Scraping knife control method and pole piece coating scraping method

A control method and scraper technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using tools, etc., can solve inaccurate control, difficult implementation, and difficulty in determining the relationship between input compensation value and output deviation value And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

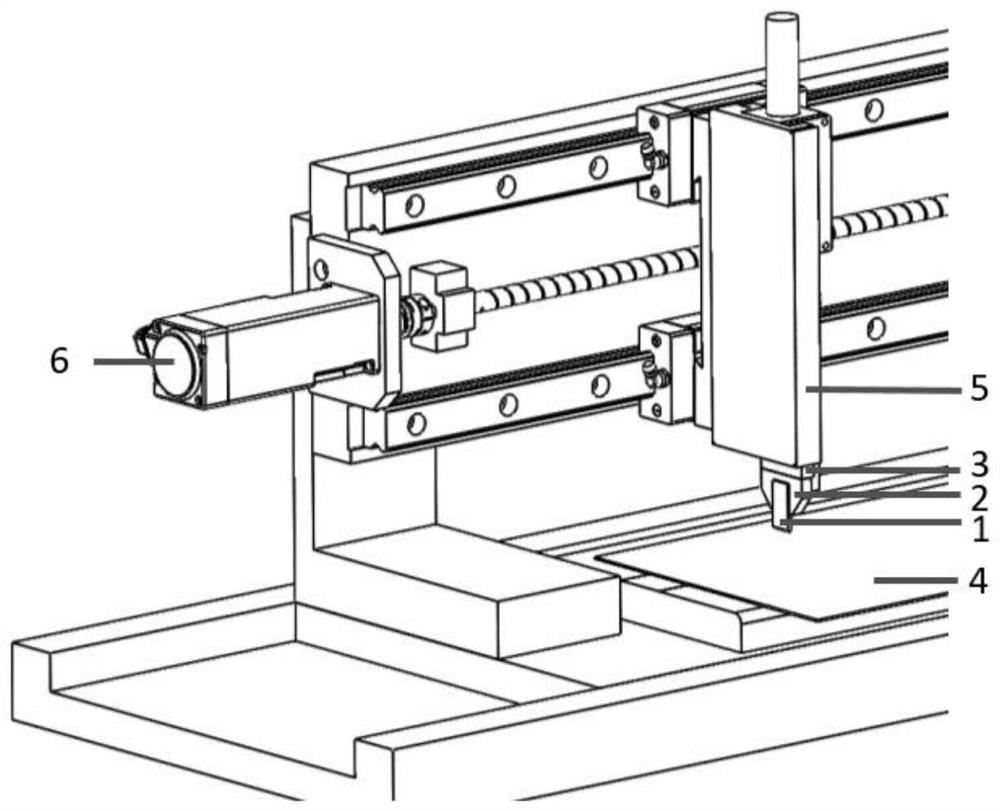

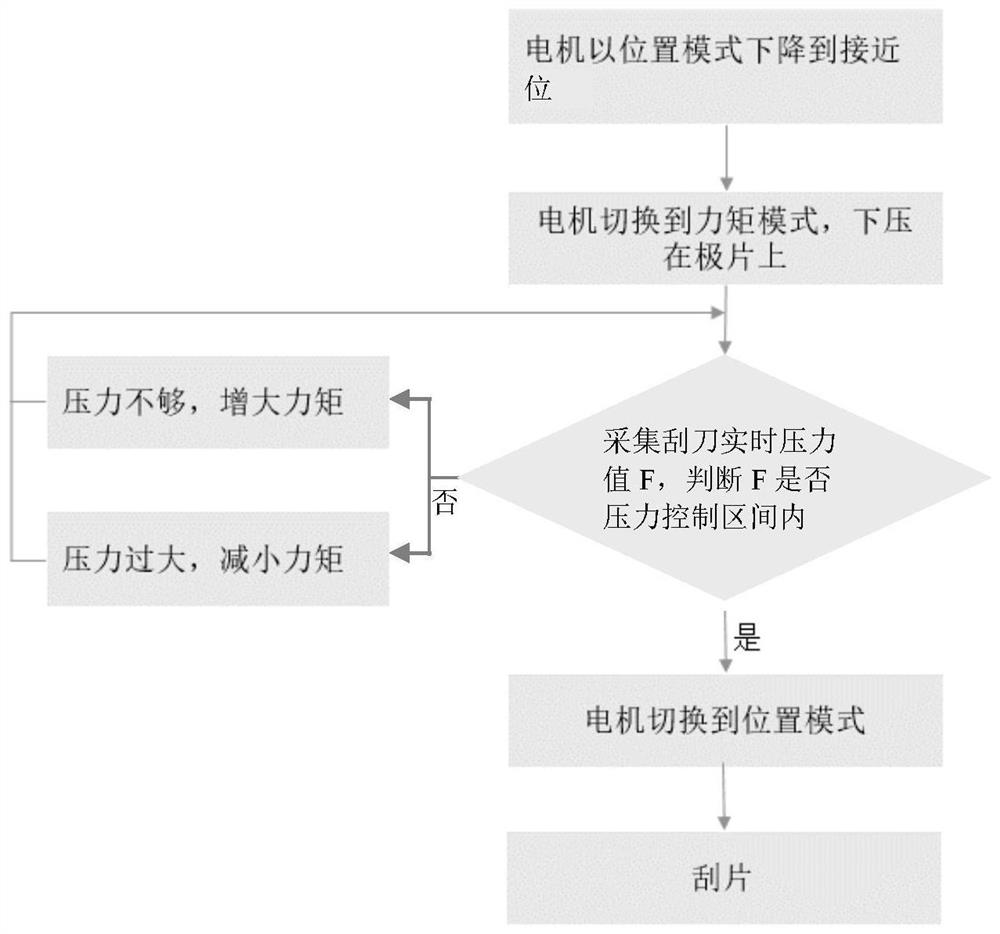

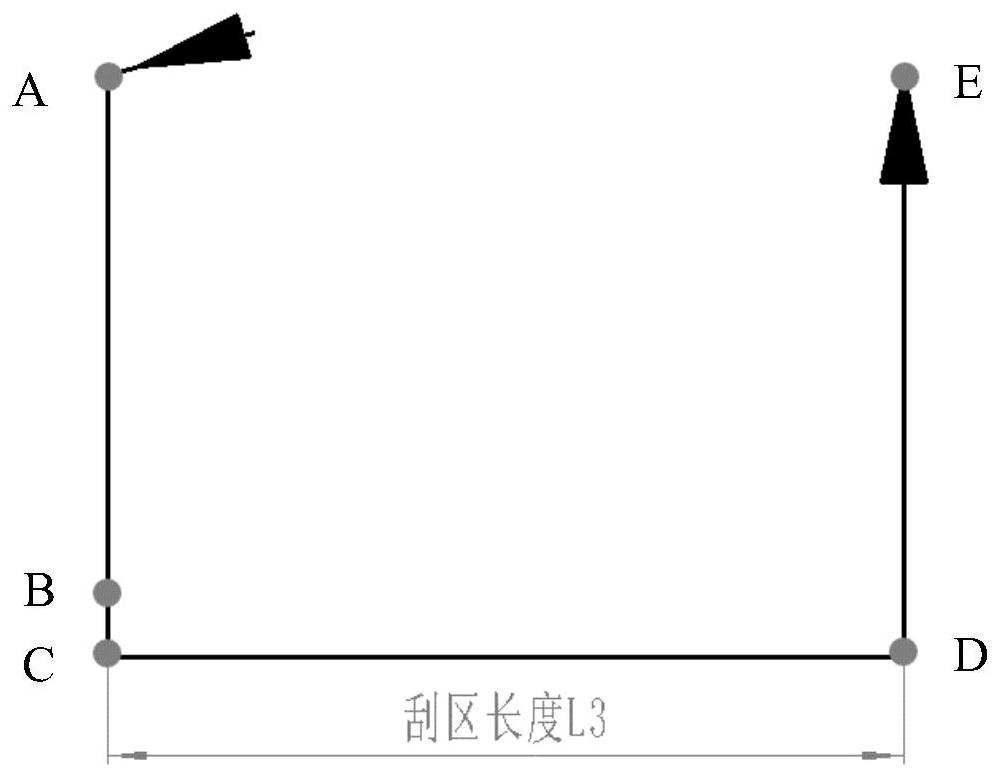

[0038] Combine below figure 2 with image 3 , the scraper control method of this embodiment will be described. In the sheet making process, when the pole piece is sent to the scraper position by the sheet feeding mechanism, the scraper is located above the pole piece. At this time, the position (initial position) of the scraper is the first waiting position A. The steps of the control method of the scraper are as follows :

[0039]S1. The controller sends a position command to the lifting motor driver, controls the lifting motor 5 to operate in position mode, and drives the scraper 1 to move vertically from the first waiting position A to the approaching position B (the approaching position is higher than the first waiting position) through the lifting motor 5 The position is closer to the pole piece), after the scraper 1 moves to the position B, the lifting motor driver controls the lifting motor 5 to stop, and feeds back the positioning completion signal to the controller...

Embodiment 2

[0049] In the actual production process, there may be a situation where the coating on the pole piece cannot be completely removed by one scraping, so the scraping blade can perform multiple scraping actions in the scraping area. Combine below Figure 4 , to describe the method of scraping off the pole piece coating that needs to be scraped multiple times. The lowering control process of the scraper when scraping multiple times is the same as the lowering control process of the scraper when scraping once, that is, the steps S1 to S4 are the same. The pole piece coating scraping method of this embodiment includes the following steps: the pole piece is sent to the scraper position by the sheet feeding mechanism, the scraper is located above the pole piece, and the position of the scraper at this time is the first waiting position A;

[0050] S1. The controller sends a position command to the lifting motor driver to control the lifting motor to operate in position mode. The lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com