Laminated material and lamination method by using mask with preset pattern on substrate

A technology of layer materials and luminescent material layers, which is applied in the field of color display equipment, can solve problems such as component damage, and achieve the effects of improving precision, reducing costs, and increasing lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

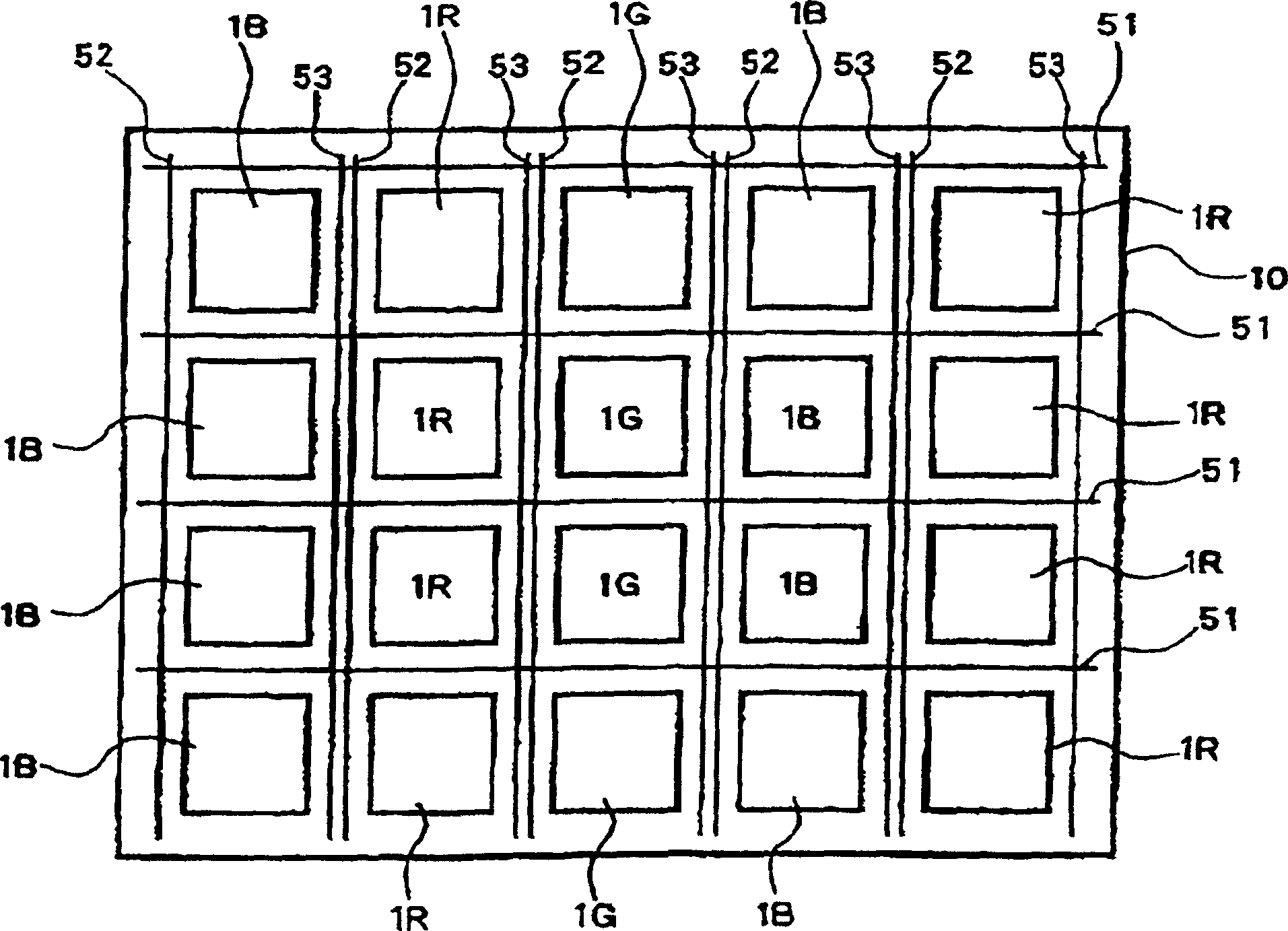

[0048] An organic EL display device produced by the method for producing a color display device according to the present invention will be described below.

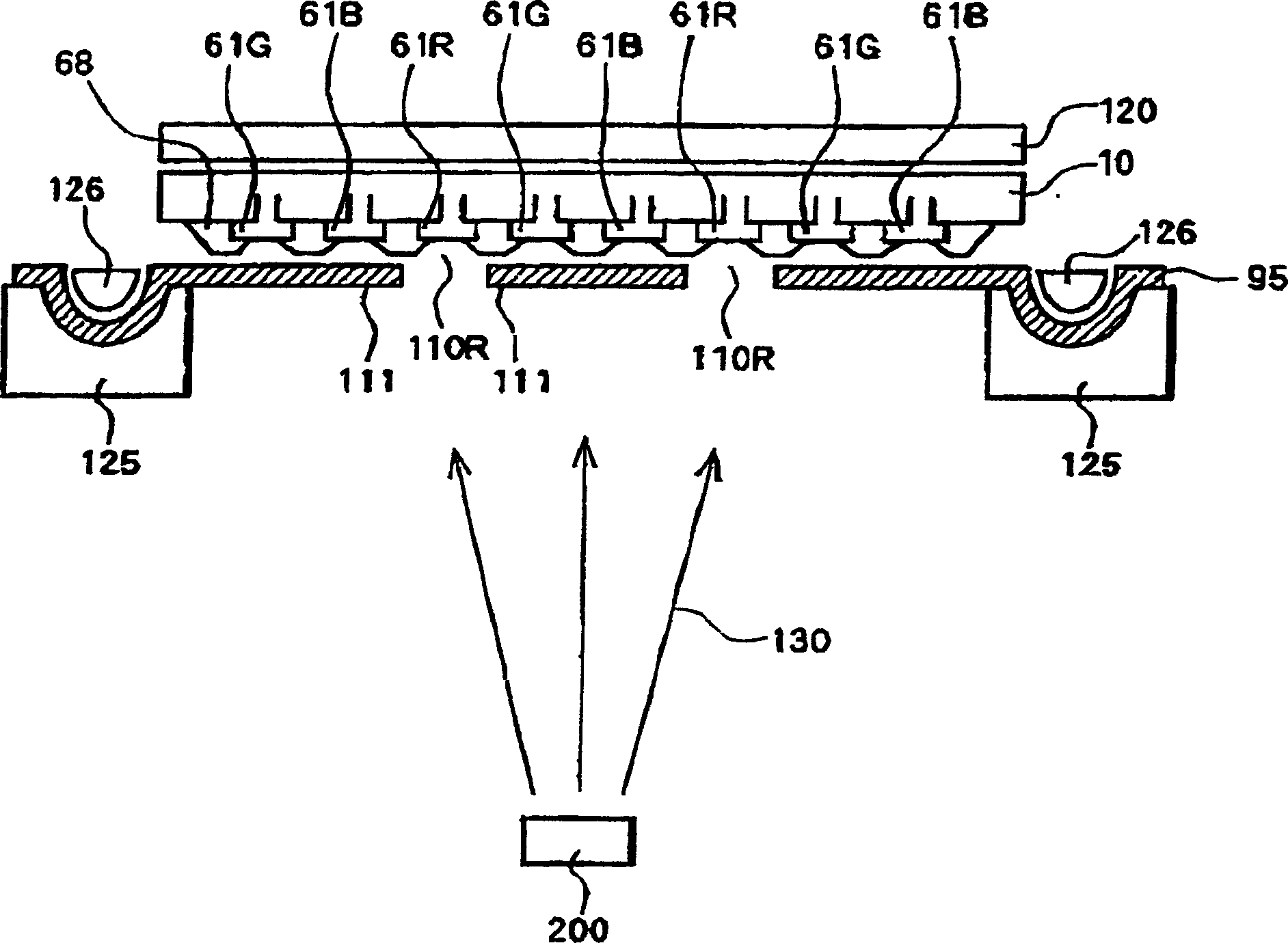

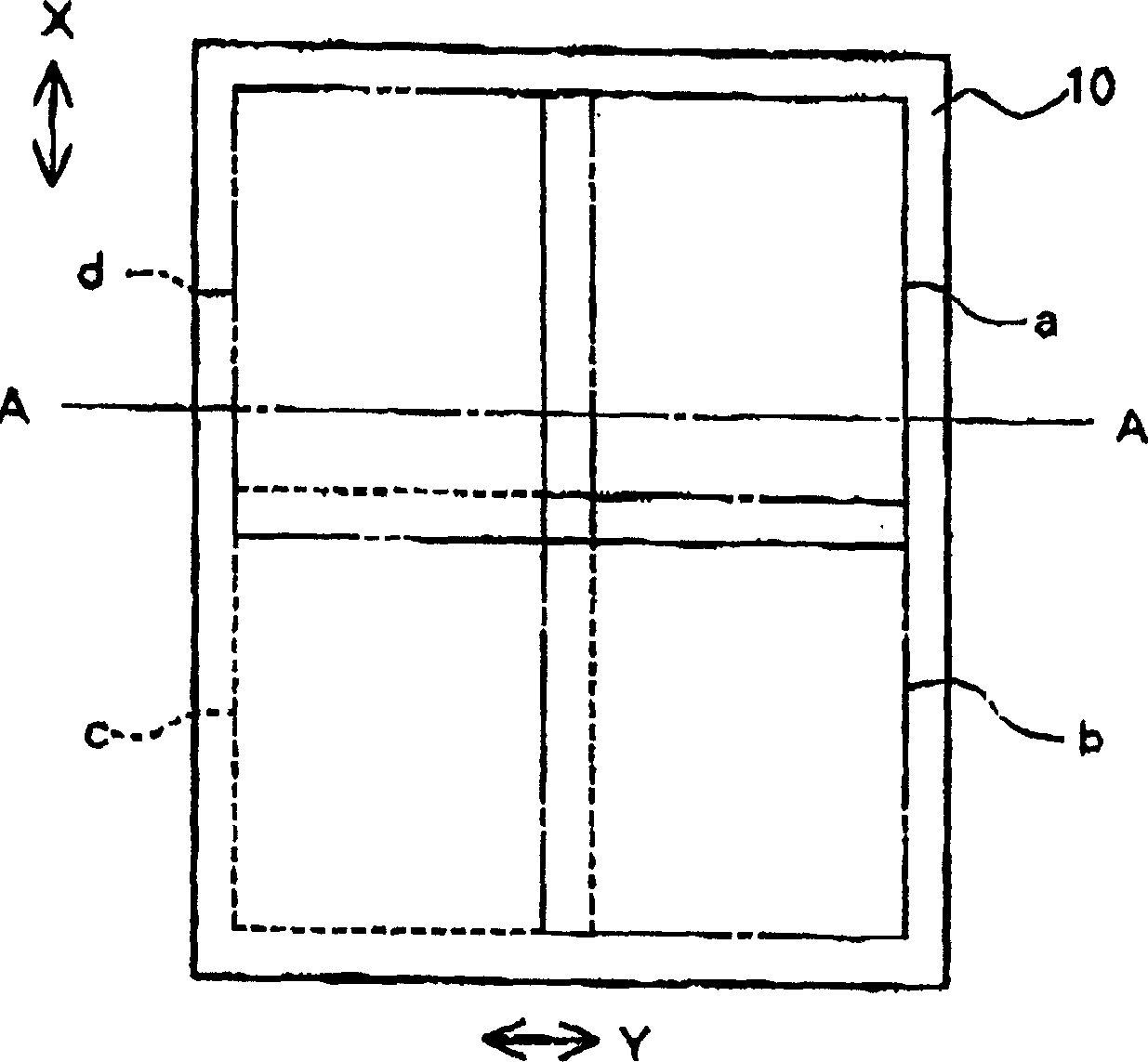

[0049] image 3 A planar structure is shown illustrating a method for moving an insulating substrate onto which an organic material is evaporated according to the inventive method for producing a color display device, and Figure 4 show along image 3 The cross-sectional structure cut by the line A-A in . It should be noted that, Figure 4 Shows a cross section at the step of evaporating organic light-emitting materials of each color onto an insulating substrate such as a glass substrate 10 having a part corresponding to a TFT, an anode of an organic EL element, and a cover for covering by an evaporation method An insulating film 68 surrounding the region of the anode, and in this particular embodiment a red light-emitting element layer, is deposited onto the anode 61R by evaporation.

[0050] The evaporation mask 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com