Anode current collector and preparation method thereof, negative electrode sheet, and lithium ion battery

A lithium-ion battery and negative pole piece technology, which is applied in the field of electrochemical batteries, can solve the problems of difficult control of the doping amount and uneven distribution of lithium, and achieve the effects of light weight, improved distribution uniformity, and improved battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

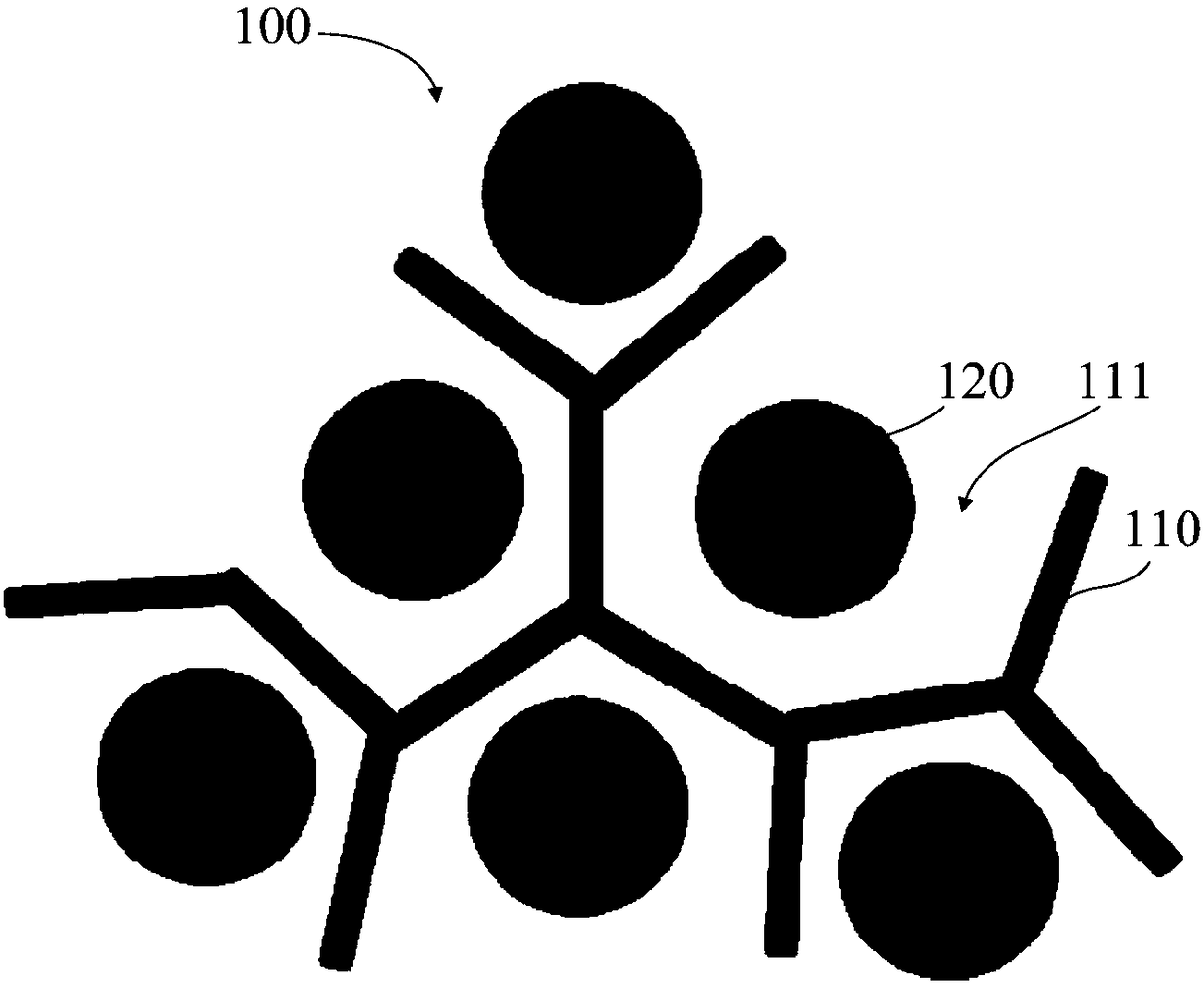

[0050] The embodiment of the present invention also provides a method for preparing the negative electrode current collector 100, comprising the following steps:

[0051] S110, providing the porous metal substrate 110;

[0052] S120, providing a lithium source, the lithium source is used to provide the lithium-containing material 120;

[0053] S130, load the lithium source in the pores 111 of the porous metal substrate 110 .

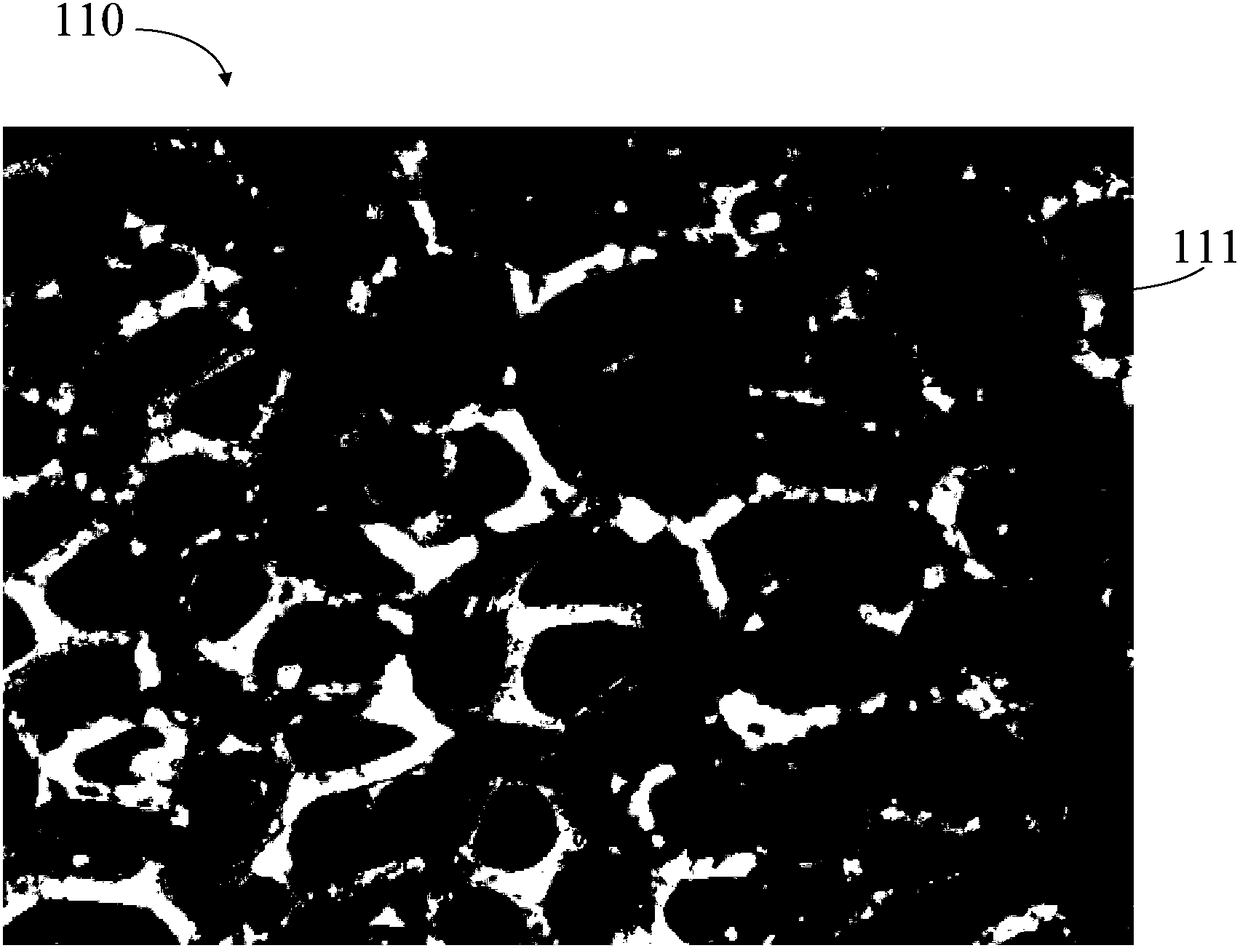

[0054] In step S110, the porous metal substrate 110 can be obtained by self-preparation or commercial purchase.

[0055] In one embodiment, the porous metal substrate 110 is prepared by utilizing the difference in solubility of different metals in acid. The step of preparing the porous metal substrate 110 may include:

[0056] uniformly mixing a first metal soluble in a specific acid solution and a second metal soluble in the specific acid solution to obtain an alloy; and

[0057] The alloy is treated with the specific acid solution to dissolve the f...

Embodiment 1

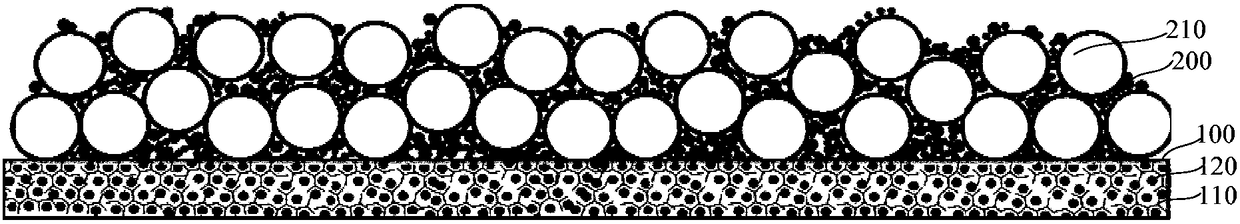

[0077] Negative pole piece preparation:

[0078] According to the ratio of the areal density of the negative active material layer 200 to the areal density of the positive active material is 1.0˜1.2, the mass of the positive active material is calculated. According to the mass of the lithium-containing material 120 accounting for 0.1%-1% of the positive electrode active material, the content of the lithium-containing material 120 to be loaded in the negative electrode current collector 100 is calculated.

[0079] The carbon-coated lithium-containing material 120 and NMP were mixed, and ultrasonicated at 25° C. for 5 hours to obtain a dispersion with a molar concentration of 3 mol / L. Soak the porous copper substrate in the dispersion liquid for 5 hours, remove the porous copper substrate loaded with the lithium-containing material 120 from the dispersion liquid, and vacuum dry at 80° C. for 5 hours to obtain the negative current collector 100 .

[0080] The graphite of 92%-98%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com