Method for detecting weld defect of stainless steel runner blade of water turbine

A technology of runner blades and detection methods, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems of high difficulty and low sensitivity, achieve high sensitivity, loose environmental requirements, and improve detection efficiency and detection sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

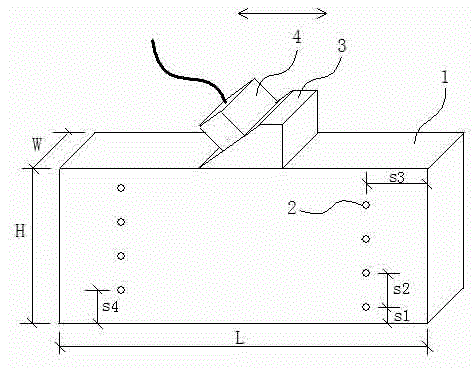

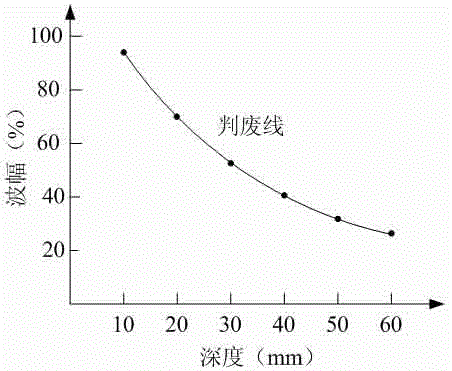

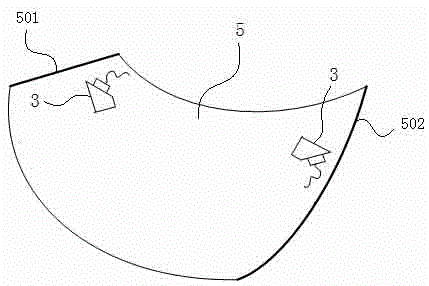

[0022] The upper crown, lower ring and blades of unit 2 of a hydropower plant are all made of 0Crl3Ni5Mo martensitic stainless steel. After the blades are molded, they are welded with the upper crown and lower ring to form a runner. The maximum thickness of the blades is about 50mm. Since the unit was put into operation, the runner blades have cracks in different degrees on the upper crown and the lower ring outlet edge, and the cracks of individual blades are relatively serious. In November 2010, in the process of welding triangular ribs to water turbine blades during C-level maintenance, in order to ensure that the cracks in the weld seams of the blades were cleaned and the welding quality of the triangular ribs was removed, ultrasonic waves were carried out on the welding seams of the runner blades, the upper crown and the lower ring. Phased array detection. The specific method is as follows:

[0023] Step 1, select the instrument: the present invention adopts the Omniscan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com