Method of producing magnetic head and magnetic head

A manufacturing method and magnetic head technology, applied to magnetic recording heads, orthogonal magnetized magnetic heads, magnetic heads using thin films, etc., can solve the problems of difficulty and trouble in the magnetic layer 26, and achieve the effects of preventing thickness changes and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

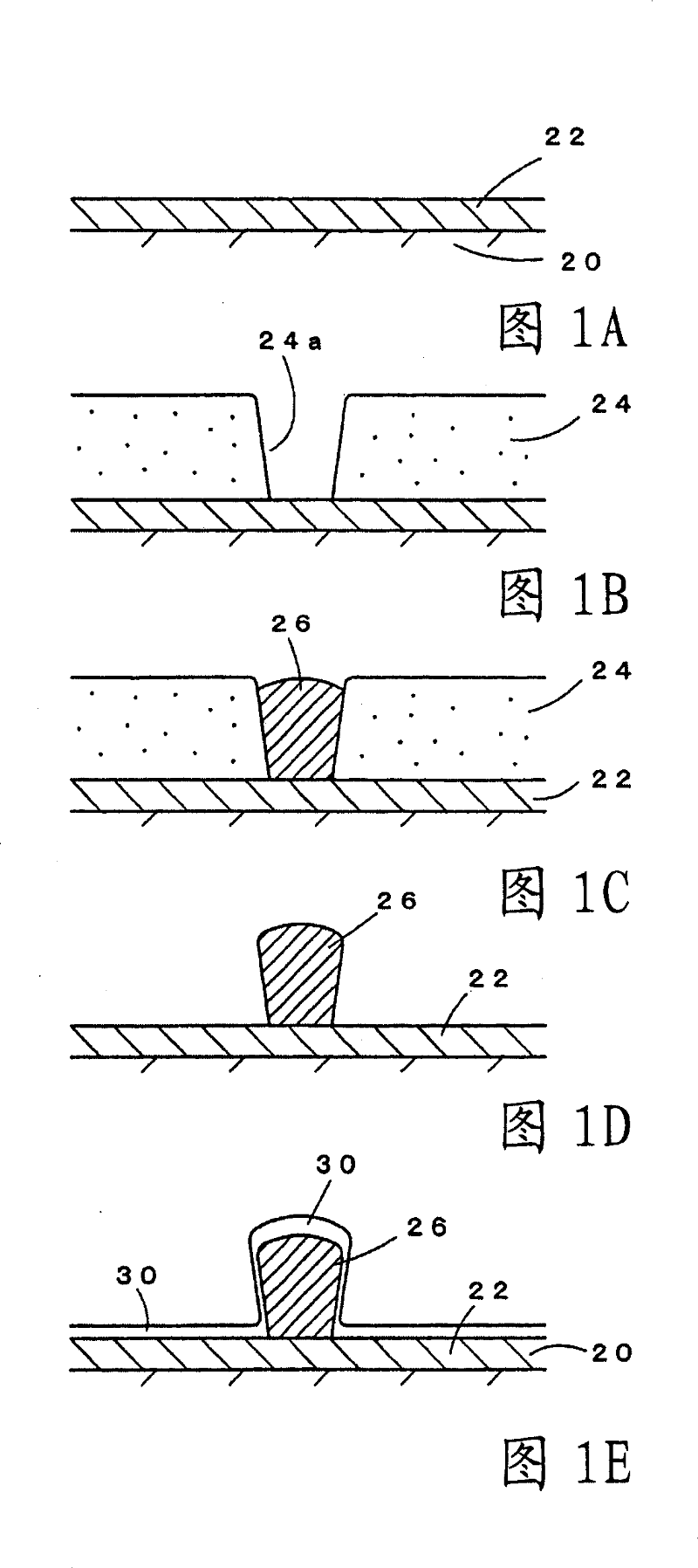

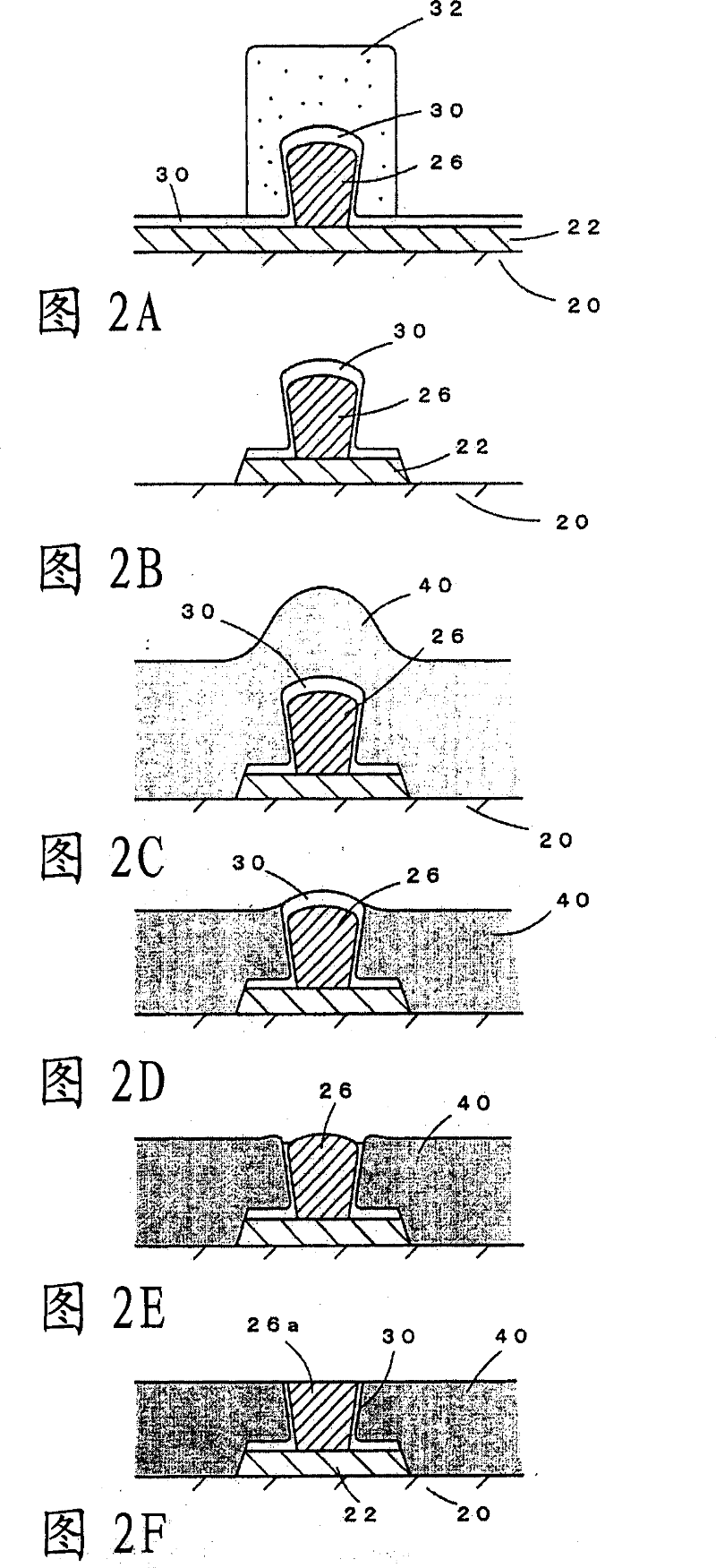

[0032] Referring to FIGS. 1A-1E and 2A-2F, the first embodiment of the magnetic head fabrication method will be described. Note that the magnetic head of the present invention is a perpendicular magnetic head.

[0033] Like the typical vertical magnetic head shown in FIG. 4, the vertical magnetic head of the present embodiment includes a read head 8 and a write head 10, and the lower shield layer 5, the MR element 6 and the upper shield layer 7 of the read head 8 are plated or sputtering formed on the substrate. The main magnetic pole 12, the return yoke 14, the coil, and the like of the write head 10 are formed in a predetermined pattern by plating or sputtering.

[0034] Next, the forming process of the main magnetic pole 12, which is a unique feature of the present invention, will be described.

[0035] 1A-1E show the steps up to the formation of the magnetic layer 26, which becomes the main magnetic pole.

[0036] In FIG. 1A, a seed layer 22 made of, for example, ruthen...

no. 2 example

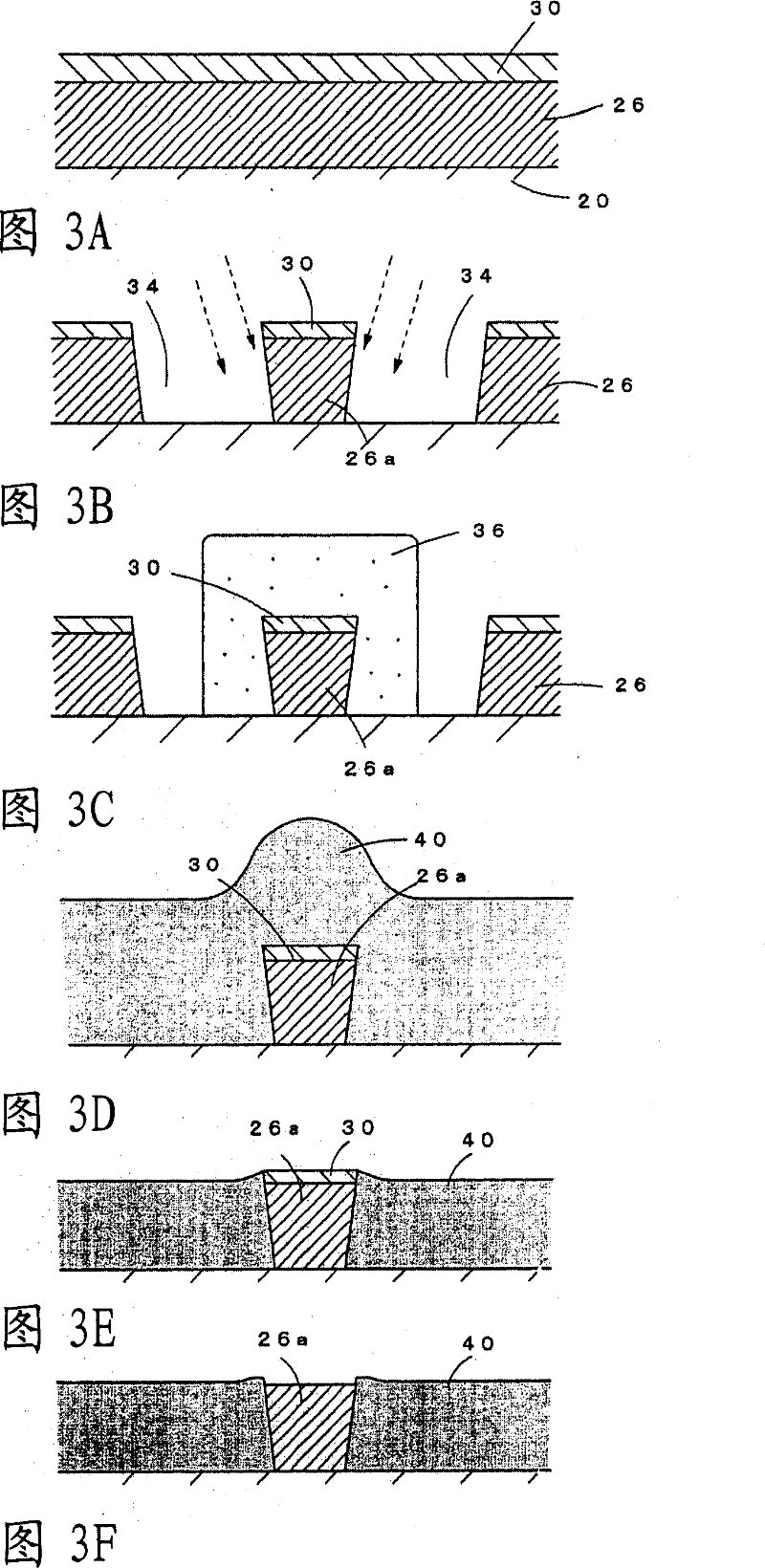

[0058] Next, with reference to FIGS. 3A-3F , the second embodiment of the magnetic head manufacturing method will be described. Note that, like the first embodiment, the magnetic head of the present invention is a perpendicular magnetic head. In this embodiment, the magnetic layer 26 is formed by a dry process such as sputtering, and the magnetic poles are formed by a FIB process. The same reference numerals are assigned to the structural elements explained in the first embodiment.

[0059] In FIG. 3A , the magnetic layer 26 is formed on the base layer 20 by sputtering, and the blocking layer 30 is formed on the surface of the magnetic layer 26 . The thickness of the magnetic layer 26 corresponds to the thickness of the main magnetic pole 26a in advance. Like the first embodiment, the stopper layer 30 is made of a material having a low polishing rate such as tantalum. The blocking layer 30 acts as a blocking layer when the magnetic layer 26 is etched by the FIB. Therefore,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com