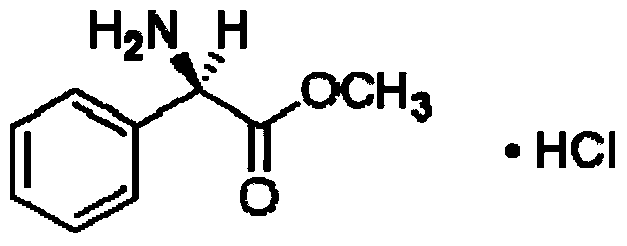

A kind of preparation technology of d-phenylglycine methyl ester hydrochloride crystallization

A technology of phenylglycine methyl ester and preparation process, which is applied in the preparation of organic compounds, cyanide reaction preparation, organic chemistry and other directions, can solve the problems of production difficulties, high production energy consumption, and insufficient utilization of reaction heat in downstream enterprises, and achieves The effect of low production cost, simple production process and excellent color grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 70g of D-phenylglycine, measure 300mL of methanol, add them into a 500mL four-neck flask reactor in turn, start stirring, after mixing evenly, measure 60mL of thionyl chloride, and slowly dissolve thionyl chloride through a constant pressure dropping funnel Add it into the flask, drop it for 1.5 hours, keep the temperature in the reactor at 55°C during the dropwise addition, keep the temperature in the reactor at 60°C after the dropwise addition, reflux for 0.5h, and the reaction ends. Then control the temperature in the reactor at 45°C, stir the liquid in the reactor, add cyclohexane to the reactor for vacuum azeotropic distillation, maintain the vacuum degree in the reactor at 0.05MPa, and add the entrainer continuously Add to keep the liquid level in the reactor constant. After the mass content of methanol in the solution in the reactor is lower than 20%, stop the vacuum azeotropic distillation, carry out temperature-controlled cooling and crystallization, cont...

Embodiment 2

[0028] Weigh 25g of D-phenylglycine, measure 200mL of methanol, add them into a 500mL four-neck flask reactor in turn, start stirring, and after mixing evenly, measure 20mL of thionyl chloride, and dilute the thionyl chloride through a constant pressure dropping funnel. Slowly add to the reaction system, keep the temperature in the reactor at 50°C during the dropwise addition, control the temperature of the reactor at 65°C after the dropwise addition, reflux for 1 hour, and the reaction is completed. Then the temperature in the reactor is controlled at 40°C, the liquid in the reactor is stirred, and the entrainer toluene with 30% volume of the solution in the reactor is quickly added to the reactor to carry out vacuum azeotropic distillation, and the vacuum degree in the reactor is maintained at 0.08 MPa, when the volume of the distillate reaches the volume of toluene added, add the toluene of the same volume again, after adding 4 times, when the mass content of methanol in the...

Embodiment 3

[0030] Weigh 94g of D-phenylglycine, measure 300mL of methanol, add them into a 500mL four-neck flask reactor in turn, start stirring, after mixing evenly, measure 85mL of thionyl chloride, and slowly dissolve thionyl chloride through a constant pressure dropping funnel Add it into the reaction system, drop it for 1.5 hours, keep the temperature in the reactor at 50°C during the dropping process, and control the temperature of the reactor at 60°C to reflux for 1 hour after the dropwise addition, and the reaction is complete. Then control the temperature in the reactor at 40°C, stir the liquid in the reactor, add n-hexane to the reactor for vacuum azeotropic distillation, and add the entrainer continuously to keep the liquid level in the reactor constant . The vacuum degree in the reactor is maintained at 0.07MPa. When the mass content of methanol in the solution in the reactor is lower than 5%, the vacuum azeotropic distillation is stopped, and the temperature is controlled fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com