Edge and corner tapping equipment for aluminum plate

A corner, aluminum technology, applied in the field of aluminum plate corner tapping equipment, can solve the problems of prone to accidents, long tapping time, single performance, etc., to save collection time, precise tapping operation, convenient The effect of collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

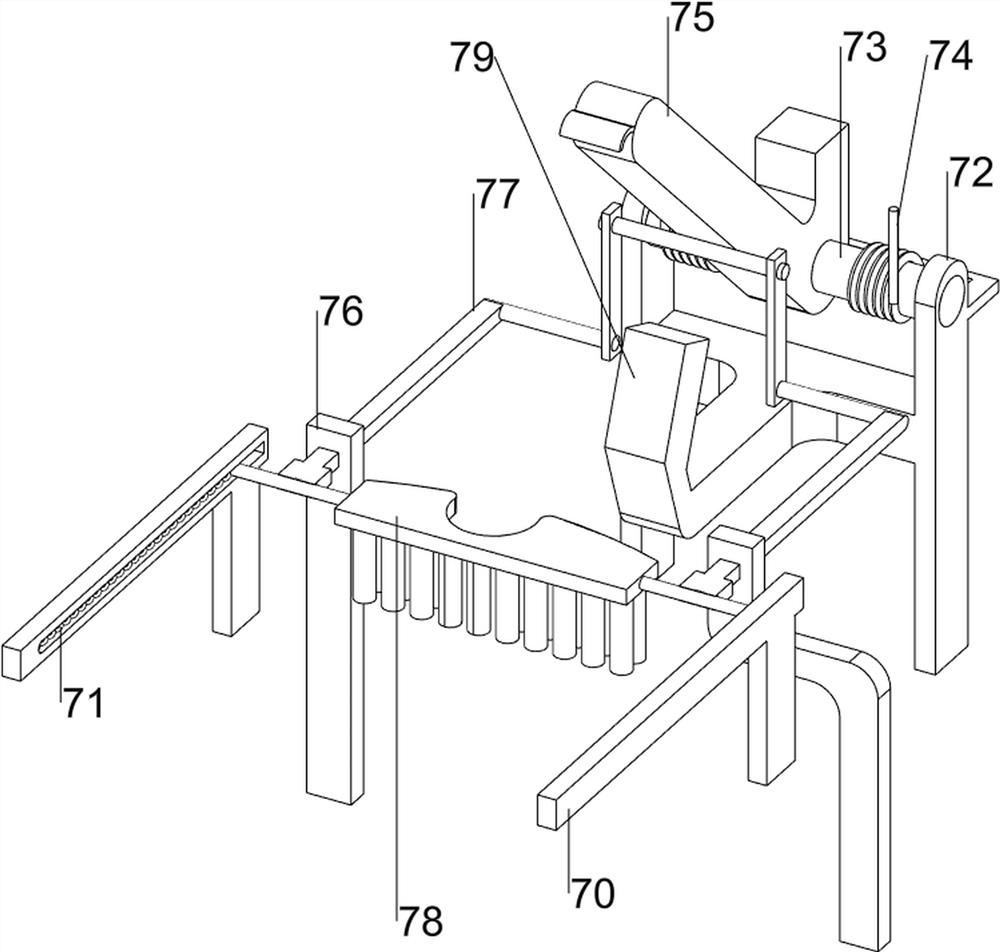

[0073] A kind of tapping equipment for the corner of aluminum plate, such as figure 1 As shown, it includes a base 1, a first mounting plate 2, a tapping mechanism 3 and a cooling mechanism 4. It is provided with three bases 1, and a first mounting plate 2 is arranged between the tops of the bases 1. On the first mounting plate 2 A tapping mechanism 3 is provided, and a cooling mechanism 4 is provided on the left rear side of the tapping mechanism 3 .

[0074]When people need to tap the material, the material is placed on the tapping mechanism 3, and then the cooling mechanism 4 is filled with cutting fluid. At this time, people start the tapping mechanism 3, and the tapping mechanism 3 quickly and easily removes the material Tapping operation, while the tapping mechanism 3 drives the cooling mechanism 4 to move, so that the cooling mechanism 4 cools the material in the tapping. After tapping, people close the tapping mechanism 3, and the cooling mechanism 4 stops moving.

Embodiment 2

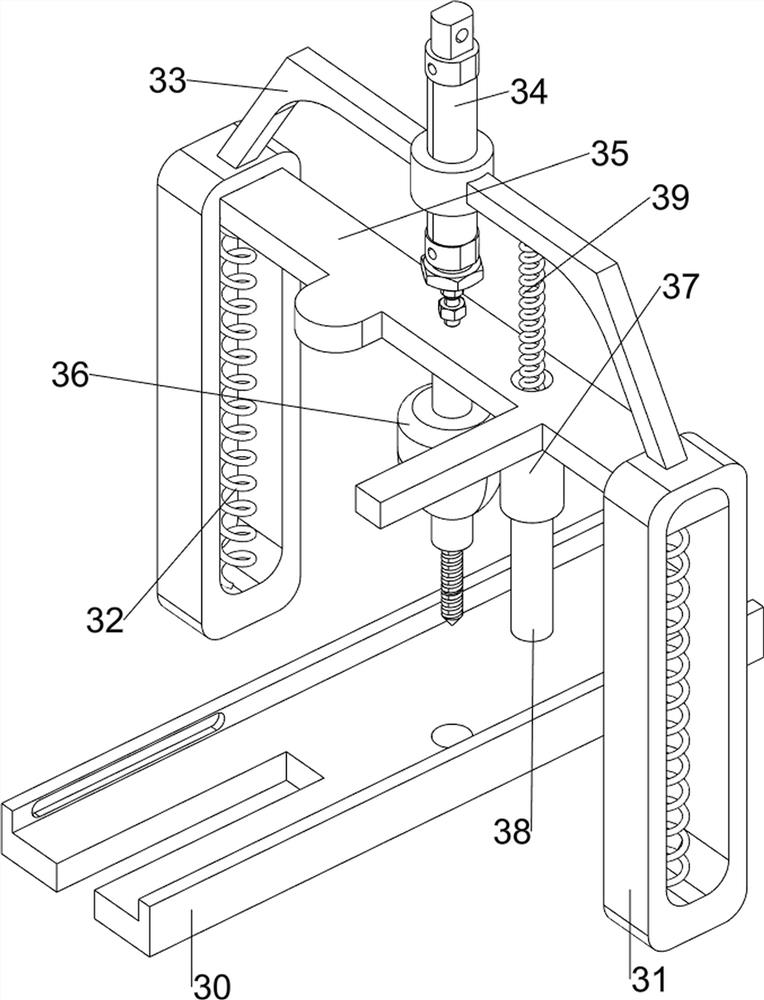

[0076] On the basis of Example 1, such as figure 2 As shown, the tapping mechanism 3 includes a first slide rail 30, a second slide rail 31, a first spring 32, a bracket 33, a cylinder 34, a second mounting plate 35, a tapper 36, a first sleeve 37, a first A round bar 38 and a second spring 39, the first mounting plate 2 is provided with a first slide rail 30, the left and right sides of the first mounting plate 2 are provided with a second slide rail 31, and the tops of the second slide rails 31 are connected Support 33 is arranged, and support 33 is provided with cylinder 34, and the second mounting plate 35 is slidably connected between the second slide rail 31, and cylinder 34 is connected with second mounting plate 35, and the left and right sides of second mounting plate 35 are connected with the second mounting plate 35. A first spring 32 is connected between the slide rails 31, a tapper 36 is provided at the bottom of the second mounting plate 35, a first sleeve 37 is...

Embodiment 3

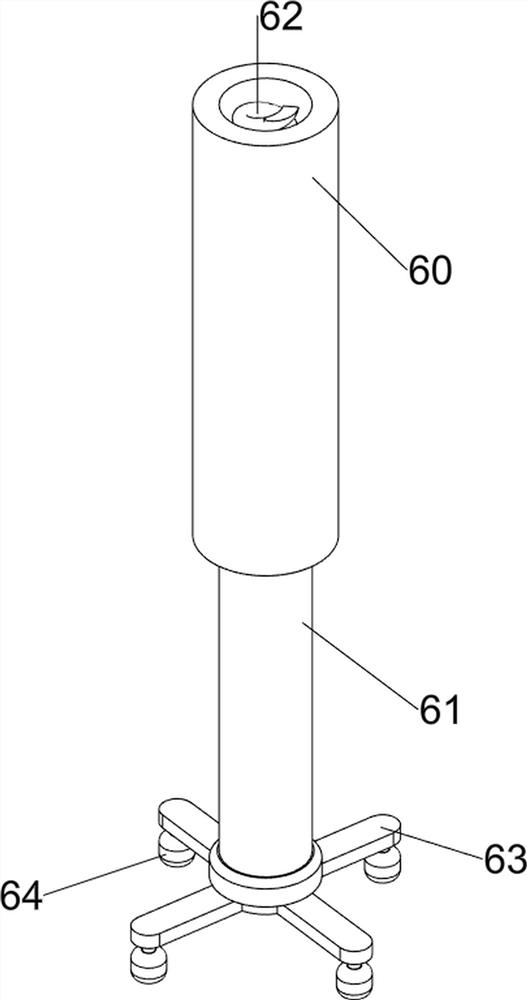

[0079] On the basis of Example 2, such as Figure 3 to Figure 8 As shown, the cooling mechanism 4 includes a second sleeve 40, a chip fluid outlet pipe 41, a chip fluid storage tank 42, a chip fluid addition port 43, and a third spring 44. There is a chip fluid outlet pipe 41 on the front side of the second sleeve 40, and a chip fluid storage tank 42 is slidably connected to the second sleeve 40. A small opening is opened at the lower part of the chip fluid storage tank 42. A chip fluid addition port 43 is provided, and two third springs 44 are connected between the chip fluid storage tank 42 and the second sleeve 40 .

[0080] When people need to tap the material, the cutting liquid is poured into the cutting liquid storage tank 42 through the cutting liquid adding port 43, and then people start the cylinder 34, and the cylinder 34 stretches to drive the second mounting plate 35 to move downward, The first spring 32 shrinks and moves. When the second mounting plate 35 is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com