Deep well filling pipeline operation condition ultrasonic diagnosis system and method

A technology for filling pipelines and ultrasonic diagnosis, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc. The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

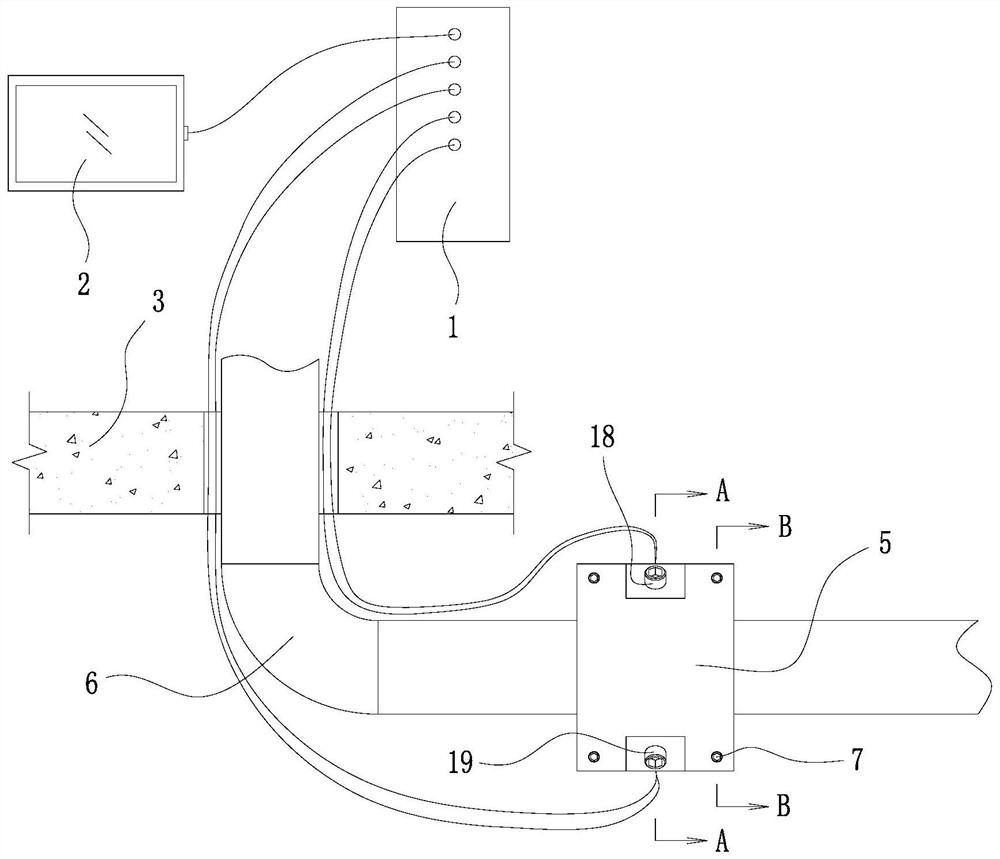

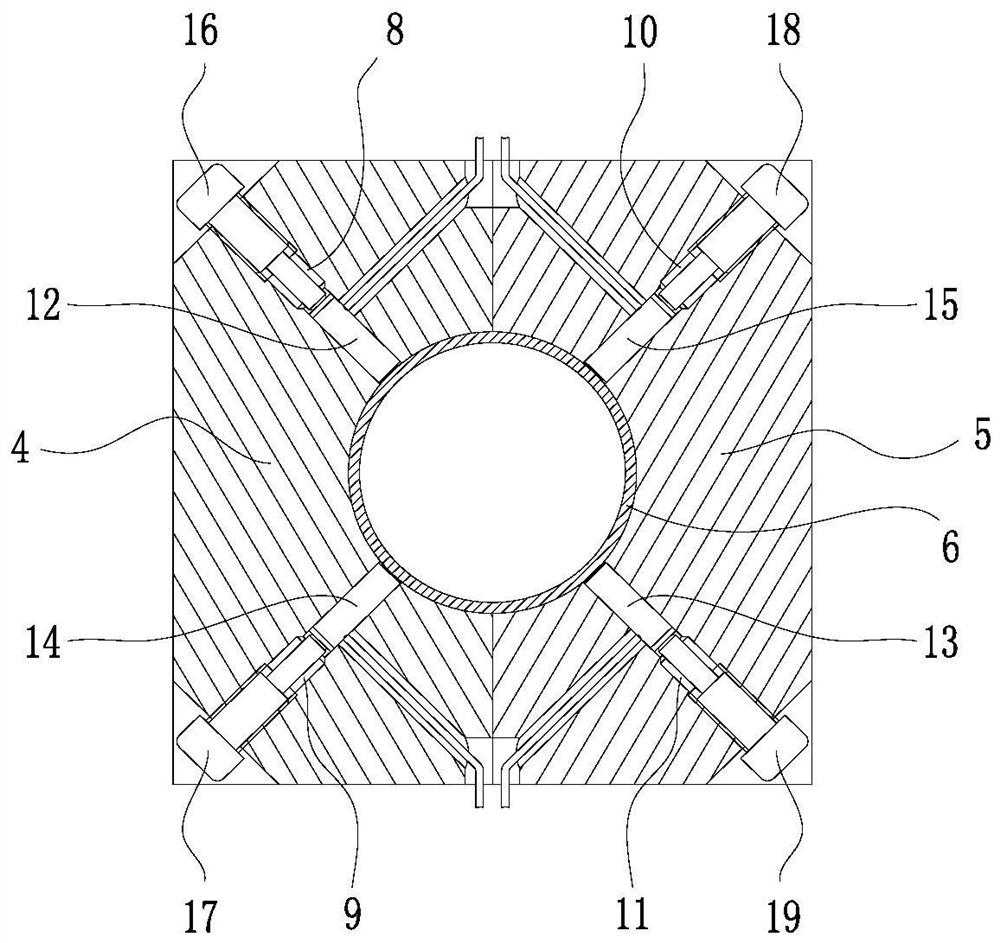

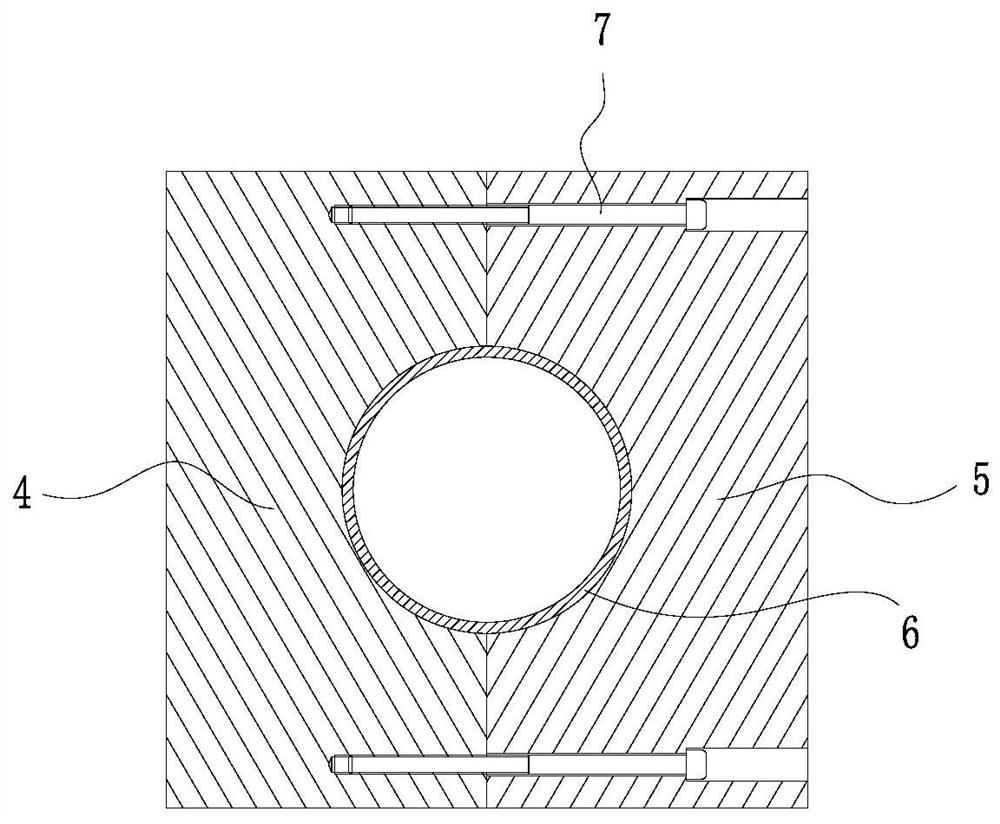

[0025] Such as Figure 1~3 As shown, an ultrasonic diagnostic system for deep well filling pipeline operating conditions includes an ultrasonic probe set, an ultrasonic probe positioning seat, a control box 1 and a display 2; the control box 1 and the display 2 are located on the ground 3, and the display 2 passes through The data line is electrically connected to the control box 1; the positioning seat of the ultrasonic probe adopts a two-half combination structure, which is divided into the left half positioning seat 4 of the ultrasonic probe and the right half positioning seat 5 of the ultrasonic probe; when the positioning seat of the ultrasonic probe is in a combined state , the center of the ultrasonic probe positioning seat is the wearing and holding hole of the filling pipeline 6, and the outer contour shape of the ultrasonic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com