A steel pipe fixture for pipe thread processing equipment

A technology for processing equipment and pipe threads, which is applied in the direction of metal processing equipment, manufacturing tools, metal processing machinery parts, etc., can solve problems such as poor synchronization of clamping heads, unequal moving distances, and deviation of the clamping position from the specified position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

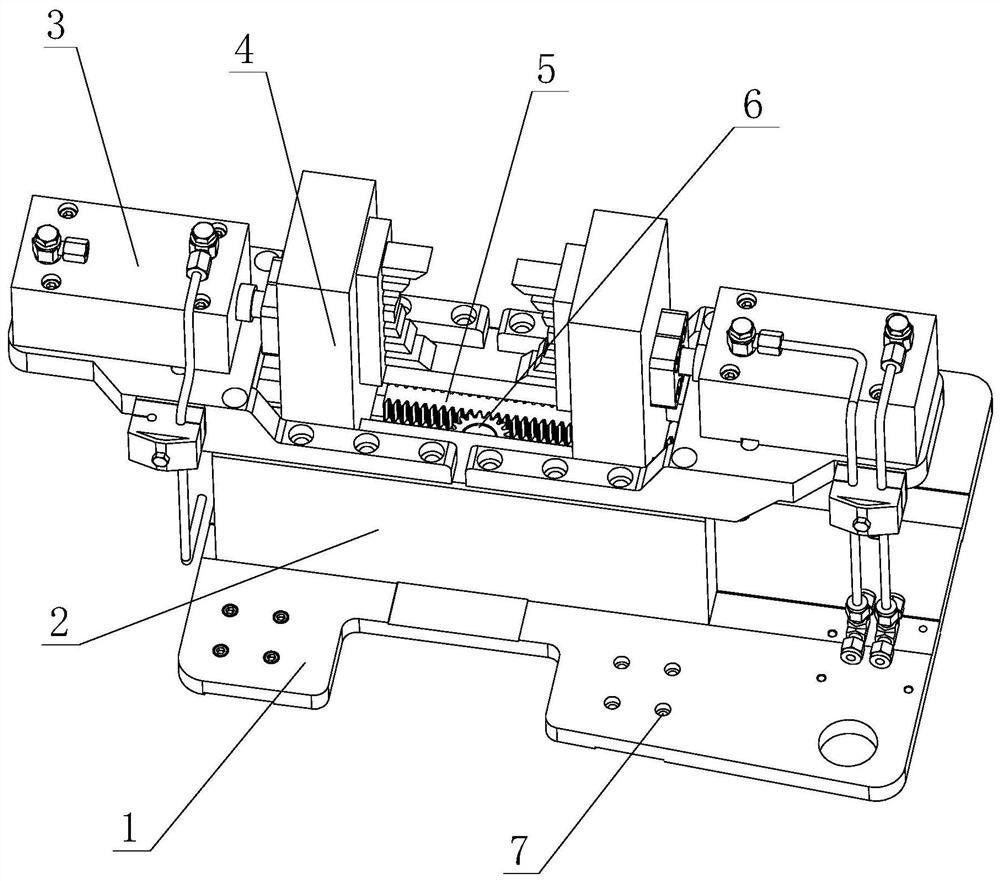

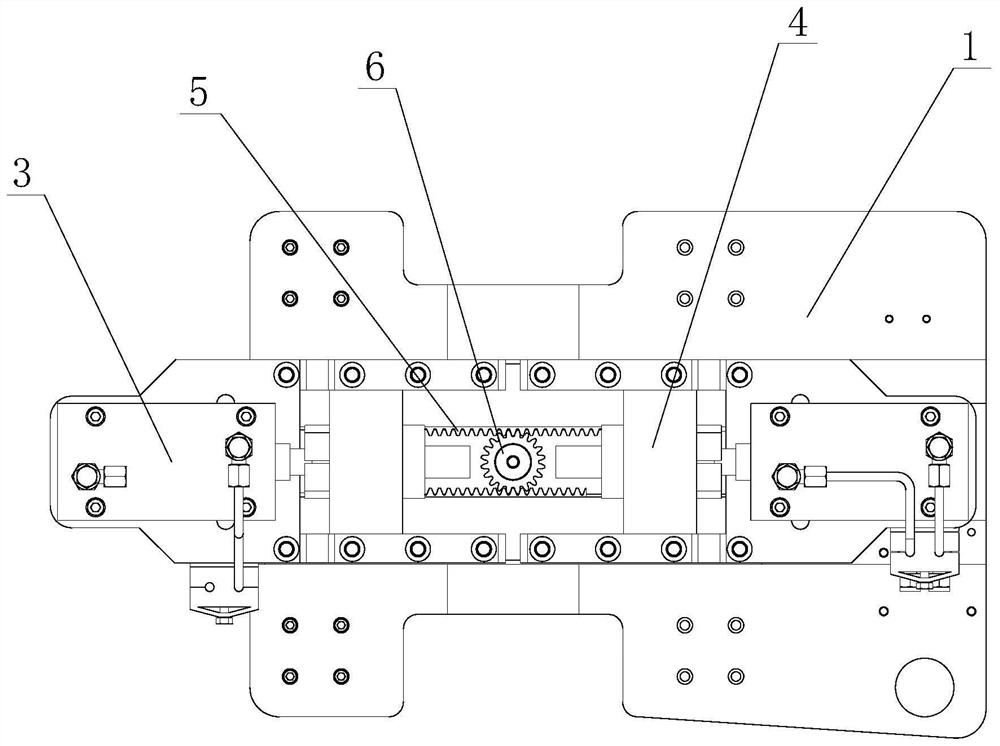

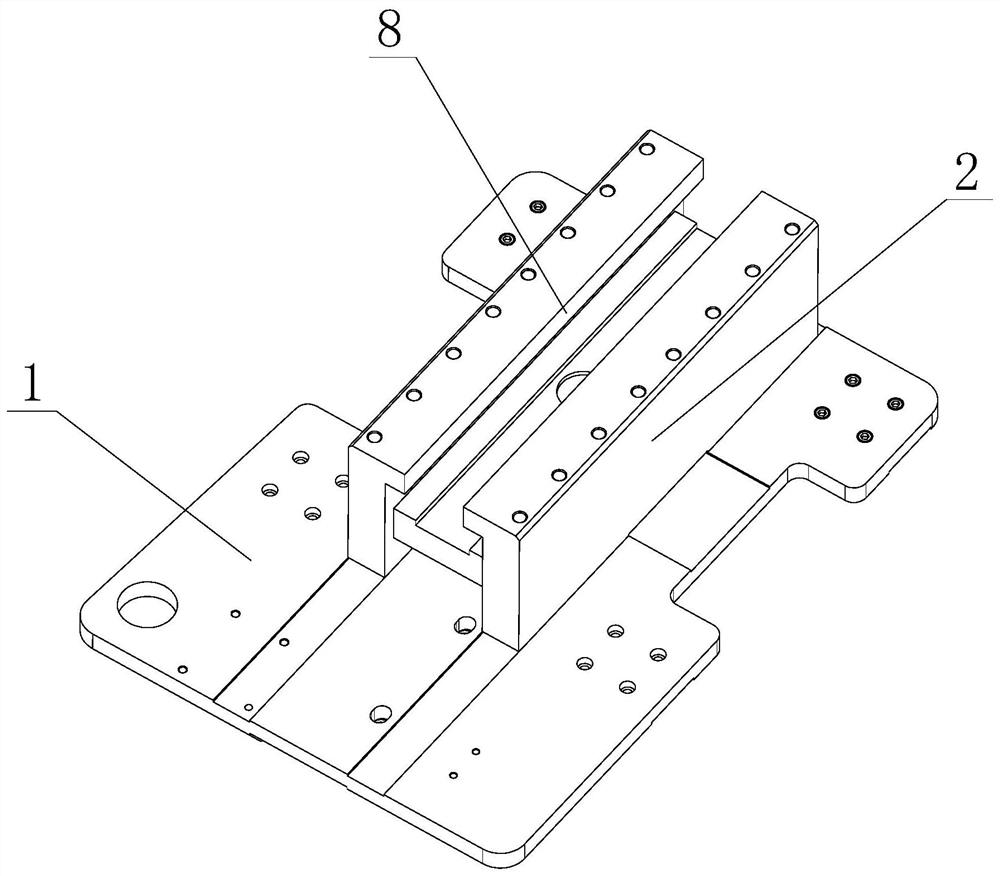

[0023] Such as Figure 1 to Figure 7 As shown, a steel pipe clamp for pipe thread processing equipment includes a bottom plate 1 on which a mounting hole 7 is arranged. The bottom plate 1 is provided with a guide platform 2 , and the guide platform 2 is provided with a guide boss 8 . Two clamping parts 4 are slidably connected to the guide table 2 , and the clamping parts 4 are provided with guide grooves 13 matching with the guide bosses 8 , and the guide bosses 8 snap into the guide grooves 13 . Both ends of the guide table 2 are respectively provided with telescopic devices 3 for driving the two clamping parts to move 4 . The moving direction of the clamping component is constrained by the cooperation of the guide groove and the guiding boss, so that the clamping component can move along the length direction of the guiding boss. A rack 5 is respectively connected to the two clamping parts 4 , and the two racks 5 are parallel to each other. A gear 6 is rotatably connected ...

Embodiment 2

[0028] The difference between embodiment 2 and embodiment 1 is that in embodiment 2, the telescopic device 3 is an air cylinder, and other structures are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com