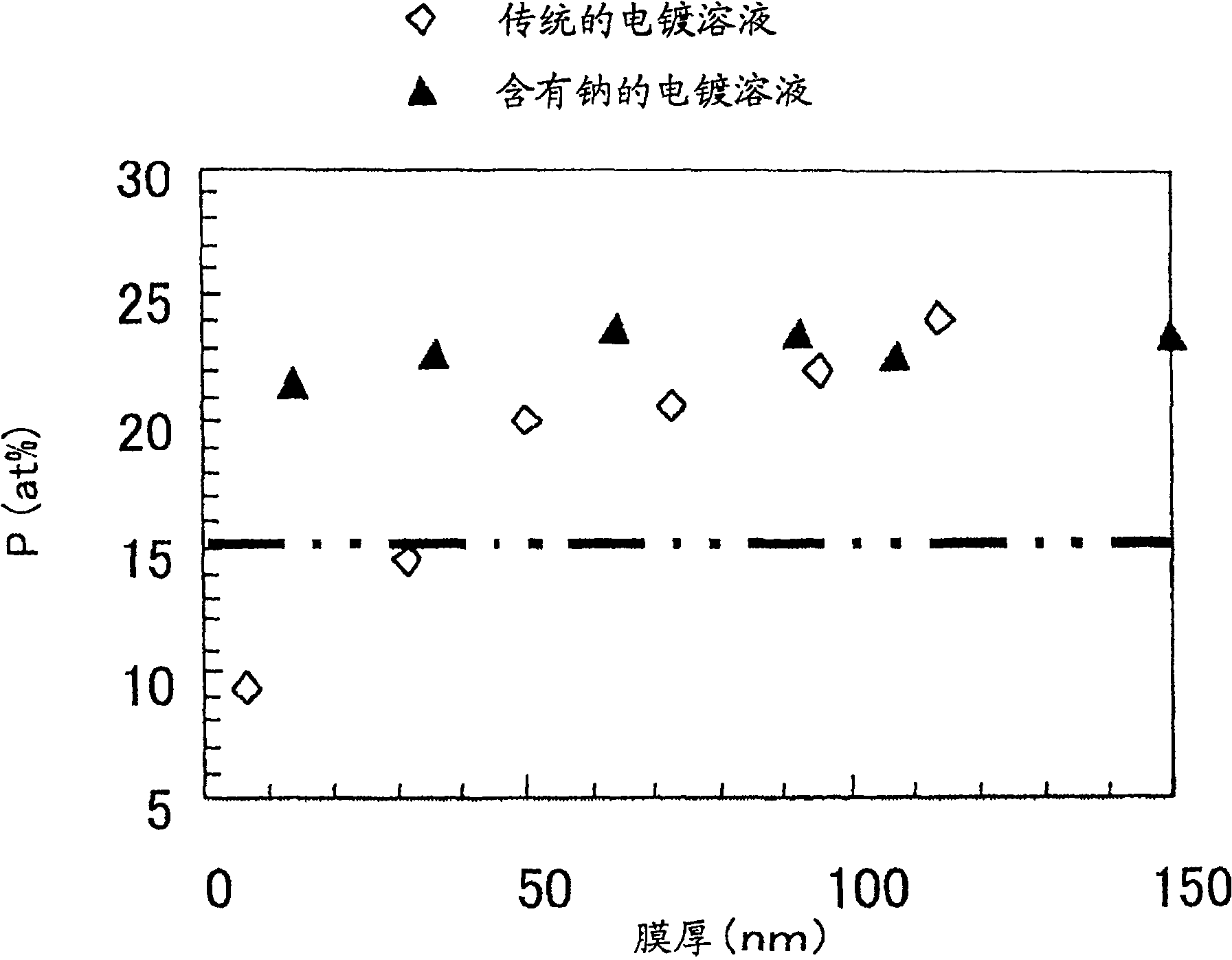

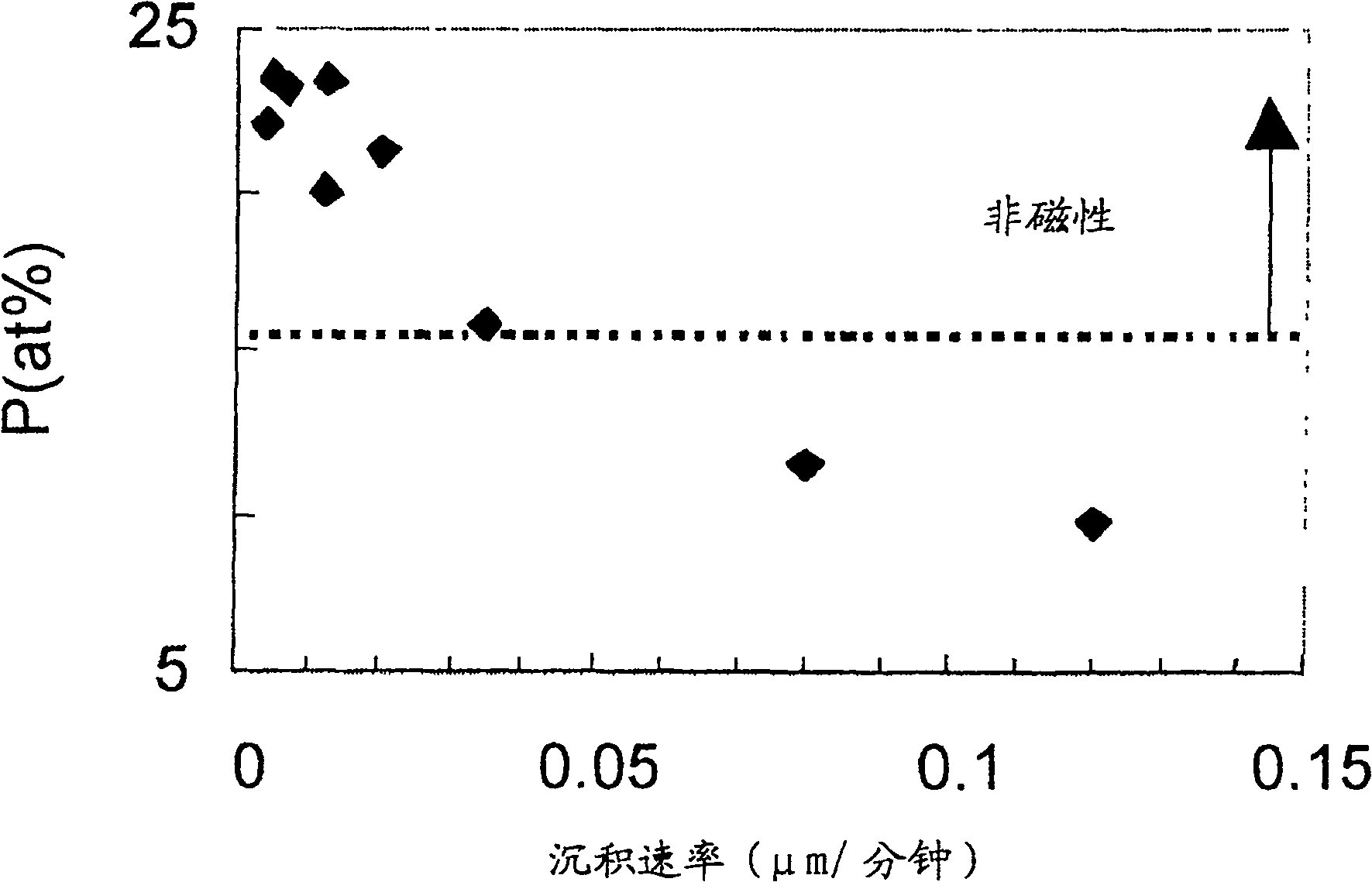

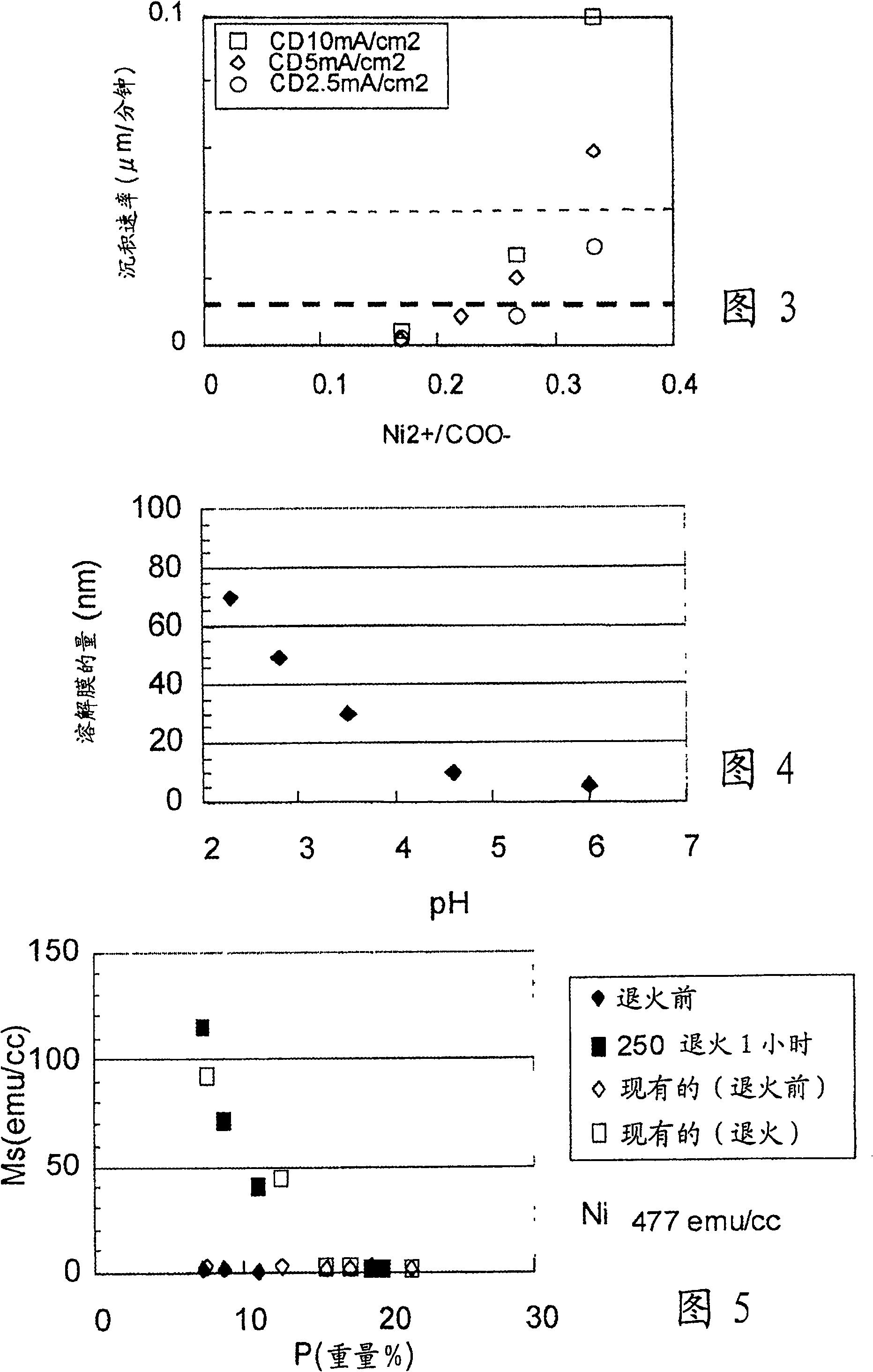

[0027] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0028] The following table lists examples of the composition of the NiP plating solution for forming the NiP nonmagnetic film by electrolytic plating. The NiP plating solution contains: nickel sulfate and nickel chloride as reagents for providing nickel (Ni); and phosphoric acid and sodium hydrogenphosphite as reagents for providing phosphorus (P). In addition, sodium citrate providing carboxylate was added to the NiP plating solution.

[0029] It should be noted that the carboxylate-donating reagents that can be added are not limited to sodium citrate. Other reagents that donate carboxylate groups can also be used, but sodium tartrate, which tends to form insoluble precipitates with Ni, cannot be used.

[0030] surface

[0031] Reagent

Concentration ratio (Mol / l)

nickel sulfate

0.095~0.19

nickel chloride

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com