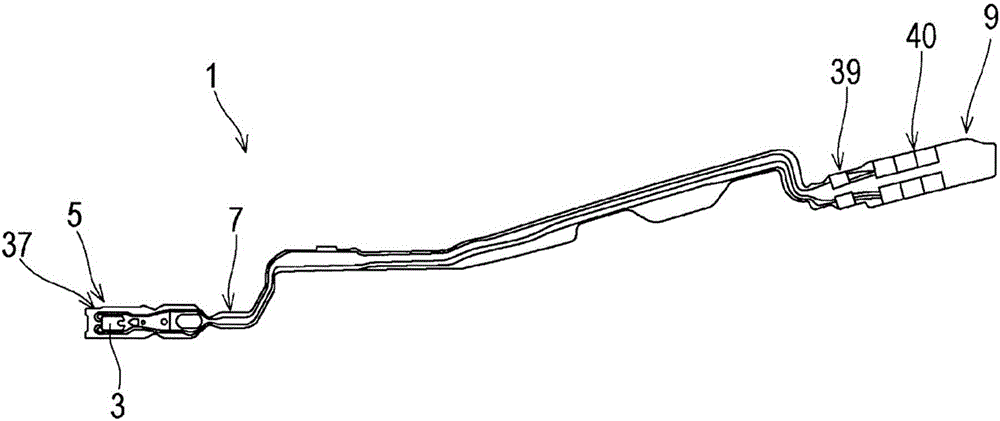

Wiring thin plate having aerial wiring portion and method of manufacturing the same

一种布线、薄板的技术,应用在印刷电路制造、头的流体动力学间距、记录头的配置/安装等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

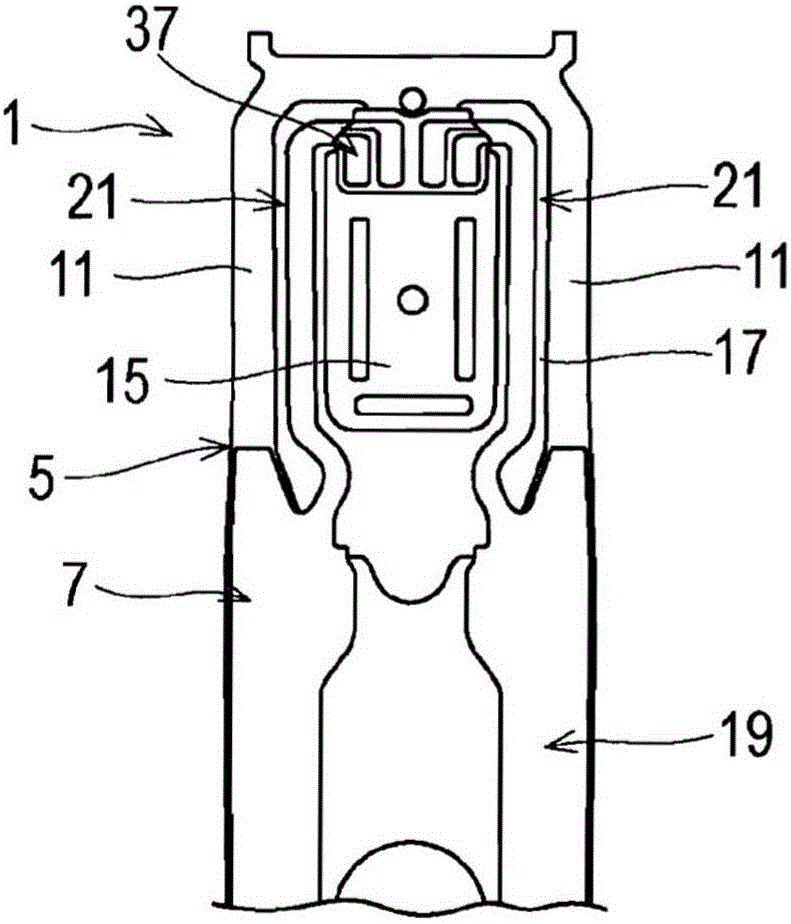

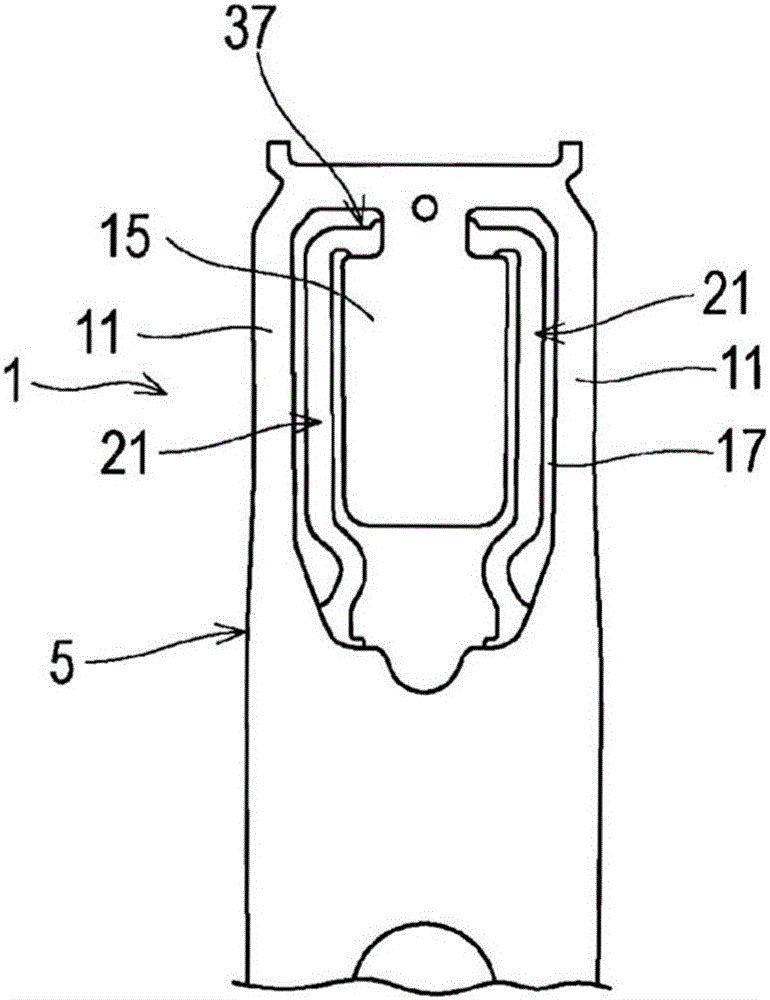

[0031] The wiring sheet according to the embodiment of the present invention will be described in detail. Each embodiment embodies one of the first to third wiring sheets to suppress deterioration of electrical characteristics and variation in thickness of the overhead wiring portion while promoting reduction in stiffness of the overhead wiring portion.

[0032] The first wiring sheet has: a support layer, which is made of metal; an insulating base layer, which is provided on the top surface of the support layer; a wiring part, which has a plurality of wiring traces provided on the top surface of the base layer; A covering layer, which covers the wiring traces; a void, which is defined in the support layer; an overhead wiring portion, which is a part of the wiring portion which passes over the void; an overhead base layer, which is provided at the respective wiring traces in the overhead wiring portion on the base layer and spaced apart from each other; and an overhead cover l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com