Construction method of hydraulic climbing formwork conversion system for special-shaped pier towers

A technology of hydraulic climbing formwork and construction method, applied in construction, bridge construction, bridges, etc., can solve the problems of flexible rods of upper frame, formwork deformation, affecting construction period, low efficiency, etc., and achieves low replacement and disassembly work intensity and construction efficiency Improve and ensure the effect of integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

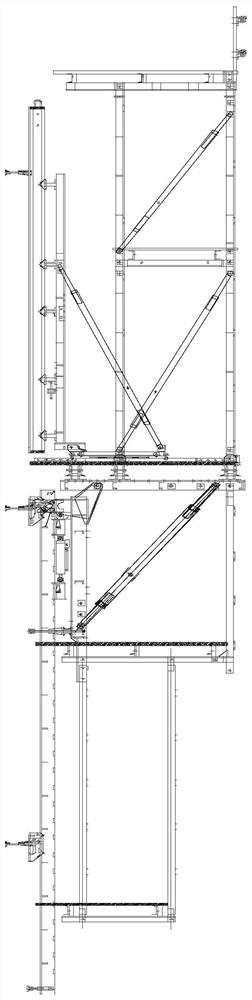

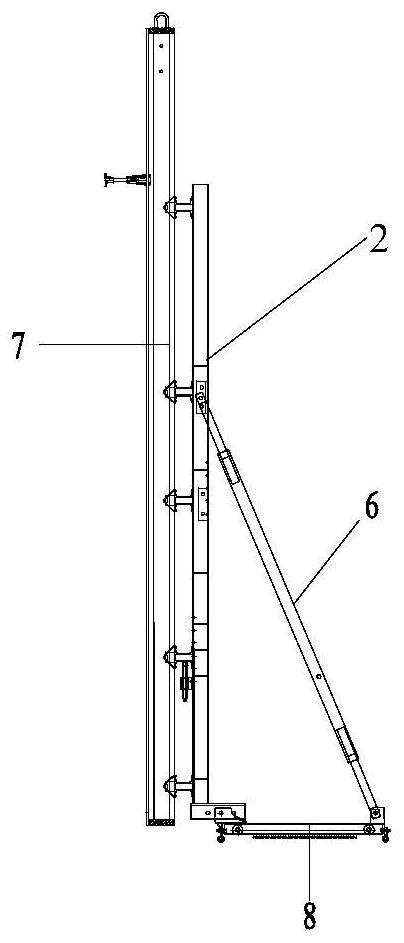

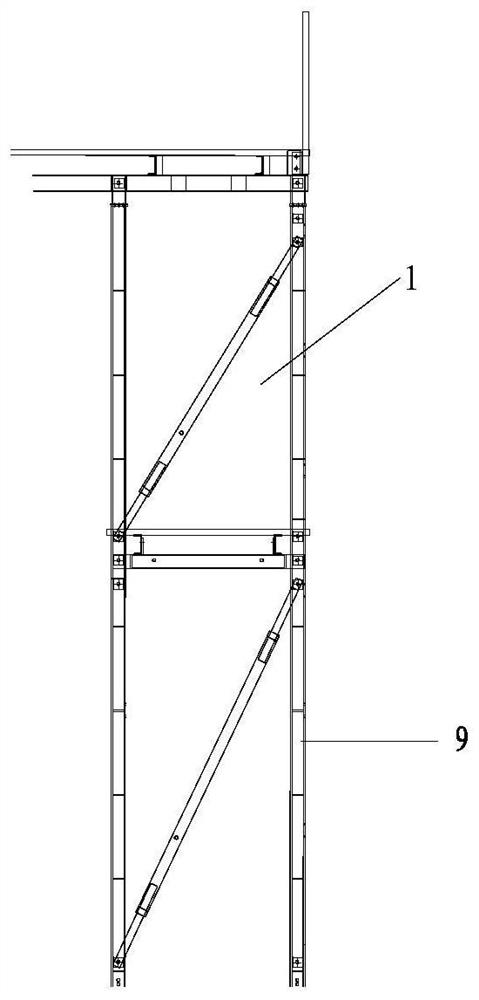

[0049] Such as Figure 1-6 The structure diagram of the hydraulic climbing formwork conversion system shown includes the upper frame body 1, the formwork structure 2, the main platform load-bearing connection structure 3, the attached tower hydraulic sliding structure 4, the lower frame body 5, the formwork brace 6, the formwork 7, and the sliding platform 8. Embedded parts 10, embedded parts hanging seat 11, guide rail 12, hydraulic drive device 13, tripod beam 14, tripod brace 15, tripod pole 16, pin hinge 17, Y-shaped tower column 25, middle Tower column conversion base segment 26, upper tower column conversion base segment 28, etc. The hydraulic climbing formwork conversion system mainly consists of upper frame body 1, formwork structure 2, main platform load-bearing connection structure 3, attached tower hydraulic sliding structure 4 and The structure of the hydraulic climbing formwork conversion system is basically the same as that of the traditional hydraulic climbing f...

Embodiment 2

[0060] This patent also provides a construction method for the hydraulic climbing formwork conversion system, including the following steps:

[0061] (1) Universal configuration and numbering of hydraulic climbing formwork: According to the section size of the lower tower column section of Y-shaped tower column 25, a common hydraulic climbing formwork conversion system is equipped on each side of the pier tower. For the four sides of Y-shaped tower column 25 The hydraulic climbing formwork is numbered, the upper frame body 1 in the direction of the bridge is numbered A1, A2 and B1, B2 respectively, and the lower frame body 5 in the direction of the bridge is numbered A1', A2', B1', B2' respectively. The upper frames 1 facing the bridge are numbered C1, C2 and D1, D2 respectively, and the lower frames 5 along the bridge are numbered C1', C2', D1', D2' respectively.

[0062] (2) Pre-embedding of embedded parts: When the lower tower column is constructed vertically upwards, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com